Patents

Literature

63results about How to "Flexible size control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multilevel structure ZSM-5 zeolite molecular sieve, as well as synthetic method and application thereof

ActiveCN106673008AImprove diffusion abilityHigh catalytic activityMolecular sieve catalystsOrganic compound preparationMolecular sieveSide reaction

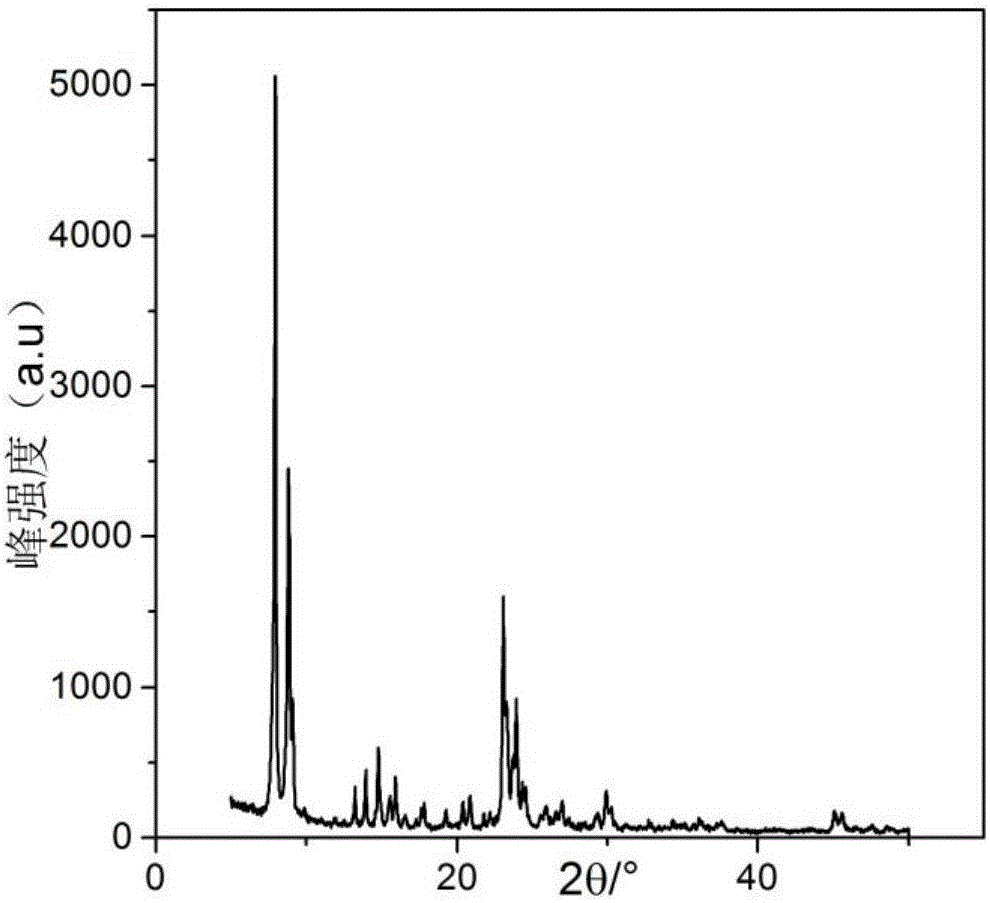

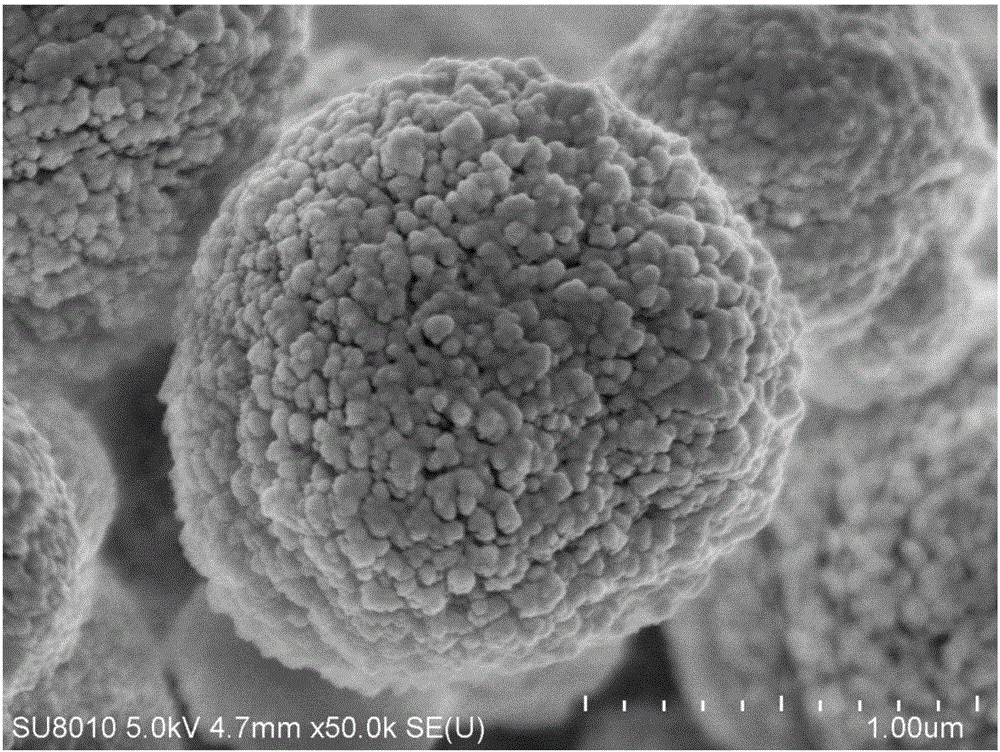

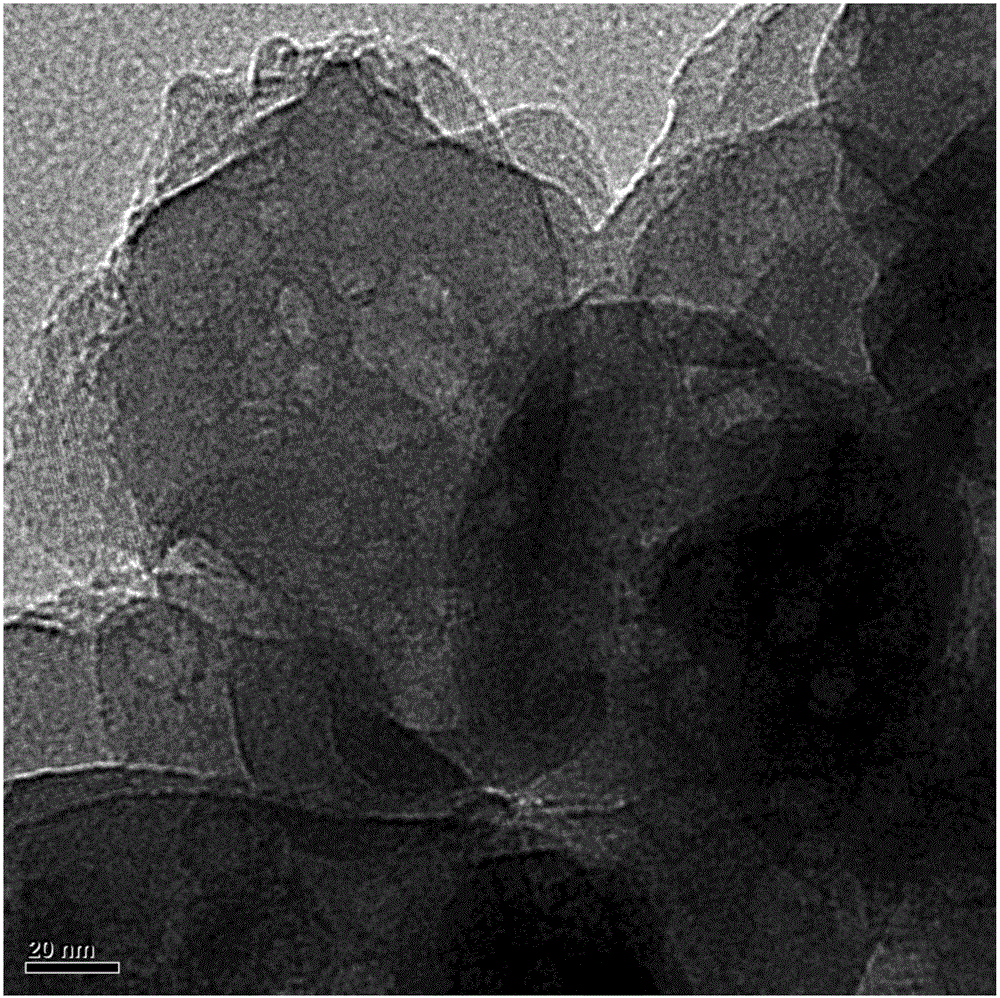

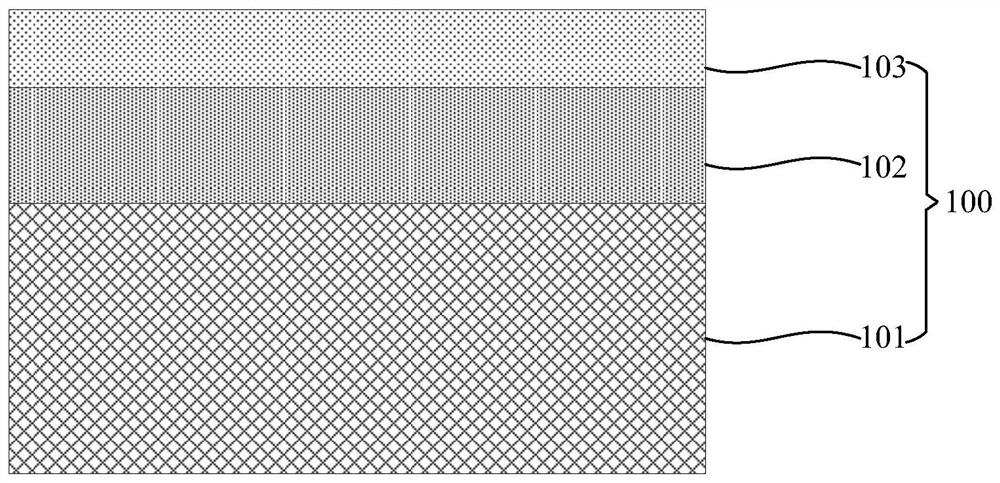

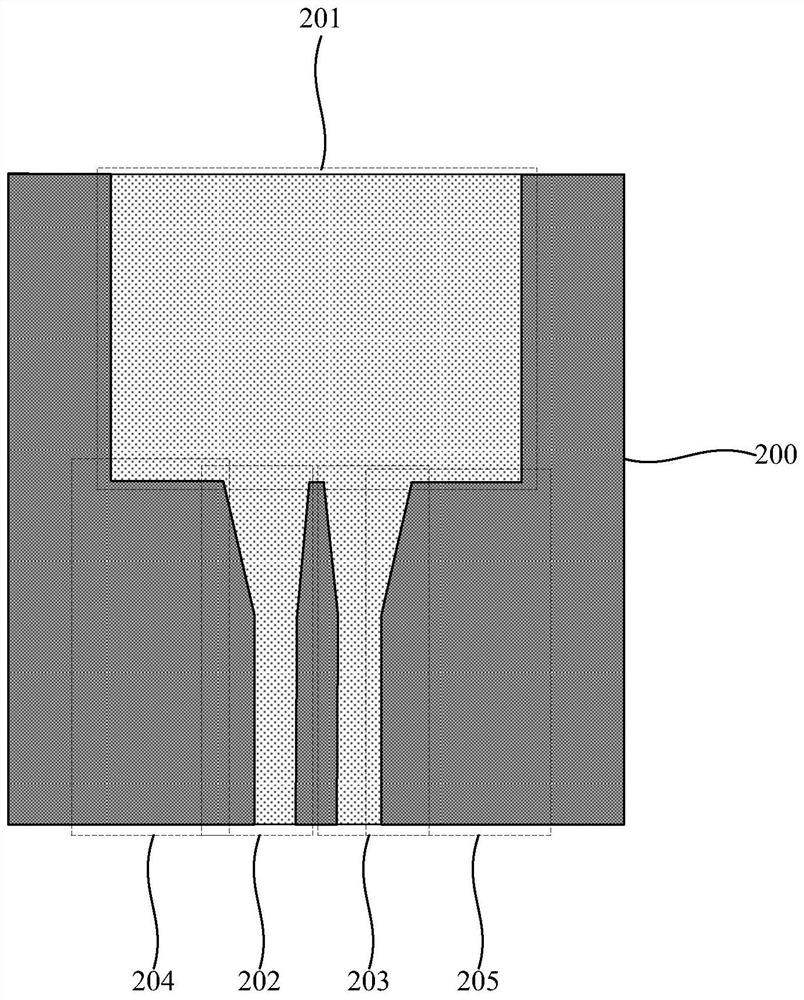

The invention relates to a synthesized multilevel structure ZSM-5 zeolite molecular sieve with intracrystalline meso pores and intercrystalline meso pores, as well as a synthetic method and an application thereof. Except micropores of the zeolite structure, the multilevel structure ZSM-5 zeolite molecular sieve comprises the intracrystalline mesoporous and intercrystalline mesoporous structure, wherein primary nanometer crystal grain size is 40-500nm, and secondary accumulated particle size is 500nm-5[mu]m. The structure greatly improves diffusion performance and the catalyst activity of the molecular sieve, reduces possibility of generation of side reaction and carbon deposit, improves carbon accommodating capability of the molecular sieve catalyst, and prolongs life of the catalyst.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

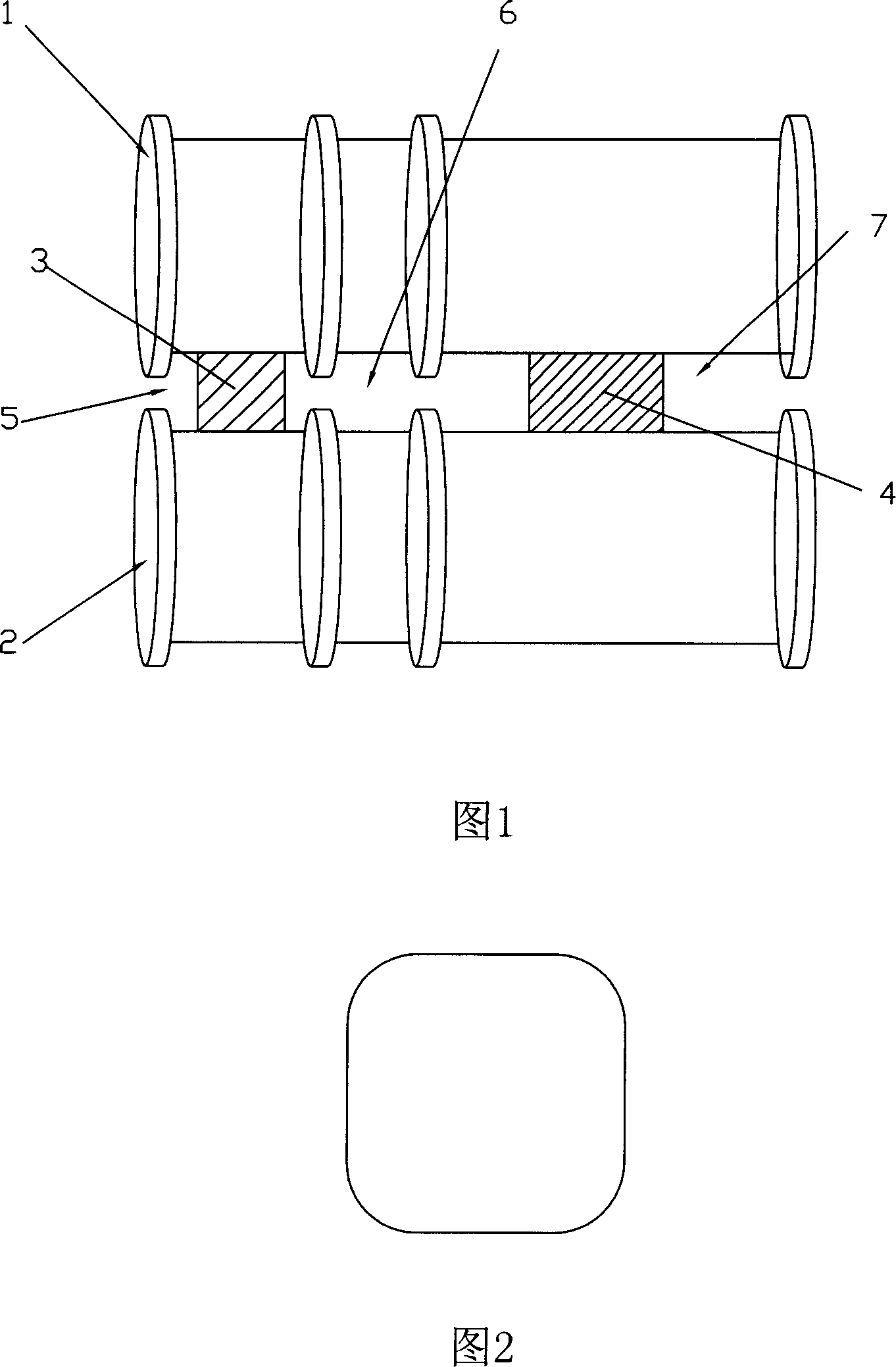

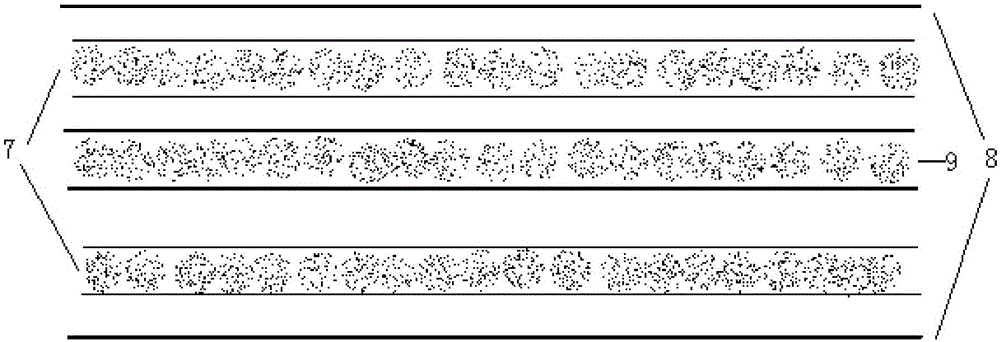

Production method for graphite film

ActiveCN104015468AThe fracture is clean and tidyRegular shapeLamination ancillary operationsLaminationCarbonizationWork in process

The invention discloses a production method for a graphite film. The production method comprises the following steps of (1) winding; (2) low-temperature carbonization; (3) high-temperature graphitization; (4) unwinding and taking-up, namely respectively rolling a semi-finished product of an artificial graphite film and flexible graphite paper; (5) rolling, namely pressing the artificial graphite film semi-finished product on a release film or a protection film; and (6) winding and packaging. The winding working procedure comprises the following steps of a, performing half-breakage type die cutting on a macromolecular film at intervals being 0.2-5m by a dotted line cutter to form cut dotted lines; b, coiling a graphite barrel core with a high-temperature resistant elastic material; c, attaching the macromolecular film with the cut dotted lines to the flexible graphite paper to obtain integrated macromolecular film and flexible graphite paper, and coiling the integrated macromolecular film and flexible graphite paper on the graphite barrel core on the basis of the step b; d, after the integrated macromolecular film and flexible graphite paper which is coiled in the step c reaches a specific thickness, fastening the integrated macromolecular film and flexible graphite paper through a carbon rope.

Owner:李鹏

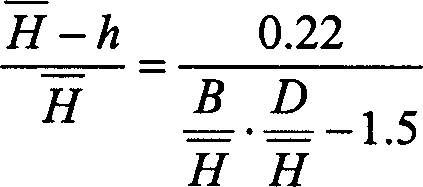

Method for rolling large-size square steel by single machine frame without groove

ActiveCN101024227AIncrease profitReduce manufacturing costMetal rolling arrangementsEngineeringLarge size

The invention discloses single frame non slot rolling large size square steel method. It adopts big delivery head two-high reversing blooming mill system. Each of blank side is repeatedly made into roller pressing underside and free spread side, processed reciprocating many passes non slot rolling by the horizontal mill to form finished product. It uses critical percent of reduction control method to control the size of the single and double drum ratio in the approved range, control width to height ratio to remove rolling off square. Thus the invention can reduce pass positioning, produce the large square steel product with high quality and flexible size by using non slot rolling technique.

Owner:BAOSHAN IRON & STEEL CO LTD

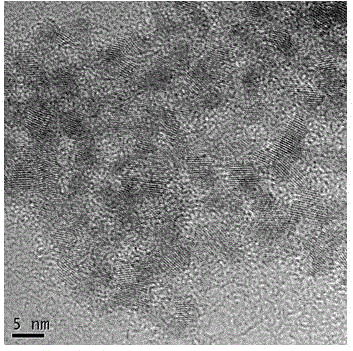

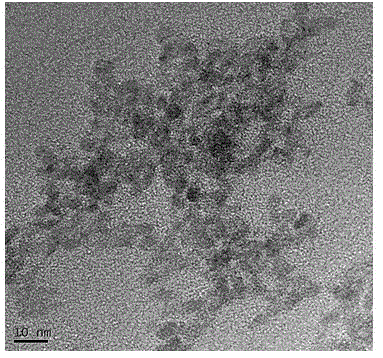

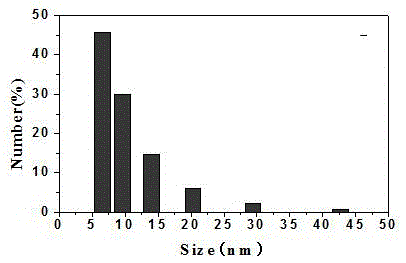

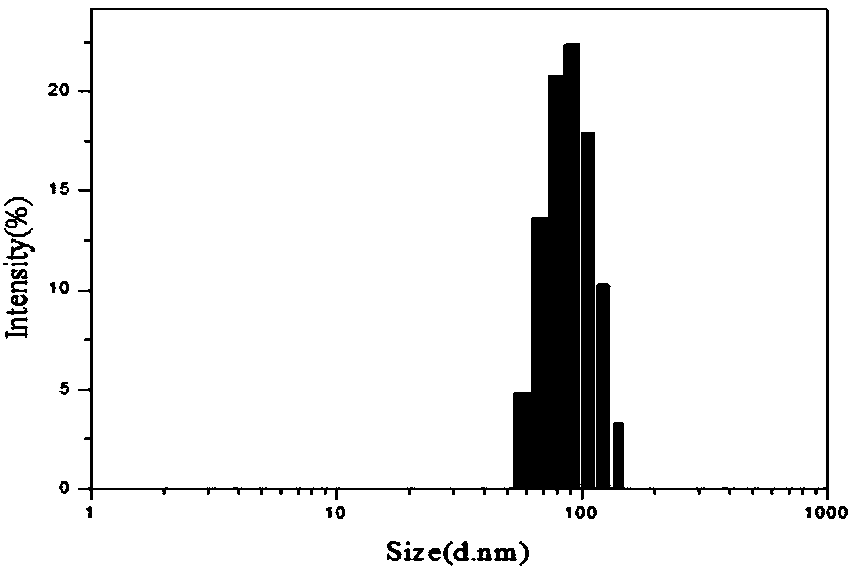

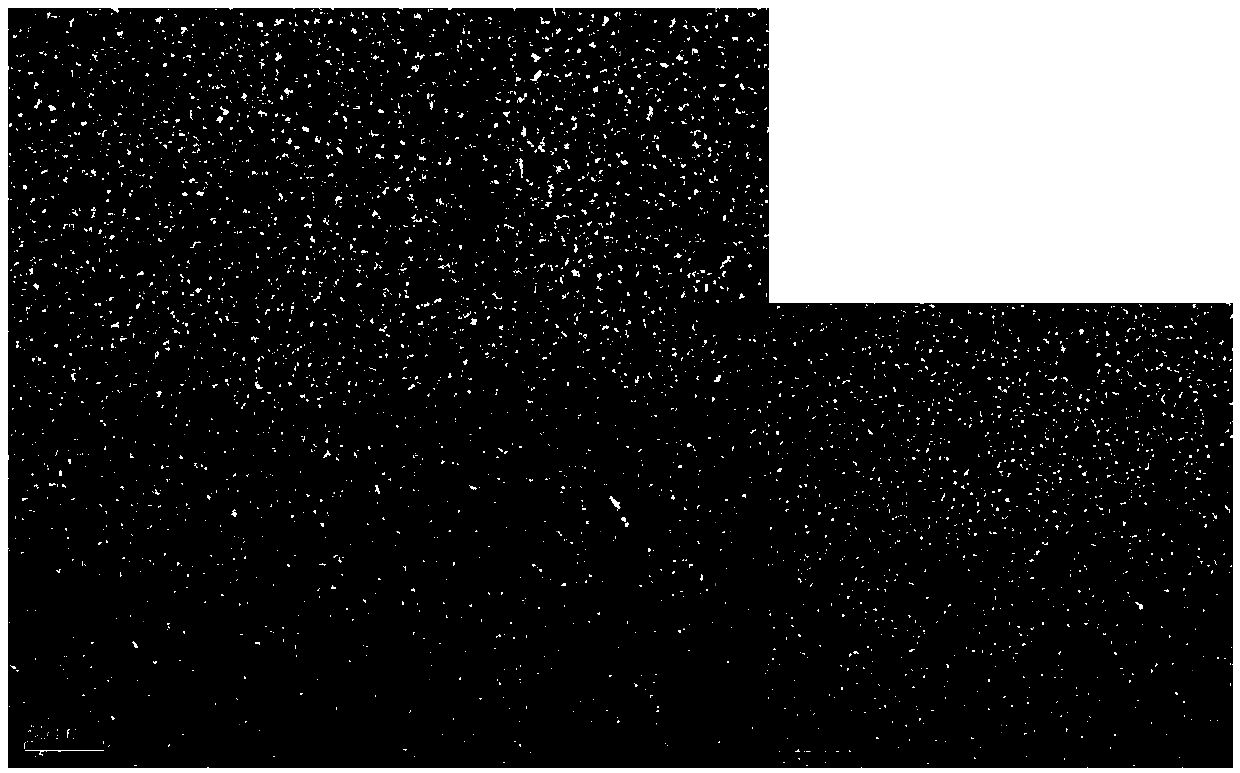

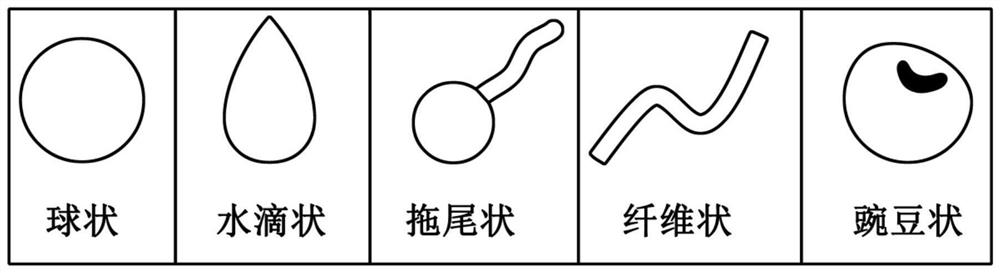

Preparing method for CdSe@CdS core-shell structure quantum dots

InactiveCN105586028AImprove monodispersityProduct particle size is smallNanoopticsLuminescent compositionsPhysicsChemistry

