Construction method of graphene protecting structure

A protective structure and graphene technology, which is applied in the field of building graphene protective structures to improve its mechanical properties, can solve the problems of slag falling and easy peeling, and achieve the effect of improving shear resistance, improving mechanical properties, and meeting application requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

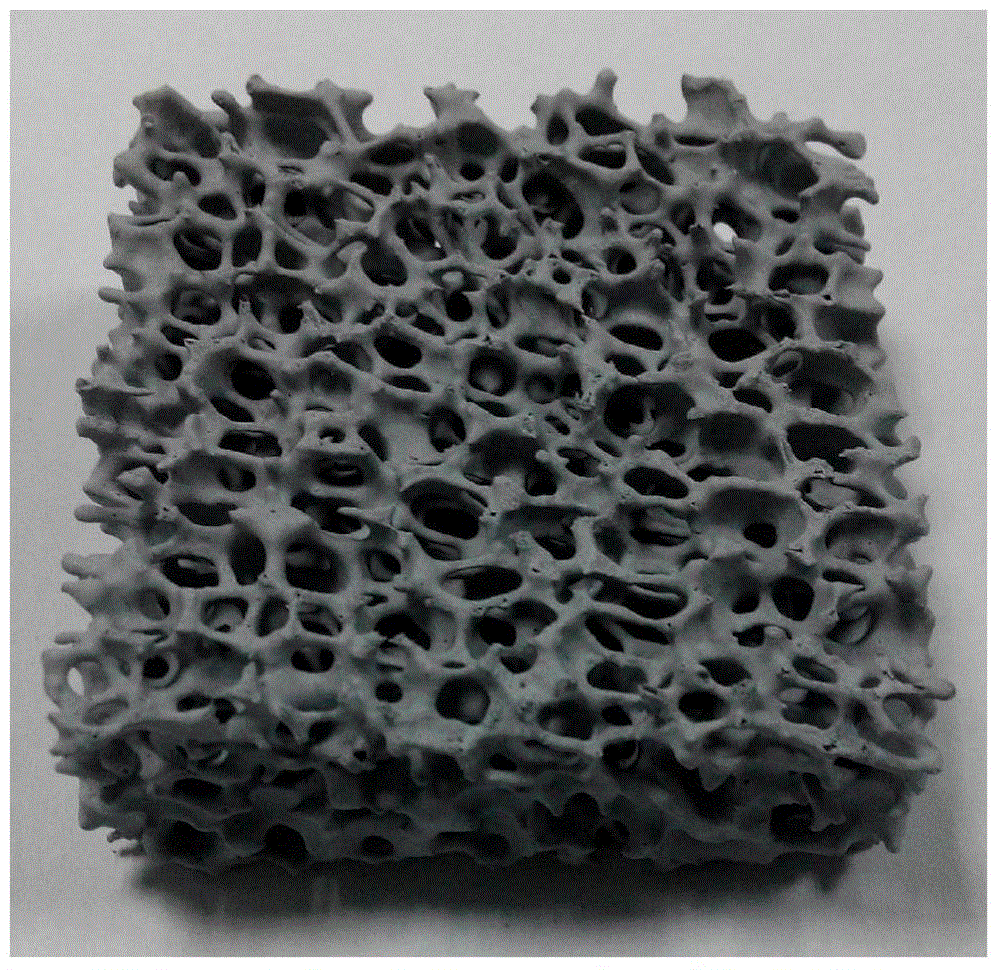

[0019] The first step, get the graphene oxide deionized water dispersion liquid 200ml of 10mg / ml, the ceramic foam (as figure 1 ) is completely immersed in it;

[0020] In the second step, after soaking for a period of time, put the ceramic foam into a freeze-drying box for freeze-drying;

