Winding type iron core magnetically controlled saturated reactor

A reactor, winding technology, applied in the direction of variable inductors, inductors, variable transformers, etc., can solve the problems of poor overload capacity of solenoid valve controllable reactors, and achieve simple structure and easy processing. , control simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

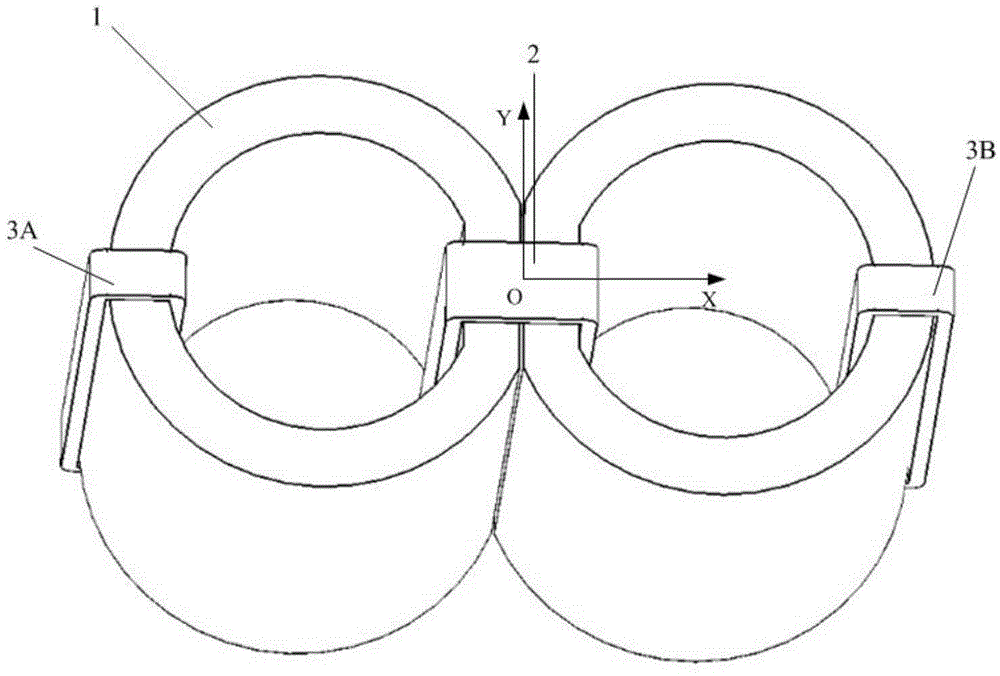

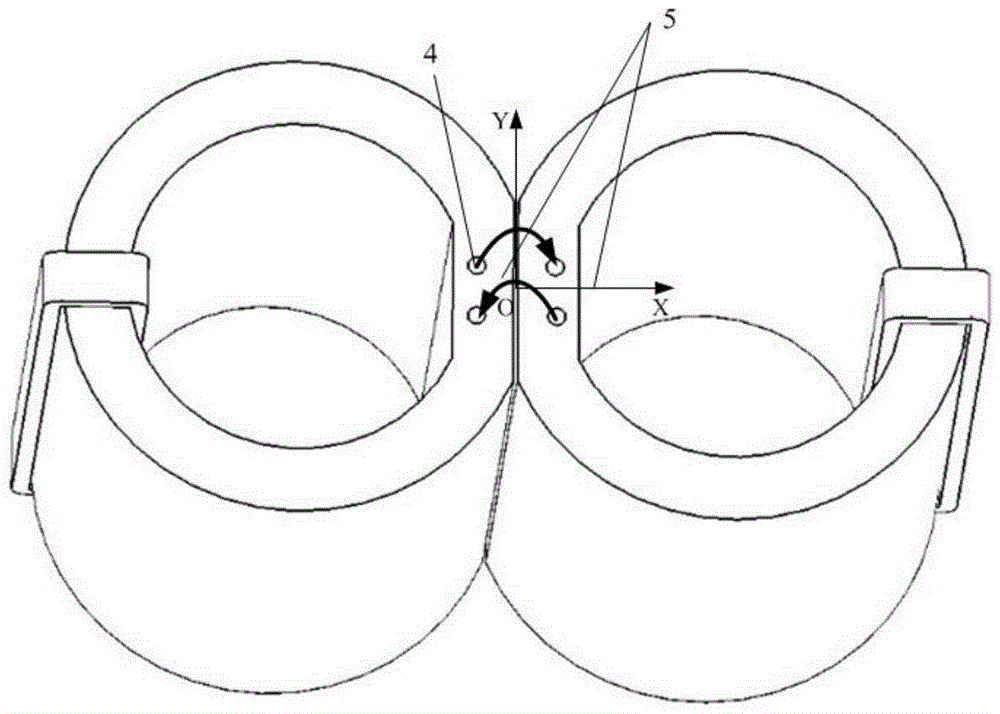

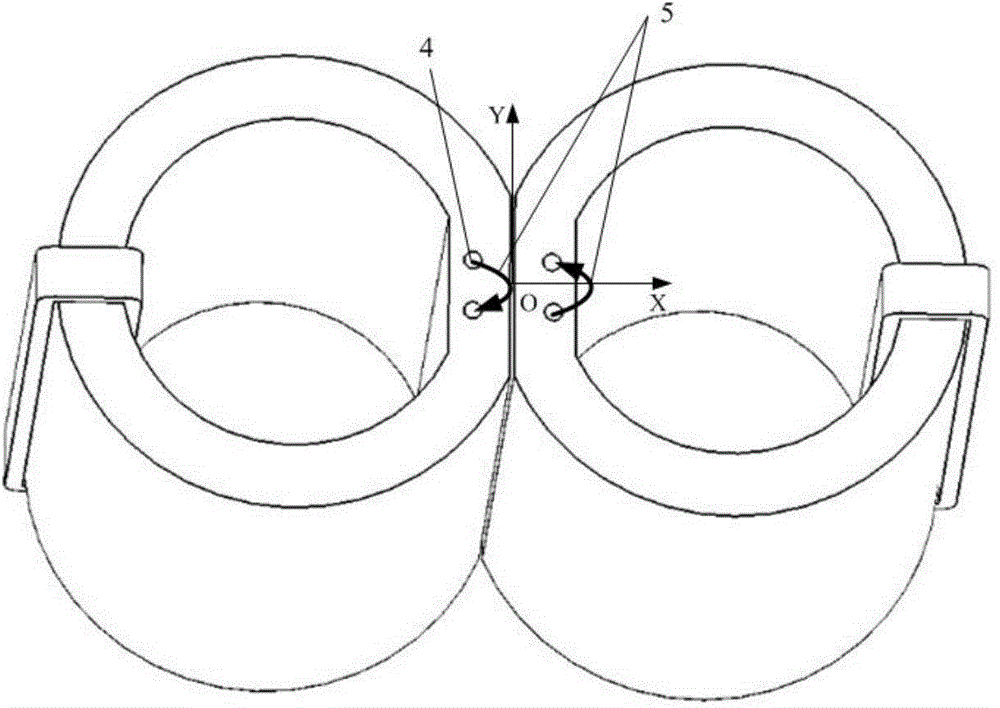

[0020] Such as figure 1 A coiled iron core magnetically saturated controllable reactor is shown, including two reactor cores 1 with the same size and structure, an AC working winding 2, two sets of DC excitation windings 3, and two sets of local saturation windings 5; the two One side of the reactor core 1 is placed close to each other, and the contact surface of the two reactor cores 1 is a rectangular plane; a rectangular coordinate system is established, and the line connecting the center points of the two reactor cores 1 is the X axis, and the two centers The middle position of the point is the origin to establish the Y axis; the two reactor cores 1 are symmetrical to the Y axis; the upper surfaces of the two reactor cores 1 at the position of the contact surface are provided with the same number of local saturated Winding holes 4, and the distance between adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com