Method for baseplate drying under reduced pressure and device thereof

A drying method and technology for substrates, which are used in drying solid materials, local stirring dryers, and static materials dryers, etc., can solve problems such as decompression drying spots, and achieve the effect of easy process control, saving control process, and reducing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

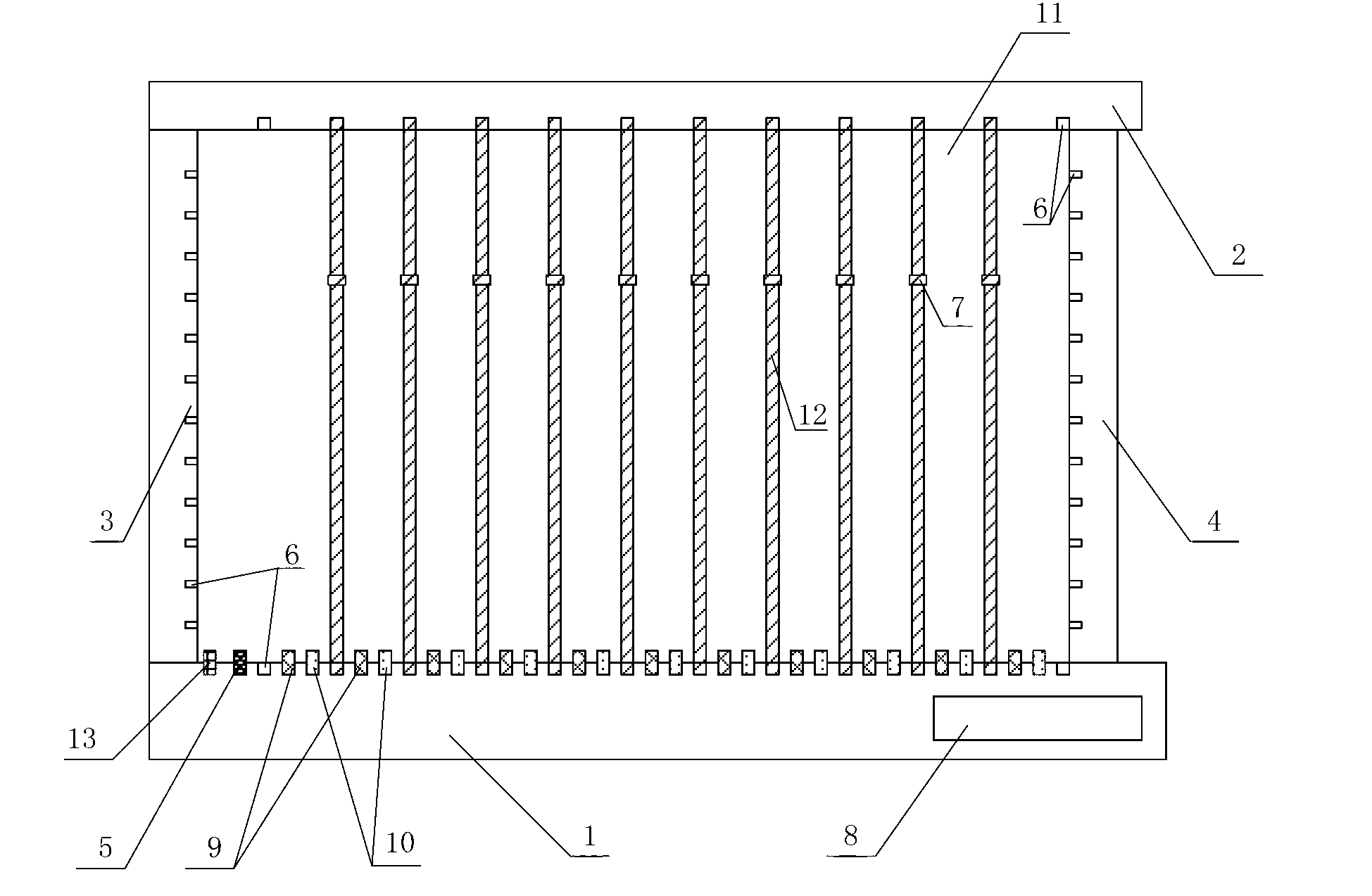

[0049] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0050] In order to solve the problem of drying spots existing in the existing substrate decompression drying process, the present invention provides a substrate decompression drying method and device.

