Fabrication construction method for fabricated floor slab

A construction method and prefabricated technology, applied to floors, structural elements, building components, etc., can solve the problems of complex floor slab construction, low degree of assembly, poor fire performance, etc., to achieve flexible construction methods, reduce the amount of cast-in-place, reduce The effect of wet work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

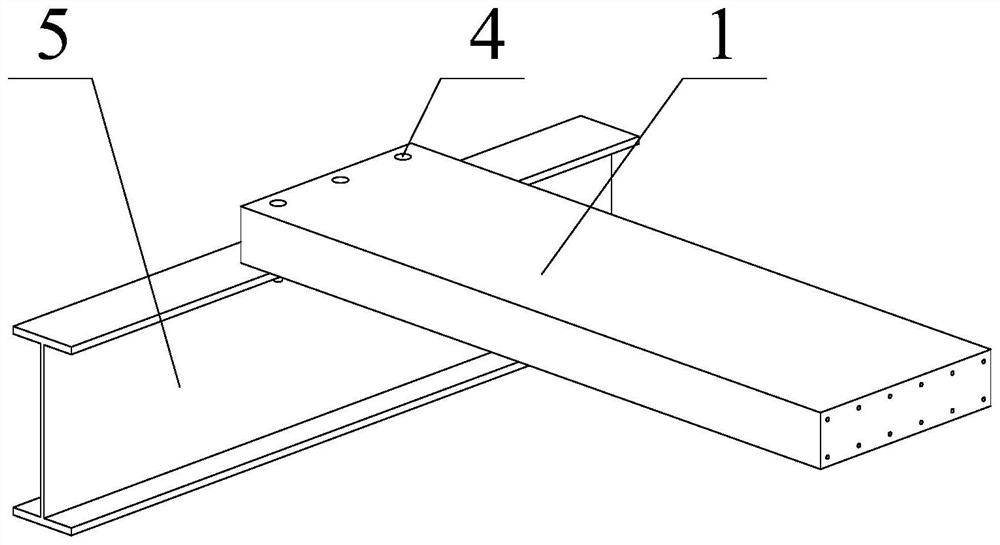

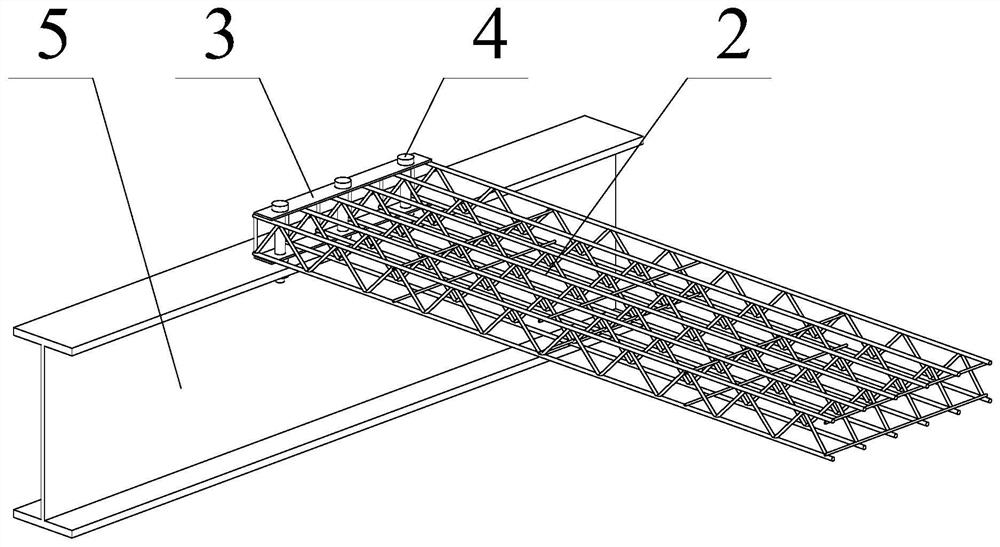

[0050] like Figure 1 ~ Figure 4 As shown, the connector 3 in this embodiment is a connecting steel bar or a connecting steel plate. The floor slab of this embodiment is also provided with mortise and tenon components for splicing.

[0051] The construction method of this embodiment is specifically as follows:

[0052] Firstly, according to the drawing size of the building to be constructed, the autoclaved aerated concrete floor 1 is prefabricated in the factory, and then the autoclaved aerated concrete floor 1 is spliced by mortise and tenon components to form a whole floor. The splicing seams can be bonded with high-strength cement.

[0053] Then, the floor slab is transported to the site where the building needs to be constructed, and the whole floor slab is hoisted by a crane, and then lifted to the location where it needs to be installed.

