Level crossing rail rapid construction method

A construction method and level crossing technology, applied in the direction of tracks, roads, ballast layers, etc., can solve problems such as traffic impact, achieve the effect of reducing the amount of cast-in-place and speeding up the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

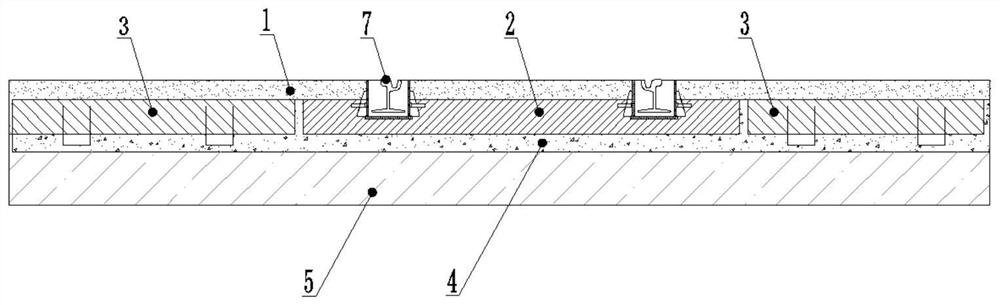

[0039] see figure 1 , the present embodiment proposes a rapid construction method for a level crossing track, which specifically includes the following steps:

[0040] S1. Prefabricated track integrated unit and crossing plate, wherein the crossing plate is formed with mortar pouring holes;

[0041] S2, at the construction site, carry out the subgrade support layer construction;

[0042] S3. Transport the prefabricated track integrated unit and crossing plate to the construction site, and lay the prefabricated track integrated unit and crossing plate on the subgrade support layer;

[0043] S4, pouring and forming a mortar adjustment layer at the bottom of the prefabricated track integration unit and the crossing plate through the mortar pouring hole;

[0044] S5. After the mortar adjustment layer is cured, a road pavement layer is laid on the top of the track slab dust collection unit and the crossing slab.

[0045] In this embodiment, prefabricated track integrated units a...

Embodiment 2

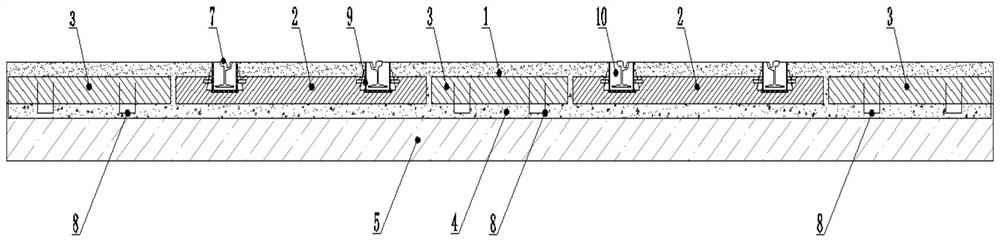

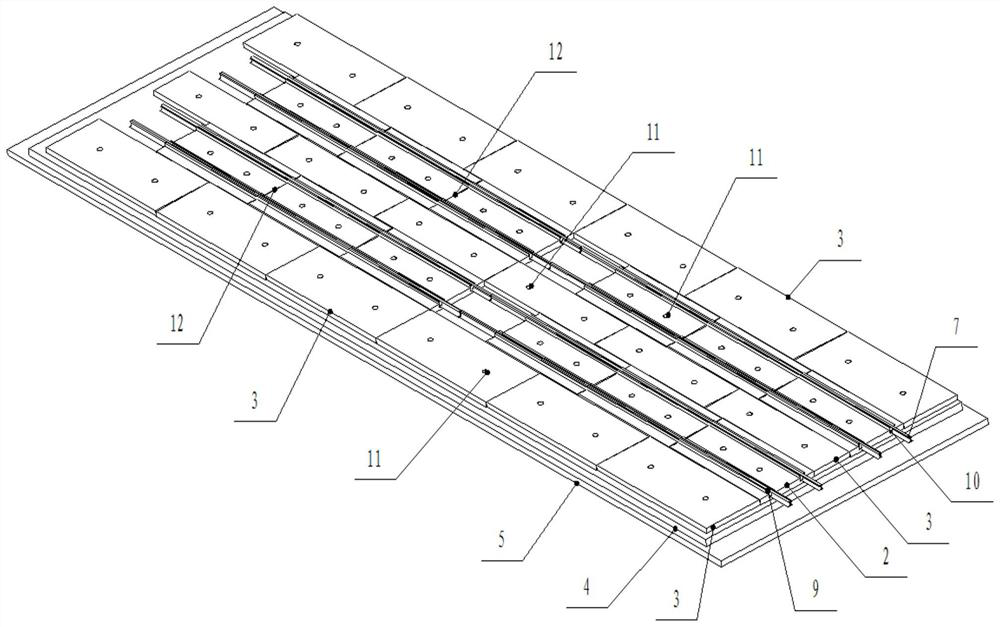

[0057] See figure 2 and image 3 , Embodiment 2 is roughly the same as Embodiment 1, but the construction objects targeted by the two are different. The construction object targeted by this embodiment is a two-way embedded track, which includes two lines, and crossing plates are laid between the two lines and on the outside of the two lines.

Embodiment 3

[0059] See Figure 4 and Figure 5 , Embodiment 3 is substantially the same as Embodiment 1, but in Embodiment 3, the prefabricated track integration unit includes: a prefabricated track slab and a rail assembly, the rail assembly includes fasteners and rails, and the rails are connected by fasteners Fixed on top of prefabricated track slabs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com