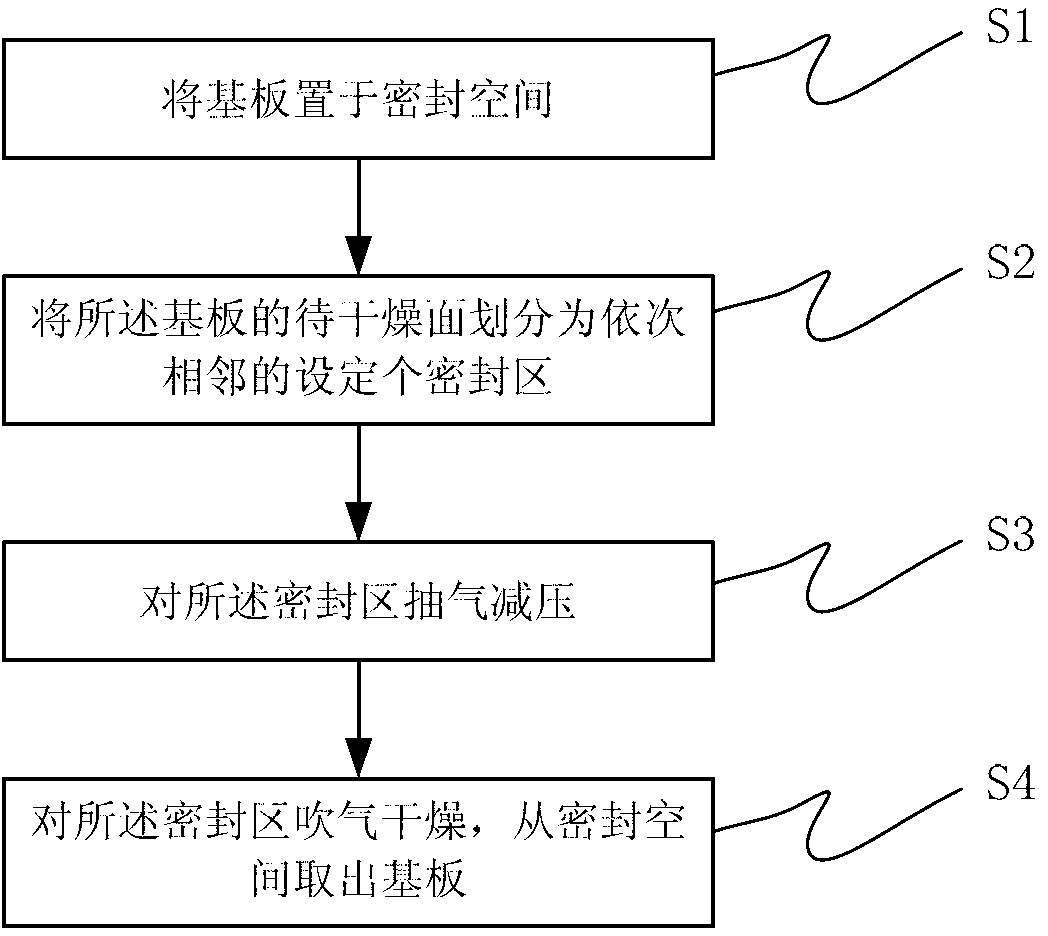

[0051] The flow chart of the inventive method is as figure 1 As shown, with reference to the diagram, the method specifically includes the following steps:

[0052] S1: placing the substrate in a sealed space;

[0053] S2: dividing the surface to be dried of the substrate into sequentially adjacent set sealing areas;

[0054] Adjacent successively means that according to the actual shape of the substrate, the substrate is divided into simple geometric sealing areas from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com