Angle valve rod joint line removing device

A clamping line and valve stem technology, which is applied in the field of powder metallurgy, can solve the problems that the clamping line cannot be completely removed, affects the sealing performance of the product, and increases the difficulty of the clamping line, so as to eliminate the risk of water leakage and improve the rationality and simplicity , The effect of enhancing product competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

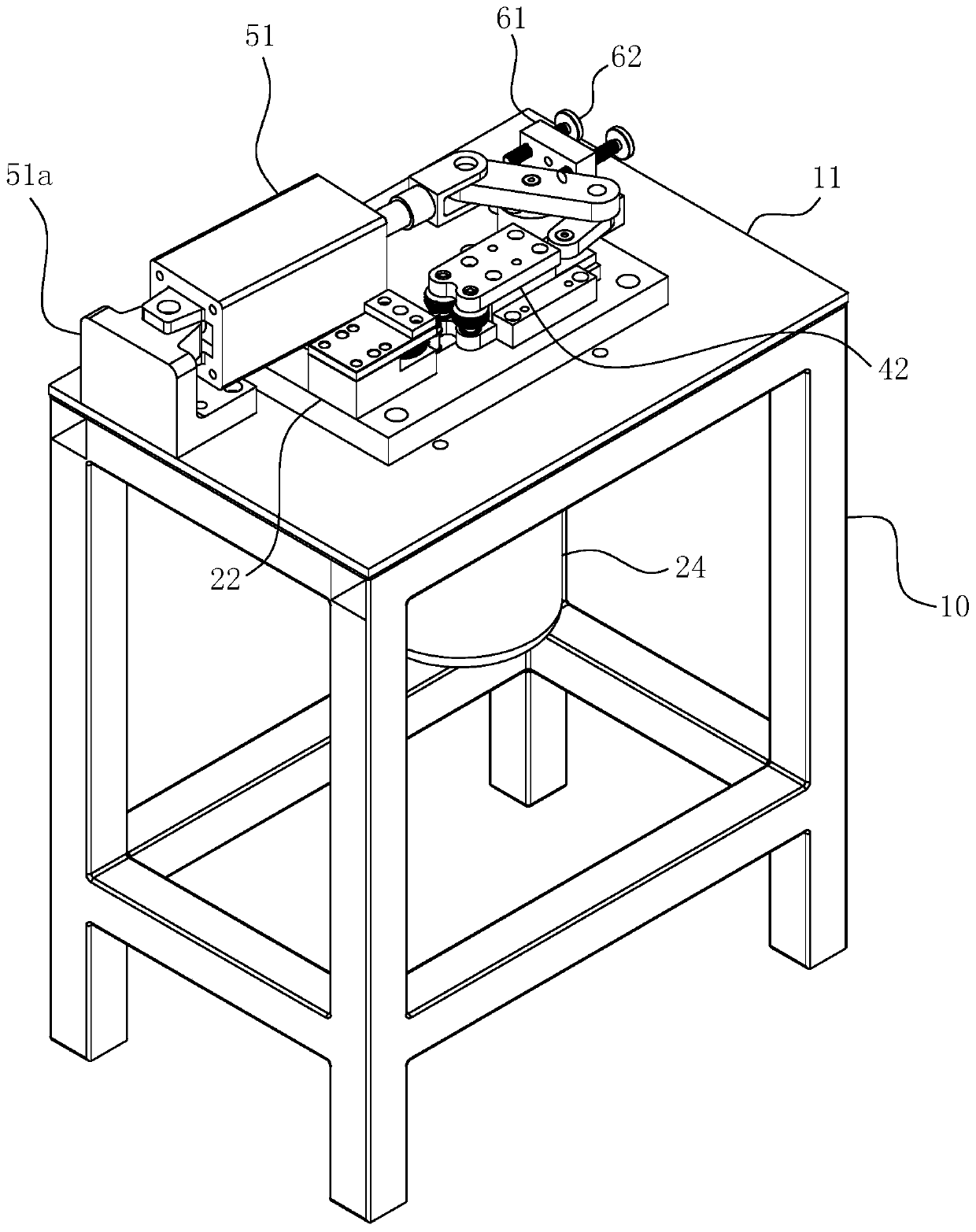