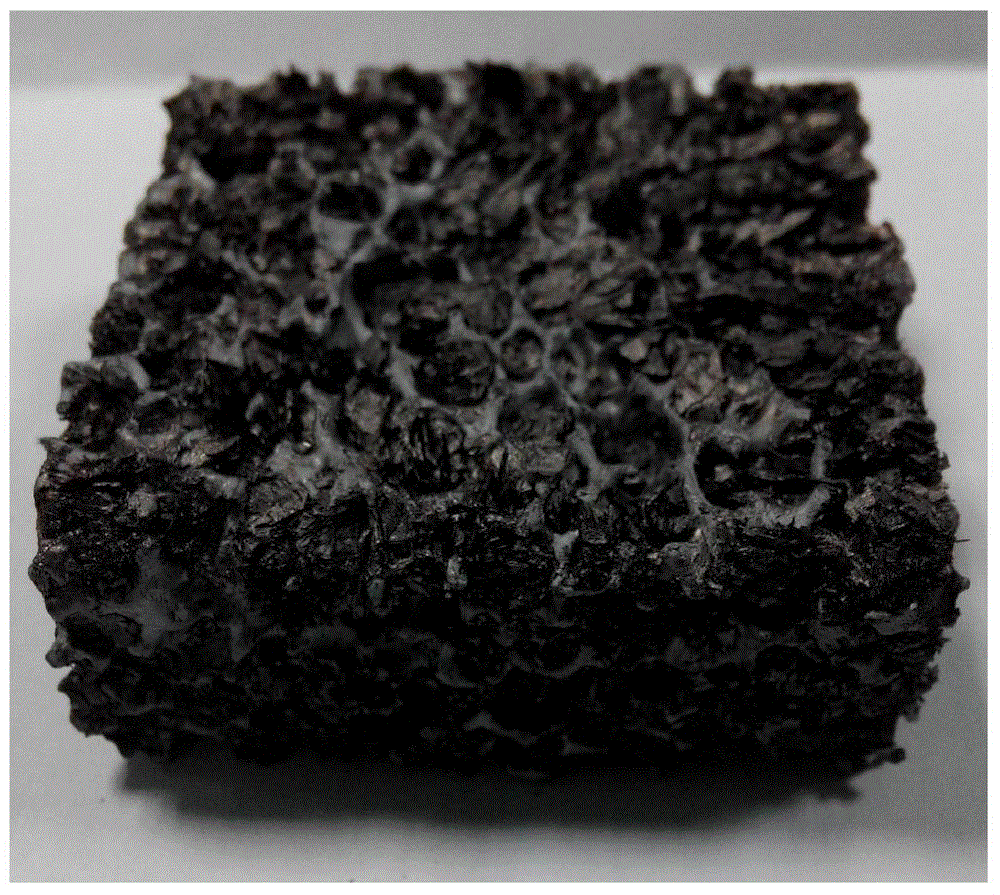

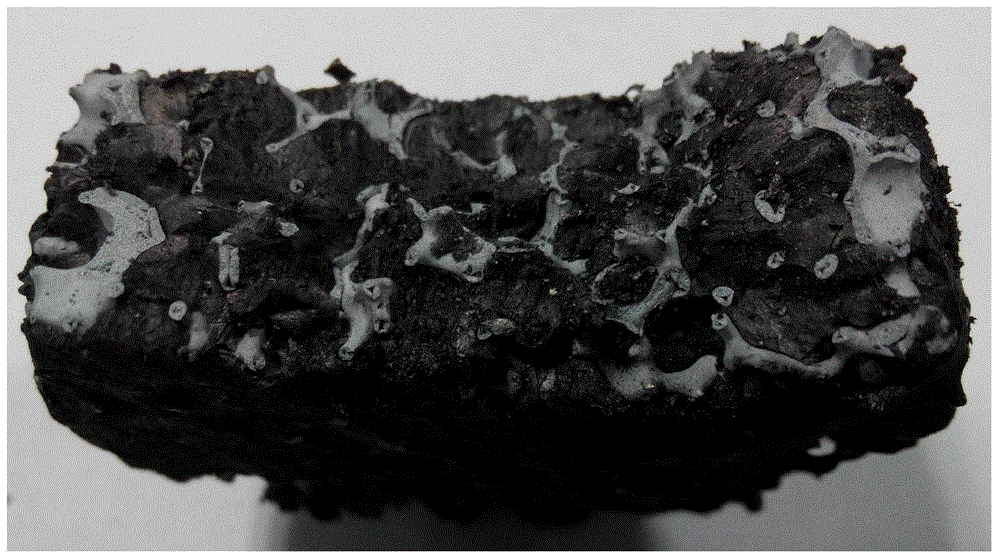

[0021] The third step is to put the obtained freeze-dried ceramic foam into a container containing hydrazine hydrate, seal it well, heat it to 95°C and maintain it for 24 hours, and use hydrazine vapor to reduce it, and finally get a graphene sponge filling Rigid ceramic foams such as figure 2 shown. image 3 The cross-sectional structure of the graphene sponge can be seen more clearly: the skeleton structure of the ceramic foam is wrapped around the outside of the graphene sponge, which plays a very good protective role.

Embodiment 2

[0023] The control method is basically the same as in Example 1, except that the concentration of graphene oxide is adjusted to 0.5 mg / ml, and a ceramic foam with a pore size of 100 microns is used;

Embodiment 3

[0025] The control method is basically the same as in Example 1, except that the graphene oxide concentration is adjusted to 20 mg / ml, and ceramic foam with a pore size of 5 mm is used;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com