Patents

Literature

65results about How to "Flexible construction methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

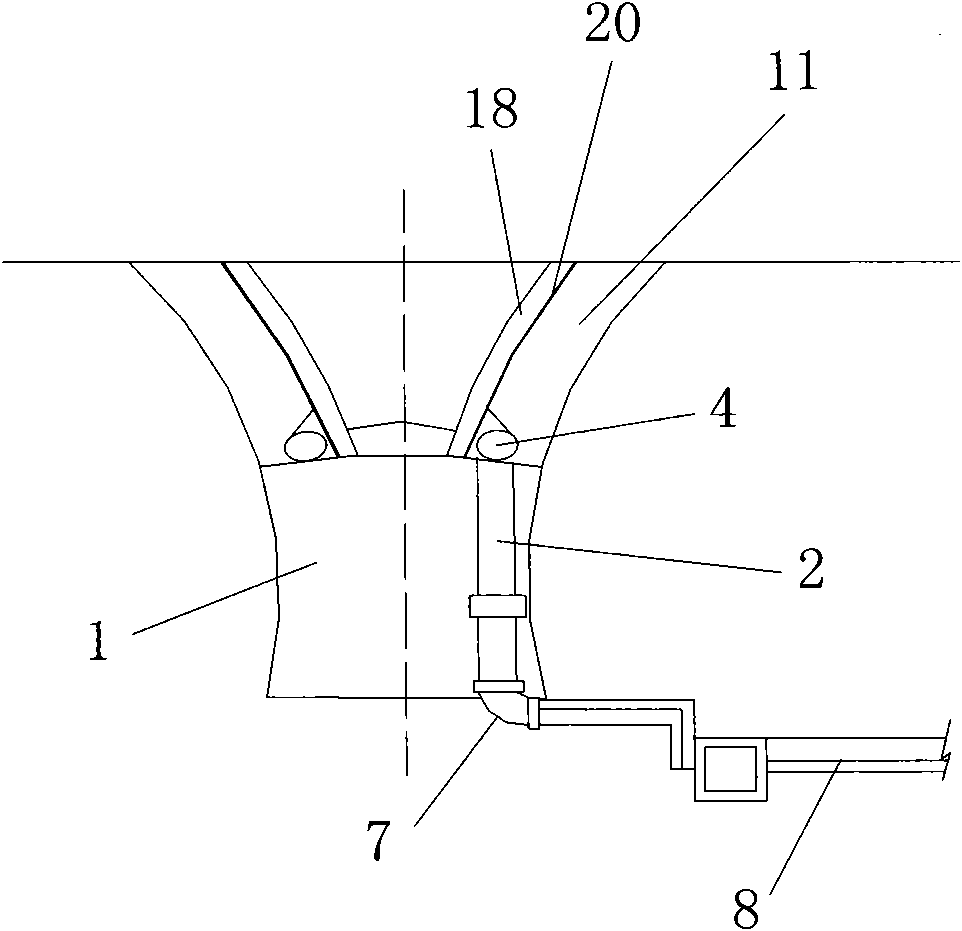

Carst region double-arch road tunnel construction method

ActiveCN101864960AReasonable designSimplify construction stepsUnderground chambersTunnel liningTunnel constructionChannel inlet