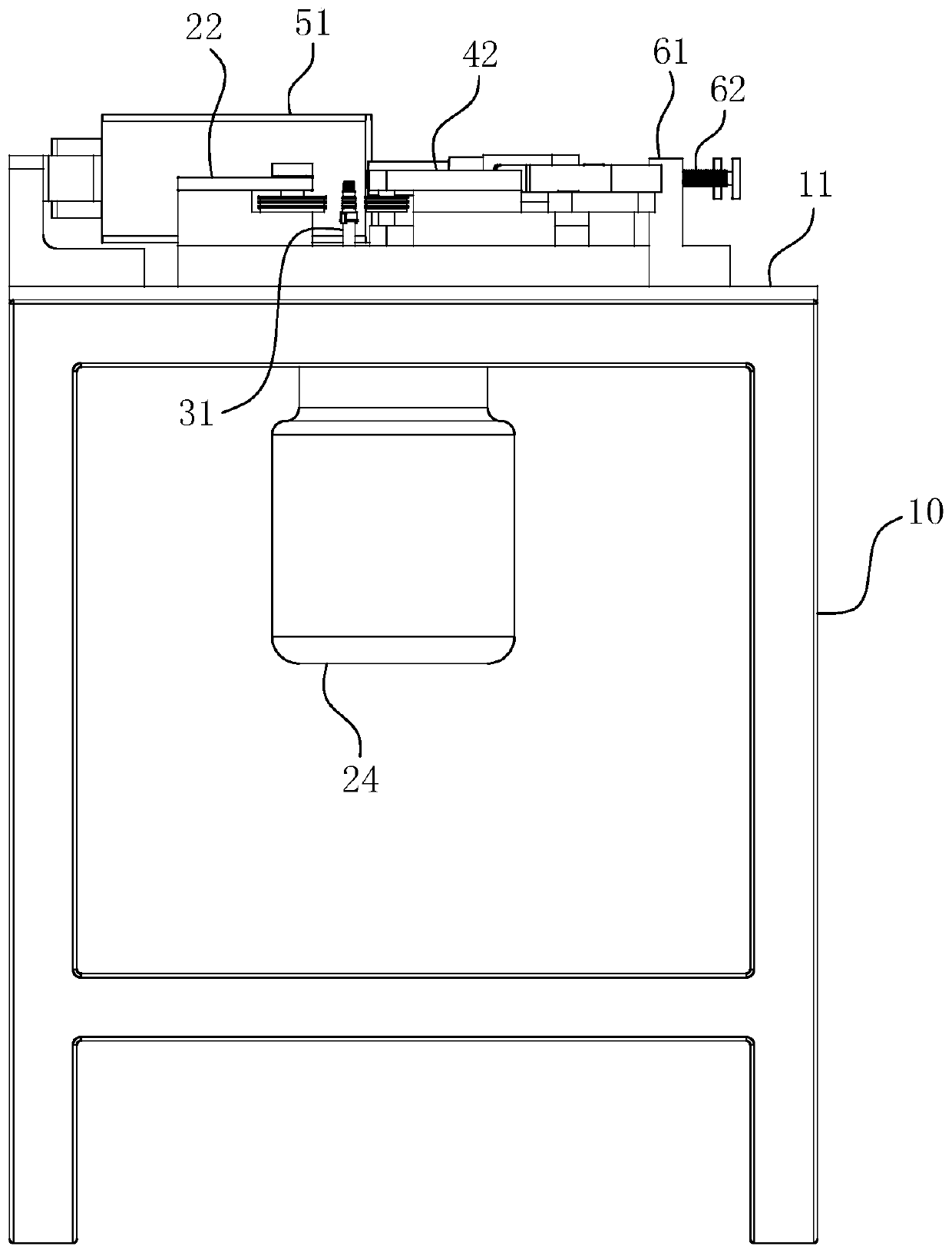

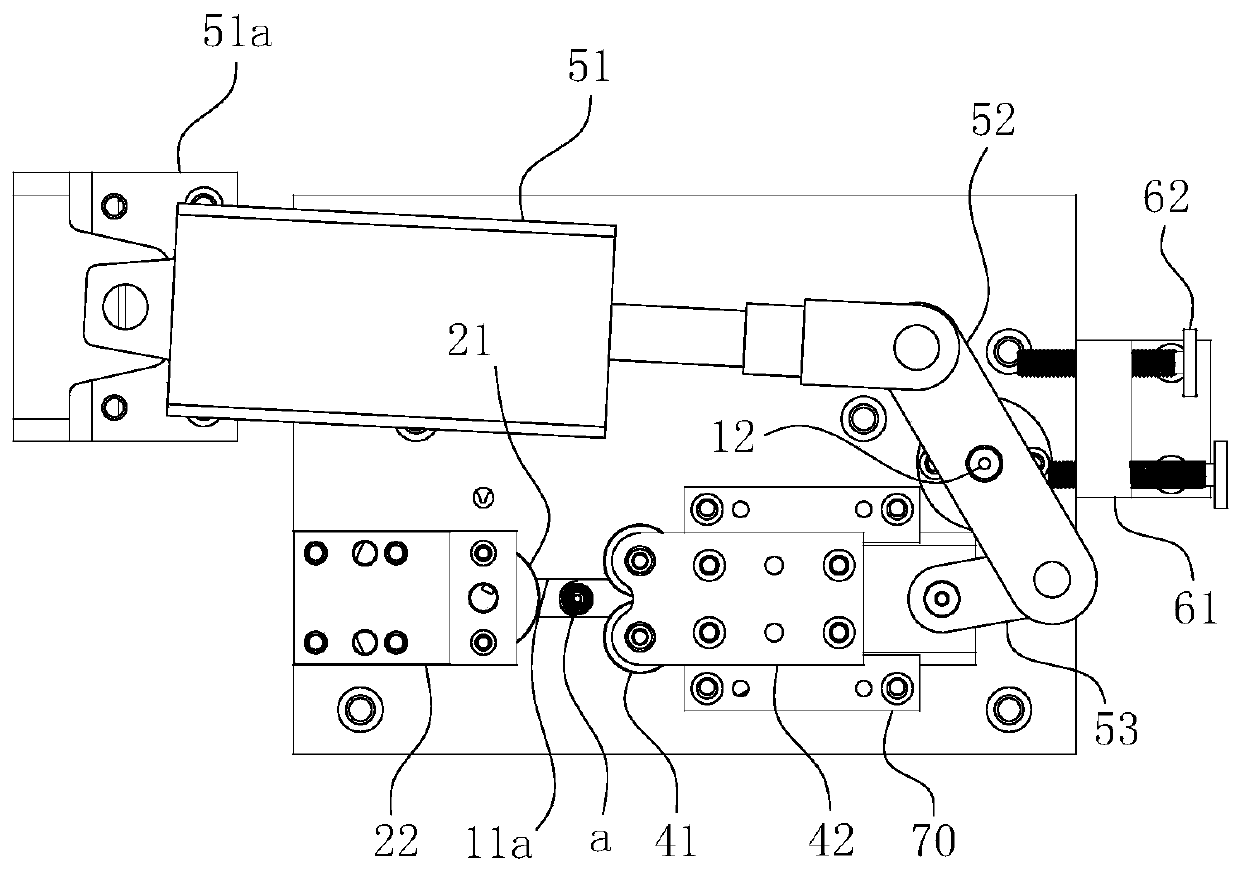

[0041] For ease of understanding, combined here Figure 1-8 , the concrete structure and working mode of the present invention are further described as follows:

[0042] The specific structure of the present invention is as Figure 1-8 As shown, it includes a frame 10 with a work surface 11, a fixed knife mounting seat 22 for fixing the driving wheel 21, a moving knife mounting seat 42 for fixing the driven wheel 41, a slide block 33 for fixing the support body 31 and The air cylinder 51 etc. used to push the movable knife mounting seat 42 to produce directional movement. in:

[0043] The frame 10 can have various shapes, and its function is to provide a bearing surface, that is, a work surface 11, so as to facilitate the placement of various working parts. The fixed knife mounting seat 22 is directly as Figure 1-8 The shown is fixed on the work surface 11. In actual operation, the fixed knife mounting seat 22 can be split into two parts, the upper block and the lower bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com