Controlled release microcapsule for adhesive and preparation method thereof

A technology for adhesives and microcapsules, which is applied in the field of controllable release microcapsules for adhesives and its preparation, can solve the problems of poor monodispersity, low loading efficiency, and low stability of microcapsules, and achieve good stability, The effect of high load rate and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

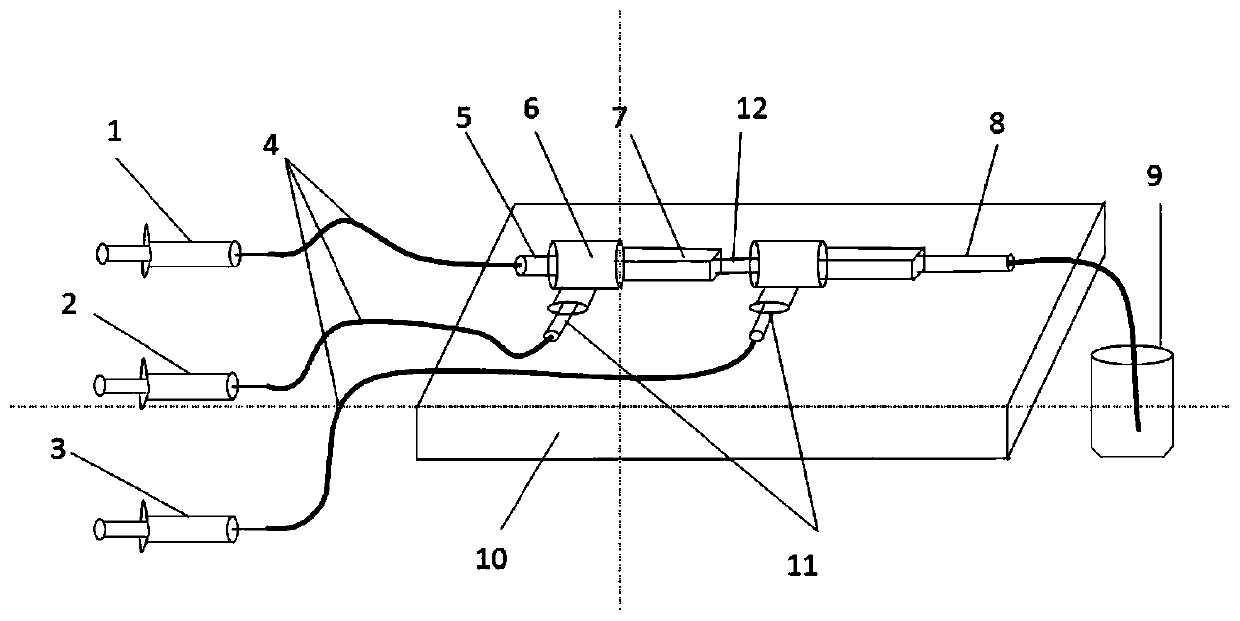

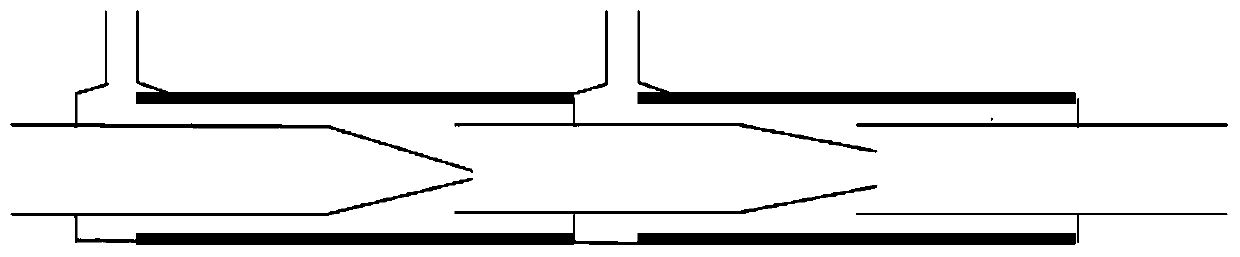

[0077] Preparation of microfluidic devices: This example uses a capillary microfluidic device with a coaxial two-stage flow structure. The overall structure of the device is as follows: figure 1 As shown, the internal structure is as figure 2 shown. Specifically, the device includes three circular glass capillaries, which are injection tube I, injection tube II, receiving tube and two square glass capillaries respectively. Injection tube I, injection tube II and receiving tube are all inserted into the square glass capillary, and the injection tube One end of Ⅰ and injection tube II is drawn into a tapered shape with a drawing machine, and one end is an untreated open end. Insert the tapered end of injection tube Ⅰ into the open end of injection tube Ⅱ, leaving a part of the gap at the insertion port. Located in the middle of the first square glass capillary; insert the tapered end of the injection tube II into the receiving tube, leaving a gap at the insertion port, and the...

