Connecting structure of fabricated steel bridge deck concrete crash barrier and complete set of construction method of connecting structure

A technology of anti-collision guardrail and steel bridge deck, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of large welding residual stress and residual deformation, affecting the service life of steel bridges, delaying construction progress, etc., to avoid The effect of welding residual stress and residual deformation, simplifying construction and reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

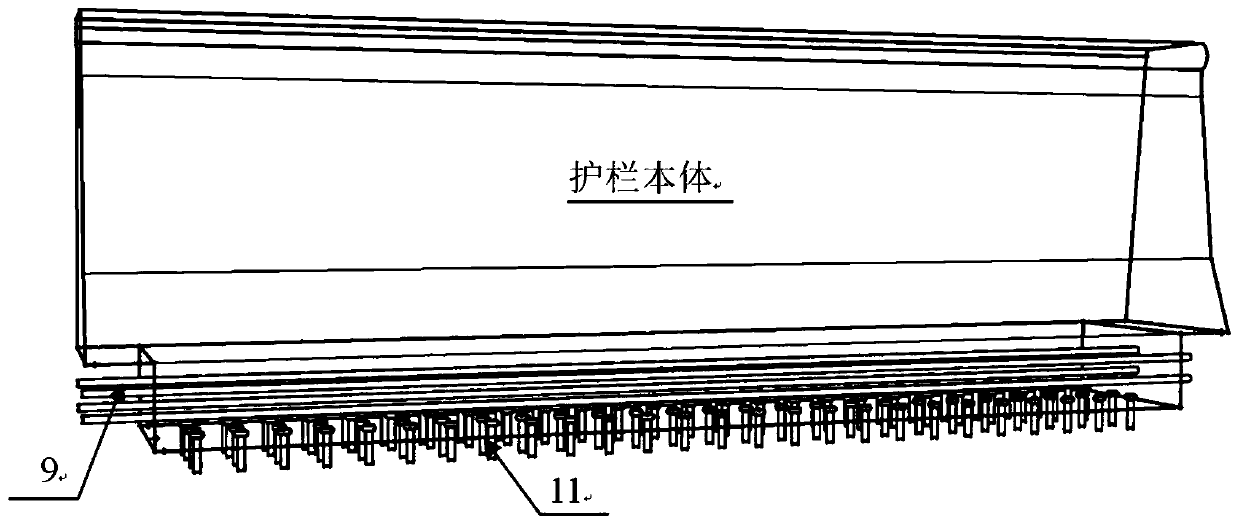

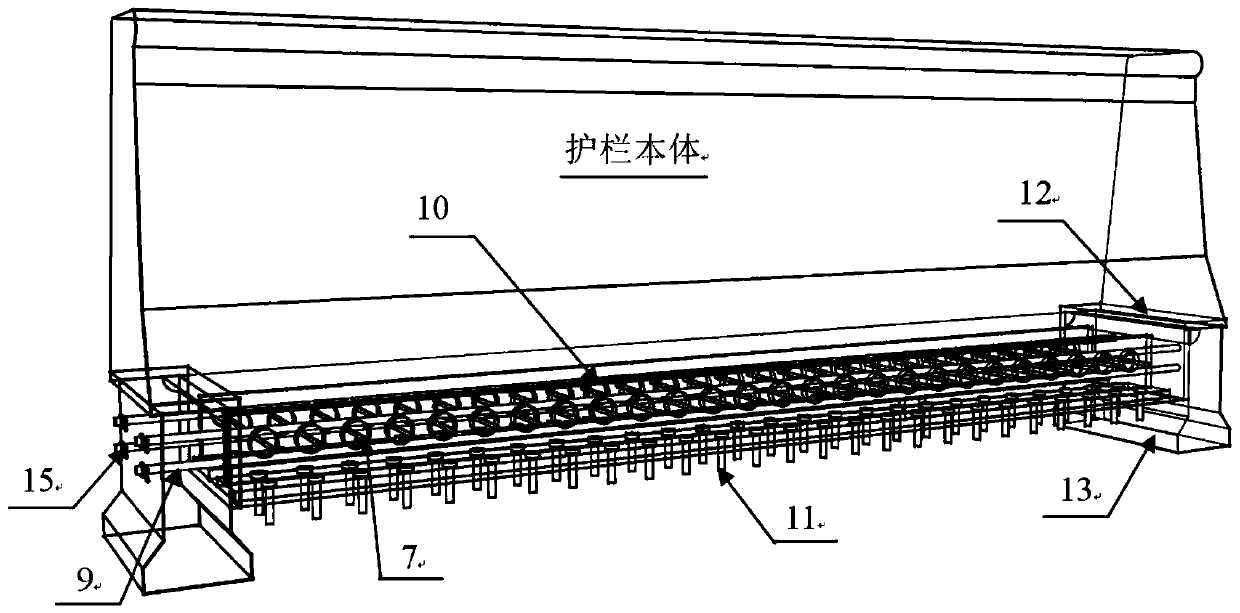

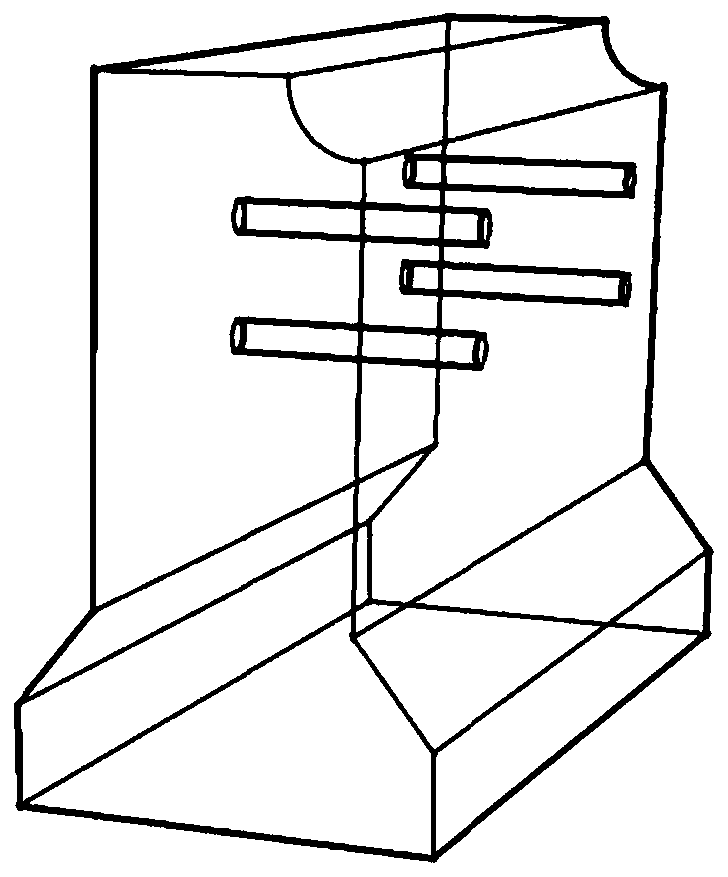

[0065] Such as figure 1 — Figure 9 , the marks 1-15 in the figure are respectively: 1—steel deck roof, 2—longitudinal stiffener, 3—transverse stiffener, 4—side sealing plate, 5—the first steel bar of precast concrete guardrail, 6—the first steel bar of precast concrete guardrail Second steel bar, 7—the third steel bar of precast concrete guardrail, 8—the fourth longitudinal steel bar, 9—the fifth longitudinal steel bar, 10—pre-embedded inverted T-shaped opening steel plate connector, 11—pre-embedded high-strength bolts, 12—pre-embedded Angle steel, 13—block, 14—high-strength steel wire, 15—ring clamp.

[0066] Such as Figure 4 As shown, the present embodiment provides a connection structure of a prefabricated steel bridge deck concrete crash barrier. The steel bridge deck is composed of a steel bridge deck roof 1 , longitudinal stiffeners 2 , transverse stiffeners 3 , and side sealing plates 4 . The concrete anti-collision guardrail includes several groups of precast con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com