Synthetic method of improved micron-scale polystyrene microspheres

A technology of polystyrene microspheres and synthesis methods, applied in the field of biomedical engineering, to achieve the effects of stable synthesis process, high reproducibility, and high monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: change the consumption of monomer

[0019] The synthesis method in this example is as described in the description, the amount of monomers is changed, and other synthesis conditions remain unchanged. The specific composition is shown in Table 1.

[0020] Table 1 Composition of reaction system under different monomer dosage

[0021]

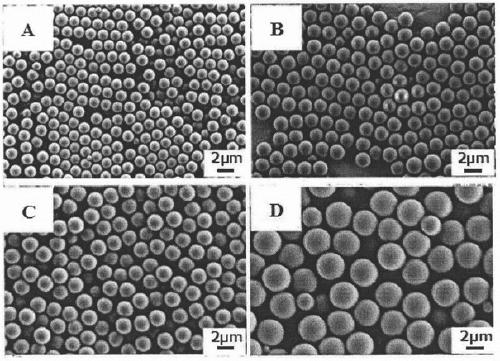

[0022] figure 1 is the corresponding product SEM.

[0023] figure 1 The SEM images in the middle show that the PS microspheres prepared when the monomer dosage is 5mL, 10mL, 15mL and 20mL all have good sphericity, and the monodispersity of the microspheres is good. However, with the increase of the amount of monomer, the average particle size of the microspheres also increases, and the particle size distribution gradually widens.

Embodiment 2

[0024] Embodiment 2: change the consumption of stabilizer

[0025] The synthesis method in this example is as described in the description, the amount of the stabilizer PVP is changed, and other conditions remain unchanged. The specific composition is shown in Table 2.

[0026] Table 2 Composition of the reaction system at different stabilizer concentrations

[0027]

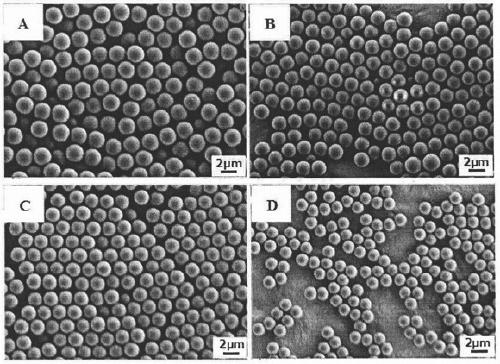

[0028] figure 2 It is the scanning electron microscope picture of the product corresponding to different stabilizers. It can be seen from the figure that the particles of the microspheres are uniform and the monodispersity is good. With the increase of stabilizer dosage, the average particle size of microspheres decreases.

Embodiment 3

[0029] Embodiment 3: change the consumption of initiator

[0030] The synthesis method in this example is as described in the description, the amount of the initiator AIBN is changed, and other conditions remain unchanged. The specific composition is shown in Table 3.

[0031] Table 3 Composition of reaction system under different initiator concentrations

[0032]

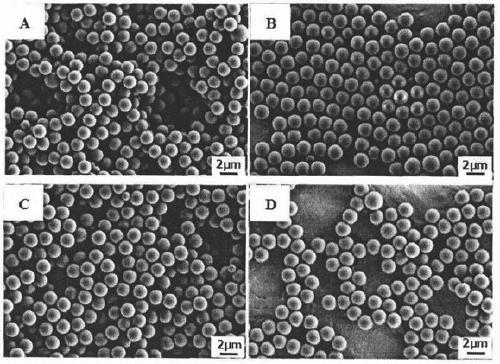

[0033] image 3 is the SEM image of PS microspheres prepared under different amounts of initiators. Such as image 3 As shown, the microsphere particles are uniform and the surface is smooth. The average particle size of the microspheres increases with the increase of the initiator dose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com