The invention belongs to the technical field of preparation, and particularly relates to a preparing method for CdSe@CdS core-shell structure quantum dots. The preparing method includes the steps that CdSe quantum dots are synthesized in a microemulsion system containing thiourea, a selenium source and excessive Cd2+ ions, then hydro-thermal treatment is conducted on the reaction system, a CdS layer is formed on the surface of CdSe with S2- generated by thiourea decomposition through epitaxial growth, and then the CdSe@CdS core-shell structure quantum dots are formed. A microemulsion and a hydro-thermal treatment method are combined, one-step charging and two-stage reacting are adopted to prepare the CdSe@CdS core-shell structure quantum dots which are small and uniform in size, high in crystallization degree and good in monodispersity, the particle size is easy to control, technological operation is simple, and the requirement for equipment is low.

Owner:FUZHOU UNIVERSITY

Hot working method for smelting molybdenum rhenium alloy casting ingot by suspending

InactiveCN101269383AReduce the amount of dislocation movementFine grainTemperature control deviceMetal rolling arrangementsRheniumDislocation

The invention discloses a thermal processing method for suspension electron beam melting molybdenum-rhenium alloy ingot. The method obtains rod-shaped ingot by melting a molybdenum-rhenium alloy sintered bar through suspension electron beam. The high temperature rolling is carried out by the first fire, the parallel ingot is axially fed, with a rolling speed ranging from 300 to 400mm / min, the temperature is kept for 1 hour; the ingot is rolled to the set thickness through rolling for three times and heated at high temperature for the second time, the temperature is kept for 1 hour, with a rolling speed ranging from 300 to 400mm / min; the ingot is rolled to the set thickness after inverting the direction; the ingot is heated at high temperature for the third time, the temperature is kept for half an hour; the ingot is rolled to the set thickness through 3 rolling for three times and is carried for cold rolling after annealing. The thermal processing method provided by the invention reduces the dislocation movement for single sliding and the speed of the dislocation movement, controls the direction of the dislocation movement, avoids the cracking at crystal boundary owing to the accumulation of the dislocation; besides, the thermal processing method ensures cogging of the ingot but not cracking, and ensures heating processing to go on smoothly. By the thermal processing method, accepted plank stuff characterized by fine crystal particles and uniform sizes can be made, with purity over 99.99 percent.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

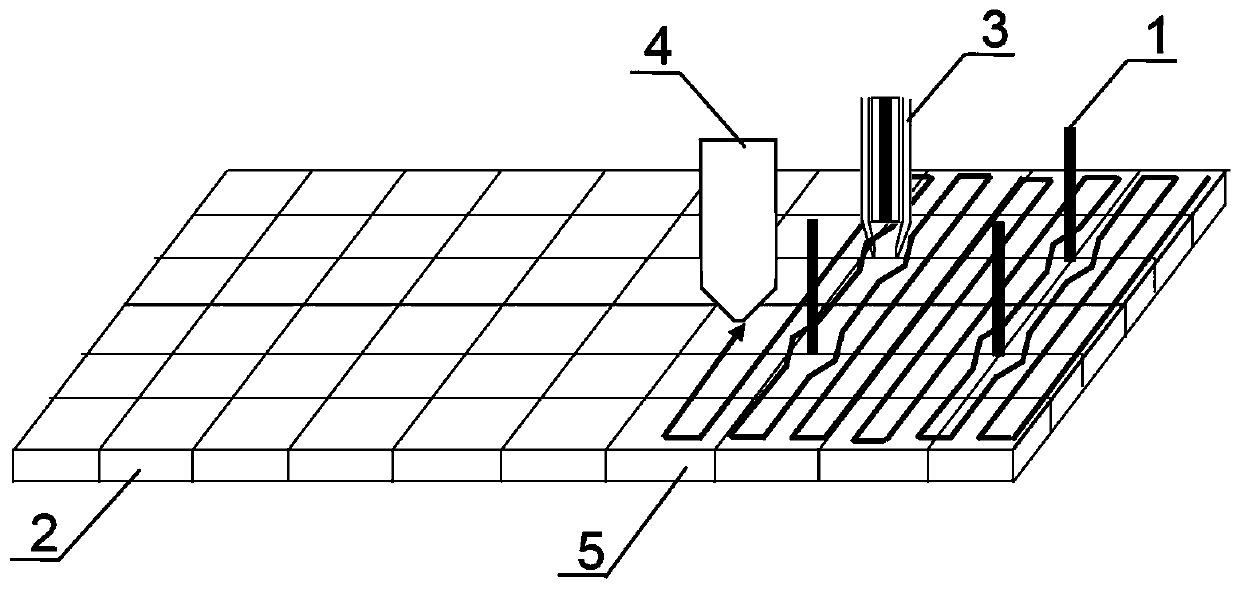

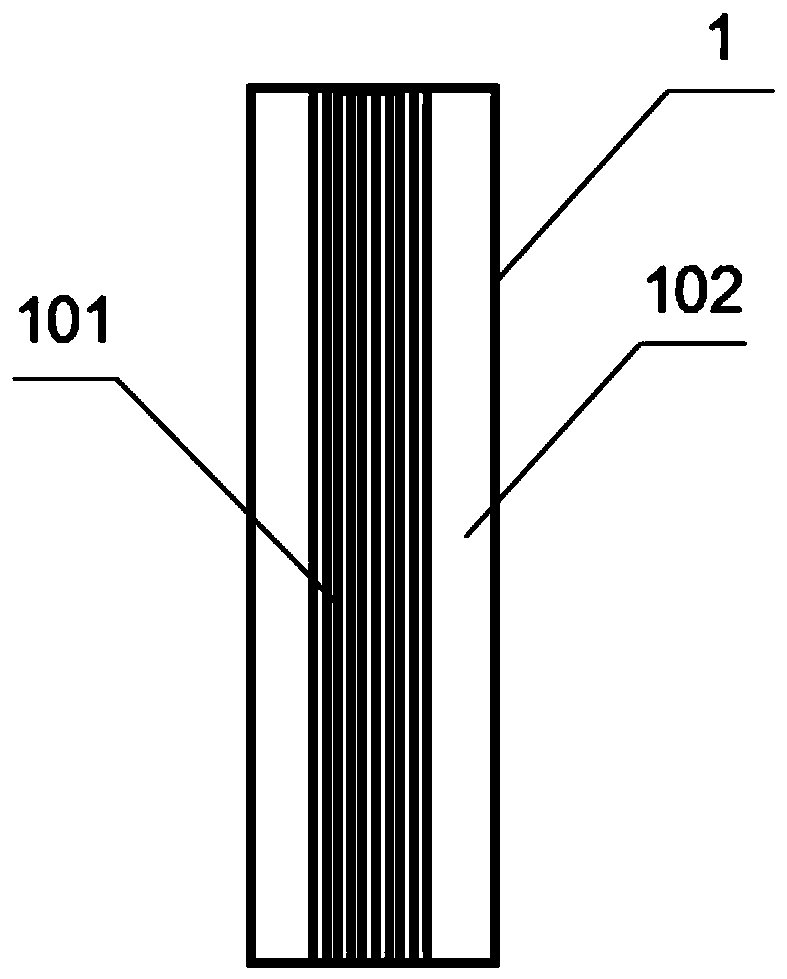

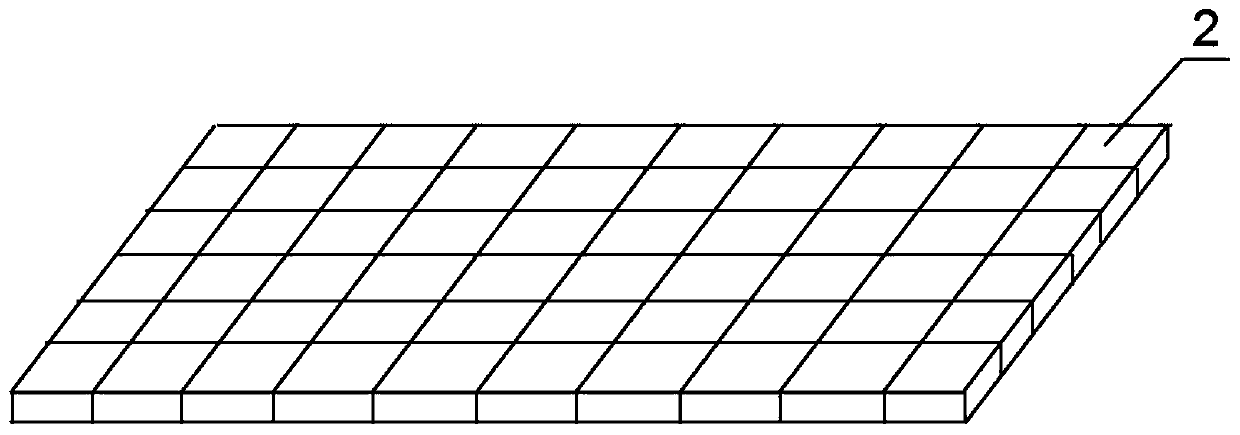

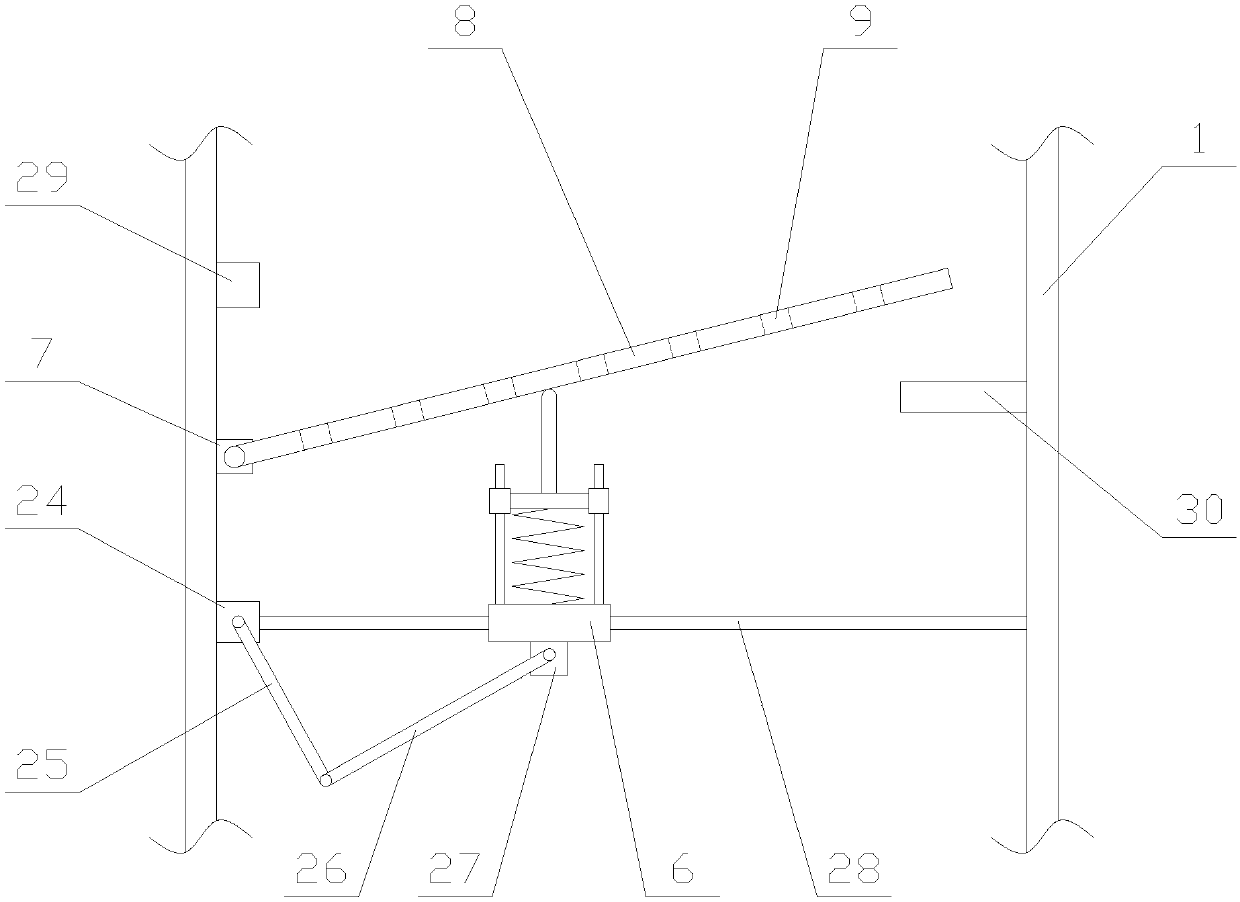

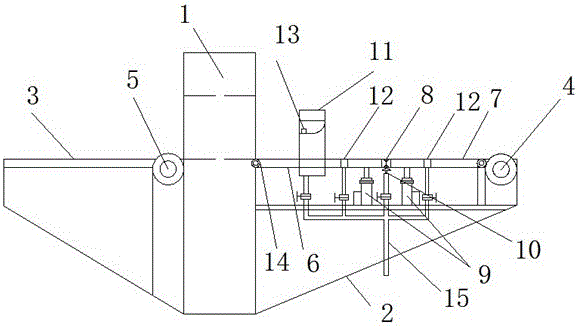

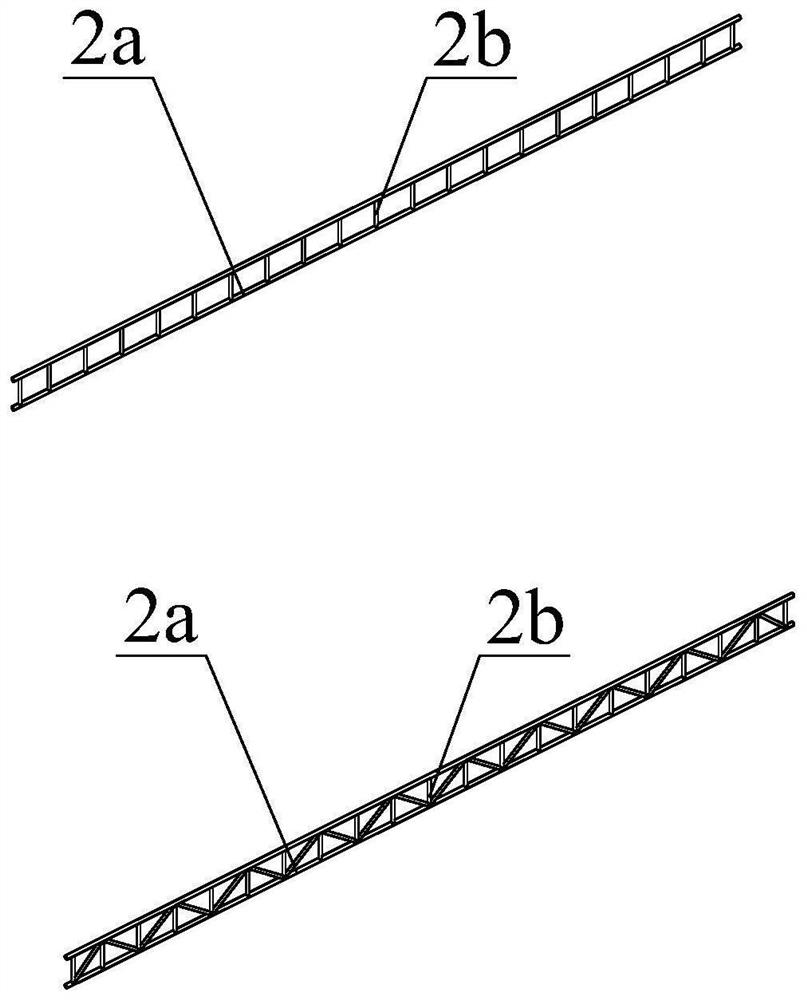

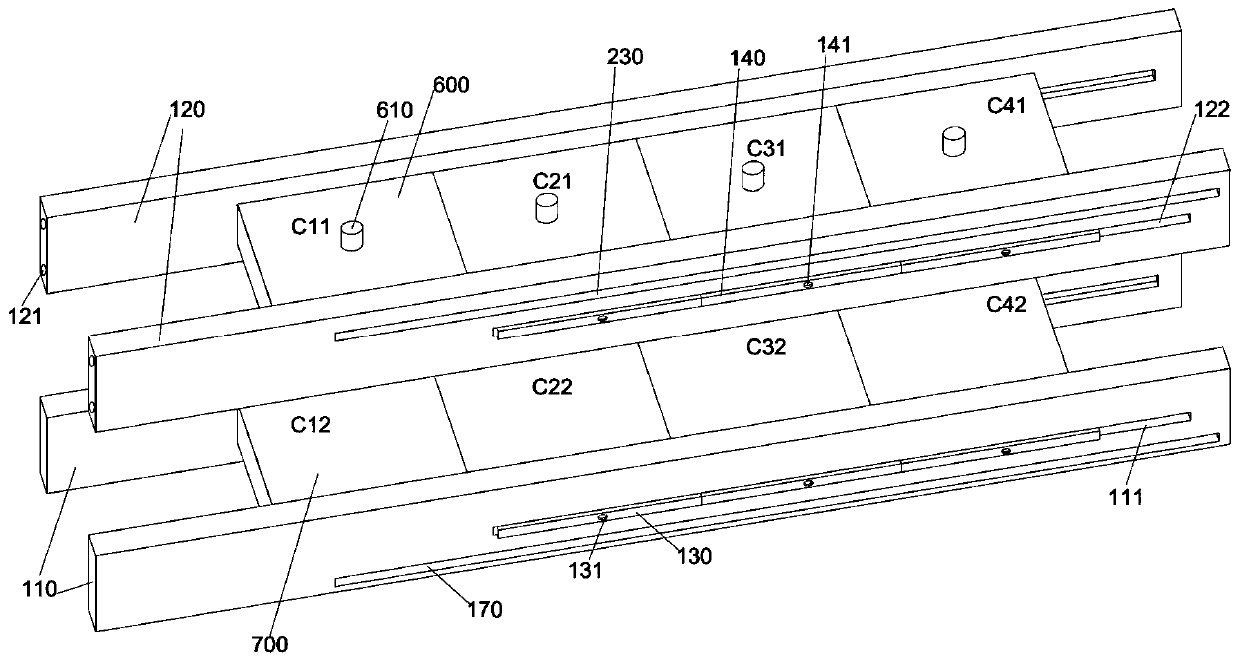

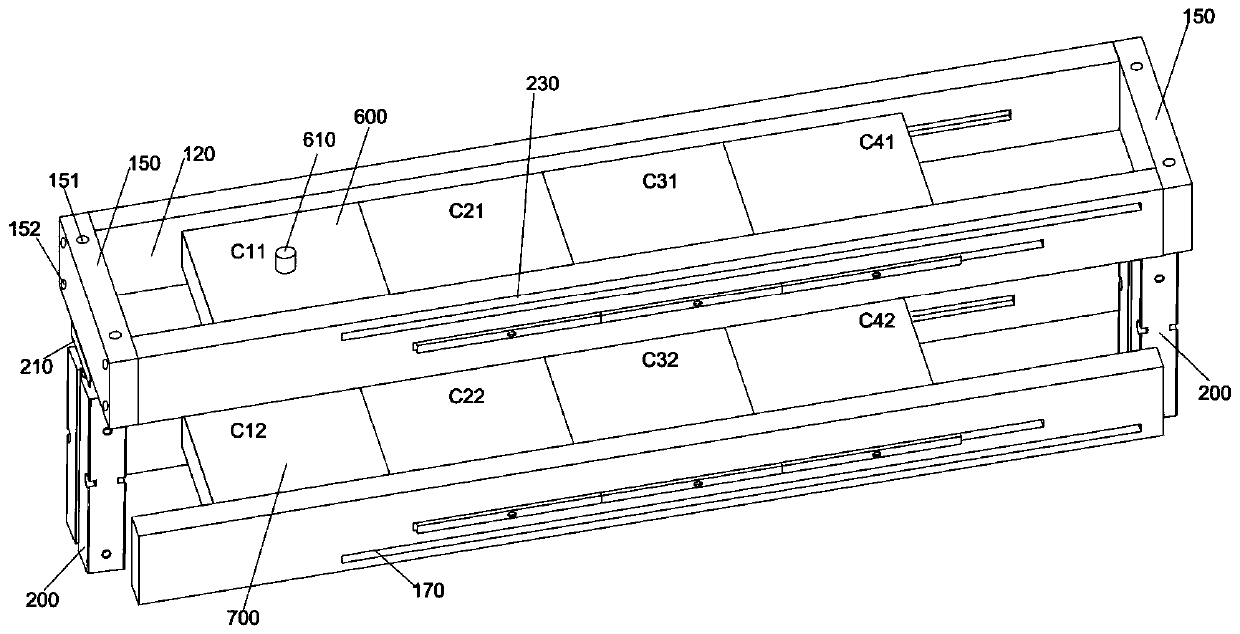

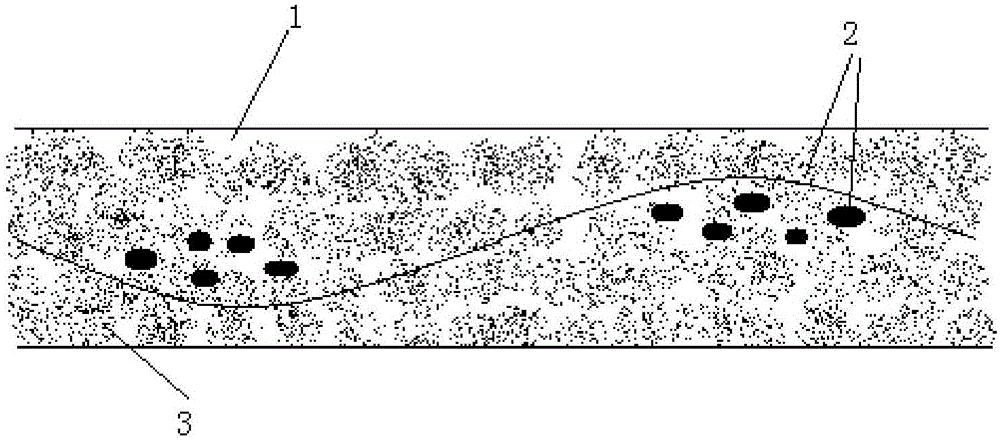

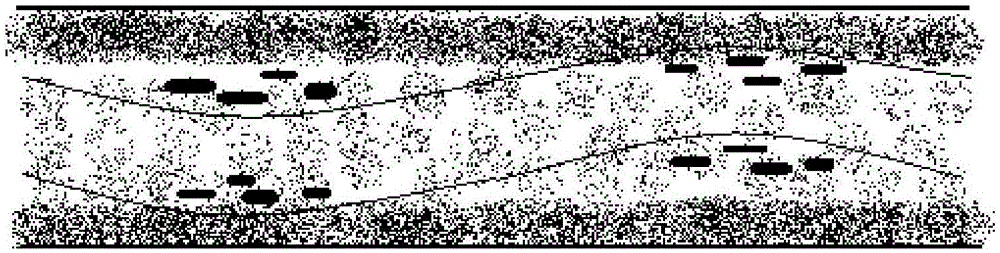

Additive manufacturing method of fiber rod-prearranged Z direction-reinforced continuous fiber composite material

ActiveCN109760336AAchieving damage distributionFlexible size controlAdditive manufacturing apparatusAdditive mnaufacturing with solid and fluidOptoelectronicsResin-Based Composite

The invention provides an additive manufacturing method of a fiber rod-prearranged Z direction-reinforced continuous fiber composite material. Firstly, fiber rods are prepared, and then a substrate isprinted through melt extrusion of pure resin; then, a printing path is planned and the fiber rods are prearranged in real time according to the prearrangement requirements of the fiber rods; after the substrate is printed, a printing end performs extrusion forming 3D printing on the continuous fiber reinforced resin-based composite material, and the number and the distribution mode of the fiber rods are estimated according to the intensity requirements; when passing through the reserved positions of the fiber rods, the printing end avoids the reserved positions according to the set interpolation path; when the printing end passes through the reserved positions and ensures that mechanical interference does not occur between the printing end and prearranged heat guns, the prearranged heat guns drive the fiber rods into the reserved positions; and printing is repeated until a formed part reaching a specified thickness is obtained according to the lengths of the fiber rods. According to the method, the Z-direction fiber rods are prearranged in the extrusion forming printing process, so that the Z-direction mechanical property is improved, and the anisotropy of the composite material product is reduced.

