A kind of nano-modified emulsified asphalt and its preparation and use method

A technology of emulsified asphalt and nano-modification, applied in building components, building insulation materials, buildings, etc., can solve the problem of affecting the stability, road performance and durability of recycled asphalt mixture, hindering the application and development of domestic cold recycling technology, Problems such as poor low temperature crack resistance and fatigue resistance, achieve significant social and economic benefits, increase compatibility and adhesion, and improve low temperature crack resistance and fatigue resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

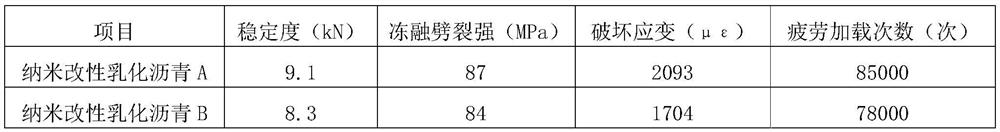

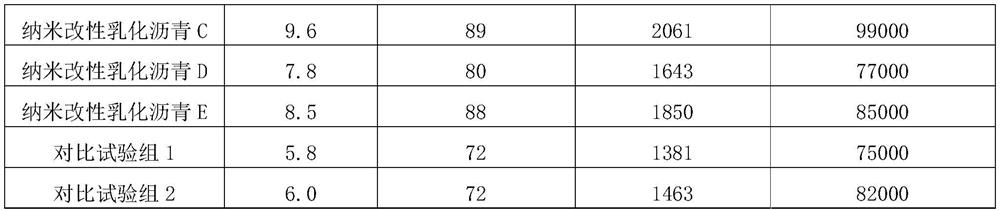

Examples

Embodiment 1

[0028] A preparation method of nano-modified emulsified asphalt, comprising the steps of:

[0029] Step 1: Dehydration of waste engine oil and screening of heavy metal impurities, and desulfurization of desulfurized rubber powder at a temperature of 200°C and a pressure of 2.5Mpa;

[0030] Step 2: Under the condition of 170°C, 7kg of desulfurized rubber powder, 32kg of 70# base asphalt, 3kg of rubber and plastic stabilizer, 13kg of waste engine oil and 3kg of graphene are sheared at high speed into soft rubber and plastic modified asphalt;

[0031] Step 3: Under the condition of 60°C, 5kg of SBR cationic styrene-butadiene latex, 34kg of water, and 3kg of emulsifier were quickly stirred evenly to obtain a mixed solution;

[0032] Step 4: Add the soft rubber-plastic modified asphalt and the mixed solution to the colloid mill at the same time, shear at a high speed at 90°C and mix thoroughly; the shear speed of the colloid mill is maintained at 1900r / min, and the shear time is 10...

Embodiment 2

[0039] The difference from Example 1 is that the proportioning of the nano-modified emulsified asphalt is different. In a preparation method of nano-modified emulsified asphalt, in step 1, 5 kg of desulfurized rubber powder, 33 kg of 70# base asphalt, rubber 3kg of plastic stabilizer, 13kg of waste engine oil and 1kg of graphene were sheared at high speed into soft rubber-plastic modified asphalt; in step 3, 6kg of SBR cationic styrene-butadiene latex, 35kg of water, and 4kg of emulsifier were quickly stirred evenly to obtain a mixed solution.

Embodiment 3

[0041] The difference from Example 1 is that the proportioning of the nano-modified emulsified asphalt is different. In a preparation method of nano-modified emulsified asphalt, in step 1, 10 kg of desulfurized rubber powder, 30 kg of 70# base asphalt, rubber 3kg of plastic stabilizer, 10kg of waste engine oil and 5kg of graphene were sheared at high speed into soft rubber-plastic modified asphalt; in step 3, 5kg of SBR cationic styrene-butadiene latex, 34kg of water, and 3kg of emulsifier were quickly stirred evenly to obtain a mixed solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com