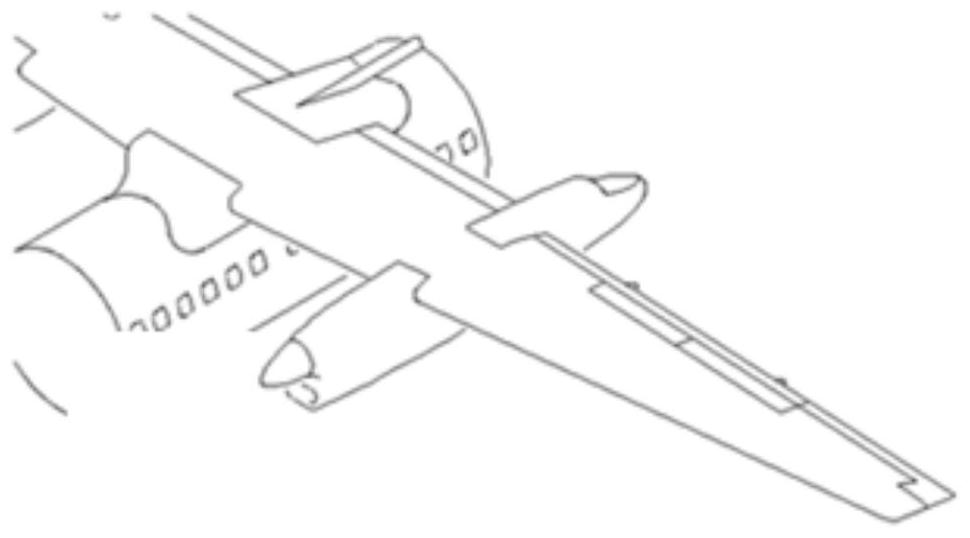

Waterproof and drainage device for wing and engine hanging butt joint based on 3D printing

A 3D printing and engine technology, used in wings, aircraft parts, transportation and packaging, etc., can solve problems such as electrical short circuit, seal failure, affecting flight safety, etc., to eliminate equipment failures and eliminate the risk of water leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

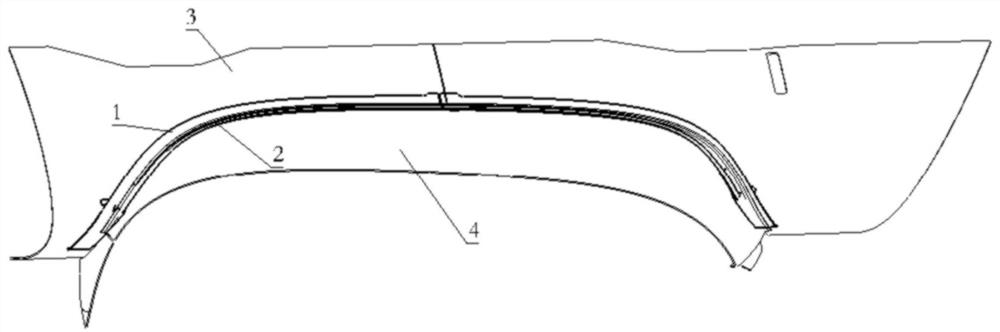

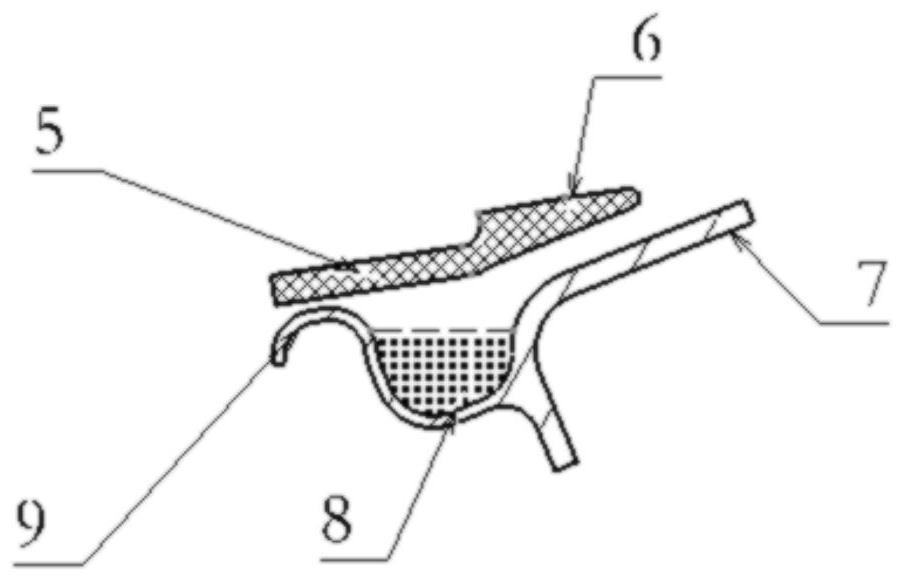

[0036] An anti-drainage device at the joint between the wing and the engine suspension, which is composed of a drainage groove 1, a waterproof rubber strip 2, a wing leading edge skin 3, and an engine suspension skin 4, and is characterized in that the skin at the leading edge of the wing 3 is connected to drain groove 1 by fasteners, and waterproof rubber strip 2 is connected to engine suspension skin 4 .

[0037] A. The 3D printing drainage groove 1 and the traditional waterproof rubber strip 2 are combined at the joint of the engine suspension at the leading edge of the wing, see Figure 1-2 ;

[0038] B. The waterproof rubber strip is a rubber part, which is used to realize the docking and sealing between the leading edge of the wing and the engine suspension skin, and offset the extrusion caused by relative deformation.

[0039] C. The cross-section of the waterproof rubber strip 2 is different along the intersecting line with the relative angle change between the shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com