Owner:XI AN JIAOTONG UNIV

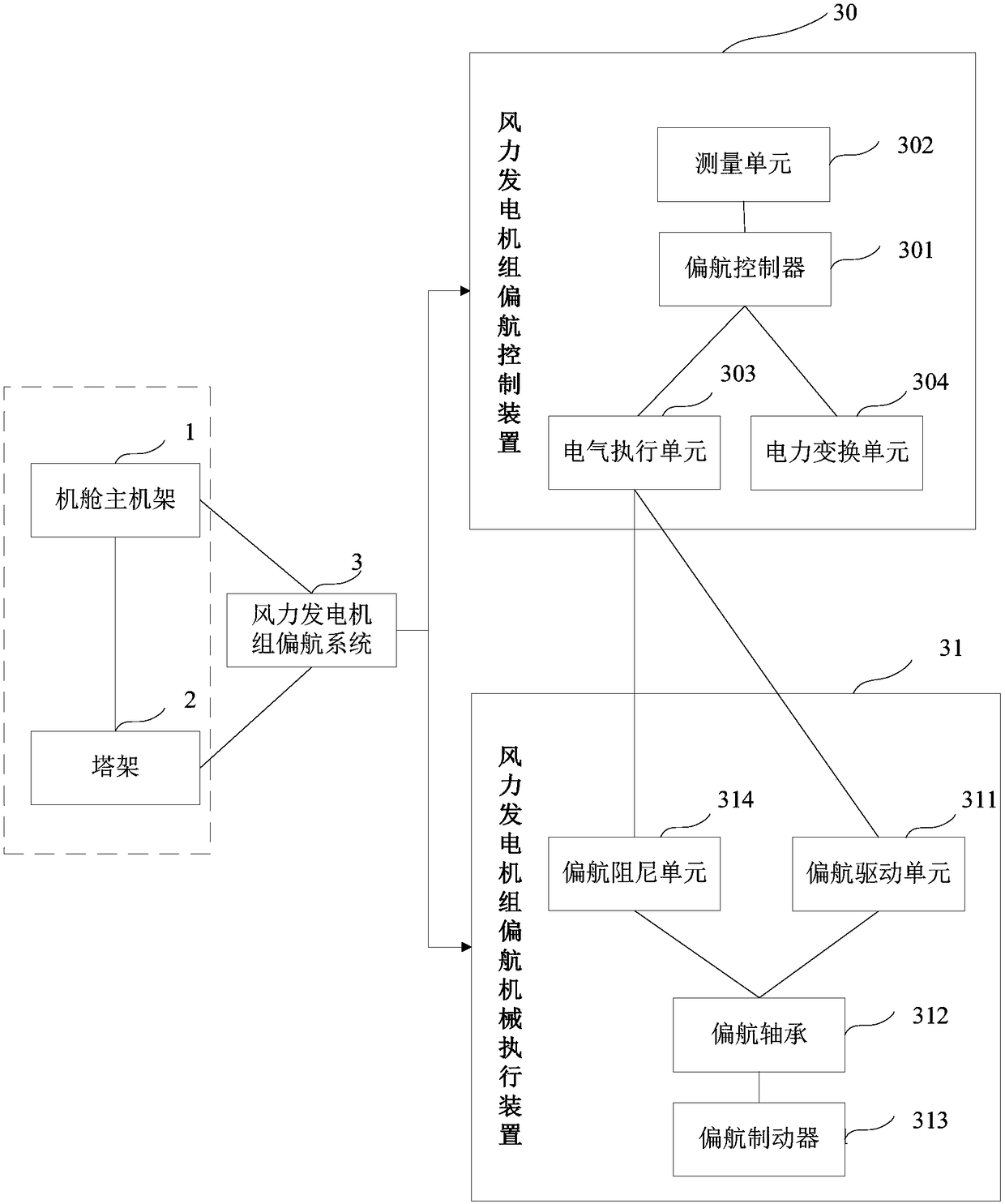

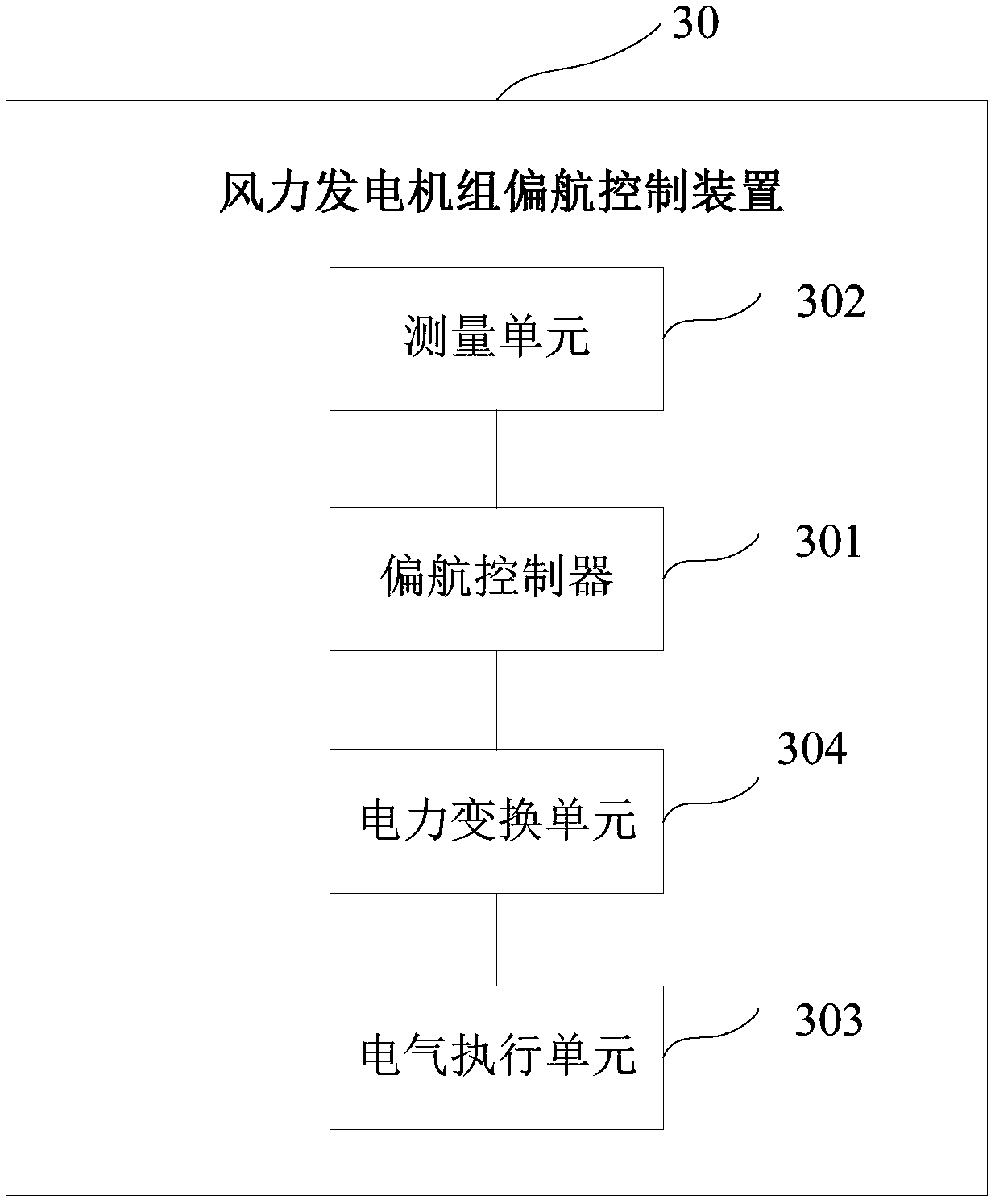

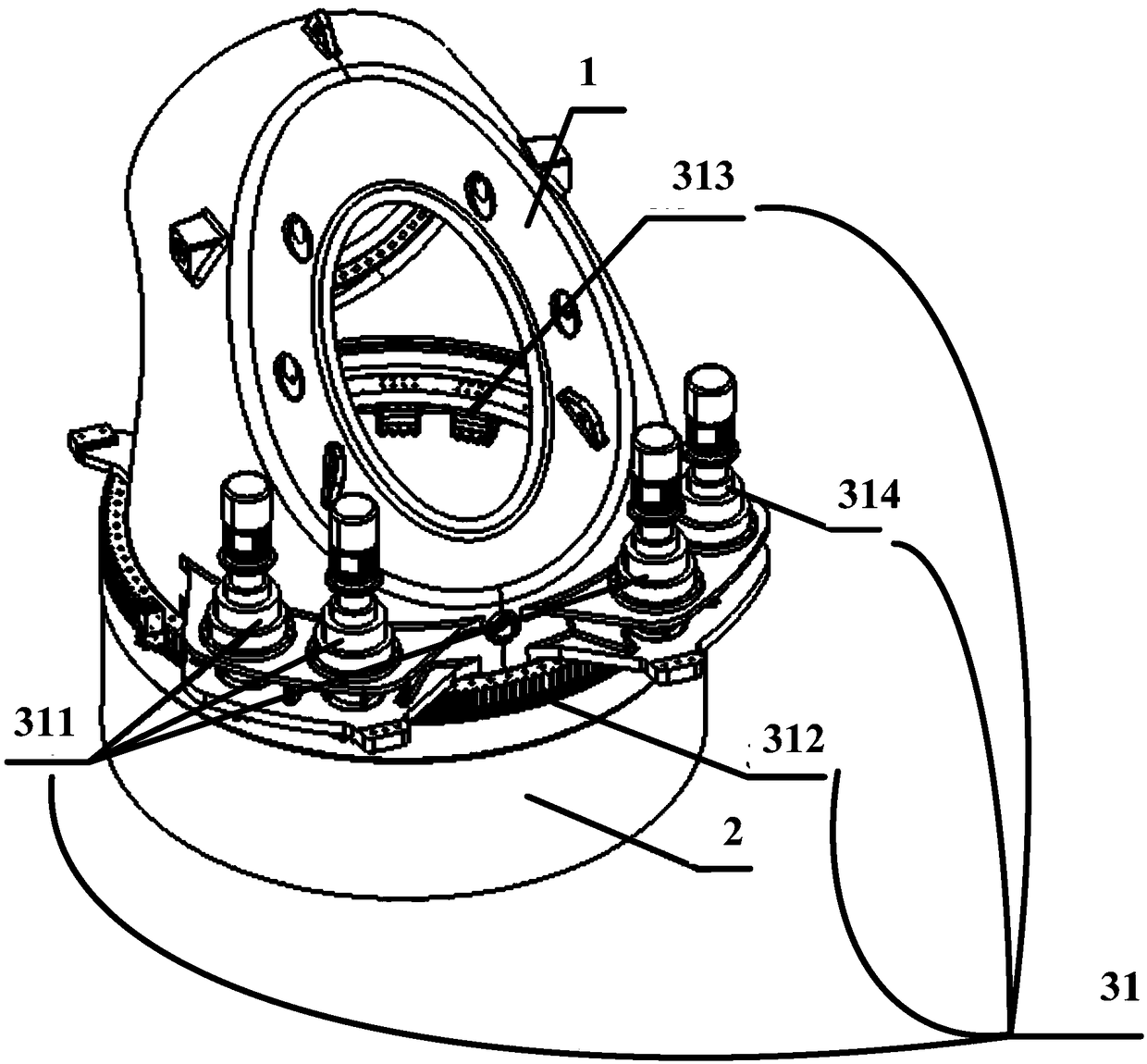

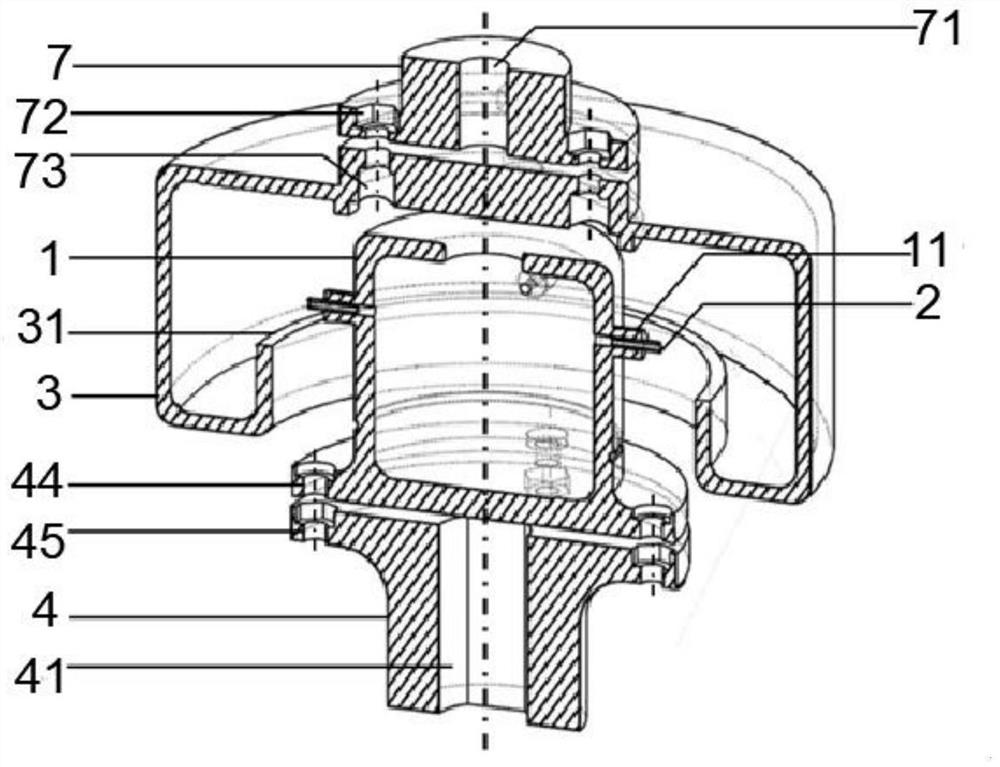

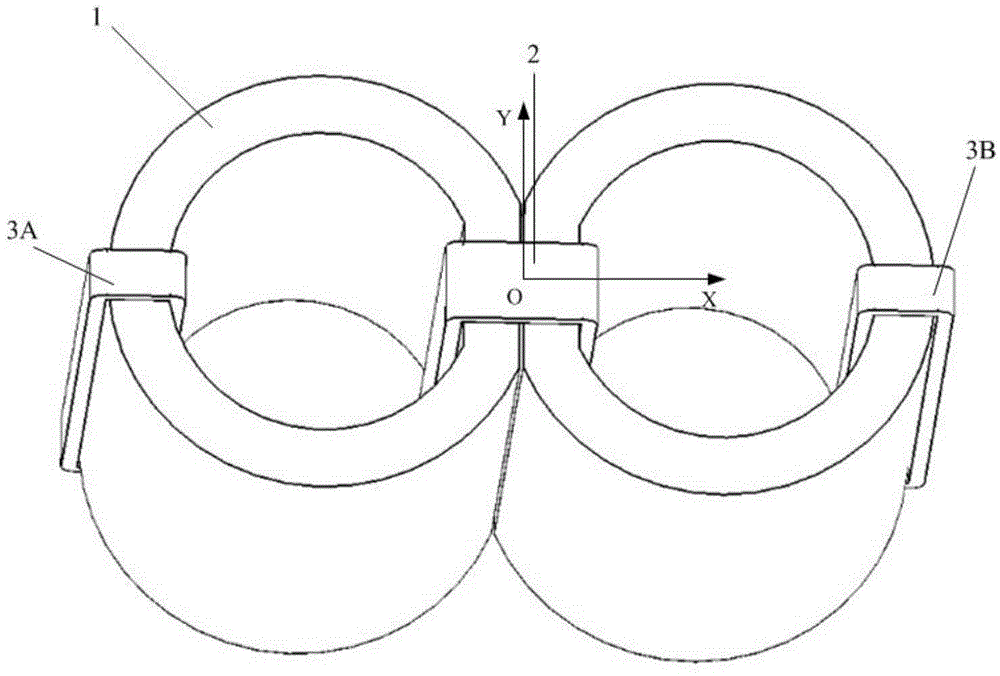

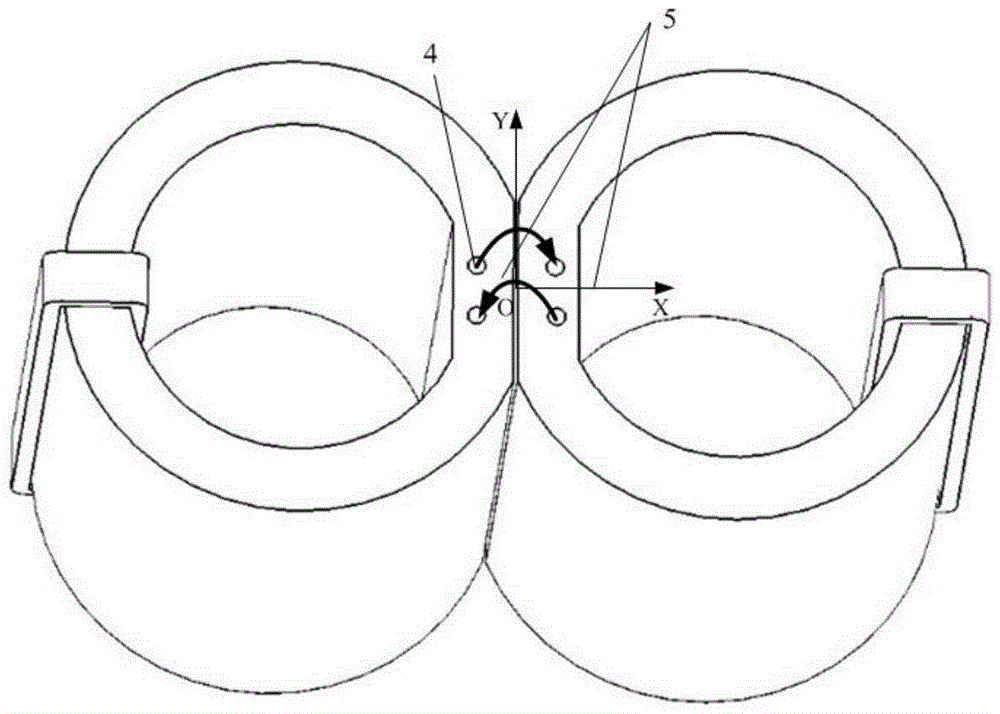

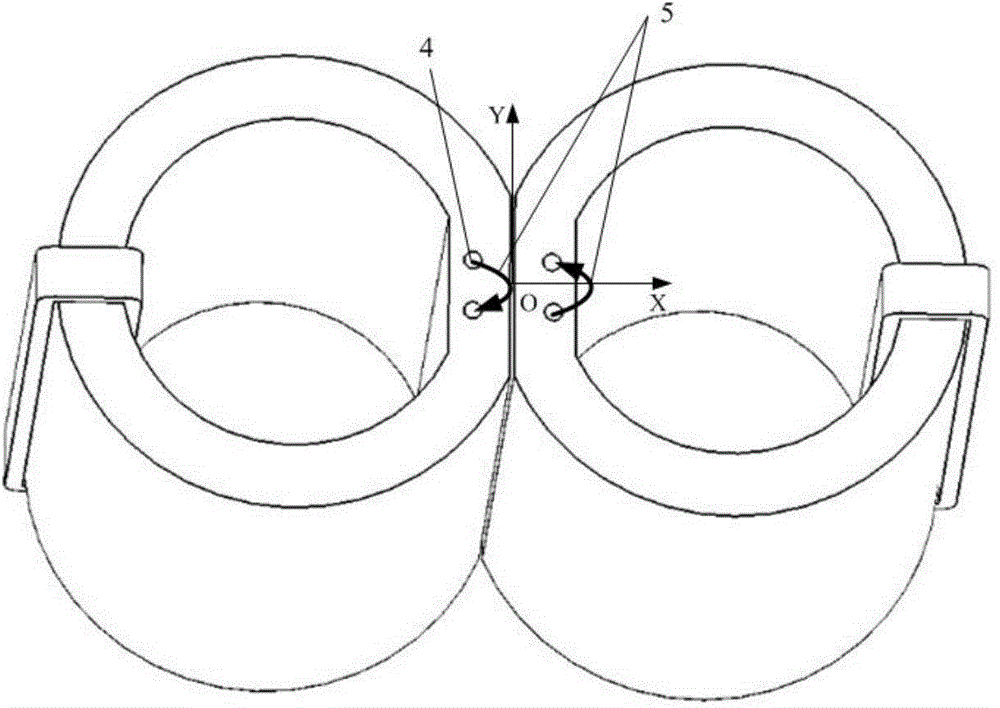

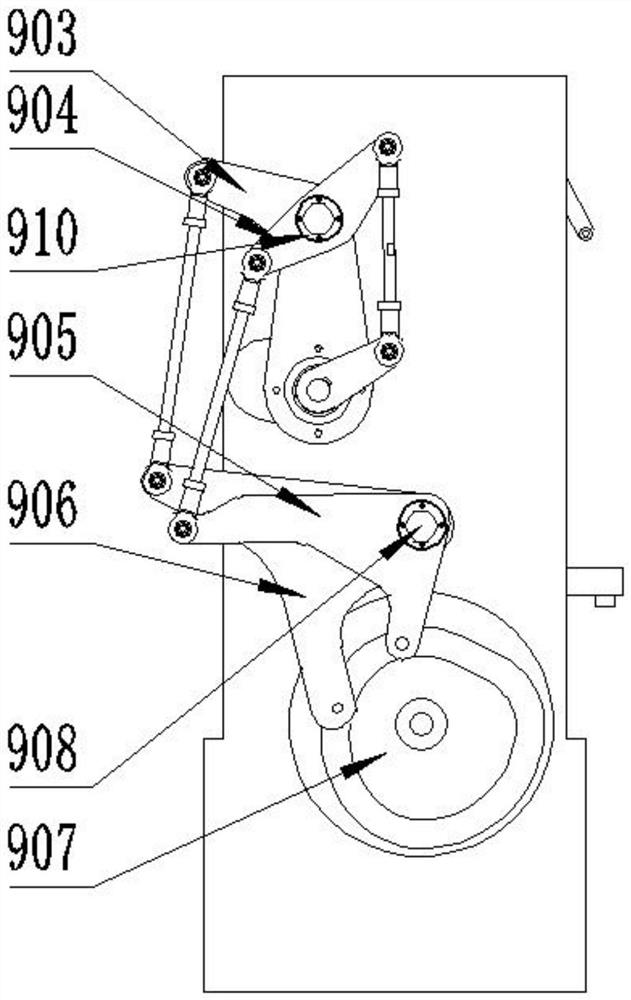

Yaw control device, executive device and yaw system and method

ActiveCN108361150AFlexible size controlFrequent trackingWind motor controlMachines/enginesYaw systemWind force

The invention discloses a yaw control device, an executive device and a yaw system and method. The yaw control device comprises a measuring unit, a yaw controller, an electric power conversion unit and an electric executive unit, wherein the measuring unit is used for measuring current wind power parameters and current yaw parameters of a wind generating set; the yaw controller is used for obtaining a current damping control electric power value for execution of damping action, and sending a damping control instruction used for performing damping control according to the current damping control electric power value to the electric power conversion unit and the electric executive unit; the electric power conversion unit is used for responding to the damping control instruction and converting a current electric power value into the current damping control electric power value; and the electric executive unit is used for responding to the damping control instruction and sending the damping action instruction used for executing the damping action on the wind generating set according to the current damping control electric power value. According to the yaw control device, the executivedevice and the yaw system and method provided by the embodiment of the invention, the damping torque at different time points can be flexibly and precisely controlled, the wind generating set can frequently track the wind direction, accordingly, the wind energy can be better captured, and the service life of equipment is guaranteed.

