Fabricated floor slab with connecting component

A technology of connecting components and assembly, which is applied in the direction of floors, building components, structural elements, etc., can solve the problems of using a large number of I-beams, complex assembly process, and low assembly level, so as to achieve low construction cost and low labor intensity , The effect of reducing the weight of the floor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

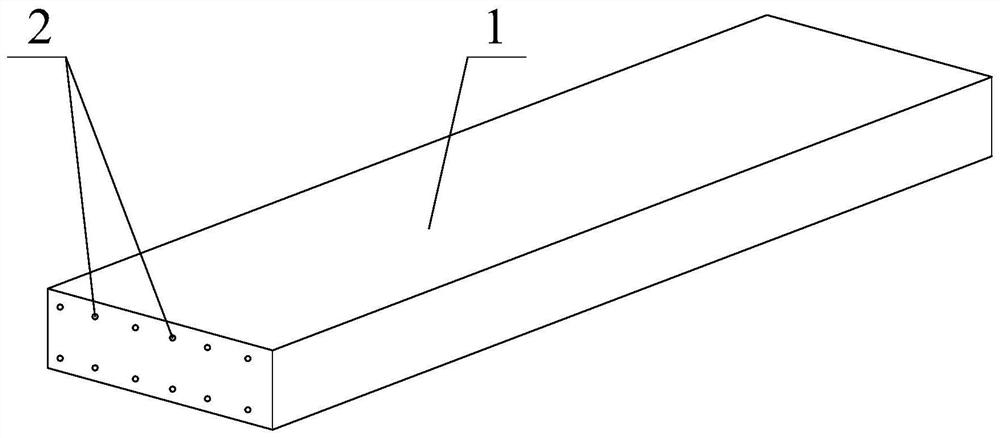

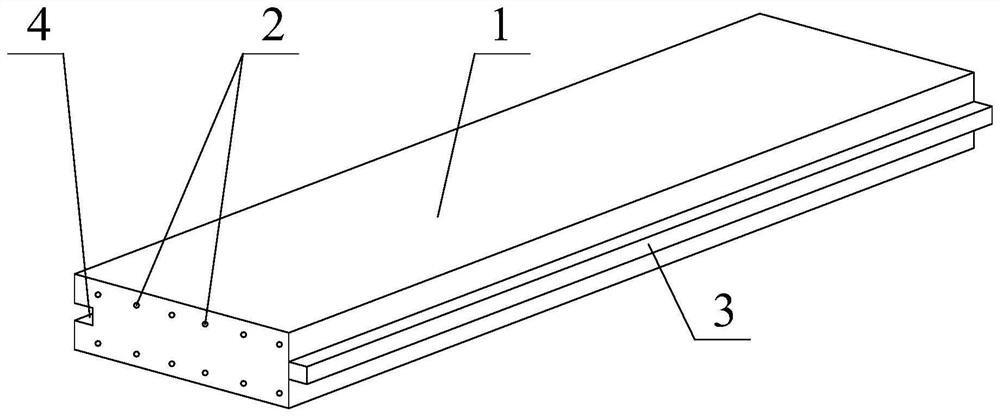

[0056] Such as figure 2 As shown, the prefabricated floor slab with connecting members in this embodiment includes a load-bearing steel truss 2 and a lightweight concrete slab 1 , and the steel truss 2 is embedded in the lightweight concrete slab 1 . The connectors in this embodiment use connecting steel bars or connecting steel plates, which are directly welded to both ends of the steel bar truss 2 after the steel bar truss 2 is fabricated.

[0057] The floor slab of this embodiment is also provided with connecting members for splicing. The connecting member in this embodiment is a mortise and tenon member, and the mortise and tenon member includes grooves 4 and flanges 3 arranged on both sides of the lightweight concrete slab 1 and matched with each other. For the present invention, all more than three hundred kinds of mortise and tenon structures in the prior art can be applied to the present invention.

[0058] This embodiment can be manufactured by using the manufactur...

Embodiment 2

[0063] The prefabricated floor slab with connecting members in this embodiment includes a load-bearing steel bar truss 2 and a lightweight concrete slab 1 , and the steel bar truss 2 is embedded in the lightweight concrete slab 1 . The lightweight concrete slab 1 is an autoclaved aerated concrete slab.

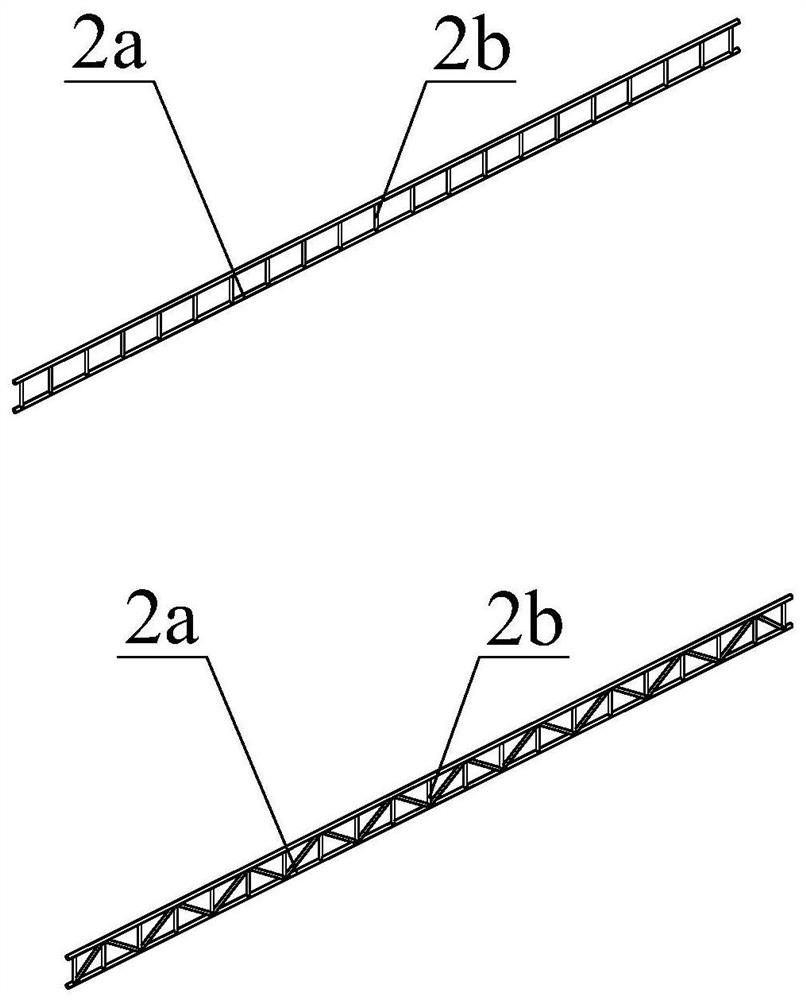

[0064] Such as Figure 3 ~ Figure 5 As shown, the steel bar truss 2 of this embodiment can adopt various structural forms.

[0065] First of all, for floors with low bearing performance requirements (such as the floor of the first floor), multiple straight steel bars can be directly configured as steel trusses.

[0066] Secondly, for middle and low-rise residential buildings, the load-carrying performance of the floor slabs has certain requirements, and reinforced structure steel trusses 2 can be used. Such as image 3 As shown, the steel truss 2 includes longitudinally arranged upper and lower chord main reinforcements 2a, and also includes web auxiliary reinforcements 2b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com