Fabricated underground structure and construction method

A technology of underground structure and construction method, which is applied to underwater structures, infrastructure engineering, excavation, etc., and can solve problems such as water leakage in underground structures, poor engineering quality, and waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] In a typical implementation of the present invention, a prefabricated underground structure includes several segments, two adjacent segments are connected, and each segment includes side walls 5 on both sides, a bottom plate 11 and a roof 9. The bottom plate is set at the bottom of the side wall, and the top plate is set at the top of the side wall, wherein the side wall includes several sections of prefabricated parts, and the top plate is a prefabricated plate or a laminated plate;

[0061] Outward steps 15 are formed on both side walls at one end of each segment, refer to Figure 12 shown so that the latter segment can wrap the other end of the preceding segment opposite the step.

[0062] Considering that the prefabricated underground structure has a set width, in order to improve the strength of the prefabricated underground structure, the segment also includes a middle wall 6, which is located between the side walls 5 on both sides;

[0063] Likewise, the middle ...

Embodiment 2

[0072] A construction method for a prefabricated underground structure, comprising the following contents:

[0073] Grooving along the length of the installation of the underground structure for sinking the fabricated underground structure;

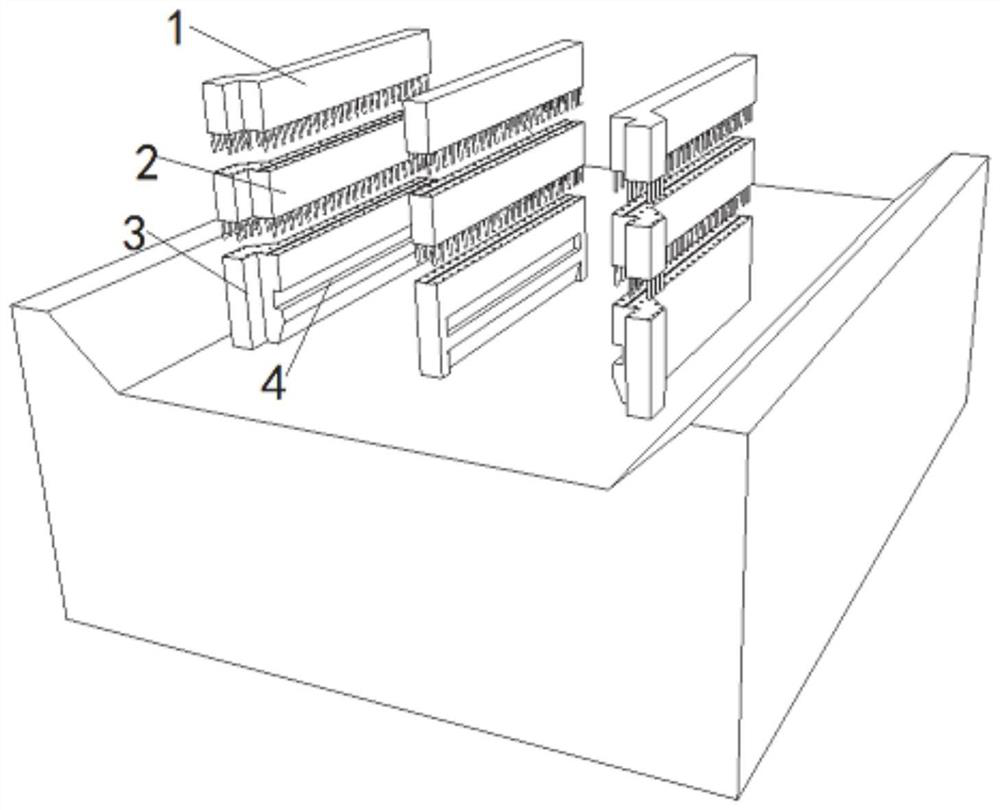

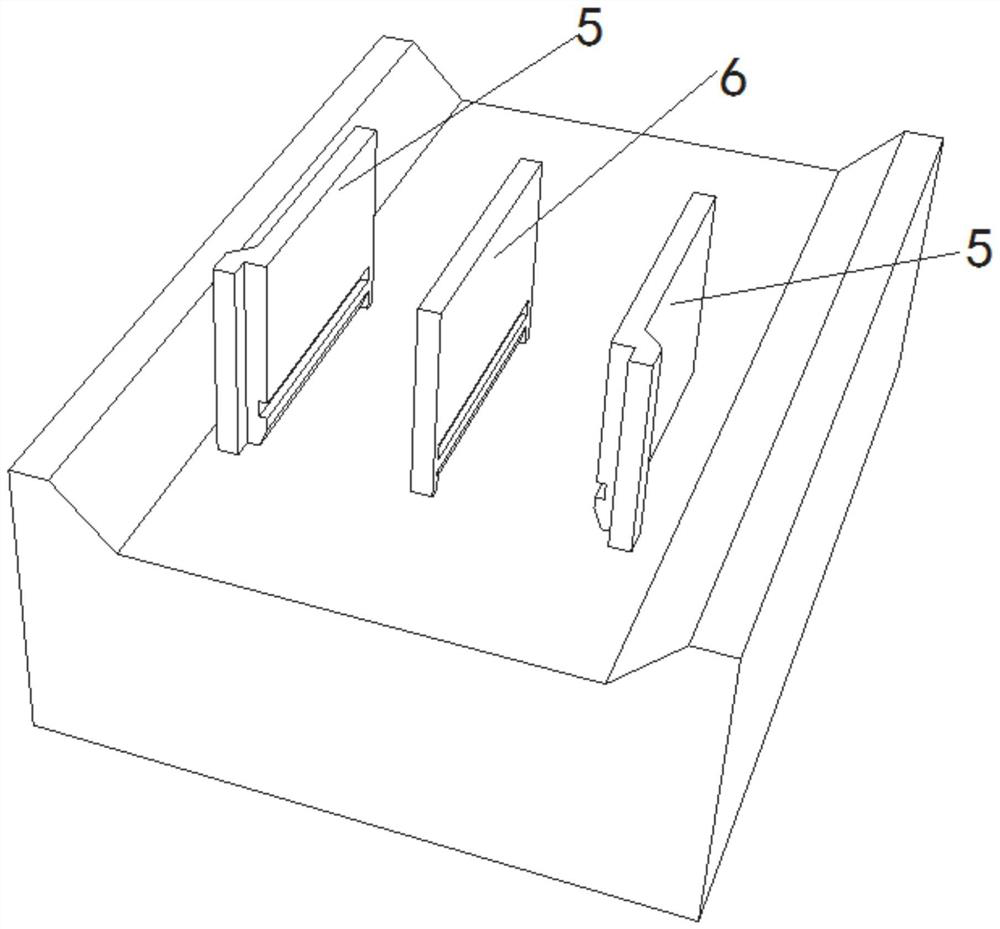

[0074] On-site assembly of the sections of the underground structure, firstly assemble the side walls and middle walls of the first section, refer to figure 2 shown;

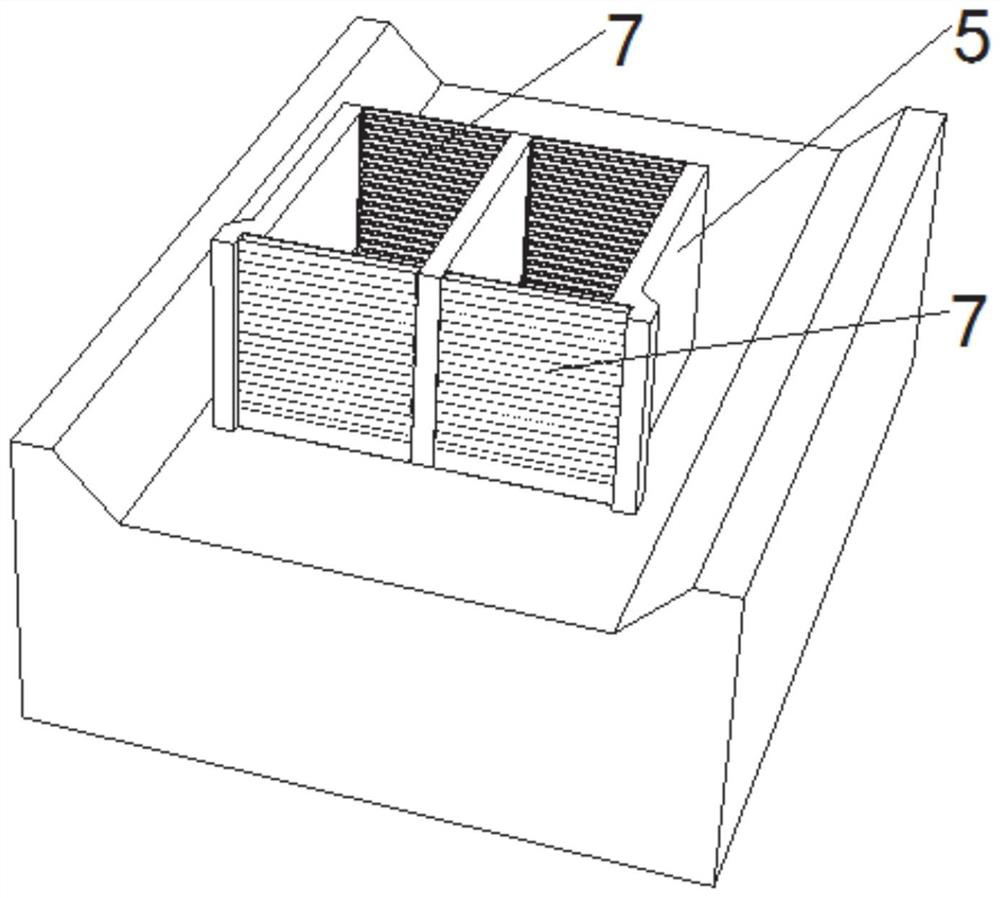

[0075] Among them, it can be understood that the side walls and middle walls of each segment are assembled separately. After the side walls and middle walls are assembled respectively, the middle wall is located between the side walls on both sides, and the middle wall and the side walls are spaced apart. The distance of setting; Steel plate wall 7 is respectively installed as supporting wall (each joint is provided with 4 steel plate walls 7) on both sides of each end of wall in the two ends of each section, refer to image 3 As shown, form the first section 8 or the nt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com