Owner:XINJIANG GOLDWIND SCI & TECH

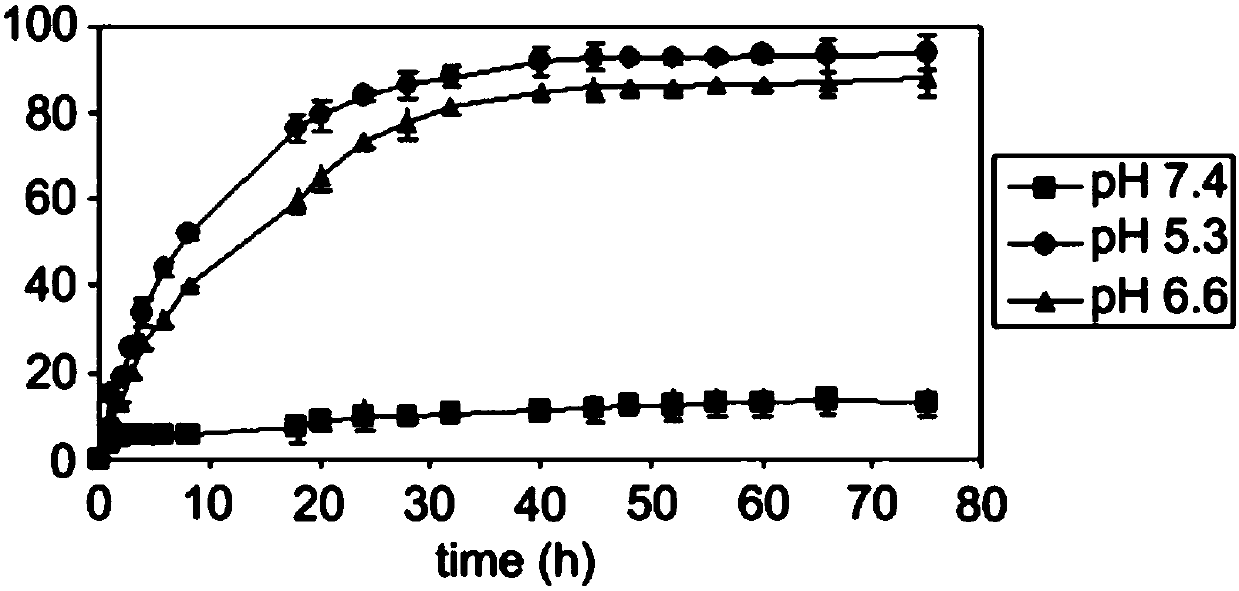

Environmental pH stimuli-responsive type tumor targeting and controlled drug release nano-carrier and preparation method of nano-carrier

InactiveCN107596385AGood water solubilityImprove stabilityOrganic active ingredientsPharmaceutical non-active ingredientsDendrimerNanocarriers

The invention discloses an environmental pH stimuli-responsive type tumor targeting and controlled drug release nano-carrier and a preparation method of the nano-carrier. Dendrimer macromolecular nano-polymer material PAMAM (polyamidoamine) is taken as a main body of a structure and connected with an amphiphilic block copolymer PEG (methoxy polyethylene glycol)-PLA (poly-l-aspartic acid), DOX (doxorubicin) is covalently conjugated to a hydrophobic fragment, namely, PLA, of an arm of the amphiphilic block copolymer and is connected though a pH sensitive hydrazone bond, so that a system has thecharacteristic of in-vivo smart drug release, and drug release can be controlled by in-vivo pH. The connection with a F3 polypeptide nucleolin targeting ligand is realized through a hydrophilic PEG chain segment, and tumor targeting of the system is realized in specific uptake of tumor and nuclear localization. The nano-carrier has potential clinical application value, and powerful technical support is provided for treatment of other types of malignant tumor cells.

Owner:WUHAN UNIV OF TECH

Controlled release microcapsule for adhesive and preparation method thereof

ActiveCN109939622AFlexible size controlMonodisperse flexible controlNon-macromolecular adhesive additivesMacromolecular adhesive additivesControlled releaseAdhesive

The invention relates to a controlled release microcapsule for an adhesive and a preparation method thereof. The preparation method comprises the following steps: S1, mixing inner phase liquid drops with middle phase liquid drops to obtain emulsified liquid drops, wherein the middle phase wraps the inner phase; S2, mixing the emulsified liquid drops with the outer phase liquid drops to obtain double emulsified liquid drops, wherein the outer phase liquid drops wrap the emulsified liquid drops; and S3, curing the double emulsified liquid drops, flushing, filtering and drying the liquid drops toobtain the controlled release microcapsule for the adhesive, wherein the inner phase is a solution containing a substance 1 capable of initiating a crosslinking reaction, the middle phase is a solution containing a substance 2 capable of being cured directly and a surfactant, the outer phase is a liquid containing a surfactant 2, and the inner and outer phases are not dissoluble to the middle phase. By way of double emulsion to form the liquid drops to further obtain the microcapsule, the preparation method is simple in process, easy to operate and low in cost. The prepared microcapsule can be flexibly controlled in dimension, shell thickness and monodispersity, and is good in monodispersity and good in stability.

Owner:SOUTH CHINA NORMAL UNIVERSITY

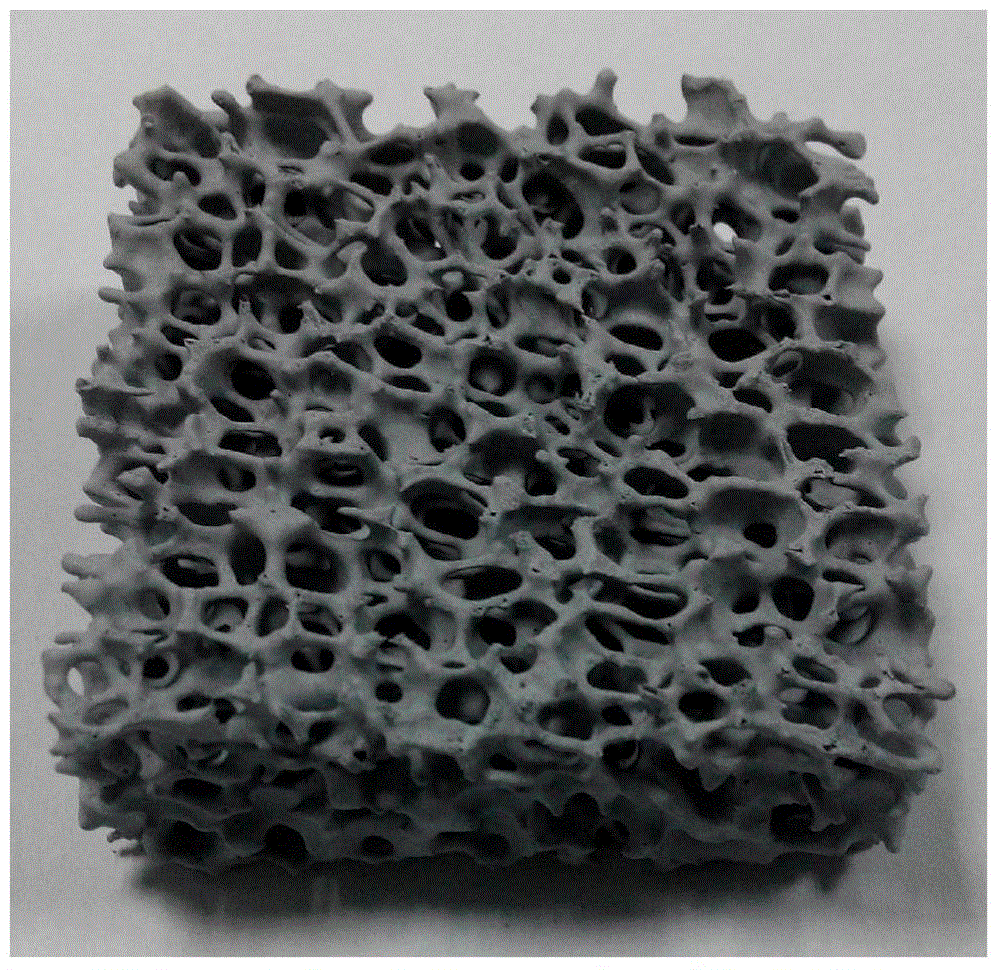

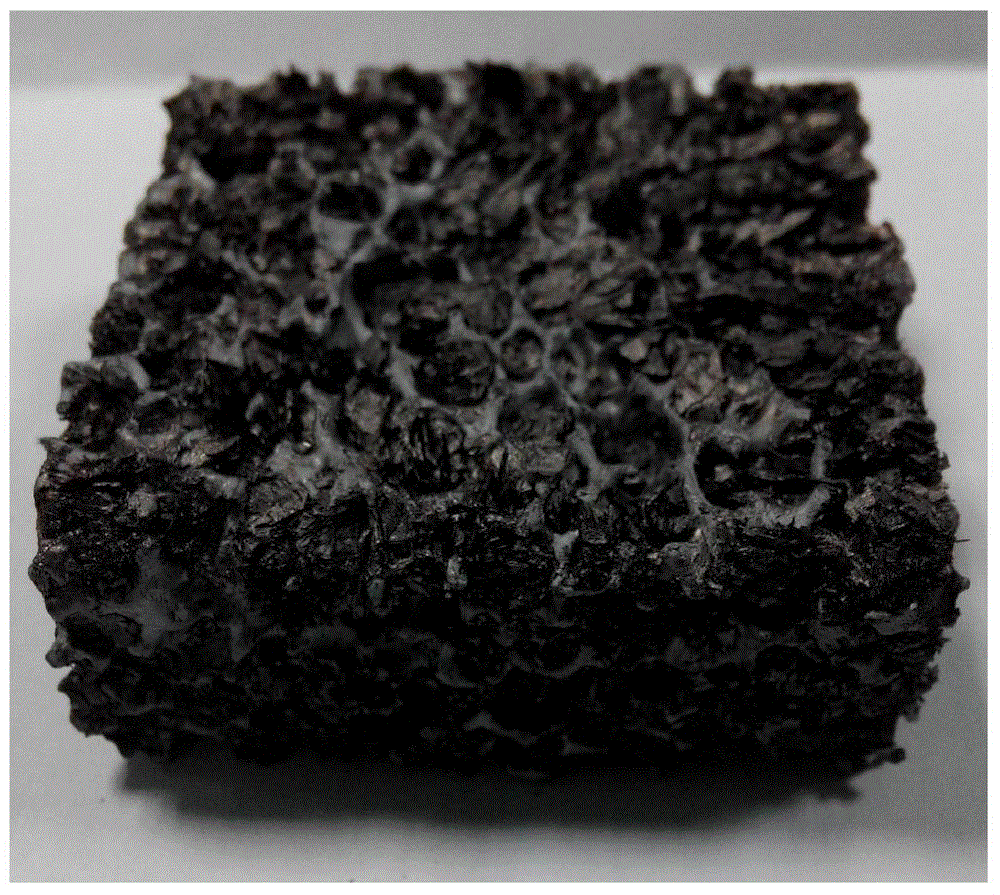

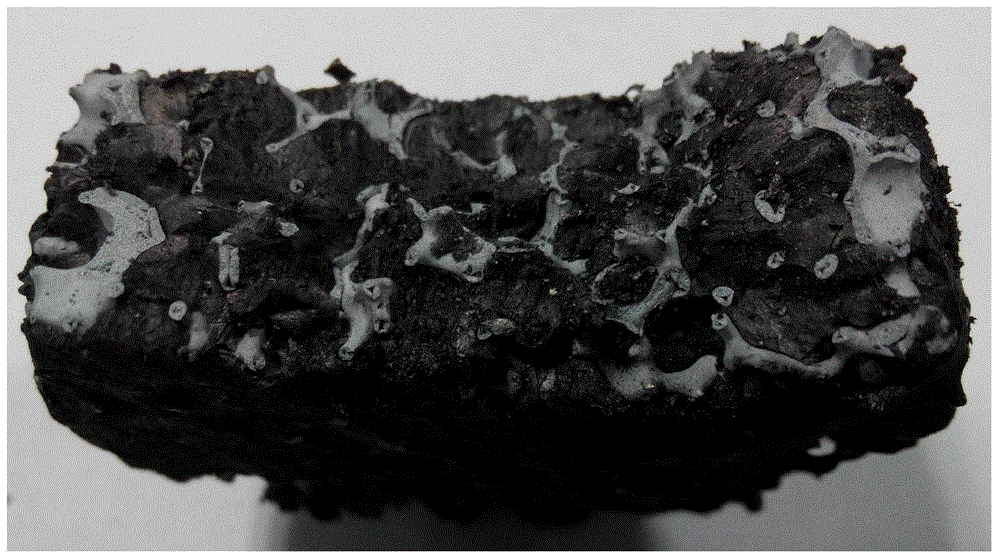

Construction method of graphene protecting structure

InactiveCN104401985AImprove mechanical propertiesImproved shear resistanceComposite structureFreeze dry

The invention discloses a construction method of a graphene protecting structure, namely a preparation method of a graphene sponge / rigid foam composite structure. The method comprises the following specific steps: entirely soaking hydrophilic rigid foam into a dispersion liquid of oxidized graphene, then carrying out freeze drying to the product, and at last utilizing hydrazine steam to reduce the product. With application of the method, the graphene is added with the rigid foam skeleton or external skeleton to protect the graphene sponge. The construction method disclosed by the invention is to build the protecting structure for graphene for the first time, so as to retain the original excellent properties such as the ultrahigh specific surface area of the graphene sponge, greatly improve the mechanical properties at the same time, and obviously improve the shear resistance; meanwhile, the size of the graphene can be flexibly controlled through change of pore size of the rigid foam, so that the various application requirements are met.

