A kind of preparation method of laminated board

A technology of lamination and thermoforming, applied in the direction of lamination, lamination equipment, chemical instruments and methods, etc., can solve the problems of high density of glue formula filler, high thermal conductivity, increase the thickness of multi-layer boards, etc., to achieve flexibility Distribution state, good economic benefits, and the effect of improving the infiltration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

[0043] Prepare laminates such as Figure 1~2 As shown, it includes the following steps:

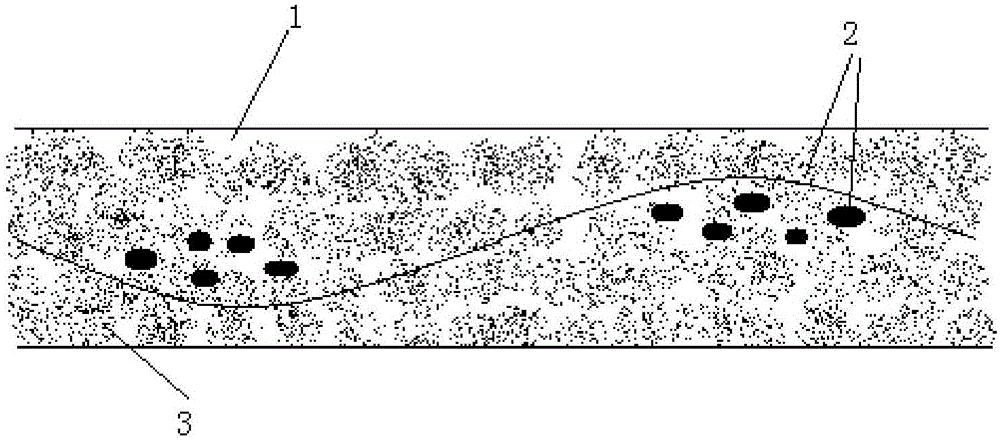

[0044] First: prepare a prepreg, prepare a thermosetting resin glue solution according to the data in Table 1, then impregnate the glass fiber cloth in the above glue solution, and heat and dry the impregnated glass fiber cloth to obtain a prepreg, see figure 1 As shown, there are resin 1, glass fiber cloth 2, and filler 3 in the prepreg; the heating and drying process conditions are baking at 100-200°C for 1-10 minutes;

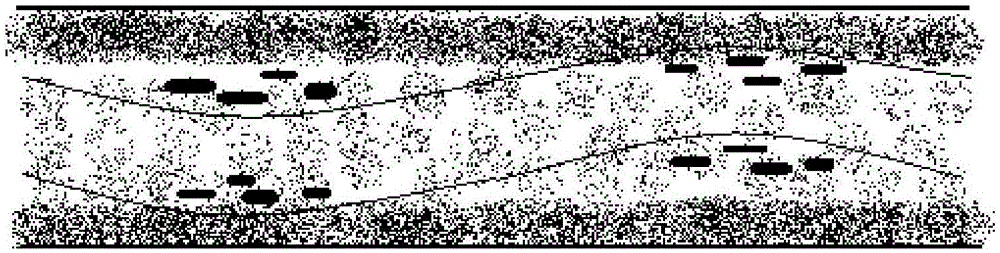

[0045] Second: After superimposing 4 pieces of the above prepregs, cover them with 70 micron copper foil on both sides for lamination, and hot press forming to obtain the laminate, wherein the lamination process conditions are 0.2-2MPa pressure and 180- Press at 250°C for 2 to 4 hours. figure 2 It is a schematic diagram of the laminate effect in the embodiment of the present invention.

[0046] During the lamination process, electrodes are arranged on the outer surf...

Embodiment 3

[0048] Prepare laminated board, it comprises the steps:

[0049]First: prepare a prepreg, prepare a thermosetting resin glue solution according to the data in Table 1, then impregnate the glass fiber cloth in the above glue solution, and heat and dry the impregnated glass fiber cloth to obtain a prepreg, wherein heating and drying The process condition is to bake at a temperature of 100-200°C for 1-10 minutes;

[0050] Second: take 4 above-mentioned prepregs and superimpose them, cover them with 70 micron copper foil on one side, attach an aluminum block on the other side for lamination, and heat press forming to obtain the laminated board, wherein the lamination process conditions are Pressing at a pressure of 0.2-2MPa and a temperature of 180-250°C for 2-4 hours.

[0051] During the lamination process, electrodes are arranged on the outer surface of the copper foil to form an electric field.

Embodiment 4

[0053] Prepare the laminate, and prepare the thermosetting resin glue solution according to the data in Table 1;

[0054] Coating glue on the rough surface of 70 micron copper foil, then attaching another 70 micron copper foil on the rough surface, and forming by hot pressing, the laminate can be obtained, wherein the lamination process conditions are 0.2-2MPa pressure and 180-250 Press at ℃ for 2-4 hours.

[0055] During the lamination process, electrodes are arranged on the outer surface of the copper foil to form an electric field.

[0056] The composition of table 1 embodiment and comparative example

[0057]

[0058]

[0059] Note: The above data are based on solid weight.

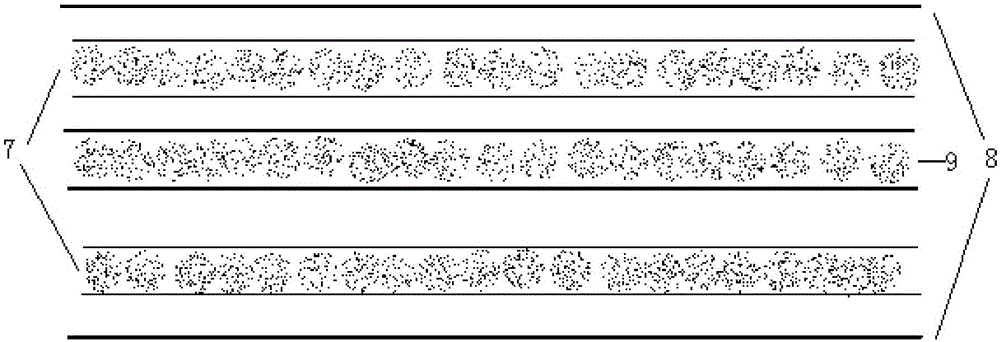

[0060] Use the laminated board that makes in embodiment 1~4 to manufacture core plate, according to image 3 Laminate according to the stacking method shown, and laminate according to the curing conditions required by the resin type of the four-layer printed circuit board, and perform thermal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com