Production method of replacement embedded copper block of circuit board

A production method and circuit board technology, applied in the directions of printed circuit manufacturing, printed circuits, printed circuits, etc., can solve the problems of high scrap rate, layered explosion, low production efficiency, etc., to reduce production costs, excellent heat dissipation performance, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

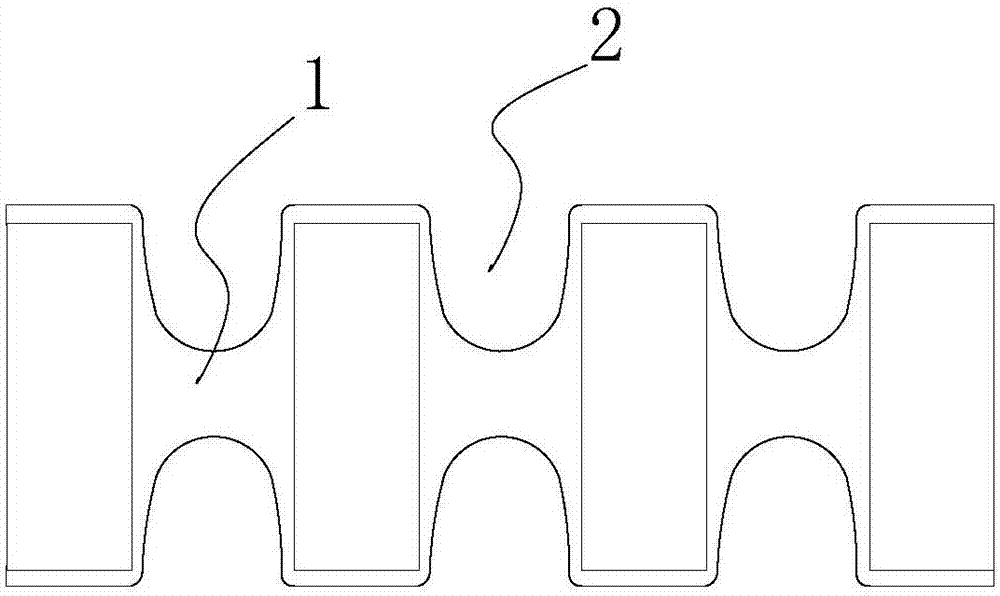

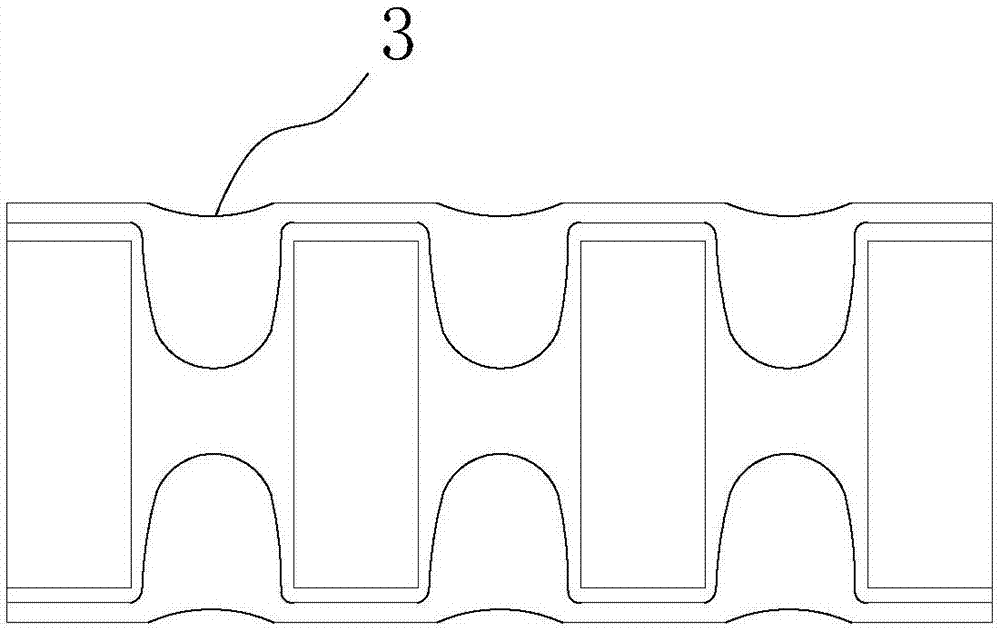

[0028] like figure 1 and figure 2 As shown, a manufacturing method for replacing buried copper blocks in circuit boards shown in this embodiment includes the following processing steps in sequence: material cutting→making inner layer circuits→pressing→drilling target holes→drilling→plasma treatment→sinking Copper 1→full board electroplating 1→pulse electroplating bridging→full board hole filling electroplating→outer layer drilling→immersion copper 2→full board electroplating 2→making outer layer lines and copper pillars→solder mask→silk printing characters→surface treatment→forming ,Specific steps are as follows:

[0029] a. Cutting: cut out the core board according to the panel size 520mm×620mm, and the thickness of the core board is 1.2mm H / H;

[0030] b. Making the inner layer circuit (negative film process): the inner layer pattern is transferred, and the photosensitive film is coated with a vertical coating machine. The film thickness of the photosensitive film is cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com