Owner:SOUTHEAST UNIV

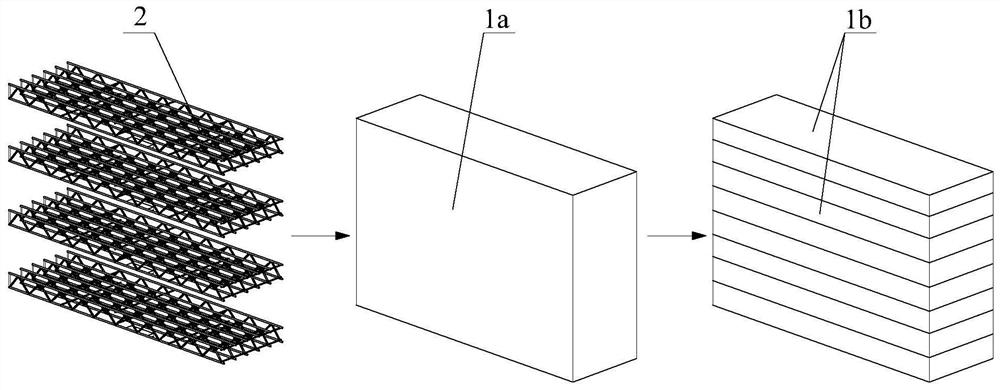

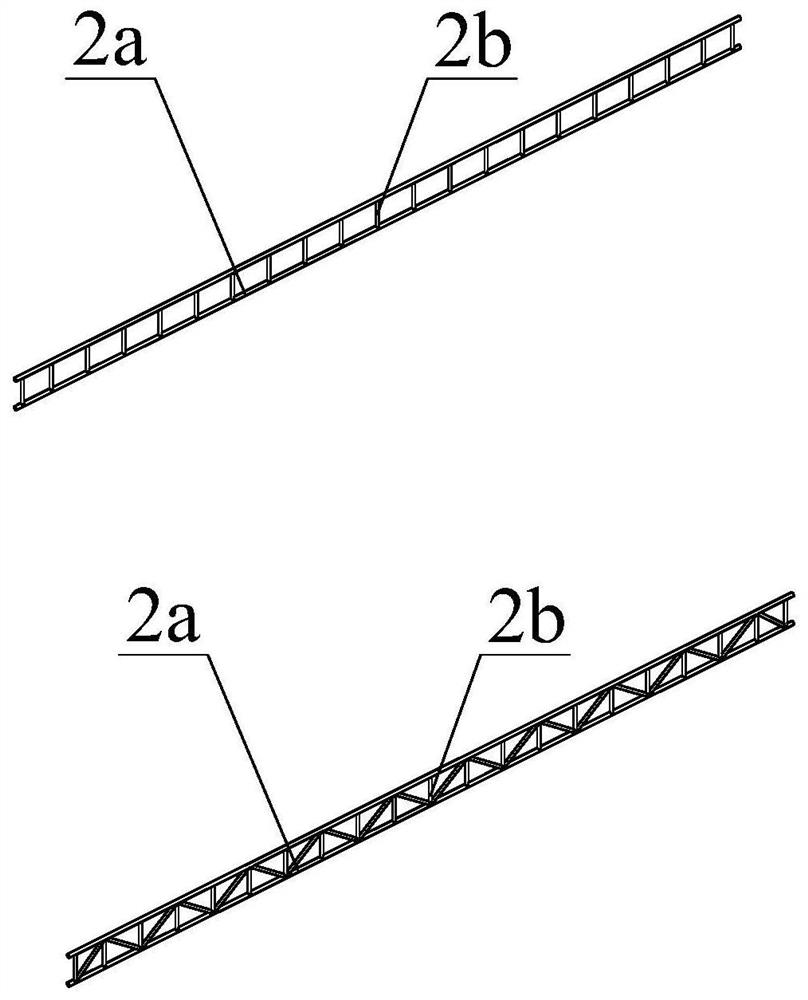

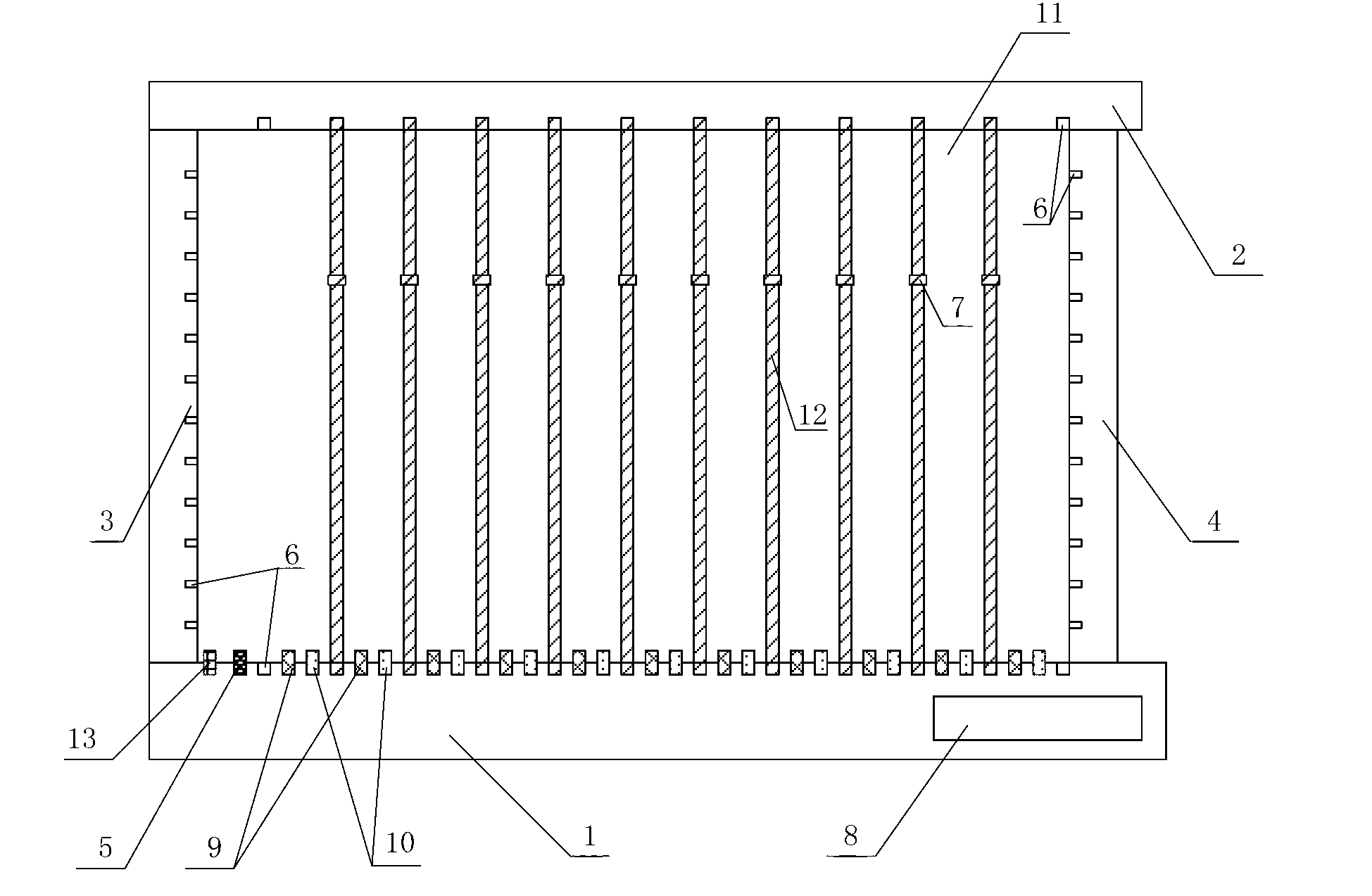

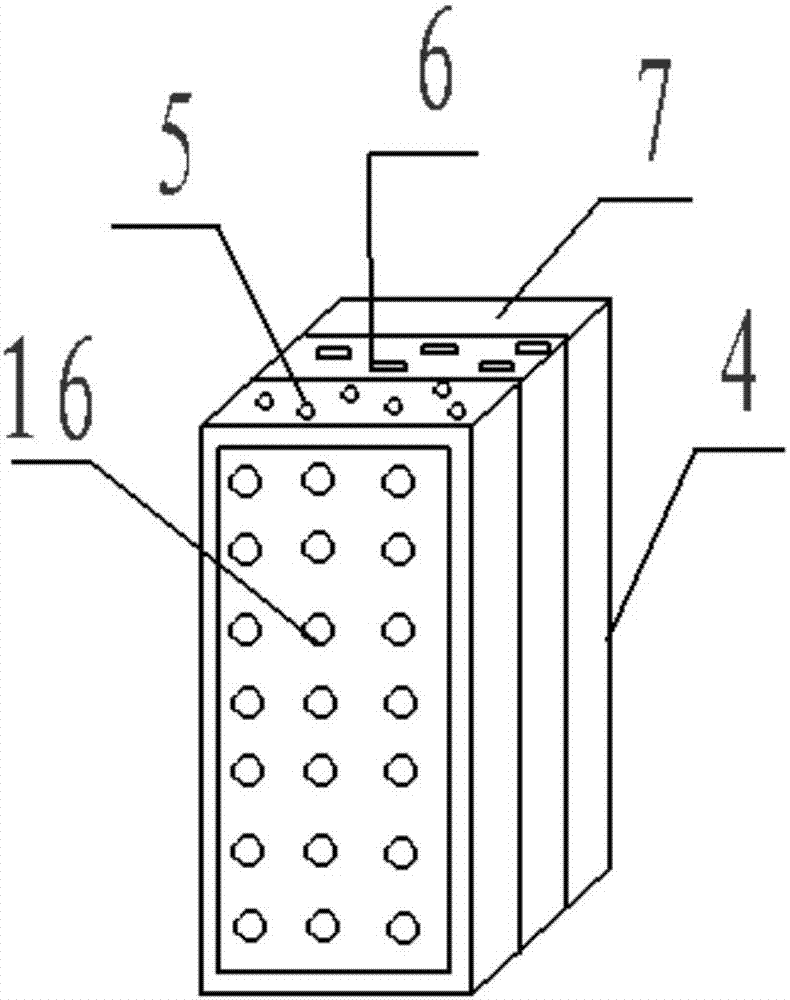

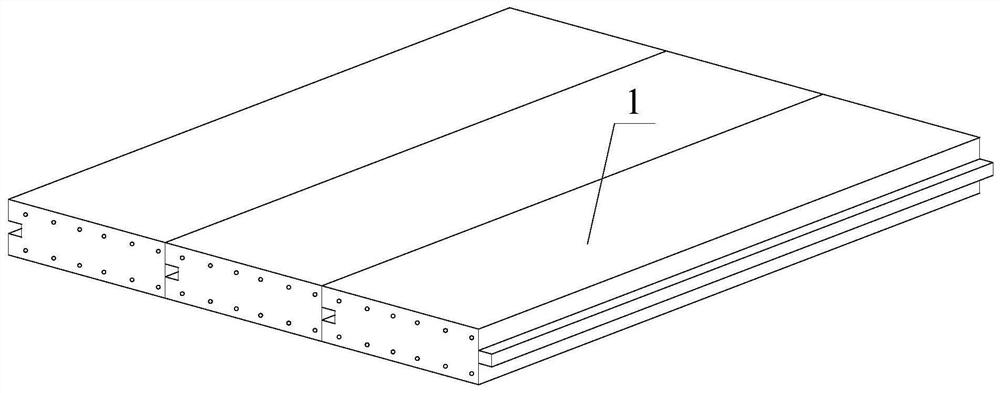

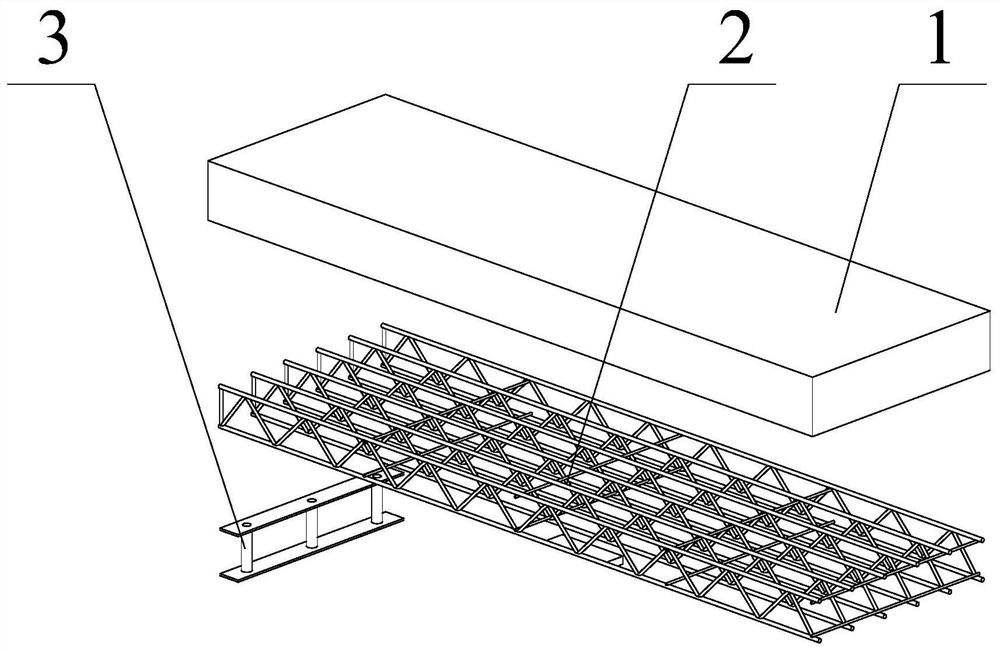

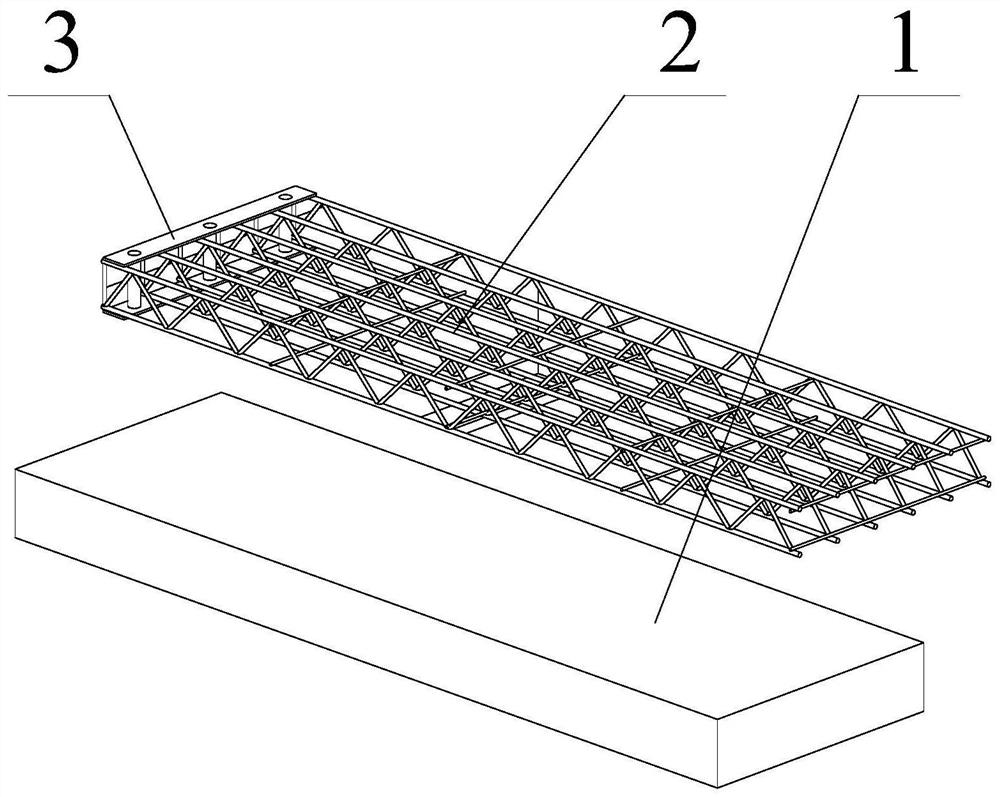

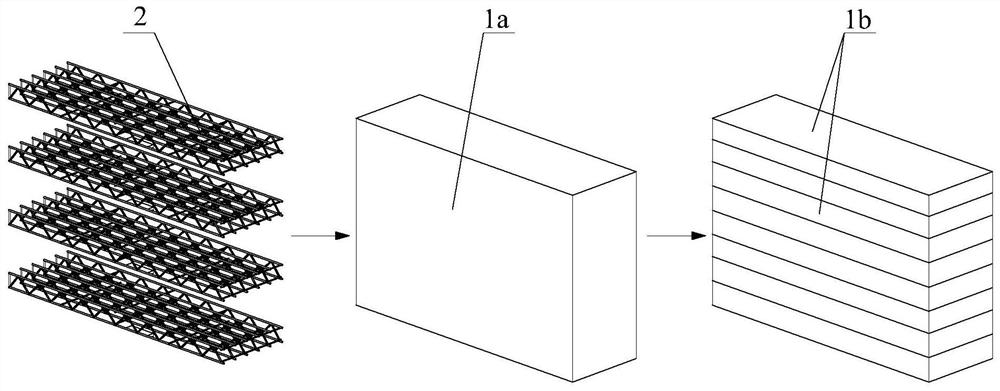

Manufacturing method of autoclaved aerated concrete floor slab

InactiveCN112060313AReduce weightReduce the amount of cast-in-placeFloorsCeramic shaping apparatusFloor slabRebar

The invention discloses a manufacturing method of an autoclaved aerated concrete floor slab. The manufacturing method comprises the following steps that S1, steel bar trusses are prepared; S2, the rawmaterials of the autoclaved aerated concrete floor slab are fed according to the raw material ratio to prepare concrete mixed pug; S3, the mixed pug prepared in the step S2 is poured into a concretemold, meanwhile, the steel bar trusses prepared in the step S1 are fixedly arranged in the concrete pug in a spaced stacking mode, compaction and forming are conducted, and an autoclaved aerated concrete rough blank is prepared; S4, the autoclaved aerated concrete rough blank prepared in the step S3 is cut according to the floor slab size requirement, and a floor slab rough blank is prepared; andS5, the floor slab rough blank prepared in the step S4 is subjected to subsequent autoclaved aerated treatment, and the autoclaved aerated concrete floor slab is prepared. According to the manufacturing method, on the premise that the bearing performance is met, complete overall prefabrication of the floor slab is achieved, and the manufactured floor slab is light in weight, high in strength and easy to assemble.

Owner:HUBEI SHENZHOU BUILDING MATERIAL

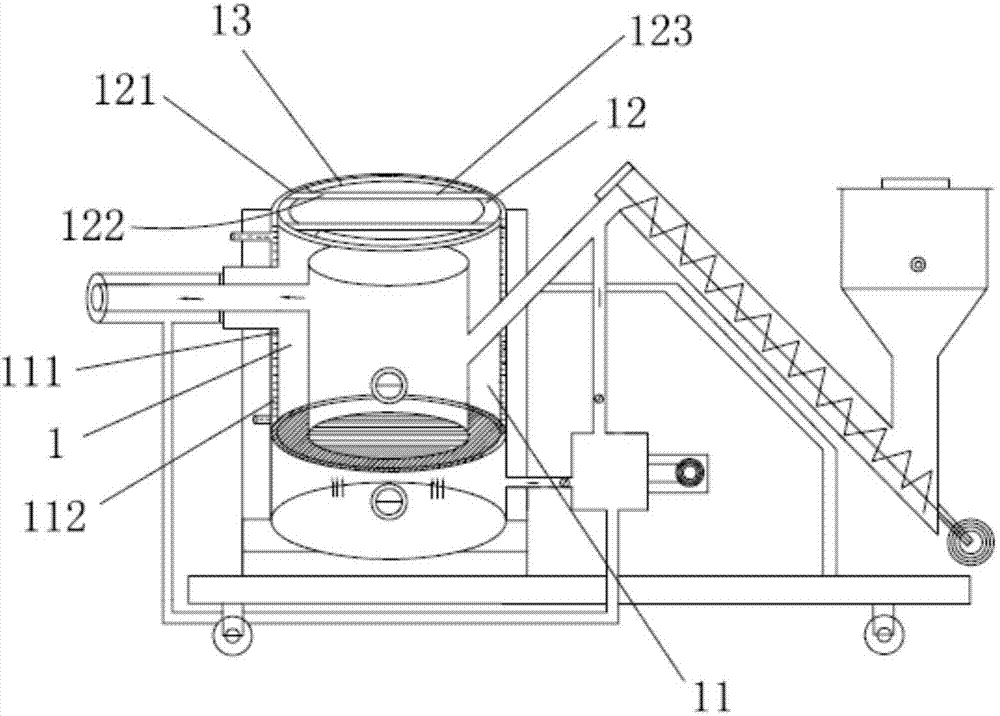

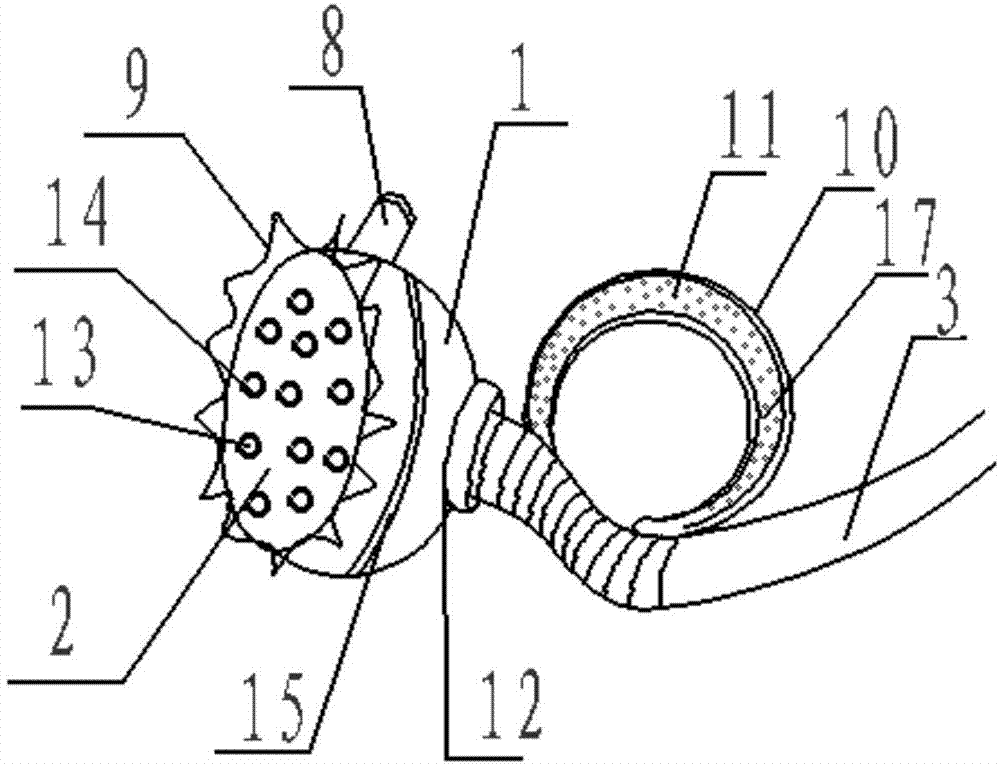

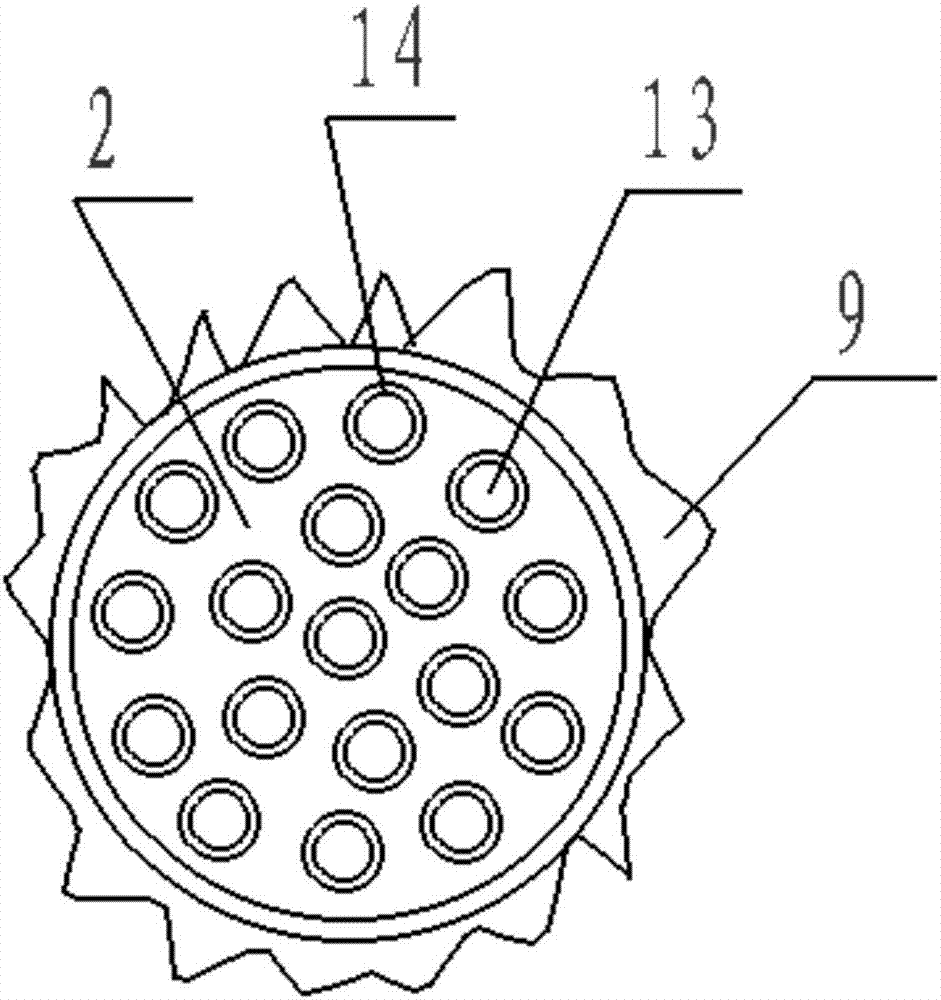

Combustion furnace structure of biomass combustor

The invention provides a combustion furnace structure of a biomass combustor. The combustion furnace structure is spanned at the two ends of a body through a beam, the beam is connected with the body, a cooling liquid capable of being circulated is provided inside the beam; the beam is communicated with a liquid layer on the inner wall of the furnace body to achieve a radiating effect; a ring-shaped tube is connected with the body, the cooling liquid capable of being circulated is filled inside the ring-shaped tube; the ring-shaped tube is communicated with the inner wall of the furnace body to achieve the radiating effect; meanwhile, the size of the ring-shaped tube can be flexibly designed according to the dimension of the body; besides, the beam and the ring-shaped tube can be used for supporting and placing refractory bricks, so that the refractory bricks are guaranteed to be spliced very well. Compared with the prior art, not only can the limitation of jointing with fewer refractory bricks be avoided, but also the combustion furnace structure with a certain size can be completed, so that the furnace top lid cannot be applied to a greater combustion furnace. Through the beam and the ring-shaped tube, the size of the combustion furnace structure can be flexibly controlled to adapt to combustors with different sizes.

Owner:中山市兴和生物能源科技有限公司

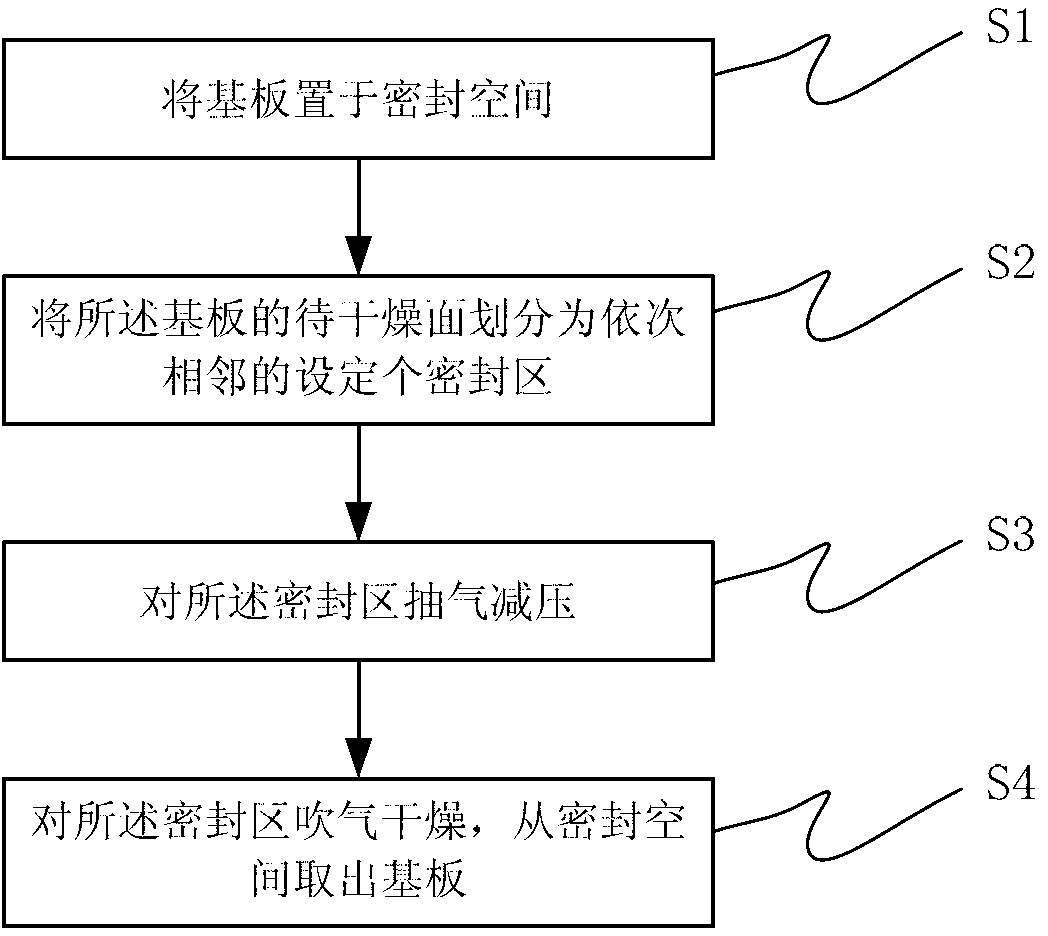

Method for baseplate drying under reduced pressure and device thereof

InactiveCN103234328AReduce difficultyAvoid formingDrying solid materials without heatSemiconductor/solid-state device manufacturingEngineeringPressure reduction

The invention discloses a method for baseplate drying under reduced pressure and a device thereof, and belongs to the technical field of baseplate manufacture. The method comprises the following steps: firstly, placing a baseplate in a sealed space; secondly, dividing the surface to be dried of the baseplate into a preset number of sealing zones; thirdly, performing air extraction and pressure reduction for the sealing zones; and fourthly, performing air blowing and drying for the sealing zones, and taking the baseplate out of the sealed space. The method disclosed by the invention can perform drying under reduced pressure for baseplates of all sizes, can guarantee the uniformity of pressure and moisture as much as possible, and prevent the formation of spots caused by drying under reduced pressure.

