Preparation method and application method of silicon dioxide nano microspheres

A technology of silica and nano-microspheres, which is applied in the direction of silica, silica, chemical instruments and methods, etc., can solve the problems of easy agglomeration of materials and small mesopore size, and achieve high specific surface area, large pore size, Effect of avoiding secondary nucleation and agglomeration problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

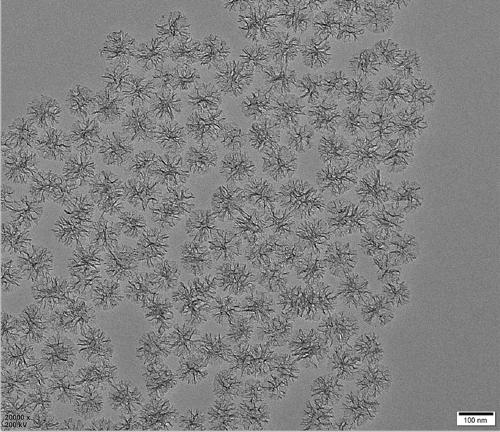

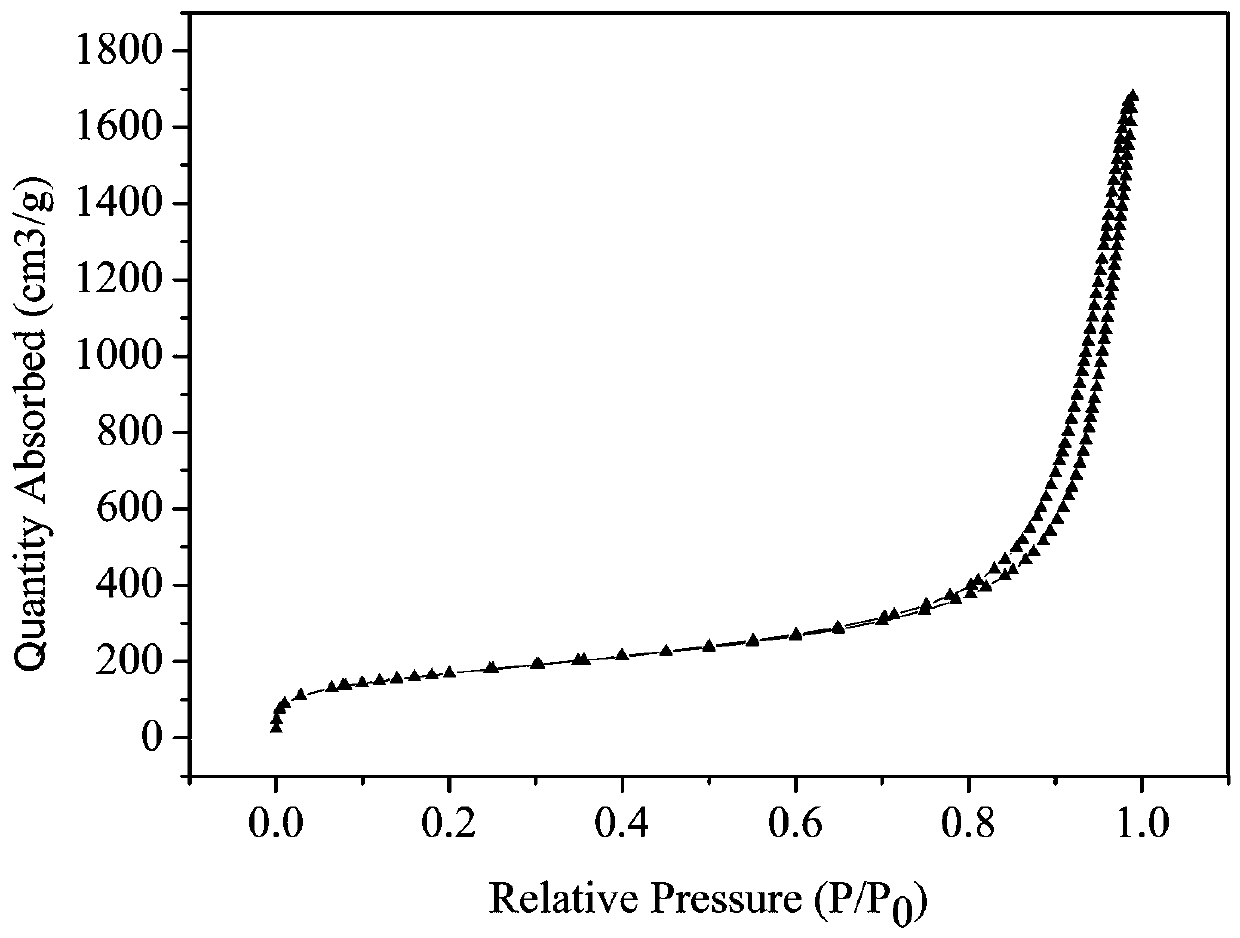

[0030] A preparation method of silica nanospheres: Weigh 1.3 g TCMAC and 10.7 g CTAC respectively and disperse them into 120 mL of water, then mix 8 mL of tetraethyl orthosilicate and 32 mL of 1-octadecene and add to the reaction system, reacted at 150rpm for 10 minutes, added 0.4 g of triethylamine, and mechanically stirred at 60°C for 12 hours. After the reaction, the mixed solution was centrifuged at 10000 rpm for 20 minutes. Then the obtained precipitate was centrifuged and washed three times with ethanol, dried at 100 °C for 13 hours, then transferred to a muffle furnace after drying, and calcined at 600 °C for 13 hours. Monodisperse mesoporous nano silica microspheres can be obtained. The material was characterized by a pore size and specific surface area analyzer, the average pore size was 4.7 nm, and the specific surface area was 667.2 m 2 g -1 , with a porosity of 0.81 cm 3 g -1 . The average particle size of the material tested by a dynamic light scattering ins...

Embodiment 2

[0032]A preparation method of silica nanospheres: Weigh 2.8 g TCMAC and 9.2 g CTAC respectively and disperse them into 120 mL water, then mix 8 mL tetraethyl orthosilicate and 32 mL 1-octadecene and add to the reaction system, reacted at 150rpm for 10 minutes, added 0.4 g of triethylamine, and mechanically stirred at 60°C for 12 hours. After the reaction, the mixed solution was centrifuged at 10000 rpm for 20 minutes. Then the obtained precipitate was centrifuged and washed three times with ethanol, dried at 100 °C for 13 hours, then transferred to a muffle furnace after drying, and calcined at 600 °C for 13 hours. Monodisperse mesoporous nano silica microspheres can be obtained. The material was characterized by a pore size and specific surface area analyzer. The average pore size was 7.5 nm and the specific surface area was 658.5 m 2 g -1 , with a porosity of 0.27 cm 3 g -1 . The average particle size of the material tested by a dynamic light scattering instrument was ...

