Preparing method for CdSe@CdS core-shell structure quantum dots

A core-shell structure and quantum dot technology is applied in the field of preparation of CdSeCdS core-shell structure quantum dots, which can solve the problems of affecting the optoelectronic properties of nano-semiconductors, difficult to control product particle size, poor crystallinity of nano-particles, etc. , the effect of reducing the particle size of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

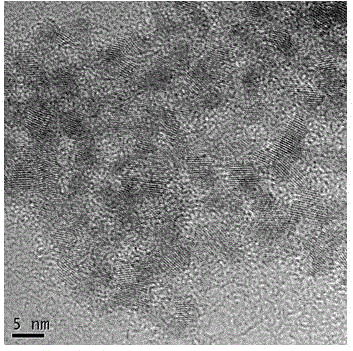

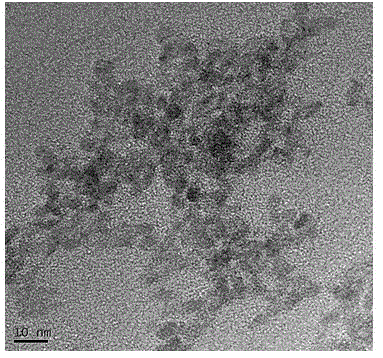

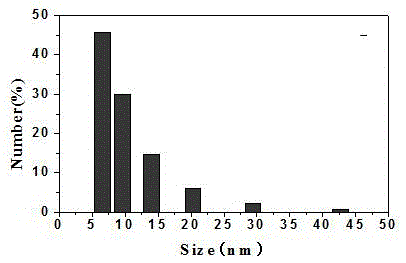

Image

Examples

Embodiment 1

[0022] The preparation method of the described CdSeCdS core-shell structure quantum dots, the specific steps are:

[0023] 1) Preparation of nuclear particle CdSe:

[0024] a. Weigh 0.016g selenium powder and 0.08gKBH 4 , added to 2 mL of secondary deionized water, and reacted for about 20 minutes under nitrogen protection to obtain a KHSe aqueous solution;

[0025] b. Prepare two microemulsions, microemulsion 1: 8.1mL cyclohexane, 6mL Tween 80, 9mL n-hexanol, 0.6mL 0.3M cadmium nitrate and 0.4M thiourea aqueous solution; microemulsion 2: 8.1mL cyclohexane , 6mL Tween 80, 9mL n-hexanol, 0.6mL0.1M KHSe aqueous solution;

[0026] c. Place the two parts of microemulsion in a constant temperature water bath at 30°C, and stir for 30 minutes under nitrogen protection until it becomes clear and transparent, then add microemulsion 2 dropwise to microemulsion 1 under stirring, and control the dropping rate to Two drops per second, the whole process is under the protection of nitroge...

Embodiment 2

[0029] The process is the same as Example 1, but the composition of the water phase of microemulsion 1 is changed to: 0.6mL of 0.2M cadmium nitrate and 0.4M thiourea aqueous solution to obtain CdSeCdS core-shell structure quantum dots with a core / shell molar ratio of 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com