Owner:BOE TECH GRP CO LTD +1

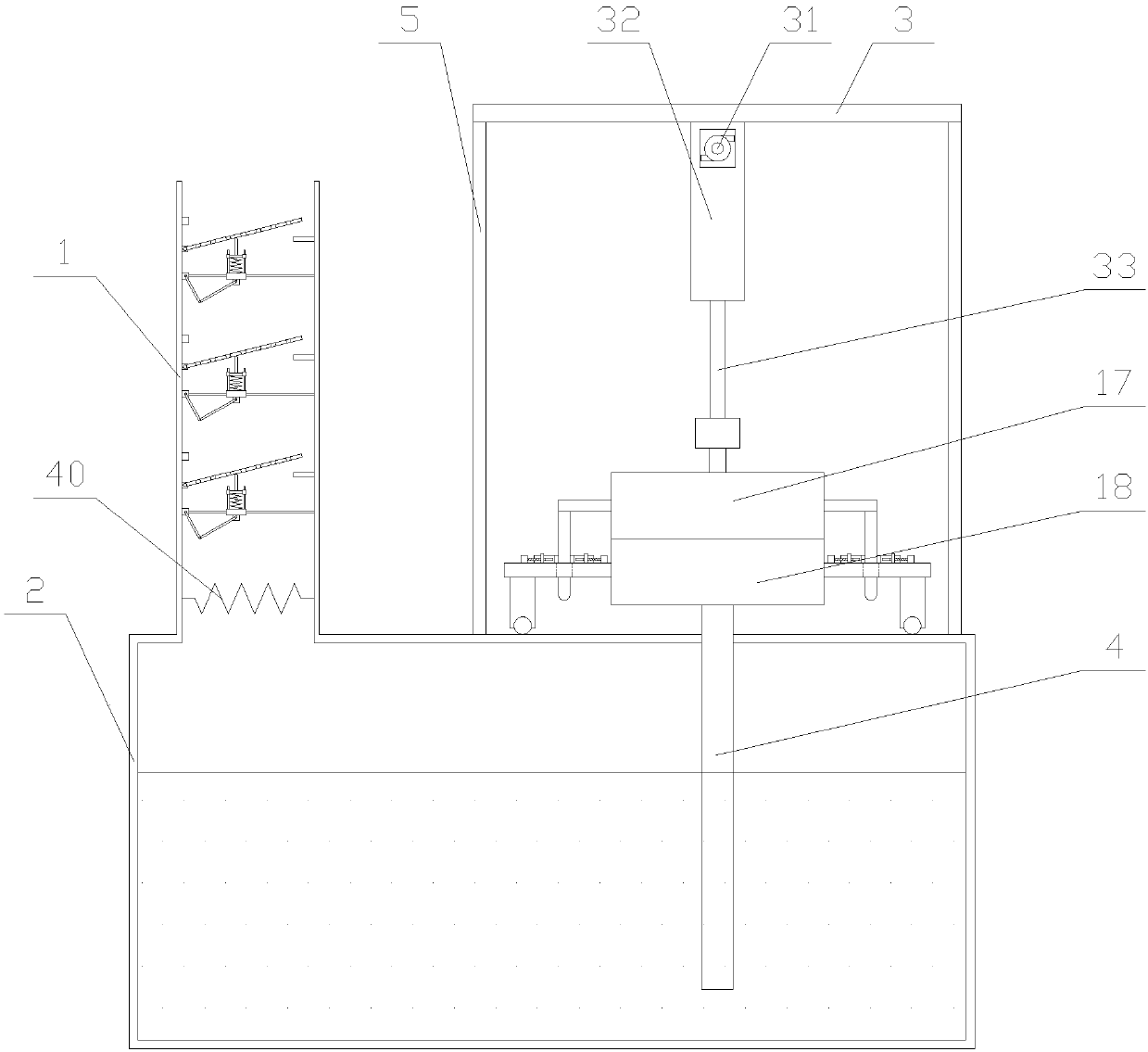

Intelligent aluminum alloy hub low-pressure casting device with speed regulation function

The invention relates to an intelligent aluminum alloy hub low-pressure casting device with a speed regulation function. The intelligent aluminum alloy hub low-pressure casting device comprises an airinlet pipe, a crucible, a lifting mechanism, a casting mechanism and a liquid lifting pipe; a plurality of speed regulation mechanisms are arranged in the gas inlet pipe; the speed regulation mechanism comprises a translation assembly, a translation block, a speed regulation plate and a speed regulation assembly; the speed regulation assembly comprises a pressure plate, a spring, a speed regulation rod and two limiting units, the casting mechanism comprises a first motor, a first driving shaft, an upper mold, a lower mold and at least two connecting assemblies, the intelligent aluminum alloyhub low-pressure casting device with the speed regulation function is used for controlling the flow speed of air through the speed regulation mechanism, and then the flow of the air is adjusted, so that the air pressure in the crucible is stably increased, the use amount of the molten aluminum is conveniently controlled accurately, and the quality of the hub forming is improved, moreover, the upper die and the lower die are driven to rotate through a casting mechanism, so that the flowing of molten aluminum is enhanced, so that the molten aluminum is uniformly distributed between the upper mold and the lower mold, and the quality of hub forming and the practicability of device are further improved.

Owner:南京卓茨机电科技有限公司

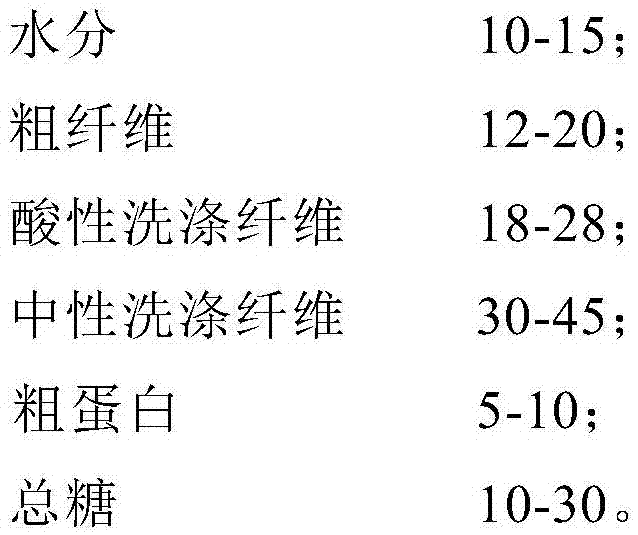

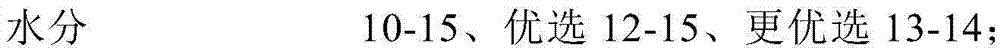

Sugarcane bagasse molasses solid compound and preparation method, use and storage method thereof

InactiveCN106922983AIncrease profitIncrease feed intakeFood processingAnimal feeding stuffCrude fibreEngineering

The present invention provides a preparation method of a sugarcane bagasse molasses solid compound, the sugarcane bagasse molasses solid compound obtained by the method, and a use and a storage method of the sugarcane bagasse molasses solid compound. The preparation method comprises the following steps: sugarcane bagasse and molasses are separately subjected to pre-treatment; then the pretreated molasses are sprayed into the sugarcane bagasse, and stirring is conducted to obtain mixed materials; and then the mixed materials are pressed into blocks or granules. The solid compound comprises 10 wt%-15 wt% of water, 12 wt%-20 wt% of crude fibers, 18 wt%-28 wt% of acidic detergent fibers, 30 wt%-45 wt% of neutral detergent fibers, 5 wt%-10 wt% of crude proteins and 10 wt%-30 wt% of total sugar. The present invention further provides the storage method of the sugarcane bagasse molasses solid compound. The preparation method of the sugarcane bagasse molasses solid compound improves the utilization rate of the sugarcane bagasse and molasses, is suitable for industrial production, and the sugarcane bagasse molasses solid compound can be used to prepare animal feeds as an additive, has good palatability, can promote animal chew ability, and improve animal feed intake.

Owner:COFCO GROUP +2

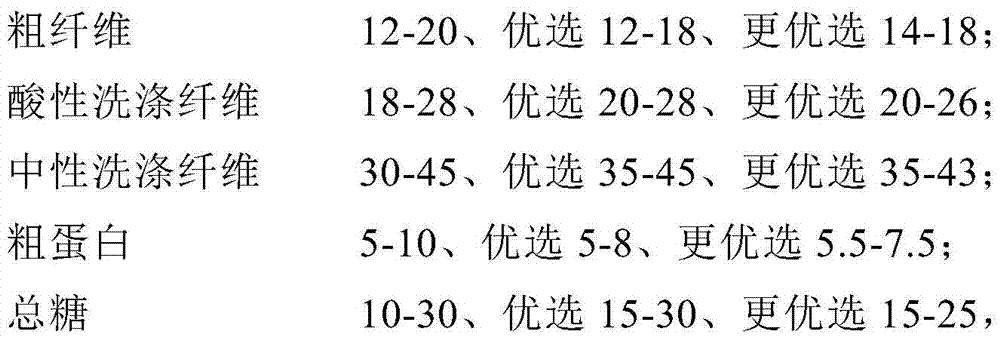

Method, system and equipment for batch migration of big data tables between databases and medium

PendingCN114153813AReduce difficultyReducing Space Constraint RequirementsSpecial data processing applicationsDatabase design/maintainanceTable (database)Datasheet

The invention provides a method, a system, equipment and a medium for batch migration of big data tables among databases, and the method comprises the following steps: generating a corresponding configuration file according to a data table needing to be migrated, the configuration file comprises at least one row, each row corresponds to 10 configuration columns, and each row corresponds to 10 configuration columns; each configuration column comprises a source database, a source database table name, a source coding mode, a target database, a target database data table name, a target database coding mode, a migration mode, a migration basis field, a start numerical value and an end numerical value; and the configuration file is circularly read, and batch migration of the data table is performed, so that the data migration difficulty and migration workload of developers are reduced.

Owner:中国农业银行股份有限公司福建省分行

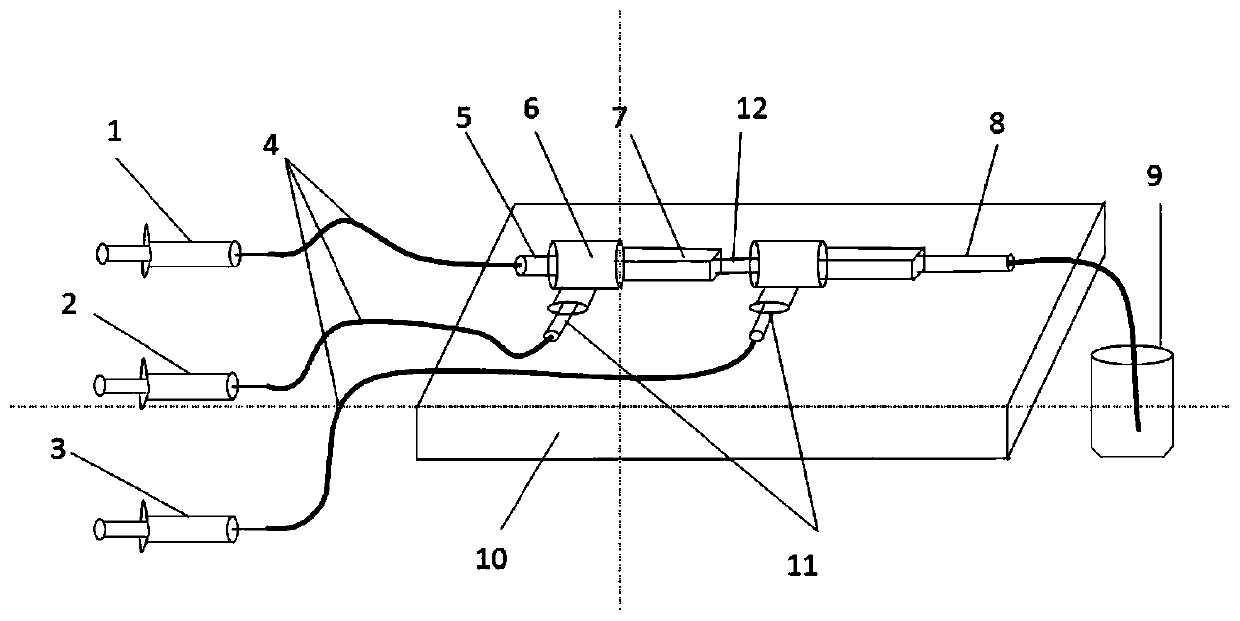

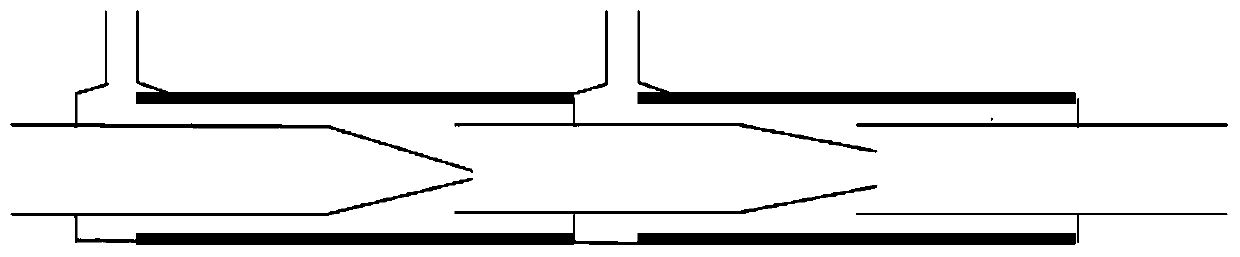

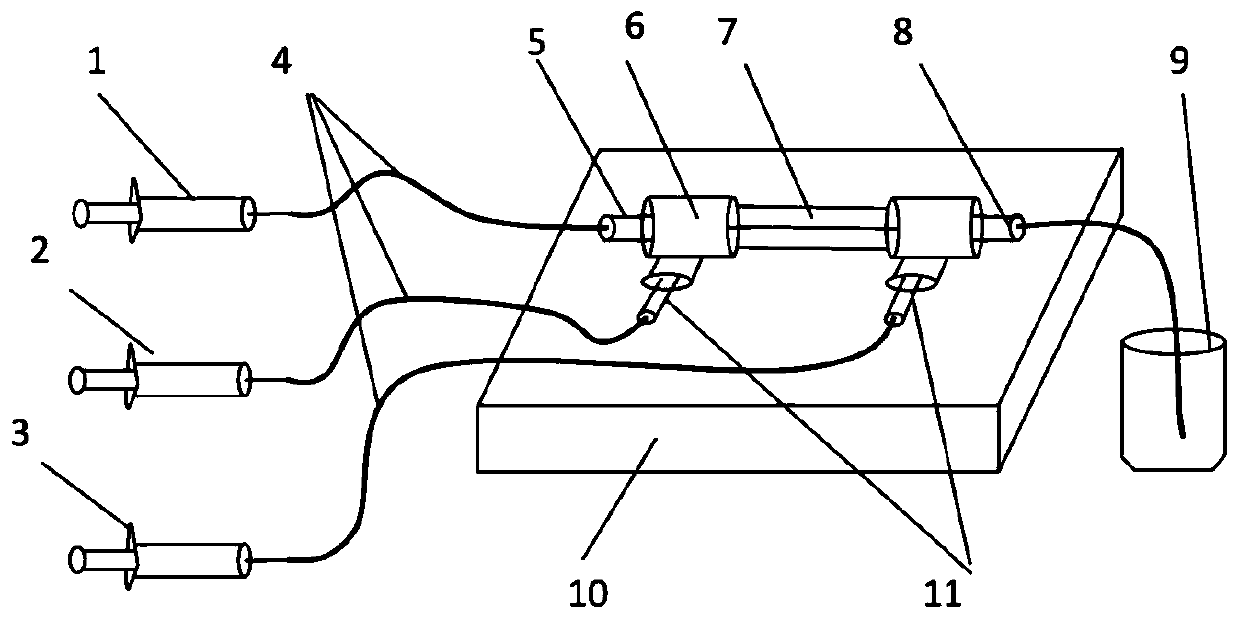

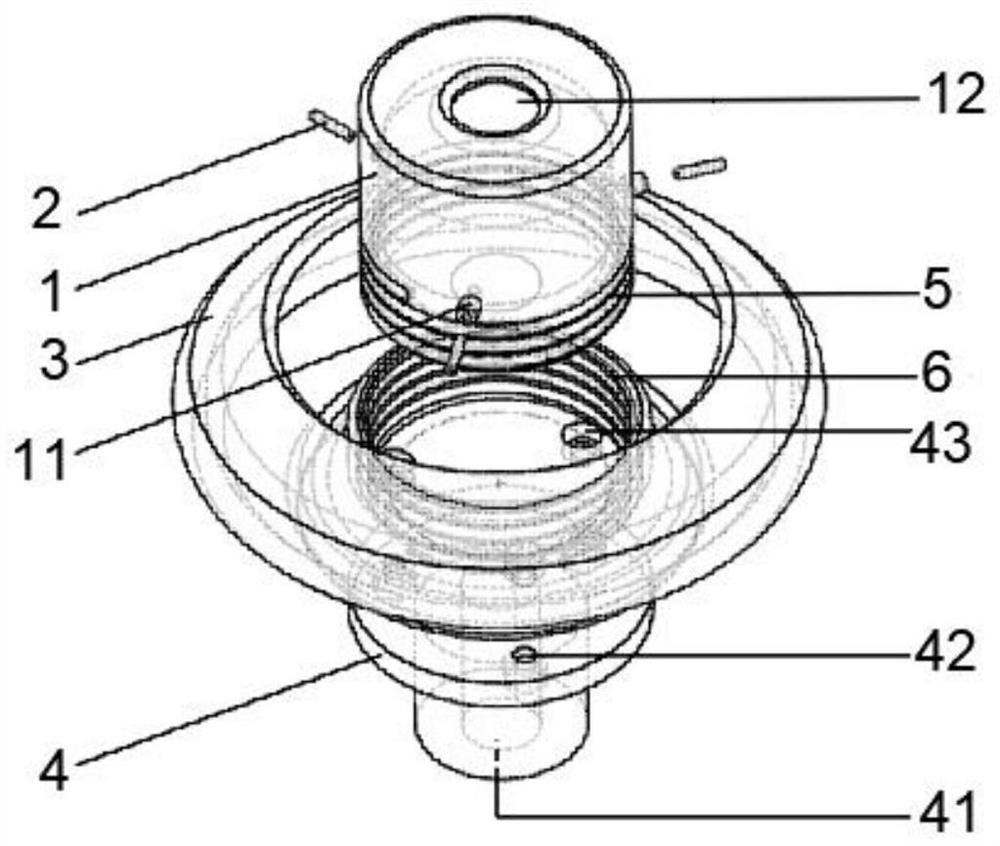

Centrifugal micro-fluidic device for rapidly preparing liquid drops and liquid drop preparation method

PendingCN113181982AEnable high-throughput productionFlexible size controlTransportation and packagingMixersCapillary TubingCentrifugal microfluidics

The invention discloses a centrifugal micro-fluidic device for rapidly preparing liquid drops and a liquid drop preparation method, and belongs to the technical field of biomedical materials.The centrifugal micro-fluidic device comprises an inner liquid storage device and an outer liquid storage device which are provided with hollow inner cavities, wherein inner phase liquid is injected into the inner liquid storage device, a collecting groove is formed in the bottom end of the inner cavity of the outer liquid storage device, outer phase liquid is injected into the collecting groove, and the inner liquid storage device and the center line are arranged in the inner cavity of the outer liquid storage device; a capillary tube installed on the inner liquid storage device, wherein one end of the capillary tube is communicated with the inner cavity of the inner liquid storage device, and the other end of the capillary tube is positioned above the collecting groove; and a centrifugal transmission mechanism which is connected with the inner liquid storage device and can drive the inner liquid storage device to rotate at a high speed and enable the inner phase liquid to do centrifugal motion in the inner liquid storage device, wherein centrifugal force borne by the inner phase liquid during centrifugal motion can extrude the inner phase liquid to enter the tube from one end of the capillary tube and generate liquid drops at the other end of the capillary tube. The device has the advantages that high-flux production of the liquid drops can be realized, and meanwhile, the size and the shape of the liquid drops are flexible and controllable.

