Additive manufacturing method of fiber rod-prearranged Z direction-reinforced continuous fiber composite material

A continuous fiber and composite material technology, which is applied in the field of Z-direction reinforced continuous fiber composite material additive manufacturing of prefabricated fiber rods, can solve the problems that limit the advantage of composite materials, the potential of fiber reinforcement, poor interlayer bonding, etc., and achieve high forming efficiency. , to achieve the effect of rapid manufacturing and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

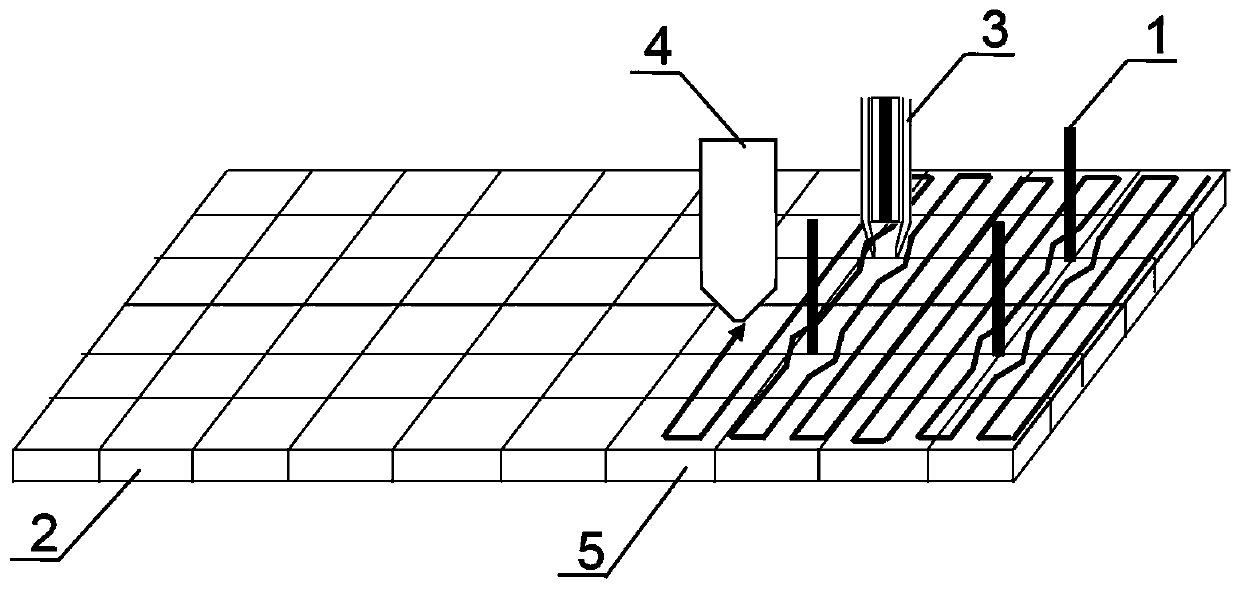

[0024] The method of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0025] A kind of prefabricated fiber rod Z direction reinforced continuous fiber composite material additive manufacturing method, comprises the following steps:

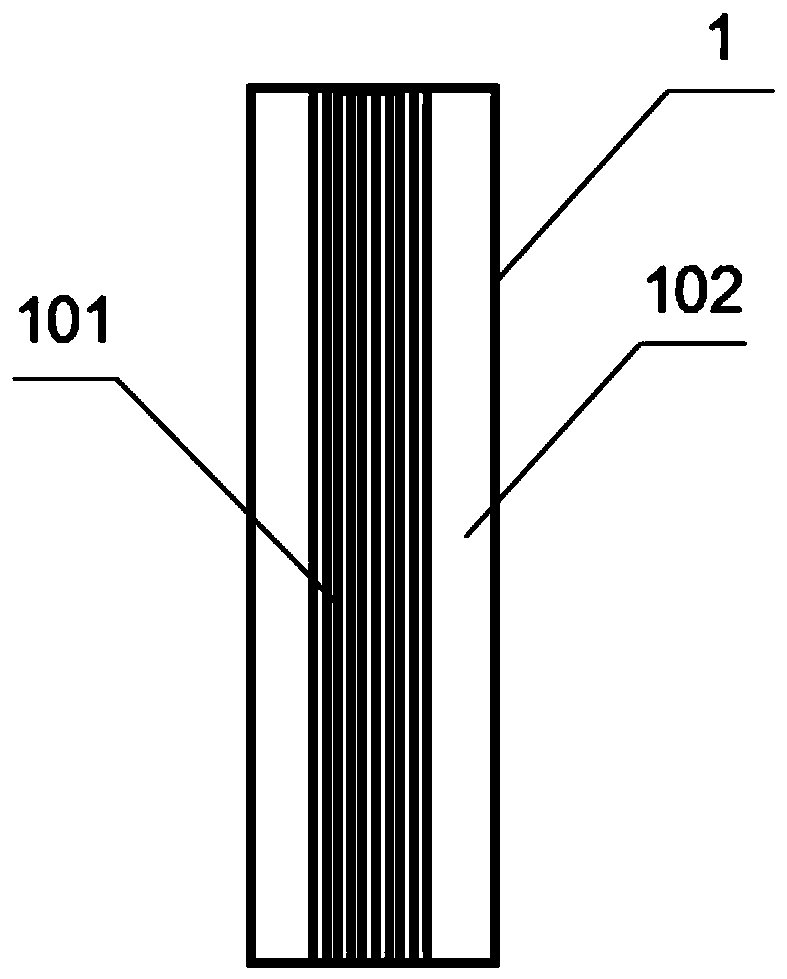

[0026] 1) Refer to figure 1 and figure 2 Preparation of fiber rod 1: select material T300 (Toray Japan) carbon fiber bundle 101 and thermoplastic resin nylon PA6 102 as objects, use existing continuous fiber composite material melt extrusion molding or continuous fiber screw extrusion process to impregnate nylon PA6 102 into In the carbon fiber bundle 101, under the action of a certain traction force, after passing through the continuous fiber extrusion nozzle, it is rapidly cooled and solidified to form a fiber rod 1 impregnated with PA6 102 and wrapped around the carbon fiber bundle 101. Adjust the extrusion amount or extrusion speed of PA6 to achieve the required Adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com