Method for preparing porous carbon loaded nano-metal through microwave assistance

A nano-metal and microwave-assisted technology is applied in the field of porous carbon-supported nano-metal oxides or nano-metal materials, and achieves great application prospects, low cost, and high monodispersity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Porous carbon loaded nano-Ni

[0029] Synthetic raw materials: glucose, urea, Ni(NO 3 ) 2` 6H 2 O (nickel nitrate)

[0030] (1) Weigh 1.5 g glucose, 2.5 g urea and 0.9 g Ni(NO 3 ) 2 9H 2 O in a 100 mL beaker, then place the beaker in a heatable magnetic stirrer. The temperature of the magnetic stirrer was raised to 120° C., and the stirring was continued for 10 min until the medicine in the beaker was in a molten state.

[0031] (2) Take out the molten liquid described in (1), put it into a microwave and heat it with a heating power of 300w, and heat it for 15 minutes to obtain a dark brown puffy solid.

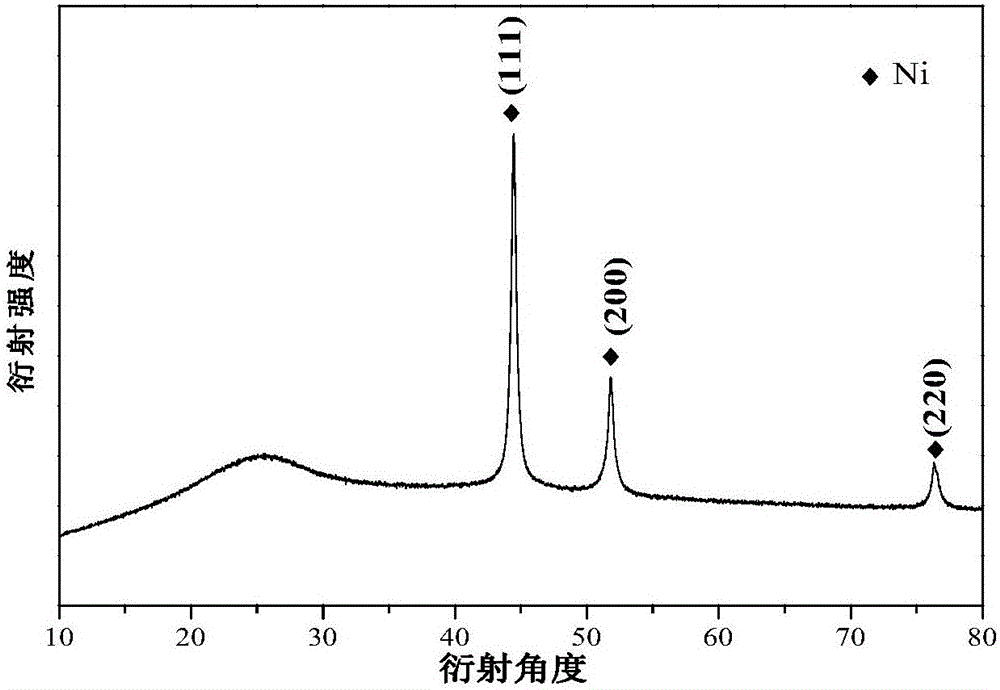

[0032] (3) Grind the sample obtained in (2) with a mortar, and put it in a crucible, at 500 ° C, 5% H 2 / N 2 After heat treatment for 5 h under the same conditions, nano-Ni supported on porous carbon was obtained. XRD test showed that the particle size of Ni was 35 nm.

[0033] figure 1 It is the XRD pattern of nano-metal Ni supported on porous ca...

Embodiment 2

[0034] Example 2: Porous carbon loaded nano-Ni

[0035] Synthetic raw materials: glucose, urea, Ni(NO 3 ) 2` 6H 2 O (nickel nitrate)

[0036] (1) Weigh 1.5 g glucose, 2.5 g urea and 0.9 g Ni(NO 3 ) 2 9H 2 O in a 100 mL beaker, then place the beaker in a heatable magnetic stirrer. The temperature of the magnetic stirrer was raised to 120° C., and the stirring was continued for 10 min until the medicine in the beaker was in a molten state.

[0037] (2) Take out the molten liquid described in (1), put it into a microwave and heat it with a heating power of 500w, and heat it for 10 minutes to obtain a dark brown puffy solid.