Embodiment 3

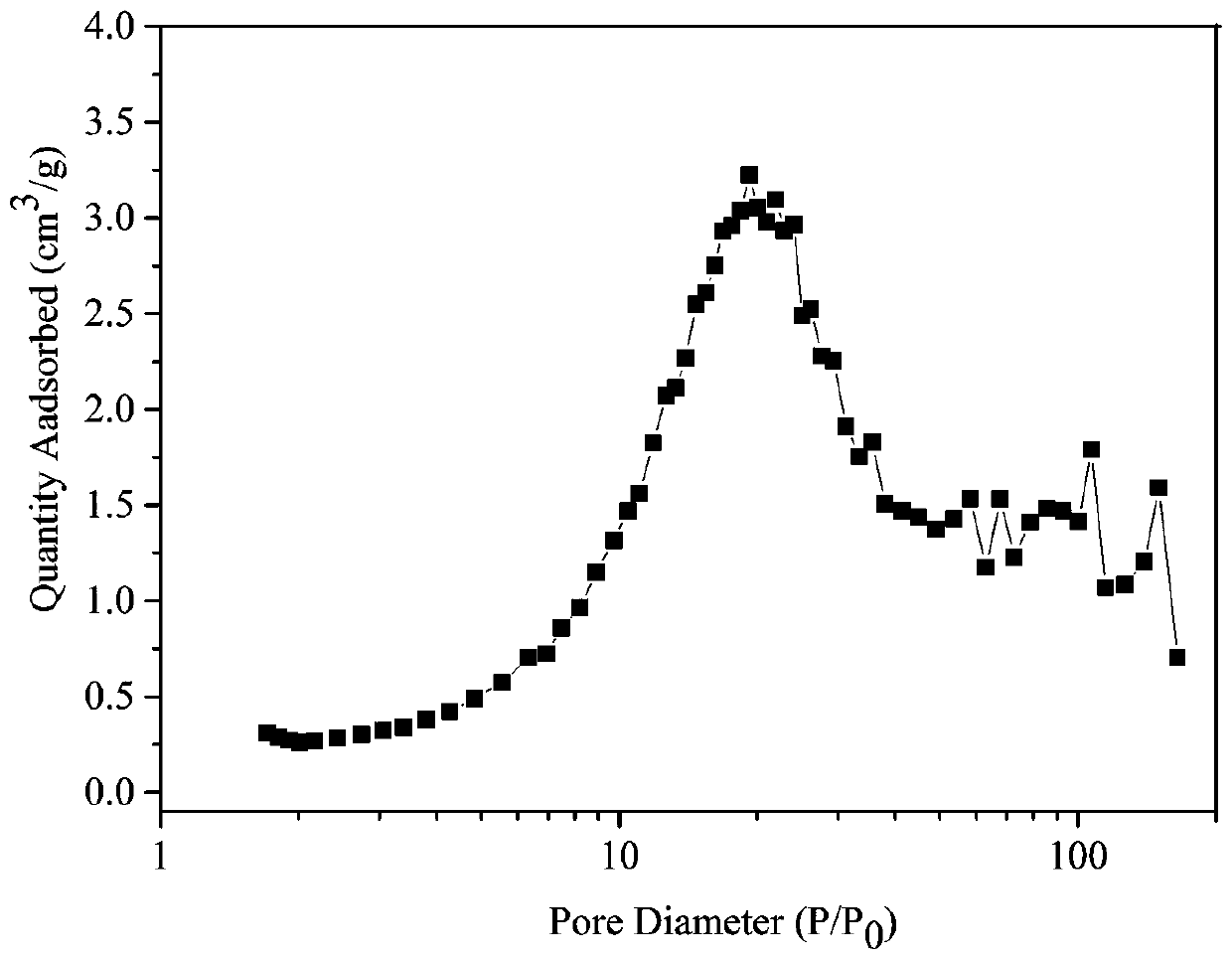

[0034] A preparation method of silica nanospheres: Weigh 4.5 g TCMAC and 7.5 g CTAC respectively and disperse them into 120 mL water, then mix 8 mL tetraethyl orthosilicate and 32 mL 1-octadecene and add to the reaction system, reacted at 150rpm for 10 minutes, added 0.4 g of triethylamine, and mechanically stirred at 60°C for 12 hours. After the reaction, the mixed solution was centrifuged at 10000 rpm for 20 minutes. Then the obtained precipitate was centrifuged and washed three times with ethanol, dried at 100 °C for 13 hours, then transferred to a muffle furnace after drying, and calcined at 600 °C for 13 hours. Monodisperse mesoporous nano silica microspheres can be obtained. The material was characterized by a pore size and specific surface area analyzer, the average pore size was 18.4 nm, and the specific surface area was 589.5 m 2 g -1 , with a porosity of 1.27 cm 3 g -1 . The average particle size of the material tested by a dynamic light scattering instrument w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com