Embodiment 2

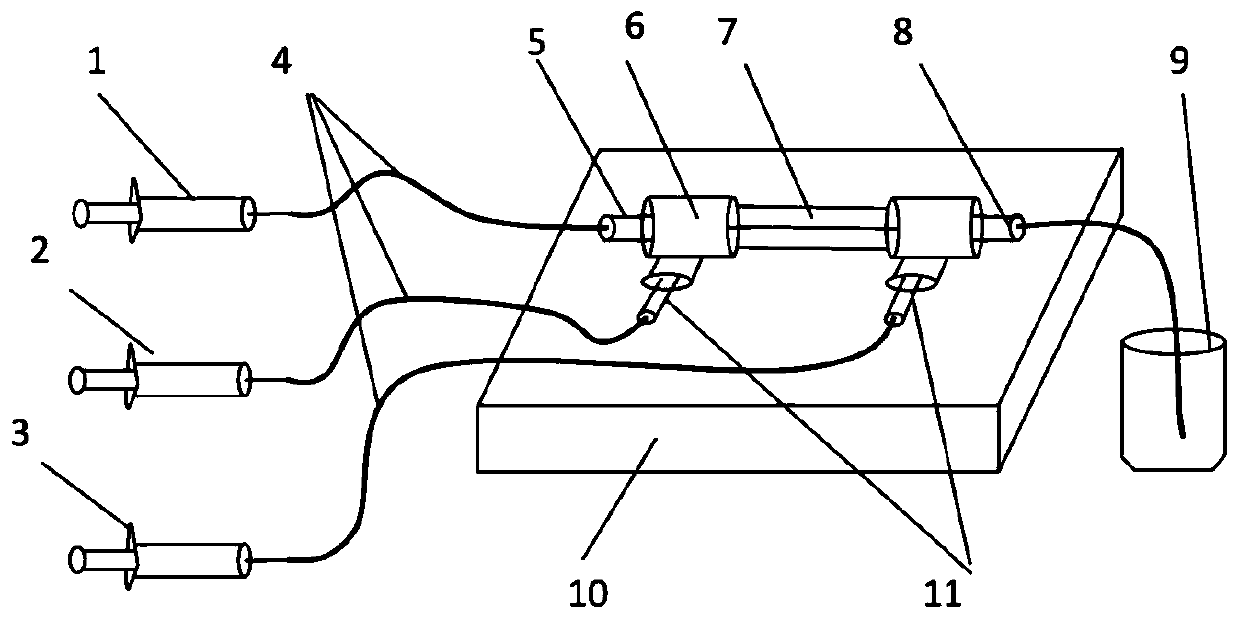

[0092] Preparation of microfluidic devices: This example uses a capillary microfluidic device with a coaxial three-phase flow focusing structure. The overall structure of the device is as follows image 3 As shown, the internal structure is as Figure 4shown. Specifically, the device includes two circular glass capillaries and a square glass capillary. One end of the two circular glass capillaries is drawn into a tapered shape with a needle puller. The diameter of one tapered end is 30 μm, and the diameter of the other tapered end is Insert the tapered ends of the drawn two capillaries into the square glass capillary in opposite directions, the distance between the tapered ends is 100 μm, and connect and encapsulate the three glass tubes with a tee and adhesive.

[0093] Internal phase, middle phase and external phase material and concentration are identical with embodiment 1.

[0094] Preparation of water-in-oil-in-water emulsion: Use three syringes to extract the inner pha...

Embodiment 3

[0098] The preparation of the microfluidic device is the same as in Example 2.

[0099] Prepare internal phase, middle phase and external phase solution: the configuration of internal phase and external phase solution is the same as in Example 1;

[0100] 0.1 wt% of the initiator 2,2-dimethoxy-2-phenylacetophenone was dissolved in tripropylene glycol diacrylate monomer (99.9 wt%), which was used as the middle phase.

[0101] The preparation method of the water-in-oil-in-water emulsion is the same as in Example 2, but the inner phase, the middle phase and the outer phase form double emulsified droplets with a flow rate of 2 μL / min, 6 μL / min, and 30 μL / min respectively ( Figure 12 ).

[0102] The collection and solidification of the emulsified droplets are the same as in Example 1.

[0103] Microcapsule size: The particle size of the formed microcapsule is about 180 μm, and the shell thickness is about 25 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com