A kind of explosion-proof plate manufacturing method of thick plate, thick copper plate and thick plate, thick copper plate

A production method and thick copper plate technology, applied in multilayer circuit manufacturing, printed circuit manufacturing, printed circuit, etc., to achieve the effect of improving the pass rate, reducing production costs, and reducing the problem of delamination explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

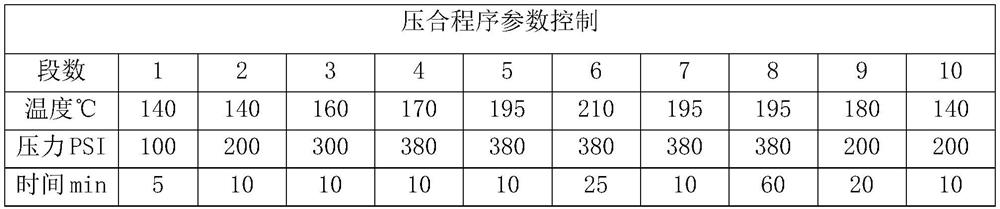

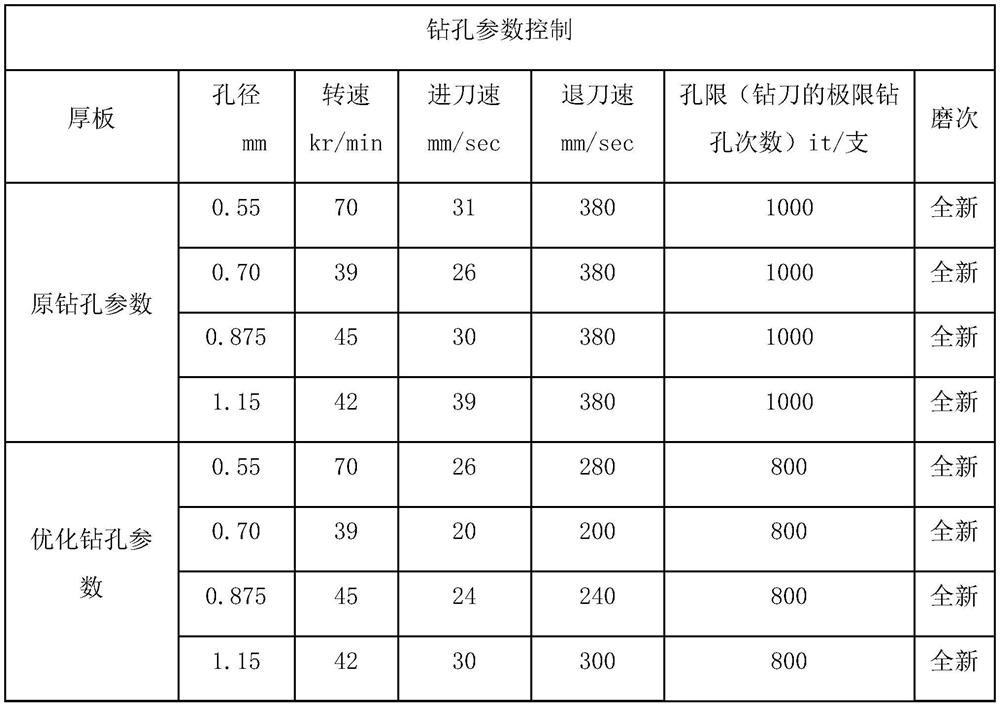

[0046] The method of fabricating a plate thickness ≥ 5 mm shown in the present embodiment, including the following processing step:

[0047] (1), the opening: The core plate and the PP sheet and the outer copper foil are opened by the puzzle size of 320 mm × 420mm. The core panel thickness is 0.15 mm (the thickness of the thickness is not copper), the outer layer of the core plate The copper surface has a thickness of 1OZ; the core panel is specifically used in the Sheet IT180A sheet.

[0048] (2), bake: Place the core plate at 180 ° C for 4h, by baking to completely melt the resin in the core plate, the core plate can be better cured, and the stress in the plate is released to ensure the core plate size. Stability.

[0049] (3), fabricate the inner line (negative sheet process): Apply a photosensitive film with a vertical coating machine on the core plate, the film thickness of the photosensitive film controls 8 μm, using a fully automatic exposure machine, exposed 5-6 exposure (...

Embodiment 2

[0072] In this example, the inner layer copper thickness ≥ 4Oz thick copper plate is made, including the following treatment step:

[0073] (1) The thickness of the copper surface is 4OZ; the core panel is specifically used in Liamao IT180A sheet.

[0074] (2), bake: Place the core plate at 180 ° C for 4h, by baking to completely melt the resin in the core plate, the core plate can be better cured, and the stress in the plate is released to ensure the core plate size. Stability.

[0075] (3), fabricate the inner line (negative sheet process): Apply a photosensitive film with a vertical coating machine on the core plate, the film thickness of the photosensitive film controls 8 μm, using a fully automatic exposure machine, exposed 5-6 exposure (21 The lattice exposure is completed in the inner layer line exposure; inner layer etching, in the core plate after exposure development, the inner layer line is measured to 3 mil; the inner layer AOI, then check the inside of the inner layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com