Centrifugal micro-fluidic device for rapidly preparing liquid drops and liquid drop preparation method

A microfluidic device and droplet technology, applied in the field of biomedical materials, can solve the problems of low yield, limited droplet yield, high cost and technical requirements, and meet production needs, good monodispersity, and sphericity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

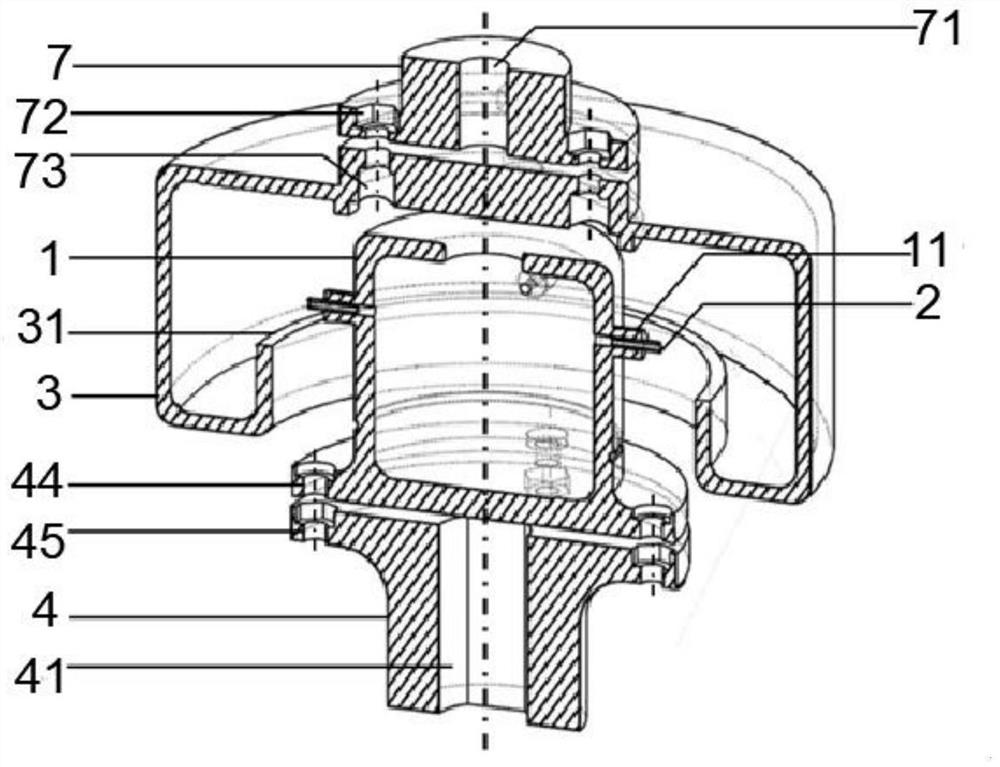

[0031] Such as figure 1 As shown, in this embodiment, a centrifugal microfluidic device for rapidly preparing droplets includes an inner reservoir 1 with a hollow inner cavity and an outer reservoir 3, the bottom of the outer reservoir 3 The end is provided with an annular boss 31 extending toward its inner cavity, and a collecting tank is provided between the annular boss 31 and the inner wall of the outer liquid reservoir 3, and the outer phase liquid is injected into the collecting tank; the inner liquid reservoir 1 is on the same centerline It is arranged in the inner cavity of the outer liquid reservoir 3 and there is a certain gap between the inner liquid reservoir 1 and the outer liquid reservoir 3; the top of the inner liquid reservoir 1 is provided with an infusion hole 12, through which the inner phase The liquid is injected into the inner liquid reservoir 1; the outer circumference of the inner liquid reservoir 1 is provided with several round tube bosses 11, and a ...