Owner:NANJING DRUM TOWER HOSPITAL

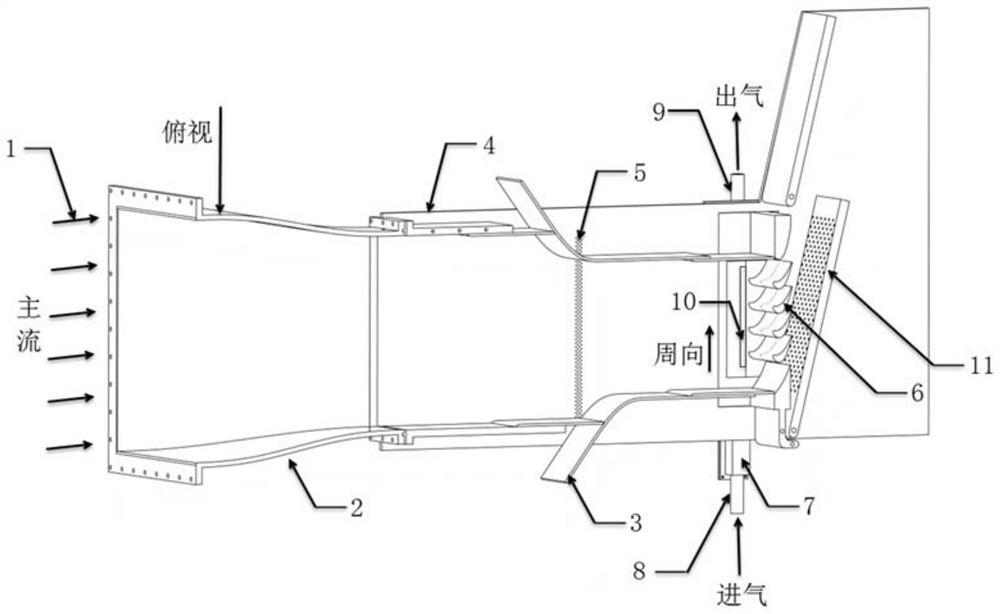

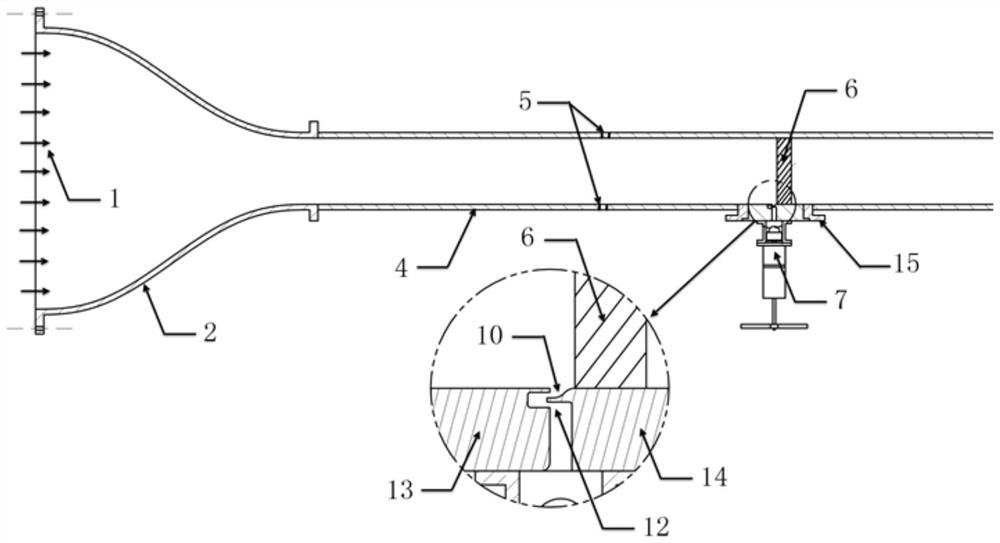

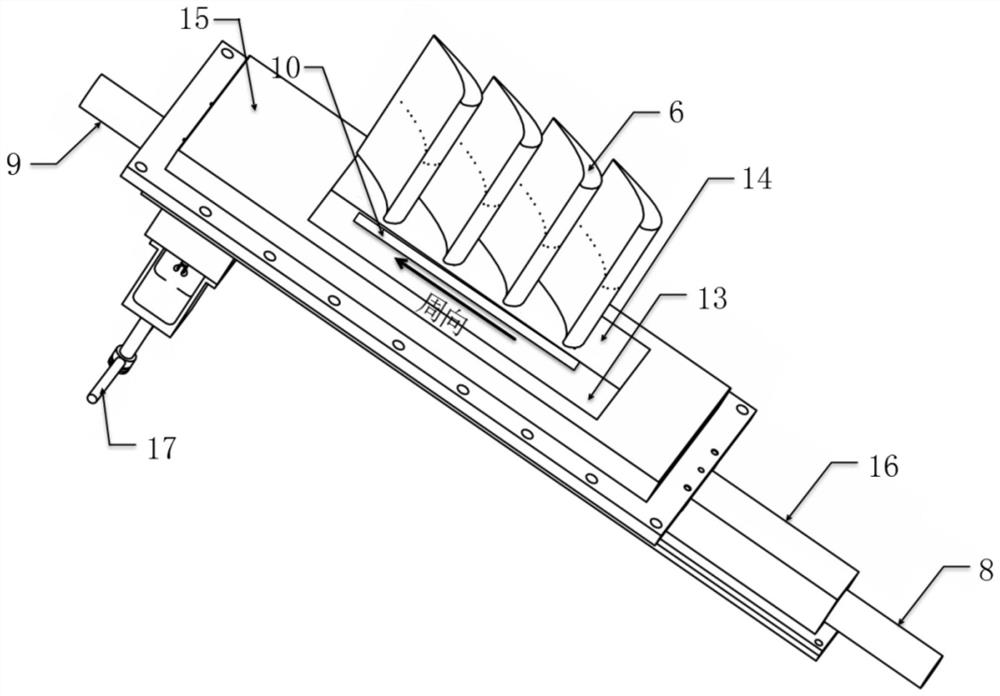

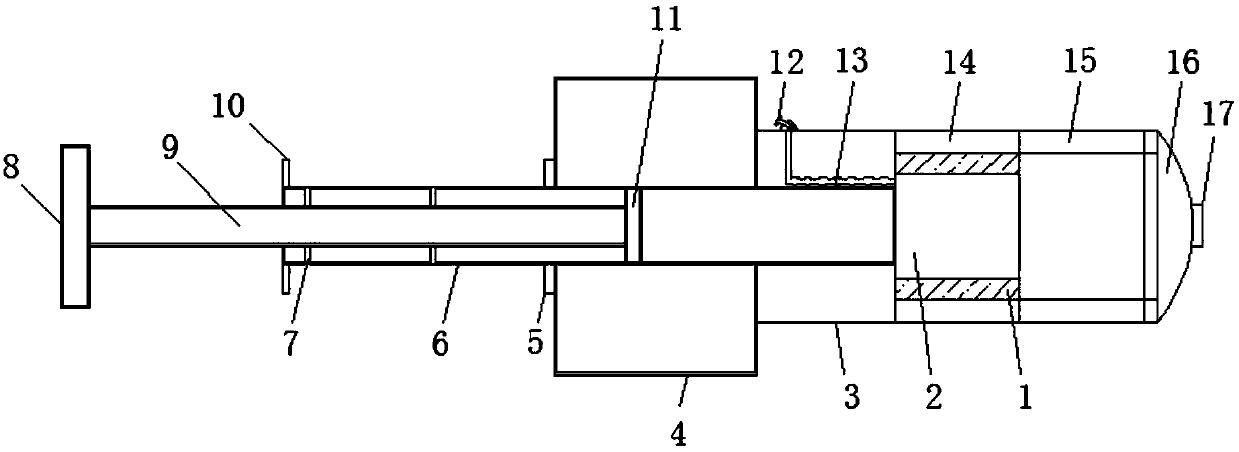

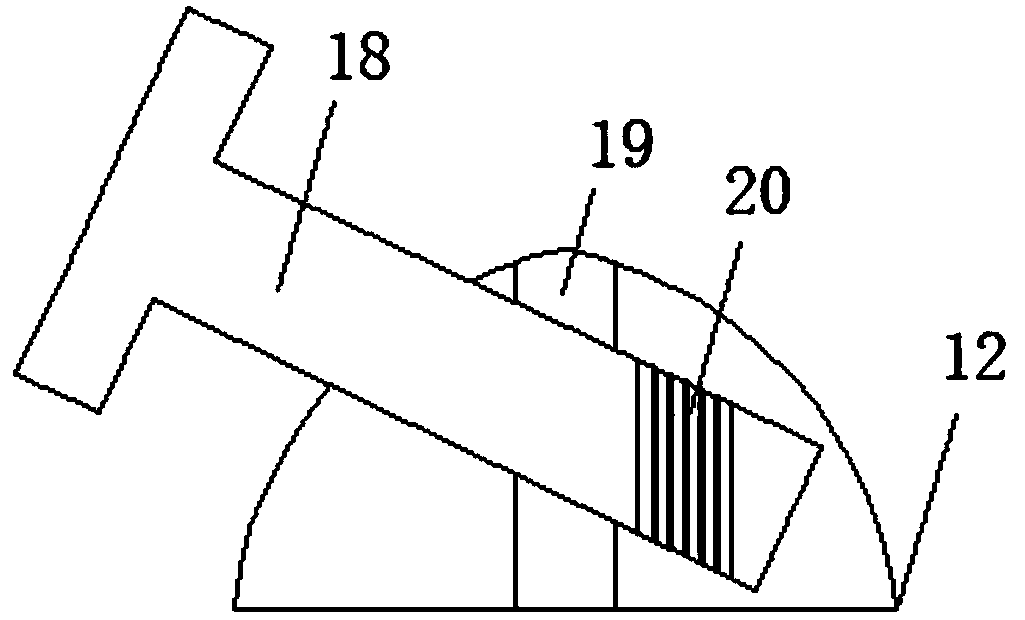

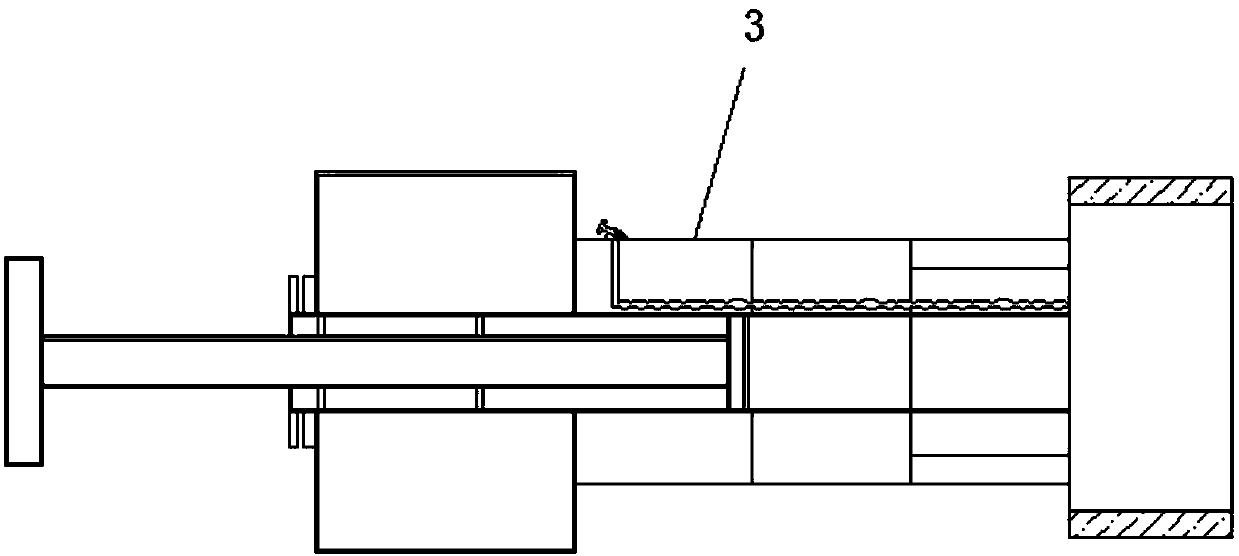

Sealing gas supply device for transonic turbine plane blade grid experiment

ActiveCN112594014AFlexible control of peripheral speedFlexible size controlGas-turbine engine testingAerodynamic testingTurbine bladeFront edge

The invention discloses a sealing gas supply device applied to a transonic turbine plane blade grid experiment. A transonic turbine blade grid is arranged on the end wall of a wind tunnel, a sealing gas supply cavity is formed in the outer side of the end wall of the wind tunnel, and a sealing gas outlet extending in the direction perpendicular to the main flow direction and located at the upstream position of the front edge of the transonic turbine blade grid is formed in the top of the sealing gas supply cavity. Sealing cold gas flowing out of the sealing gas outlet has the component velocity perpendicular to the main flow direction, is injected into a wind tunnel main flow passageway and interacts with main flow gas in the wind tunnel main flow passageway. By means of the characteristicthat the speed direction of cold gas in the sealing gas supply cavity is tangent to the circumferential direction of the transonic turbine blade grid, the circumferential speed of sealing flow can beshown again without rotation of components, and meanwhile the effect of independently changing the flow of the sealing flow and the circumferential speed of the sealing flow is achieved. The sealingjet flow condition required by the transonic turbine plane blade grid experiment can be fully simulated, the sealing flow characteristic in a real turbine is shown again, and a precise three-dimensional flow field structure is easy to obtain.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Gynecologic inflammation detecting bar

InactiveCN108042161AHigh precisionGood effectSurgeryVaccination/ovulation diagnosticsTreatment qualityPiston

The invention discloses a gynecologic inflammation detecting bar which comprises an extracting bar body, a first handle, a cylinder and a top cover. The extracting bar body is welded to one end of thefirst handle. A temporary storage box is arranged in the front end of the extracting bar body. A storage box is arranged at the rear end of the temporary storage box. The cylinder is movably arrangedin the first handle and the extracting bar body. The front end of the cylinder is arranged in the storage box in the extracting bar body. The rear end of the cylinder penetrates through the first handle to extend outward. The front end of the cylinder is connected with a rubber expansion block. A cotton ball is attached to the outer end of the rubber expansion block. The rubber expansion block isconnected with a nozzle through a folding telescopic rubber pipe. The front end of the extracting bar body is sleeved with the top cover. A piston is arranged in the cylinder. A connecting column isconnected with one end of the piston. The outward extending top end of the connecting column is fixedly provided with a first pull handle. By arranging the rubber expansion block and the cotton ball,detection is more convenient, rapid and precise, and the treatment quality is greatly improved.

Owner:玉林市玉州区万通华信科技服务部

Mini infant sprayer

The invention discloses a mini shower for infants, which includes a shower body, and is characterized in that: the shower body includes two parts: a nozzle and a nozzle; the nozzle and the nozzle are connected by threads The connection is realized in a manner; the internal thread of the nozzle is connected with a purification core; the purification core includes a carbon fiber layer, a ceramic particle layer and a nano-membrane; the upper end of the nozzle is threaded with a metal ring; The upper end is threadedly connected with an adjustment switch; the edge of the nozzle is covered with a bath flower ball. The present invention is simple in structure, easy to operate, small and light, and easy to control. Contact, massage and scrubbing solve the burden of insufficient manpower, purify the water source, improve the safety of water, and reduce the irritation to the skin of infants and young children.

Owner:叶侃

Auxiliary feeding system for gantry cutting machine

InactiveCN106272659AConvenient and precise cuttingFlexible operation and replacementCleaning using gasesMetal working apparatusAirflowEngineering

The invention discloses an auxiliary feeding system for a gantry cutting machine. The auxiliary feeding system comprises a feeding station and a discharging station, wherein the inner side of the feeding station is fixedly mounted on a rack; a feeding roller is arranged on the outer side of the feeding station; a discharging roller is arranged between the discharging station and the rack; a feeding platform is arranged between the feeding roller and the rack, and is formed by mounting a loading plate and a cutting plate in a combined manner; both ends of the feeding platform are fixedly mounted on the feeding station via rotating shafts; a joint gap of the loading plate and the cutting plate is formed in the middle of the feeding platform; hydraulic lifting rods are arranged on both sides of the joint gap, and are respectively mounted below the loading plate and the cutting plate; a blower nozzle facing up vertically is arranged under the joint gap; a height limiting baffle is arranged above the cutting plate. According to the auxiliary feeding system, dust on the upper surface of a product can be removed conveniently, while for dust on the lower surface of the product, the feeding platform is adjusted to ensure that a certain gap is formed between the lower surface of the product and the feeding platform, and the dust on the lower surface of the product in the gap is removed via air flow, so that the operation is simple and convenient.

Owner:YANCHENG XIONGYING PRECISION MACHINERY

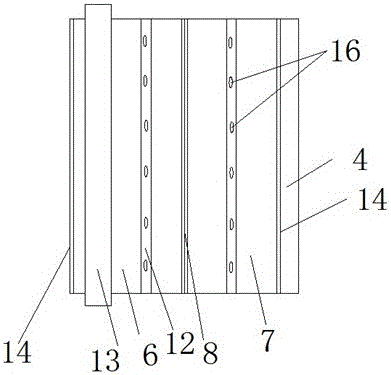

Combined-type autoclaved aerated concrete floor slab

InactiveCN112064846AReduce weightReduce the amount of cast-in-placeFloorsBuilding reinforcementsFloor slabArchitectural engineering

The invention discloses a combined-type autoclaved aerated concrete floor slab. The combined-type autoclaved aerated concrete floor slab is formed by splicing a plurality of autoclaved aerated concrete slabs, and steel bar trusses used for bearing are buried in the autoclaved aerated concrete slabs so as to ensure that the autoclaved aerated concrete slabs meet the bearing capacity of 200 kg or above per square meter. On the premise that bearing performance is met, complete overall prefabrication of the floor slab is achieved, the manufactured floor slab is low in weight, high in strength andeasy to fabricate, a steel structure frame does not need to be arranged in advance, the construction efficiency is greatly improved, and the construction cost is remarkably reduced.

Owner:HUBEI SHENZHOU BUILDING MATERIAL

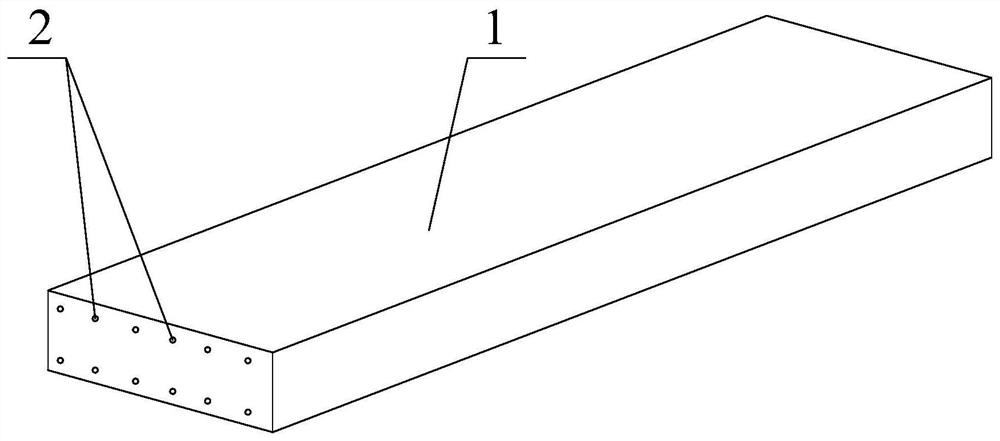

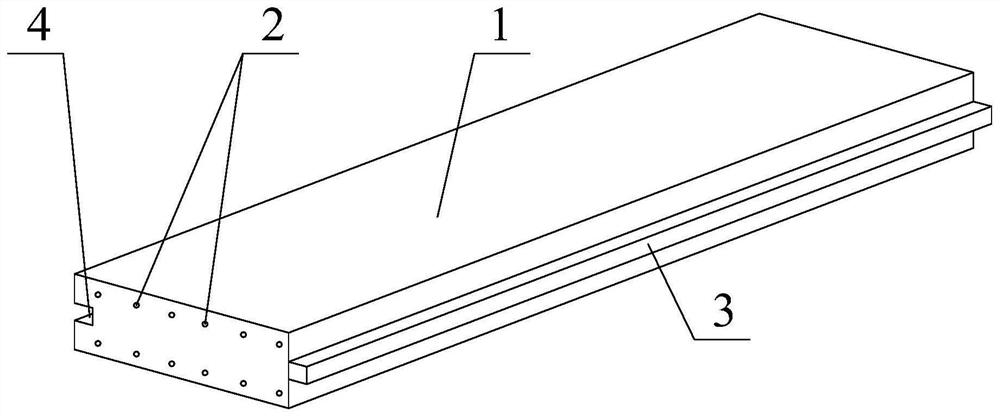

Manufacturing method of fabricated floor slab with connecting members

InactiveCN112025969AReduce weightReduce the amount of cast-in-placeConstruction materialFloorsFloor slabConstruction engineering

The invention discloses a manufacturing method of a fabricated floor slab with connecting members. The manufacturing method of the fabricated floor slab with the connecting members comprises the following steps of S1, preparing a steel bar truss, and fixedly connecting the connecting members 3 to the two ends of the steel bar truss 2; S2, after feeding raw materials of the autoclaved aerated concrete floor slab according to a raw material ratio, preparing concrete mixed pug; S3, pouring the mixed pug prepared in the step S2 into a concrete mold, and meanwhile, fixedly arranging the steel bar truss prepared in the step S1 in the concrete pug in a spaced stacking mode, and carrying out compaction and forming to prepare an autoclaved aerated concrete rough blank; S4, cutting the autoclaved aerated concrete rough blank prepared in the step S3 according to the floor size requirement to prepare a floor rough blank; and S5, carrying out subsequent autoclaved aerated treatment on the floor slab rough blank prepared in the step S4 to prepare the autoclaved aerated concrete floor slab. According to the manufacturing method of the fabricated floor slab with the connecting members, on the premise that the bearing performance is met, complete overall prefabrication of the floor slab is achieved, and the manufactured floor slab is light in weight, high in strength and easy to assemble.

Owner:罗克佐

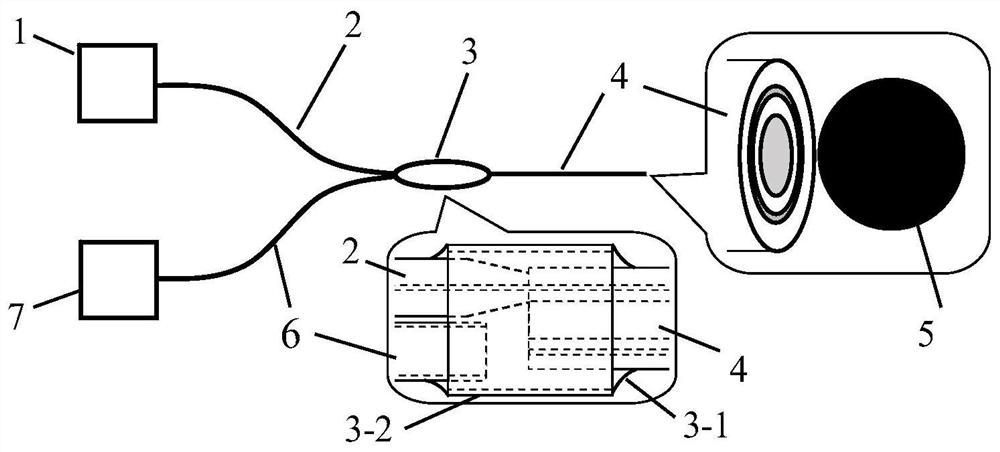

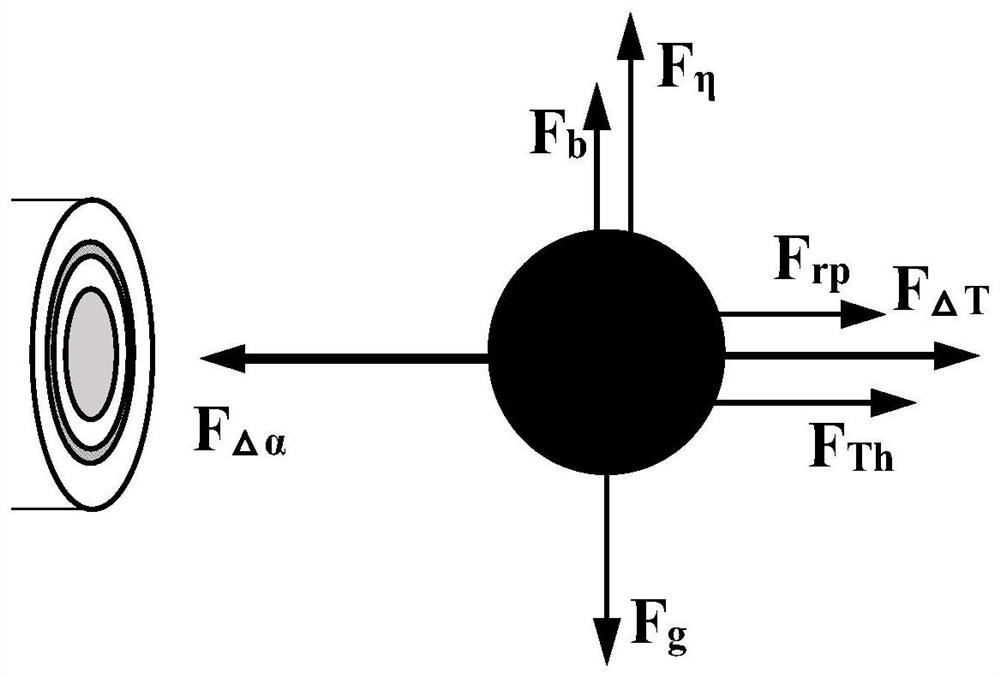

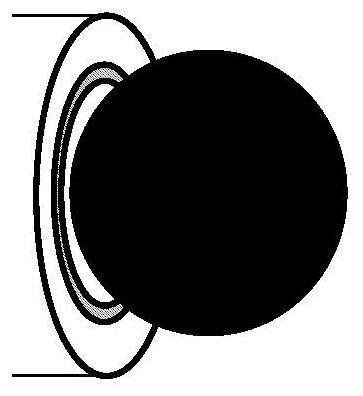

Microfluidic switch based on photophoresis effect

ActiveCN112099149AEasy to operateFlexible size controlCoupling light guidesPhotophoresisErbium lasers

According to the microfluidic switch based on the photophoresis effect, the positions of the absorptive particles are controlled through the photophoresis force borne by the absorptive particles in liquid, and the function of opening and closing a microfluidic channel is achieved. According to the optical fiber microfluid switch based on the photophoresis effect, the photophoresis force for controlling the absorptive particles is determined by heat exchange between the particles and surrounding media, and the optical fiber microfluid switch comprises a laser device, a transmission optical fiber, a microfluid laser coupling device, an optical fiber with a hole, the absorptive particles, a microfluid guide pipe and a microinjection pump. According to the invention, the photophoresis effect of the absorptive particles is utilized to achieve the light-operated microfluidic switch, the opening and closing of the microfluidic channel can be flexibly controlled on line in real time, and the microfluidic switch is simple in structure, easy to realize integration, low in cost and convenient to operate.

