Rubber water stopping plug and construction method for plugging and stopping water of opposite-pull bolt hole of underground outer wall template

A technology that pulls bolt holes and rubber waterstops, and is applied to the joints of formwork/formwork/work frame, building components, building insulation materials, etc., which can solve the difficulties in later treatment, increase engineering costs, and threaten the safety of building structures, etc. problems, to achieve the effect of eliminating the risk of water leakage along the hole, saving engineering costs, and improving construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

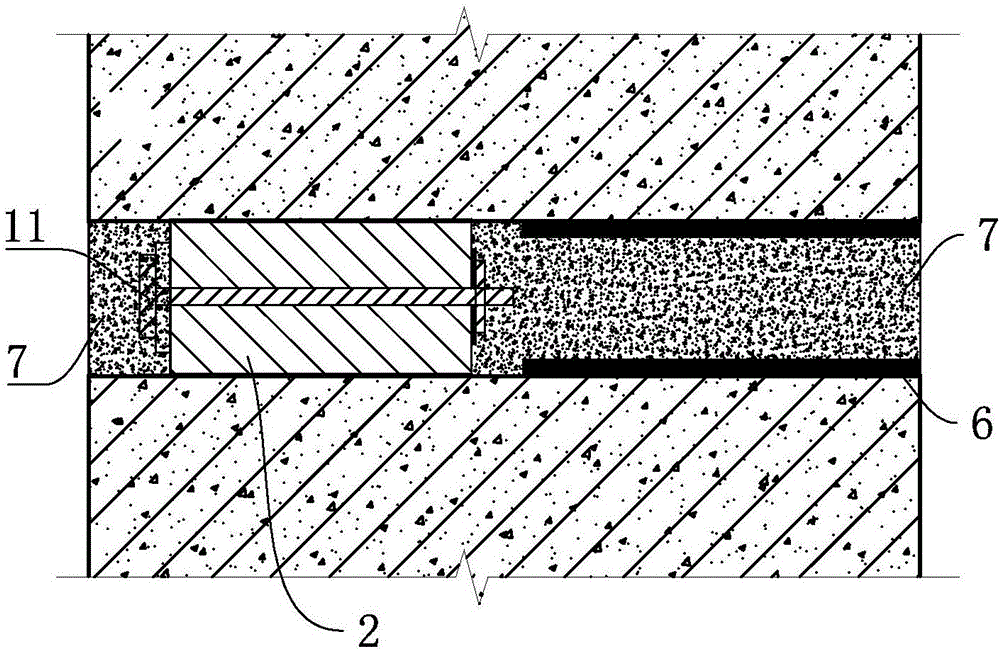

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

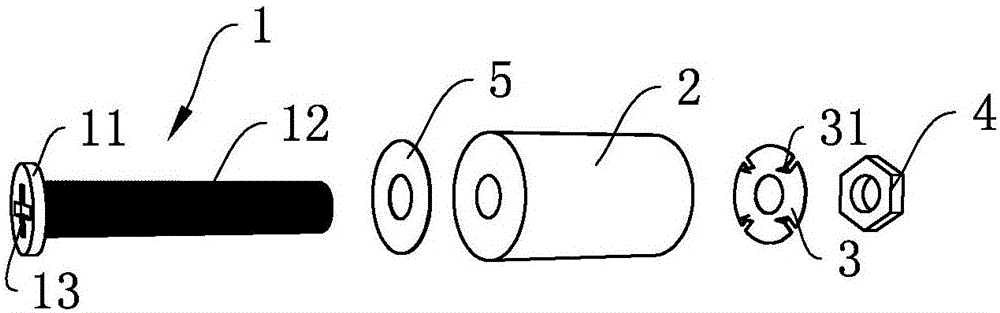

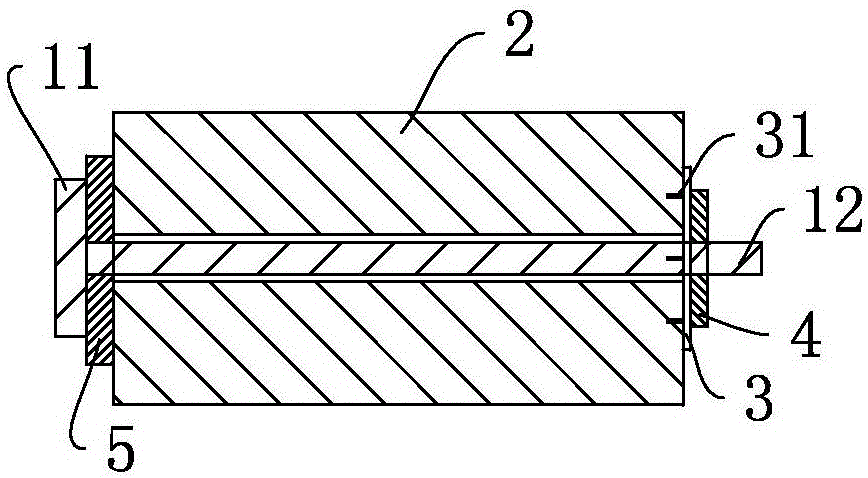

[0032] Such as figure 1 and figure 2 A rubber water stop shown, including:

[0033] The rubber plug body 2 is in the shape of a round tube.

[0034] The bolt 1 includes a bolt shank 12 and a bolt head 11. The length of the bolt shank 11 is greater than the length of the rubber plug body 2, and is inserted into the lumen of the rubber plug body 2. The bolt head 11 is provided with a groove for convenience. Turn with tools such as a screwdriver, and the bolt head 11 is against one end of the rubber plug body 2 .

[0035] The first gasket 3 is sleeved on the end of the bolt shank 12 away from the bolt head 11, against the other end of the rubber plug body 2, and the side of the first gasket 3 close to the rubber plug body 2 is provided with a plug that can be inserted into the rubber plug body The protruding teeth 31 are used to fix the first washer a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com