Auxiliary feeding system for gantry cutting machine

A technology of auxiliary feeding and unloading machine, applied in thin material processing, cleaning method using gas flow, metal processing, etc., can solve problems such as affecting equipment calibration, affecting product performance, large impact force, etc. Material, practical effect, easy to remove effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

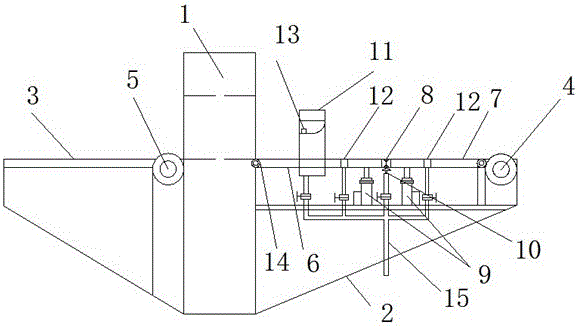

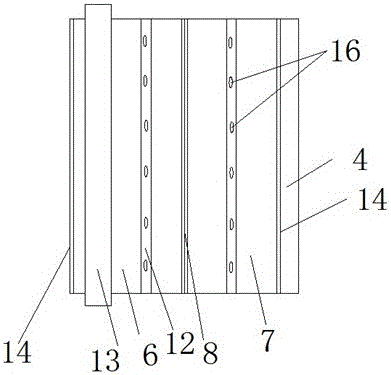

[0015] Embodiment 1: as figure 1 and 2 An auxiliary feeding system of a gantry blanking machine shown, the auxiliary feeding system is installed on both sides of the gantry blanking machine frame 1, and the auxiliary feeding system includes a feeding platform 2 and a discharge Platform 3, the inner side of feeding platform 2 is fixedly installed on the frame 1, the outer side of feeding platform 2 is provided with feeding roller 4, and between the discharging platform 3 and frame 1 is provided with discharging roller 5, A feeding platform is arranged between the material roller 4 and the frame 1, and the described feeding platform is assembled by the upper material plate 7 and the lower material plate 6, and the two ends of the feeding platform are fixedly installed by the rotating shaft 14 On the feeding table 2, the middle part of the feeding platform is provided with a joint gap 8 between the upper material plate 7 and the lower material plate 6, and the two sides of the j...

Embodiment 2

[0016] Embodiment 2: as figure 1 and 2 As shown, the height-limiting baffle 11 is fixedly installed on the feed table 2 through the adjustment brackets on both sides, and the adjustment bracket is a height-adjustable adjustment bracket; the height-limiting baffle 11 is adjusted by the height-adjustable bracket. The height is limited to meet the production needs of products with different heights. The height limit baffle 11 is mainly used to limit the feeding position of the product, so as to facilitate the precise cutting of the gantry blanking machine.

Embodiment 3

[0017] Embodiment 3: as figure 1 and 2 As shown, on the upper material plate 7 and the lower material plate 6, an upward blast section 12 is provided, and a plurality of vertically upward air outlets 16 are evenly distributed on the upward air blast section 12; on the upper material plate 7 and When the blanking plate 6 is lifted, there is a certain gap between the bottom of the product and the feeding platform, and an upward airflow is blown out through the upward blowing section 12 to facilitate blowing away the dust adsorbed on the bottom of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com