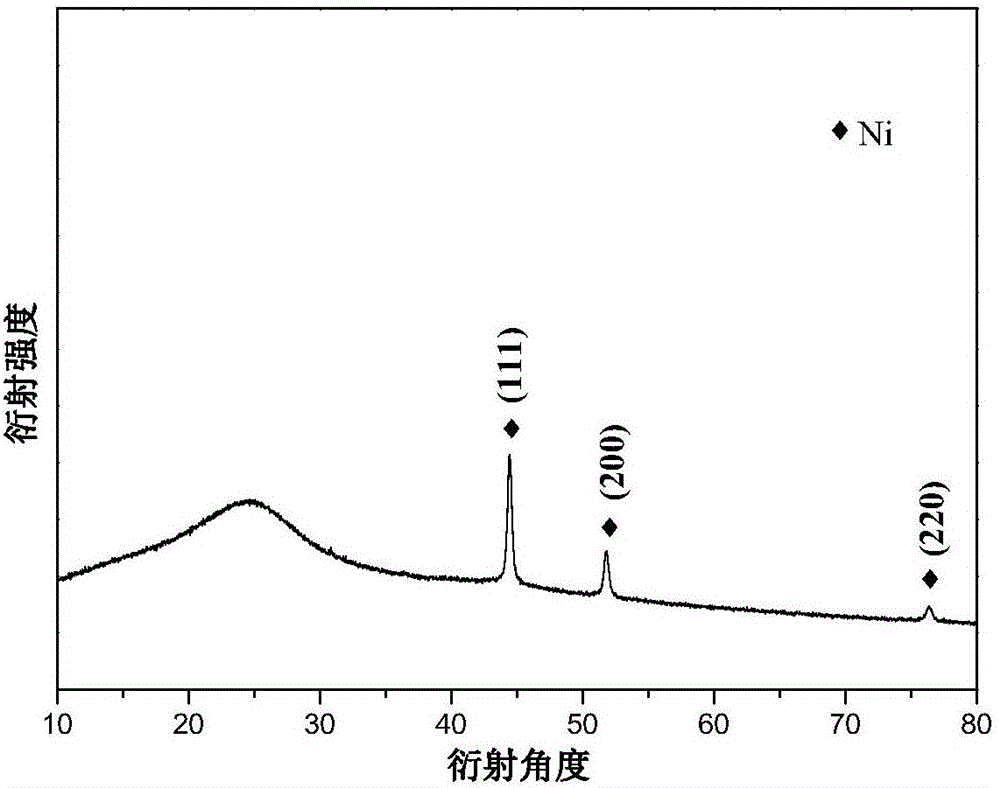

[0038] (3) Grind the sample obtained in (2) with a mortar, and put it in a crucible, at 500 ° C, 5% H 2 / N 2 After heat treatment for 5 h under the same conditions, nano-Ni supported on porous carbon was obtained. XRD test showed that the particle size of Ni was 22 nm.

[0039] figure 2 It is the XRD pattern of nano-metal Ni supported on porous c...

Embodiment 3

[0040] Example 3: Porous carbon loaded nano-Ni

[0041] Synthetic raw materials: glucose, urea, Ni(NO 3 ) 2` 6H 2 O (nickel nitrate)

[0042] (1) Weigh 1.5 g glucose, 2.5 g urea and 0.9 g Ni(NO 3 ) 2 9H 2 O in a 100 mL beaker, then place the beaker in a heatable magnetic stirrer. The temperature of the magnetic stirrer was raised to 120° C., and the stirring was continued for 10 min until the medicine in the beaker was in a molten state.

[0043] (2) Take out the molten liquid described in (1), put it into a microwave and heat it with a heating power of 700w, and heat it for 5 minutes to obtain a dark brown puffy solid.

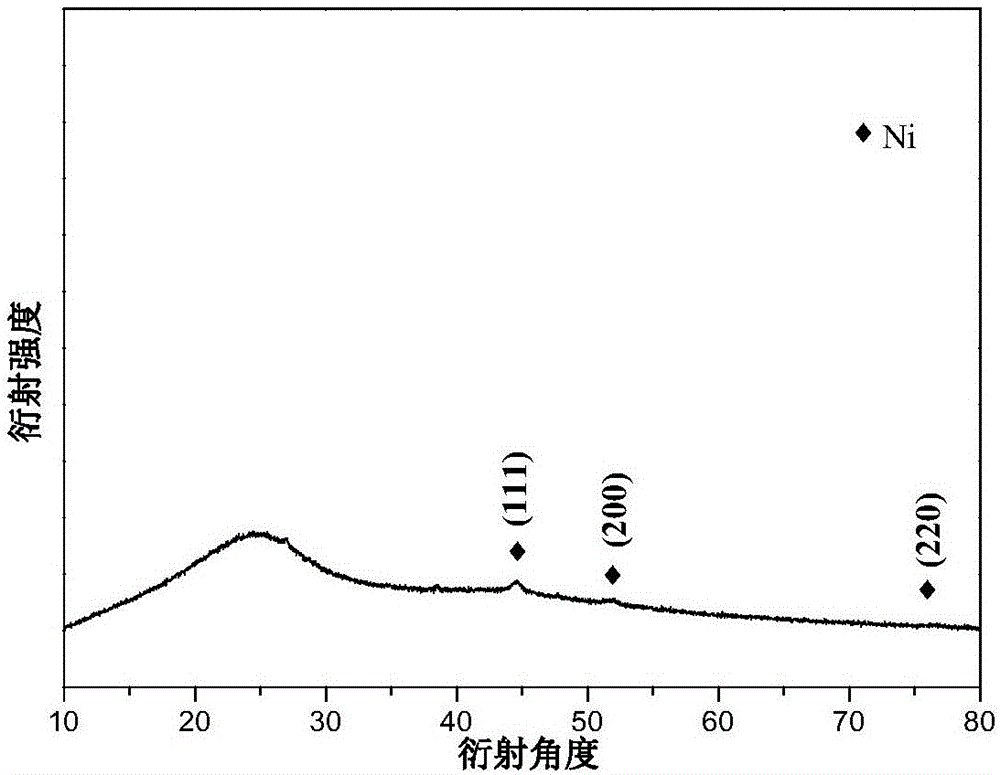

[0044] (3) Grind the sample obtained in (2) with a mortar, and put it in a crucible, at 500 ° C, 5% H 2 / N 2 After heat treatment for 5 h under the same conditions, nano-Ni supported on porous carbon was obtained. XRD test showed that the particle size of Ni was 8 nm.

[0045] image 3 It is the XRD pattern of nano-metal Ni supported on porous carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com