[0054] Then, fix the angle steel or C-shaped steel supporting the floor on the structural column.

[0055] Then, place the whol...

Embodiment 2

[0060] like Figure 1 ~ Figure 4 As shown, the connecting piece 3 of this embodiment is a connecting hook. The floor slab of this embodiment is also provided with mortise and tenon components for splicing.

[0061] The construction method of this embodiment is specifically as follows:

[0062] Firstly, according to the drawing size of the building to be constructed, the autoclaved aerated concrete floor 1 is prefabricated in the factory, and then the autoclaved aerated concrete floor 1 is spliced by mortise and tenon components to form a whole floor. The splicing seams can be bonded with high-strength cement.

[0063] Then, the floor slab is transported to the site where the building needs to be constructed, and the whole floor slab is hoisted by a crane, and then lifted to the location where it needs to be installed.

[0064] Then, fix the angle steel or C-shaped steel supporting the floor on the structural column.

[0065] Then, drill out the fixing holes matched with ...

Embodiment 3

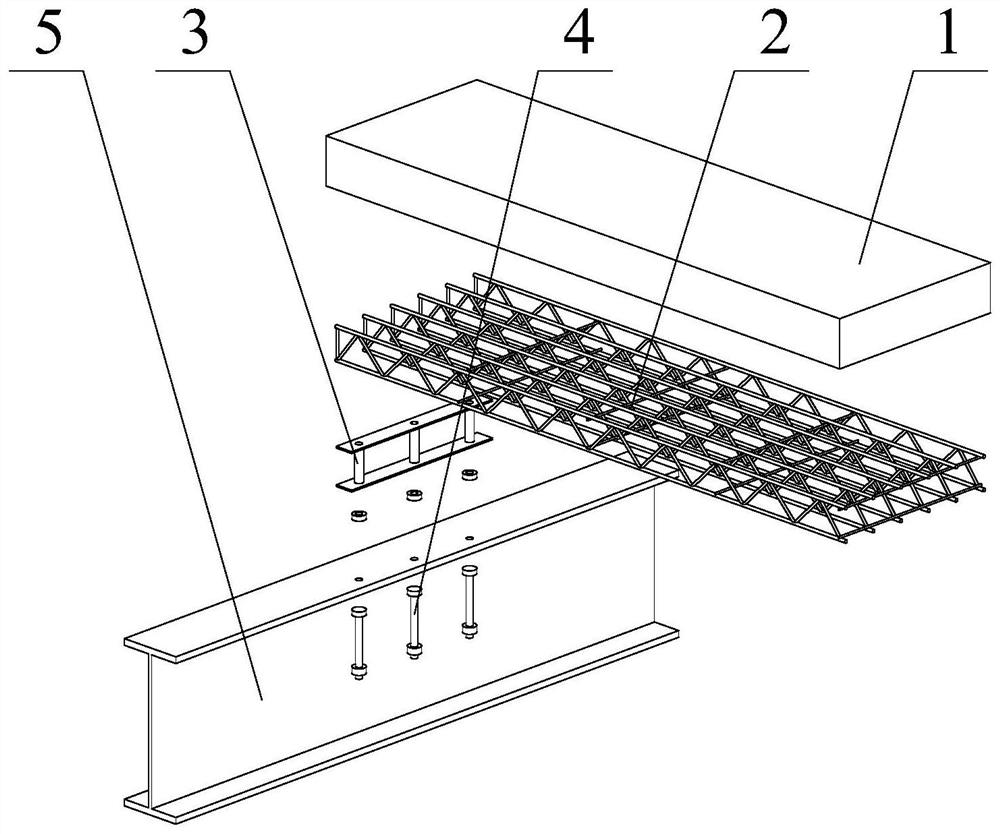

[0070] like Figure 1 ~ Figure 4 As shown, the connecting piece 3 of this embodiment is a bolt sleeve. The floor slab of this embodiment is also provided with mortise and tenon components for splicing.

[0071] The construction method of this embodiment is specifically as follows:

[0072] Firstly, according to the drawing size of the building to be constructed, the autoclaved aerated concrete floor 1 is prefabricated in the factory, and then the autoclaved aerated concrete floor 1 is spliced by mortise and tenon components to form a whole floor. The splicing seams can be bonded with high-strength cement.

[0073] Then, the floor slab is transported to the site where the building needs to be constructed, and the whole floor slab is hoisted by a crane, and then lifted to the location where it needs to be installed.

[0074] Then, fix the angle steel or C-shaped steel supporting the floor on the structural column.

[0075] Then, drill the bolt holes matched with the bolt s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com