Kiln with water cooling structure

A water-cooling and kiln technology, applied in furnaces, furnace cooling, furnace components, etc., can solve the problems of low reliability of heat exchangers, poor fluidity of cooling water, and low heat exchange efficiency, so as to prevent water leakage in the furnace body and eliminate The risk of water leakage, the effect of stable and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

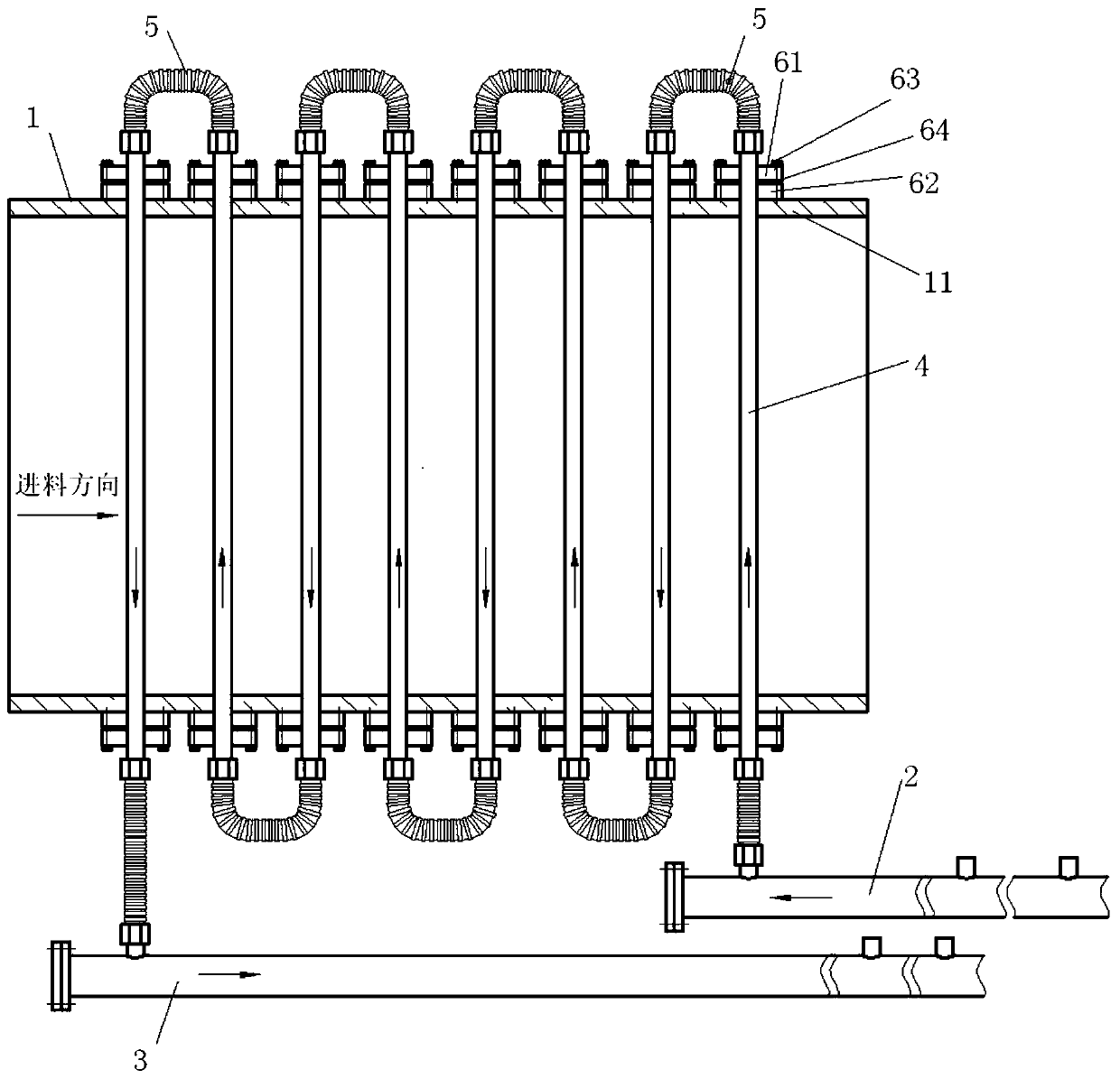

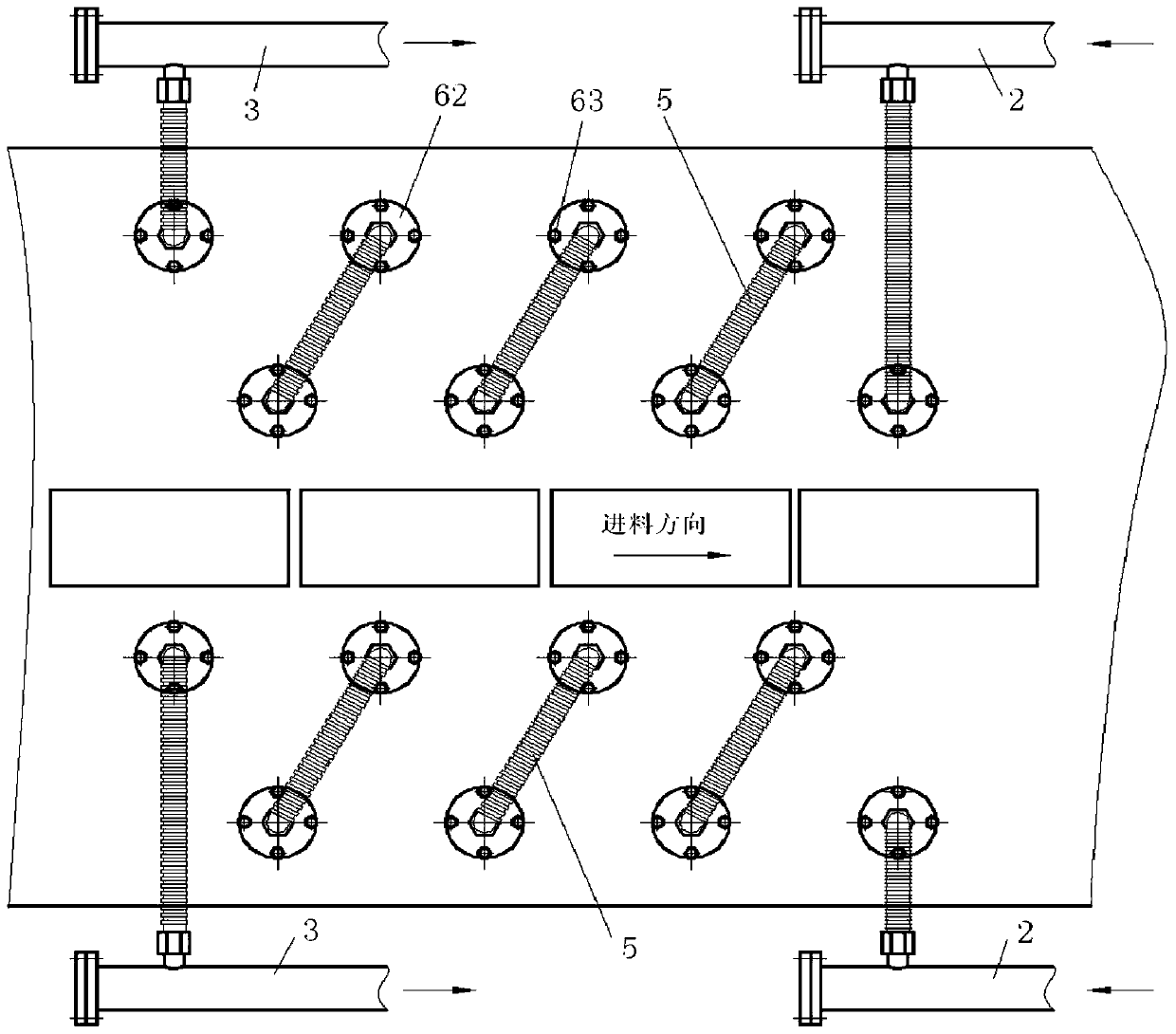

[0025] Such as figure 1 with figure 2 As shown, the kiln with a water-cooled structure in this embodiment includes a furnace body 1 and a water-cooled structure. The water-cooled structure includes a water inlet pipe 2, an outlet pipe 3 and a plurality of water-cooled pipes 4. Each water-cooled pipe 4 runs through the furnace body 1. And the two ends extend to the outside of the furnace wall 11, a plurality of water-cooled pipes 4 are connected in series through the joint pipe 5, the water-cooled pipe 4 at the head end is connected with the water inlet pipe 2, and the water-cooled pipe 4 at the tail end is connected with the water outlet pipe 3, so that the cooling water Enter from the water inlet pipe 2, flow along the water-cooled pipe 4 at the head end, pass through each water-cooled pipe 4 in the middle, reach the water-cooled p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com