Owner:HARBIN ENG UNIV

Power distribution system for optimizing power consumption efficiency of residential area

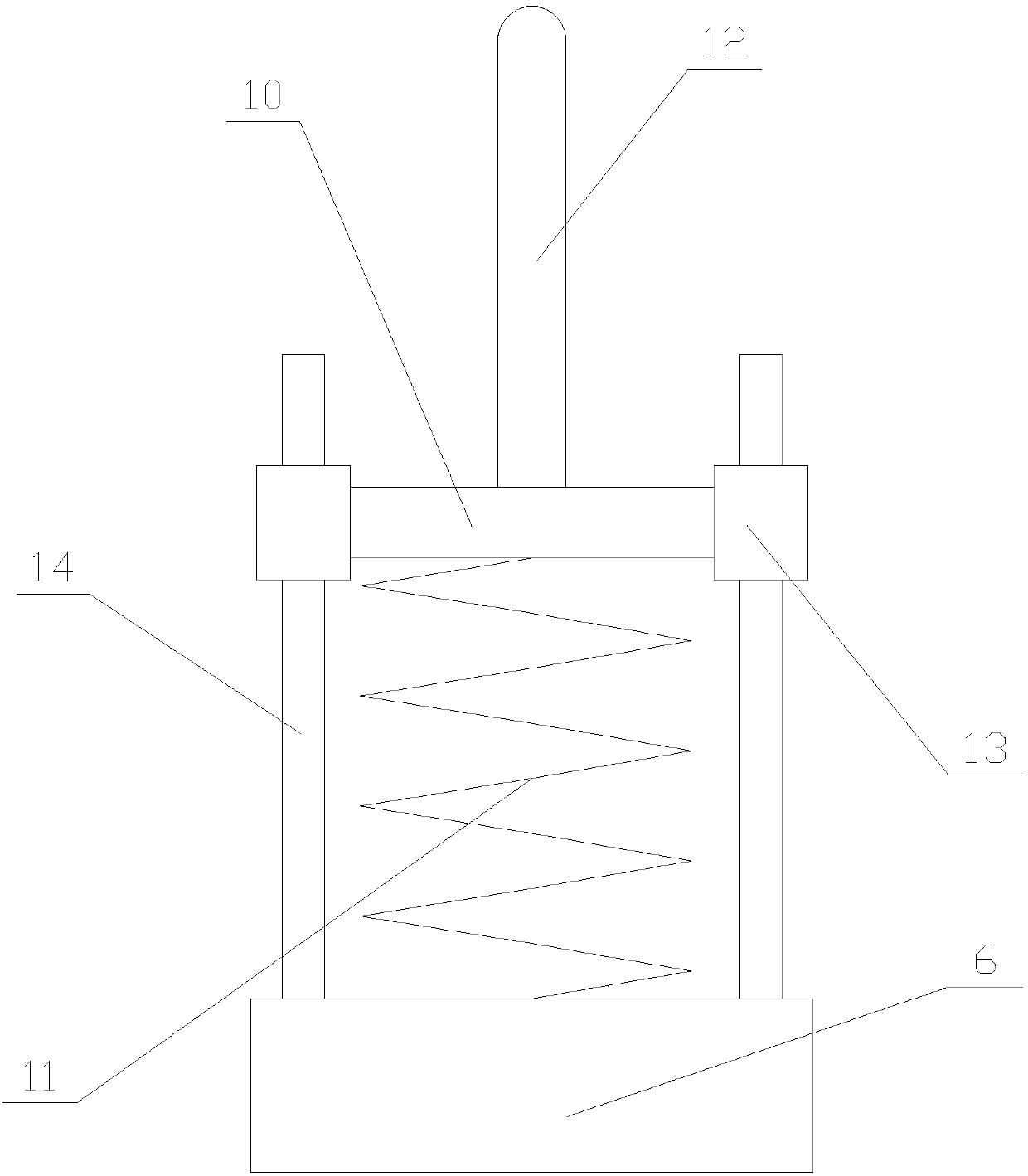

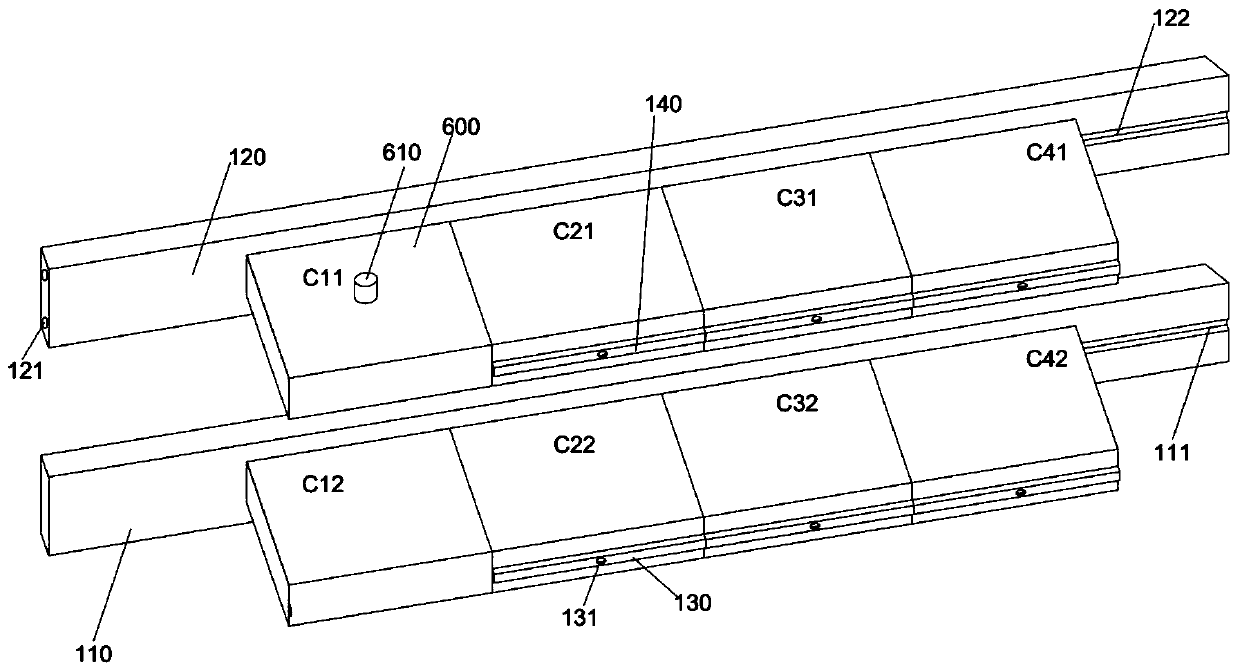

PendingCN109842125AReduce shockFlexible size controlMultiple fixed capacitorsFixed capacitor terminalsPower compensationPower grid

The invention discloses a power distribution system for optimizing the power consumption efficiency of a residential area. A first pair of guide rails includes two first guide rails arranged in parallel and at intervals. A second pair of guide rails includes two second guide rails arranged in parallel and at intervals. The second pair of guide rails moves towards or away from the first pair of guide rails. A first electrode plate is installed between the guide rails in the first pair of guide rails, and the first electrode plate includes several first sub electrode plates. The position of thefirst first sub electrode plate is fixed, and the second to last first sub electrode plates slide between the guide rails in the first pair of guide rails. A second electrode plate is installed between the guide rails in the second pair of guide rails, and the second electrode plate includes several second sub electrode plates. The position of the first second sub electrode plate is fixed, and thesecond to last second sub electrode plates slide between the guide rails in the second pair of guide rails. Each pair of first sub electrode plate and second sub electrode plate at corresponding positions moves synchronously along the lengthwise direction of the guide rails. The technical problem that reactive power compensation for the power grid of a residential area is inconvenient is solved.

Owner:YANCHENG INST OF IND TECH

A kind of preparation method of laminated board

ActiveCN104191794BSolve the problem of layer explosionImprove liquiditySynthetic resin layered productsLaminationMetal foilPhysical chemistry

The invention discloses a method for manufacturing a laminated board. The method for manufacturing the laminated board comprises the following steps: (1) adding a filler into thermosetting resin to obtain a resin composition, dissolving the resin composition with a solvent to obtain glue, and directly combining the glue, a reinforcing material and a metal foil to obtain a combined module, wherein the filler comprises a charged filler and a non-charged filler; (2) performing hot forming on the combined module to obtain the laminated board, wherein in the hot forming process of the combined module, the combined module is always in an electrical field. In the method, the charged filler is added into a glue formulation of the laminated board, and in the laminating process, the electrical field is used for manufacturing the laminated board, so that the problem of hierarchical burst of the laminated board caused by too large diffidence of thermal expansion coefficients and thermal conductivity coefficients of the resin and a copper foil is solved; experiments show that the defective rate, caused by the hierarchical burst, of the laminated board manufactured by the invention method is 0%, so that the problem of the hierarchical burst is solved.

Owner:SHENGYI TECH SUZHOU

Winding type iron core magnetically controlled saturated reactor

InactiveCN104616871ASimple structureEasy to processTransformers/inductances coils/windings/connectionsVariable inductancesProcess engineeringPower grid

The invention discloses a winding type iron core magnetically controlled saturated reactor, and belongs to a power grid automatic reactive power compensation device. The reactor comprises winding type iron cores, an alternating-current working winding, direct-current exciting windings and partial saturation windings. The iron cores include the two winding type iron cores which are adjacently placed. The alternating-current working winding is wound around the adjacent portions of the iron cores and wound on the two iron cores. The two direct-current exciting windings are connected in series and symmetrically wound on the two iron cores respectively. Four symmetrical holes in the same size are reserved in the adjacent portions of the two iron cores. The partial saturation windings penetrate through the holes to be wound on the iron cores and are used for generating partial saturation equivalent gas gaps. The adjustable reactor is simple in structure and easy to machine, the linear regulation range of the reactance value is wide, and the large overload capacity is achieved.

Owner:SOUTHEAST UNIV

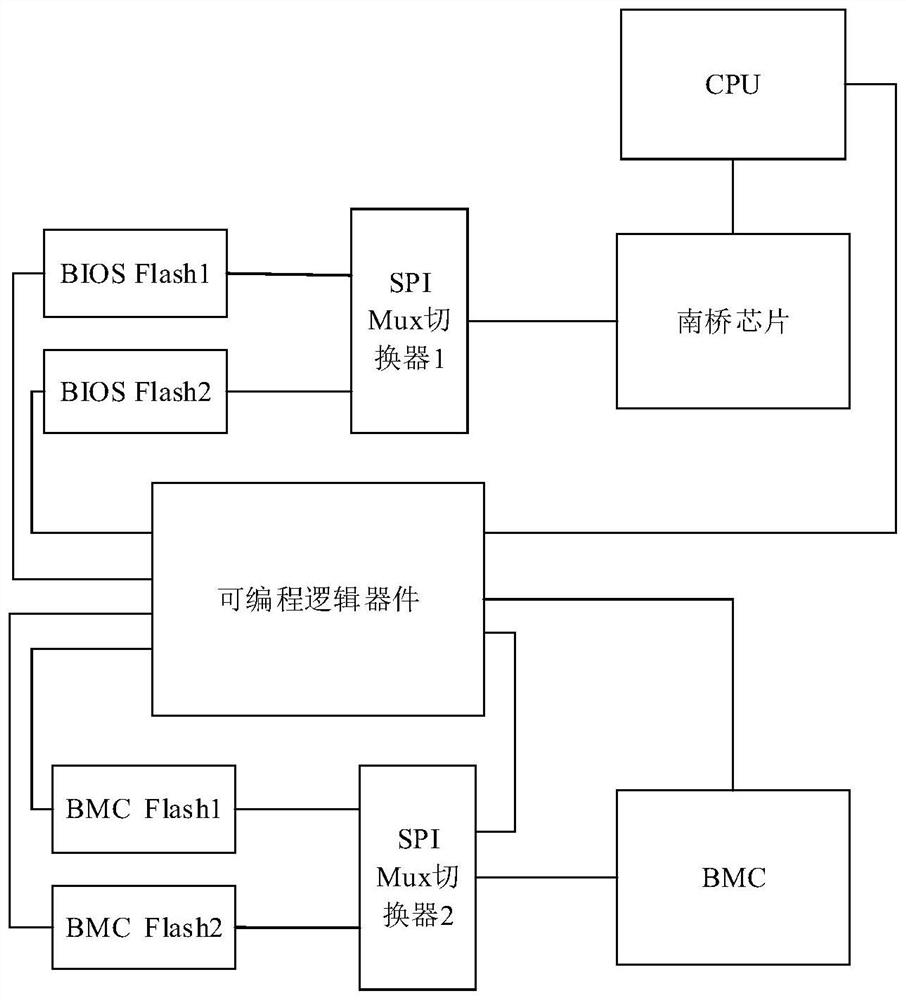

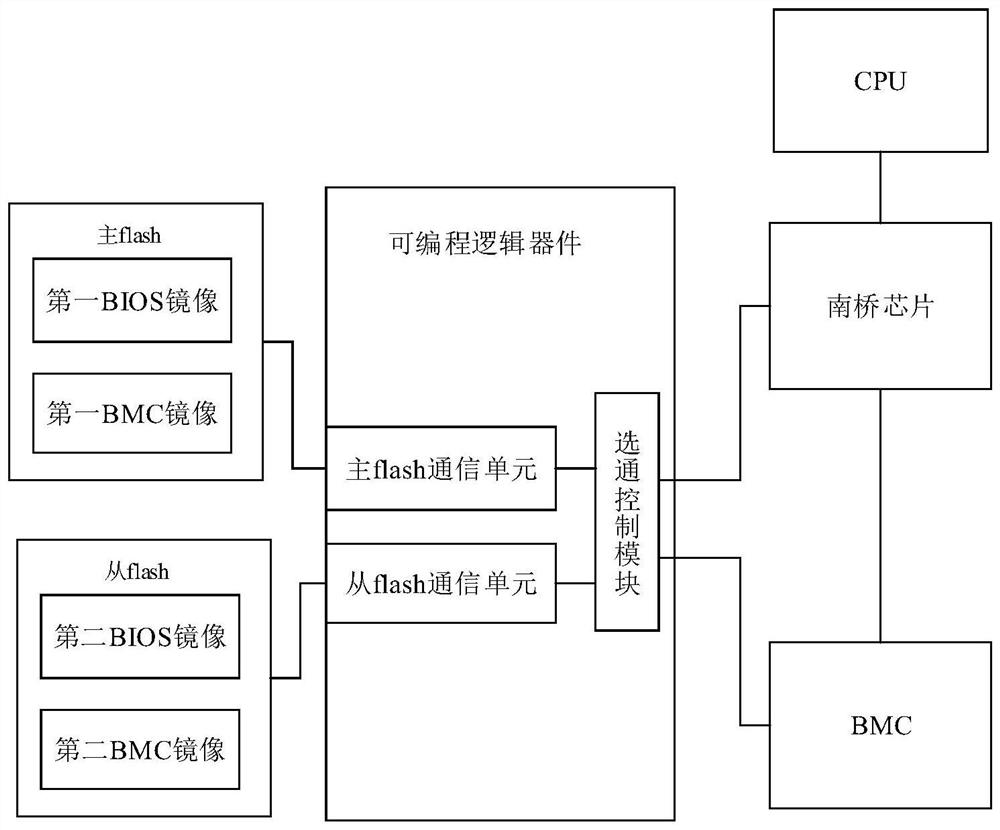

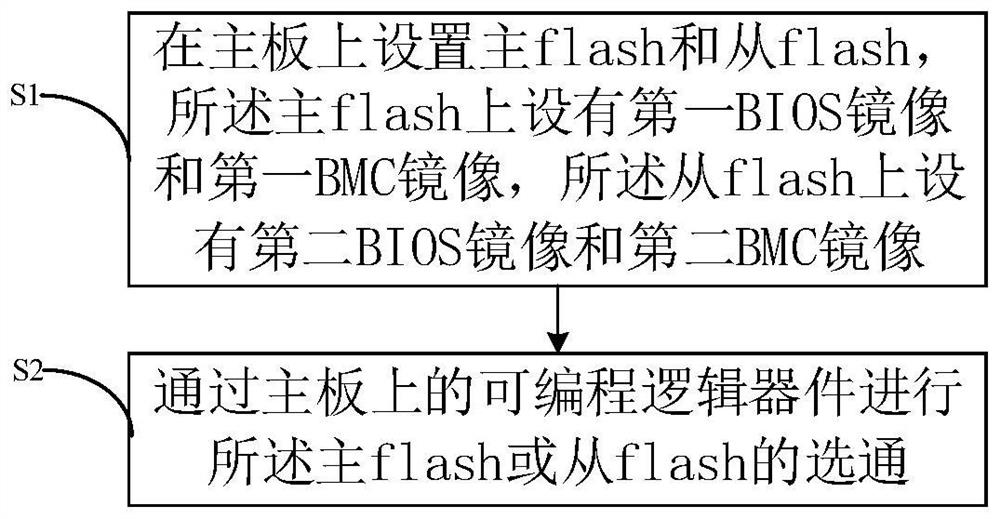

Double-flash mainboard, electronic equipment applying same and design method of double-flash mainboard

InactiveCN113805672AReduce in quantityImprove placement flexibilityDigital processing power distributionRedundant operation error correctionProgrammable logic deviceEngineering

The invention provides a double-flash mainboard, electronic equipment applying the same and a design method of the double-flash mainboard, the double-flash mainboard comprises a programmable logic device, the mainboard further comprises a master flash and a slave flash, the master flash is provided with a first BIOS mirror image and a first BMC mirror image, and the slave flash is provided with a second BIOS mirror image and a second BMC mirror image; and the programmable logic device is used for gating of the master flash and the slave flash. According to the invention, the main flash and the slave flash are arranged on the mainboard, and each flash is provided with the BIOS mirror image and the BMC mirror image, so that the requirement of double flashes of devices on the mainboard is met, the requirement can be realized by arranging only two flashes on the mainboard, and the number of the devices on the mainboard is reduced; in addition, the gating function of the master flash and the slave flash is integrated into the programmable logic device, so that the number of devices on the mainboard is further reduced. The number of solid parts on the mainboard is reduced, the space of circuit layout is optimized, the wiring difficulty is reduced, and the placing elasticity of the parts is improved.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

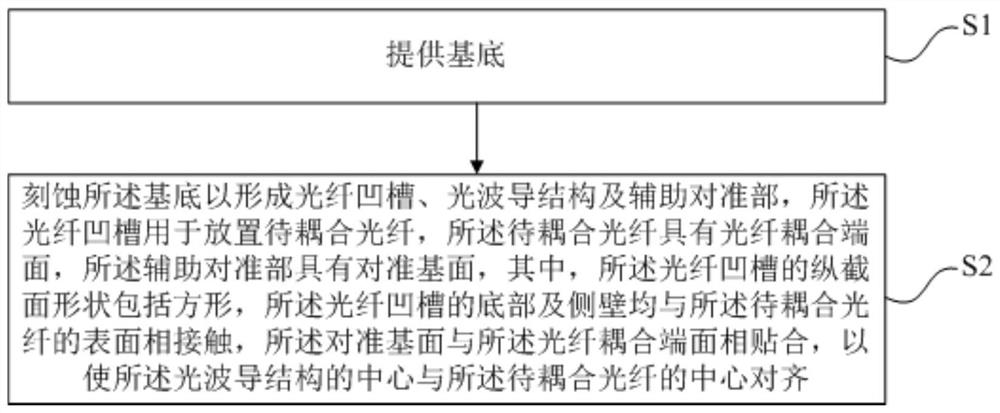

Optical fiber coupling alignment structure, preparation method and optical fiber coupling method

ActiveCN112068255AFacilitates precise alignmentFlexible size controlPhotomechanical apparatusCoupling light guidesOptical fiber couplingWaveguide

The invention provides an optical fiber coupling alignment structure of an optical fiber-to-optical waveguide structure, a preparation method and a method for coupling an optical fiber to an optical component, the preparation method of the optical fiber coupling alignment structure comprises the following steps: an optical fiber groove, the optical waveguide structure and an auxiliary alignment part are prepared in a substrate, the shape of the longitudinal cross section of the optical fiber groove includes a square; the alignment base surface of the auxiliary alignment part is attached to thecoupling end surface of the optical fiber, the three surfaces of the optical fiber groove are in contact with the optical fiber to be coupled, and the optical fiber to be coupled can be automaticallyaligned with the optical waveguide structure in the vertical direction and the horizontal direction, and the optical fiber groove with the square section with the side wall perpendicular to the bottom can be prepared based on a dry etching process. The preparation of the optical fiber alignment coupling structure is compatible with other processes (such as an MEMS process), and the size of the optical fiber groove can be flexibly controlled according to the size of the optical fiber. According to the invention, the optical fiber groove, the optical waveguide structure and the auxiliary alignment part can be formed based on the same photoetching process, thereby facilitating the precise alignment of the to-be-coupled optical fiber and the optical waveguide structure.

Owner:SHENZHEN CONJUGATE TECH CO LTD

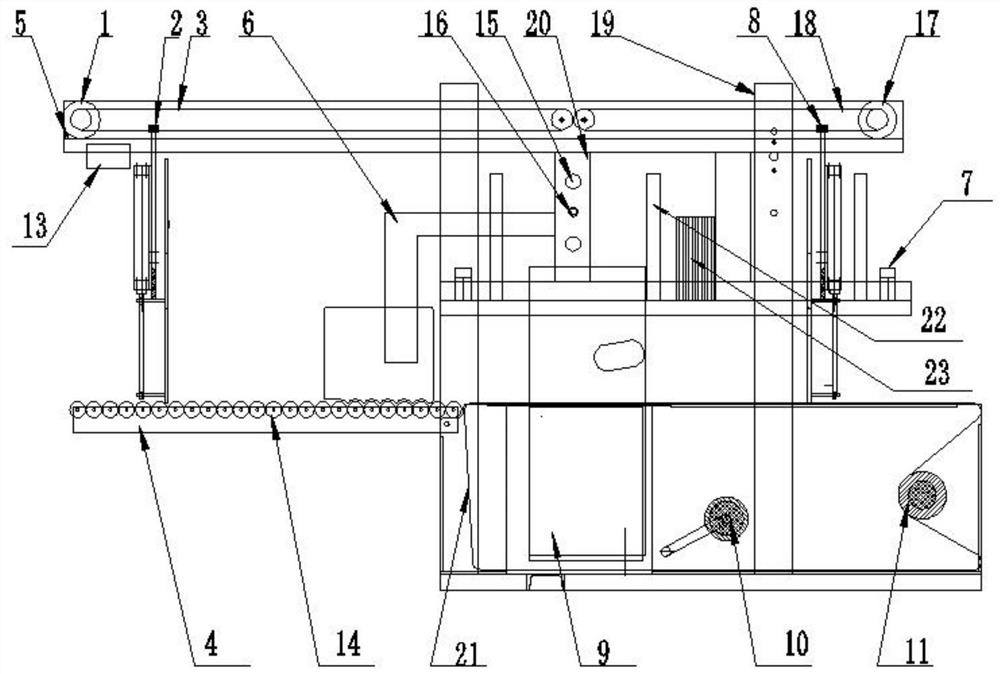

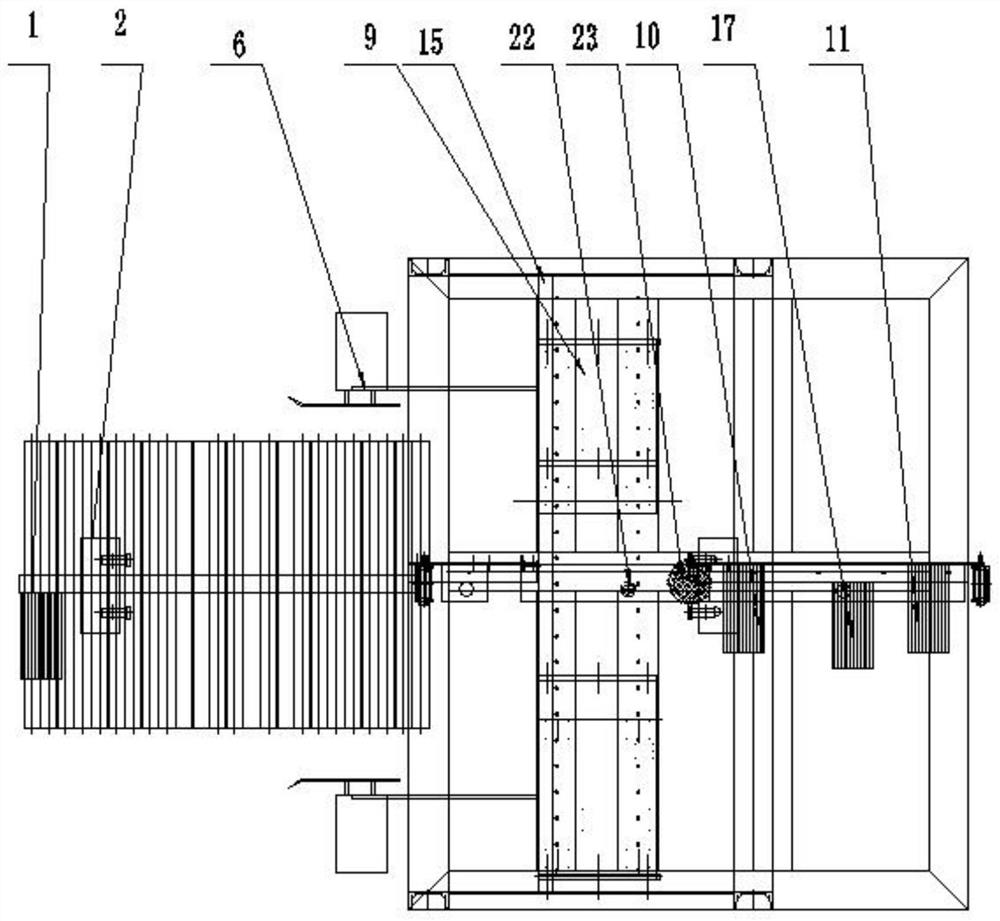

A fully automatic taobao box packing machine

ActiveCN111319818BSave human effortImprove work efficiencyBinding material applicationBundling machine detailsCardboardCarton

Owner:五岳自动化设备制造(沧州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com