no. 2 example

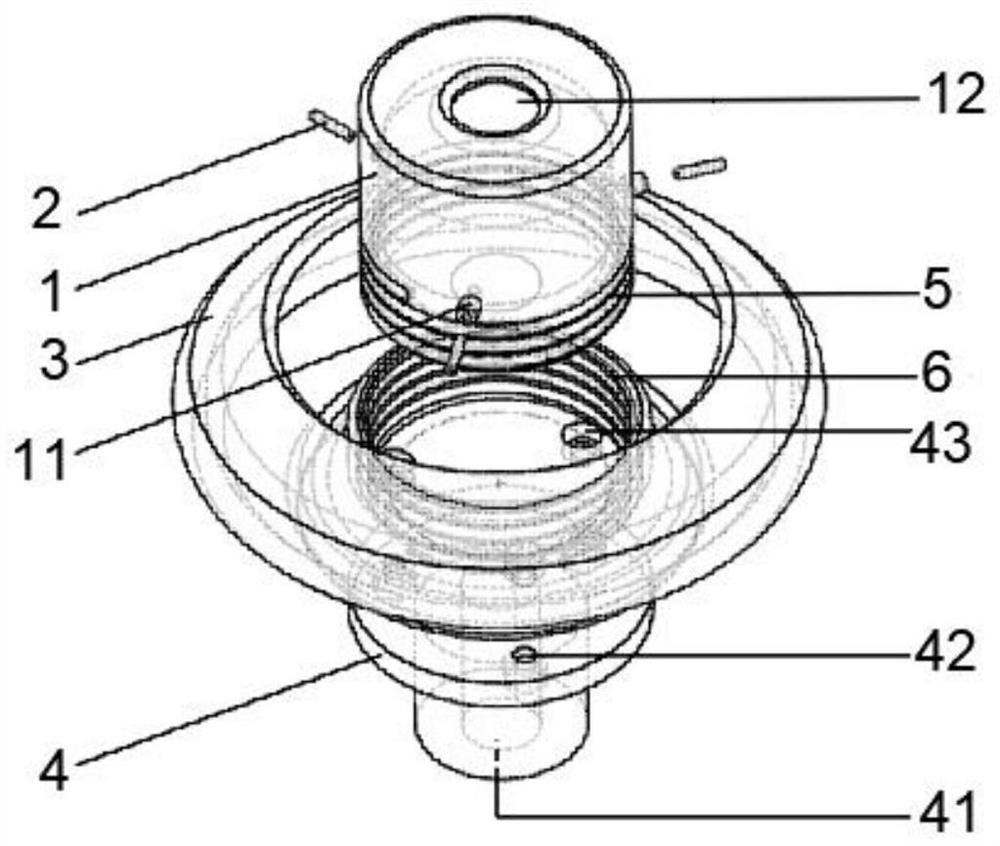

[0039] Such as figure 2 As shown, the difference between this embodiment and the first embodiment is that an external thread section 5 is provided on the outer wall of the inner liquid reservoir 1, and an internal thread section 6 is provided on the inner ring wall of the annular boss 31. The external thread section 5 is screwed into the internal thread section 6 to connect the internal liquid reservoir 1 and the external liquid reservoir 3 .

[0040] Wherein, the centrifugal transmission mechanism in this embodiment is composed of an external thread section 5, an internal thread section 6 and a combined transmission mechanism.

[0041] Wherein, the driving motor shaft sleeve 4 is equiangularly divided with several side connection holes 42, and each side connection hole 42 is equipped with a fixing piece for fixing the motor shaft; the outer liquid reservoir 3 is also provided with several vertical To the connecting holes 43, each vertical connecting hole 43 is provided with...

no. 3 example

[0048] The third embodiment: this embodiment provides a method for liquid droplet preparation based on the above device, including the following steps:

[0049] Step a: prepare the internal phase liquid and the external phase liquid, and select a capillary 2 with a suitable diameter and an internal liquid reservoir 1 with a suitable diameter according to the size requirements of the droplet preparation to complete the installation of the microfluidic device;

[0050] Step b: inject the inner phase liquid into the inner liquid reservoir 1, and inject the outer phase liquid into the collection tank between the inner walls of the outer liquid reservoir 3;

[0051] Step c: Set the rotational speed of the speed-regulating motor, use the speed-regulating motor to drive the inner liquid reservoir 1 to rotate at a high speed and further promote the centrifugal movement of the inner phase liquid in the inner liquid reservoir 1, so as to squeeze the inner phase liquid from one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com