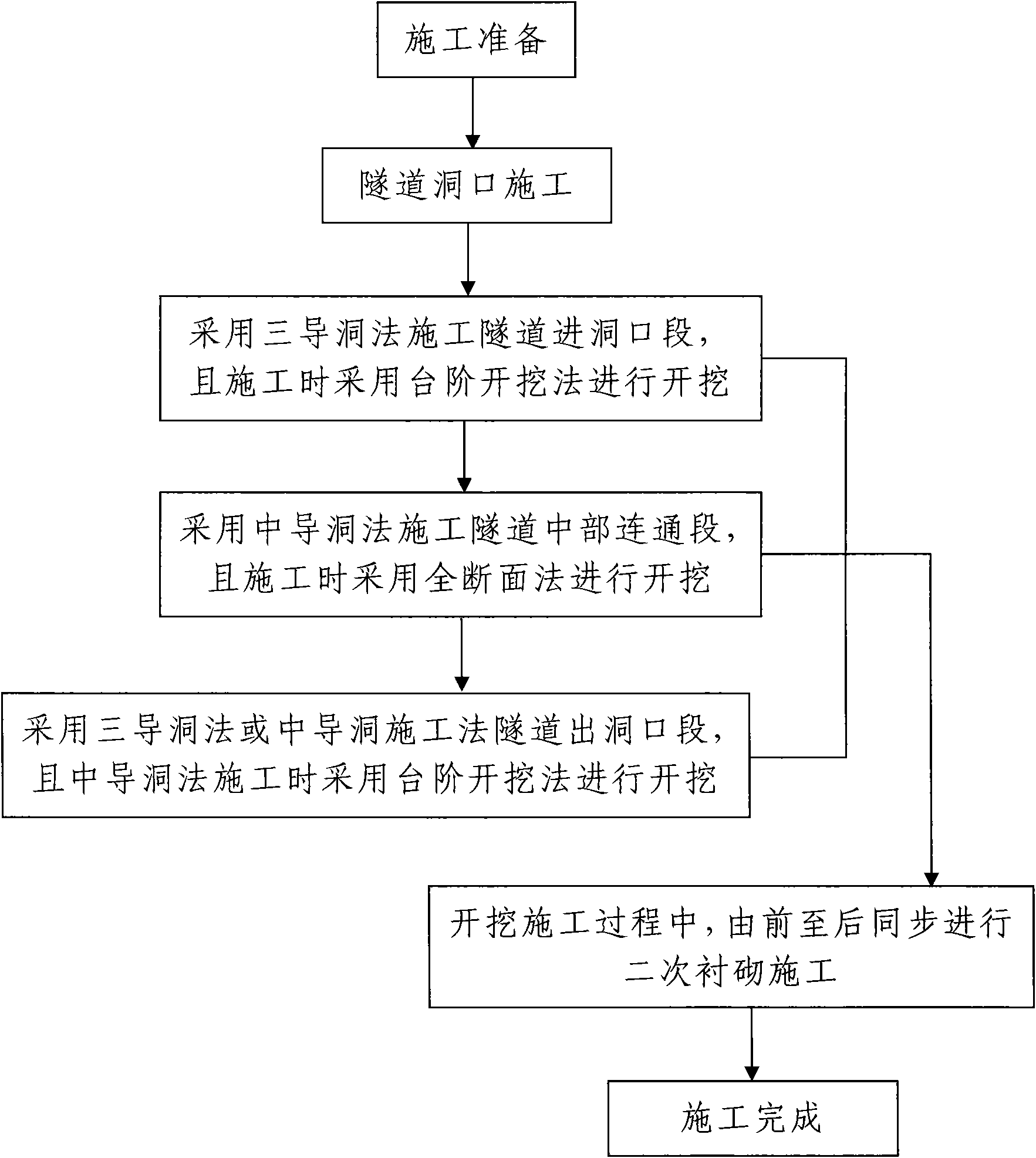

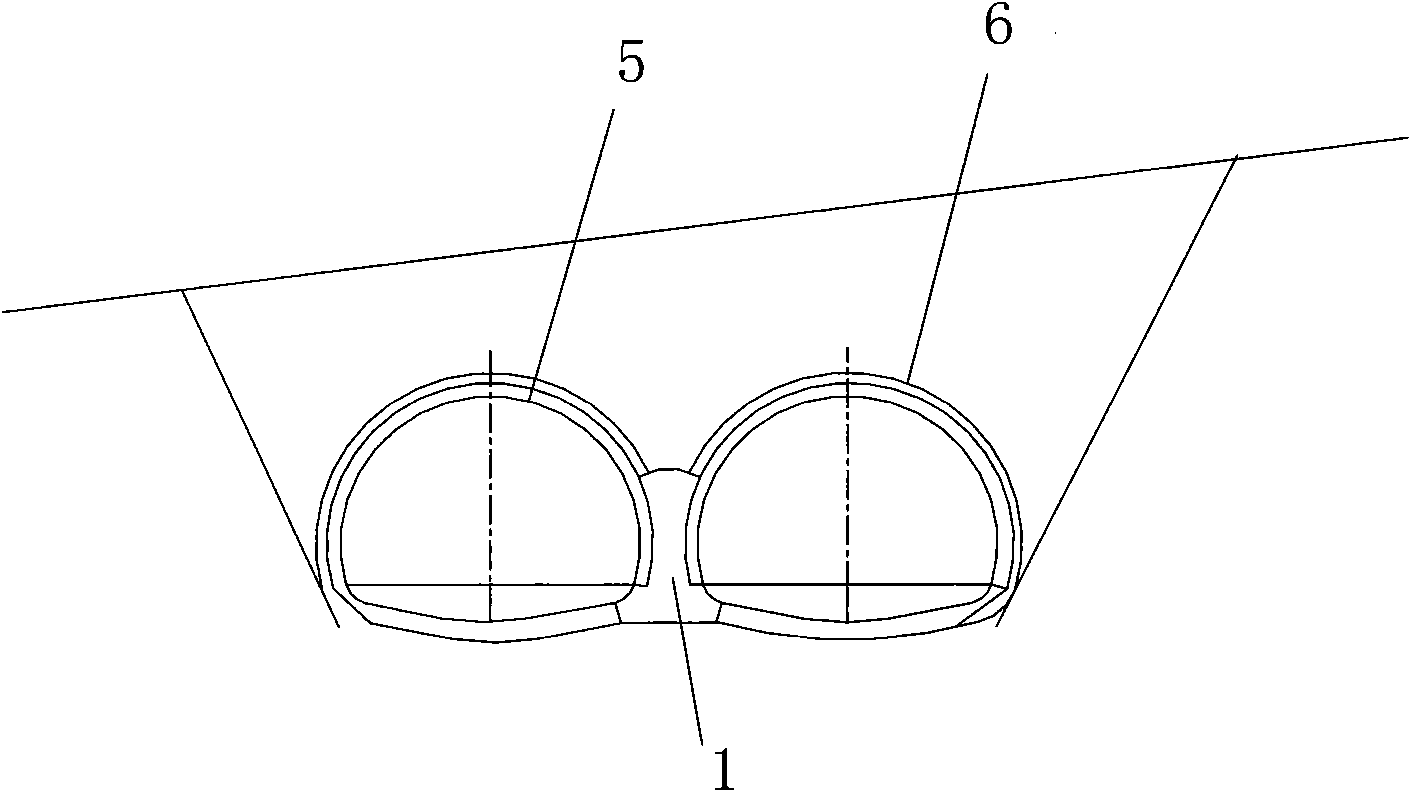

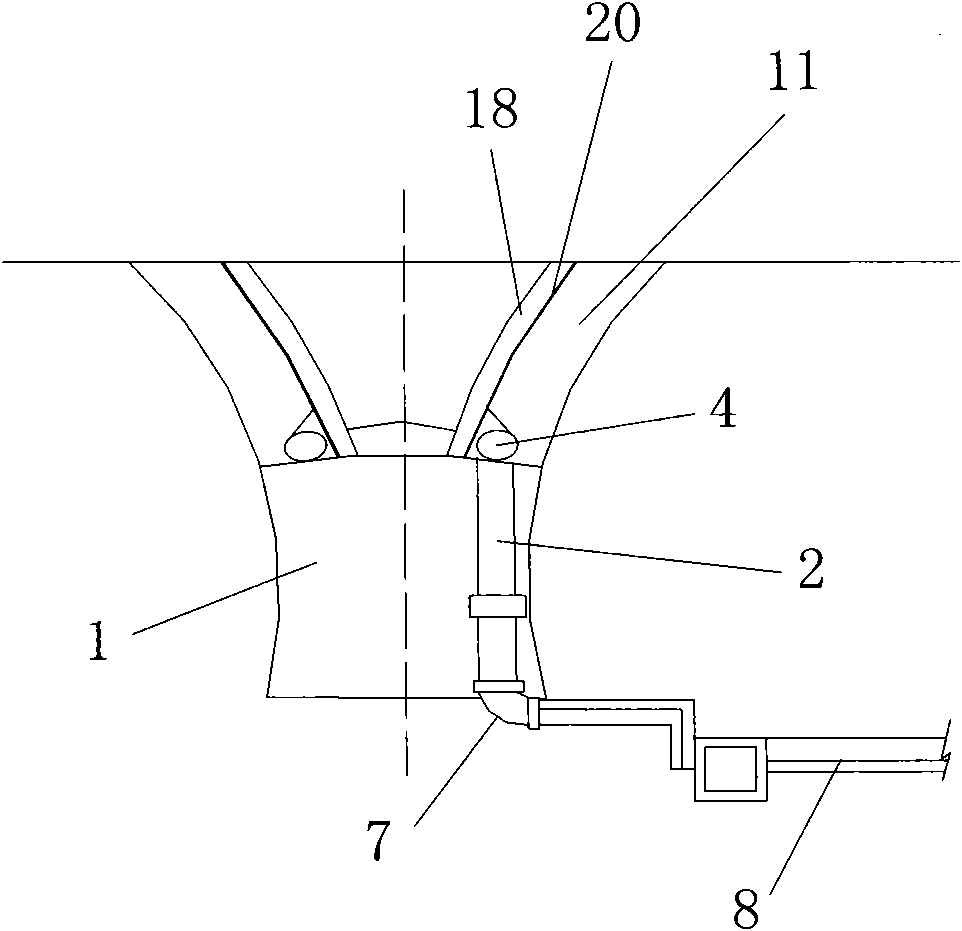

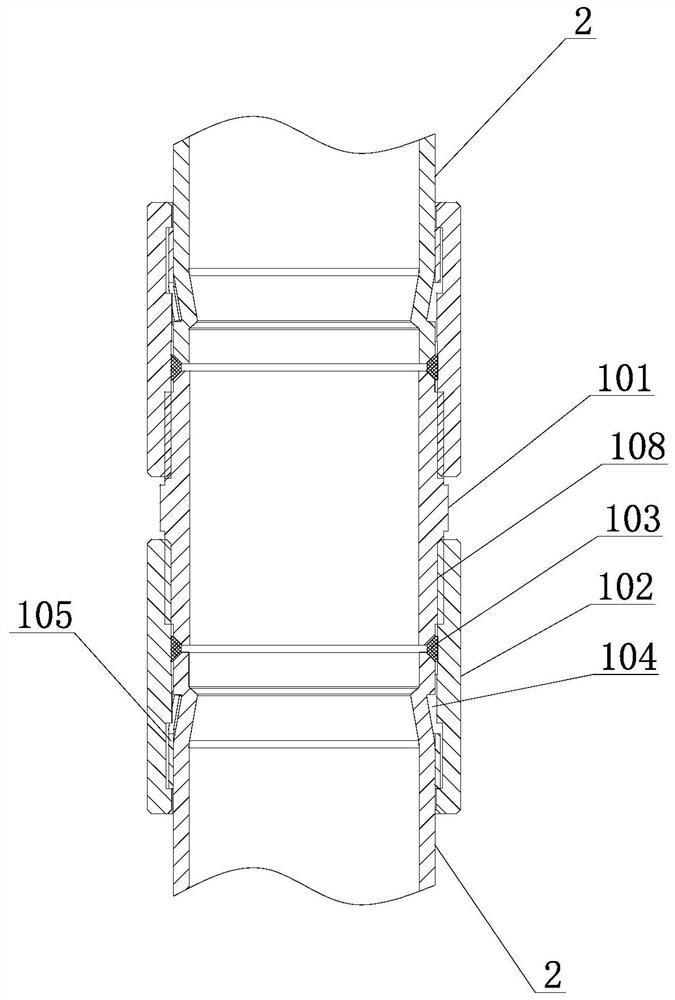

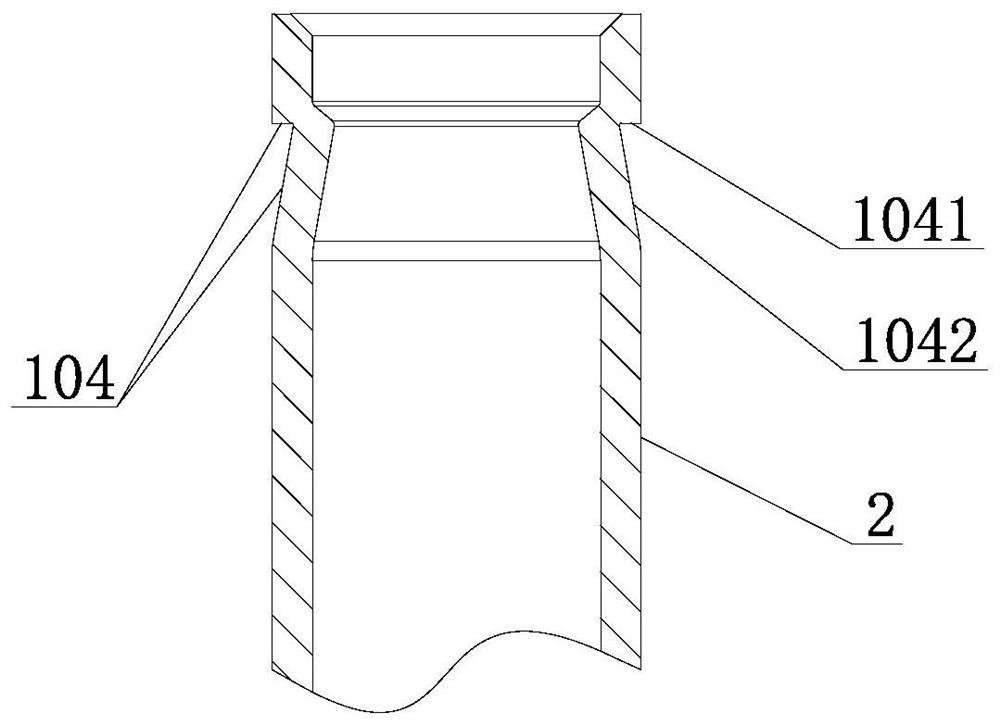

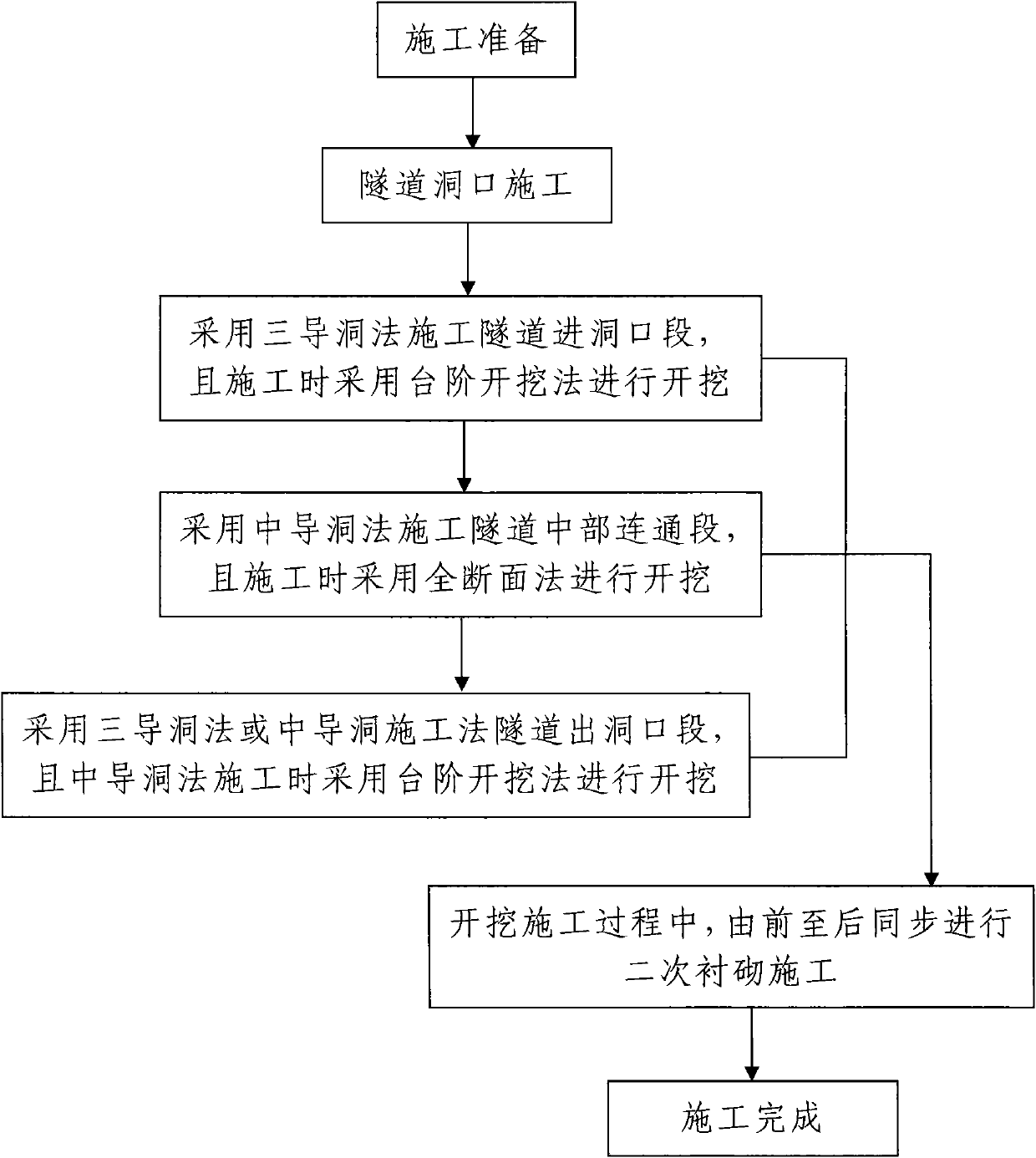

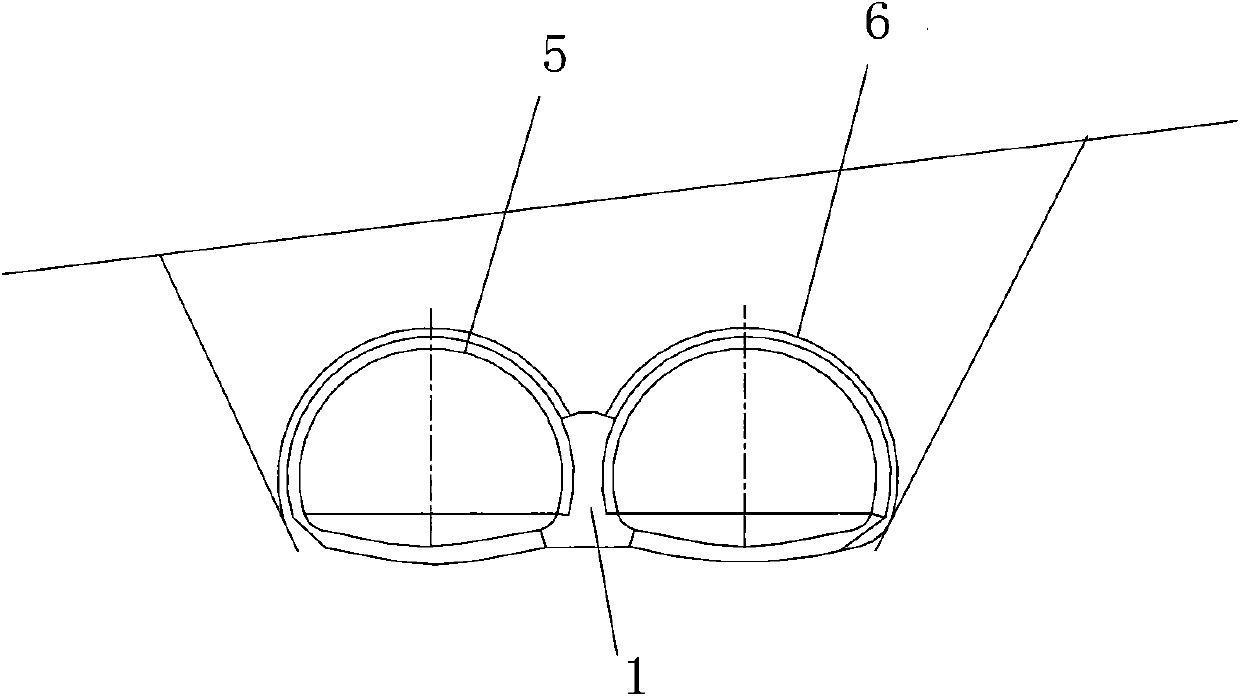

The invention discloses a carst region double-arch road tunnel construction method, which comprises the following steps; 1. carrying out construction preparation; 2. carrying out construction at channel openings; 3. adopting a three-pilot-tunnel method for constructing the channel inlet opening section, and adopting a step digging method for digging during the three-pilot-tunnel method construction; 4. adopting a middle-pilot-tunnel method for constructing the middle communication section of the channel, and adopting a full cross section method for digging during the middle-pilot-tunnel method construction; 5. adopting the three-pilot-tunnel method or the middle-pilot-tunnel method for constructing the channel outlet opening section, adopting the step digging method for digging when the middle-pilot-tunnel method is adopted for digging construction of the channel outlet opening section, and synchronously carrying out secondary lining construction from the front part to the back part in the digging construction process of the channel inlet opening section, the middle communication section of the channel and the channel outlet opening section. The invention has the advantages of reasonable design, simple and convenient construction, safe and reliable construction process, flexible construction mode, short construction period and greatly simplified construction steps, and effectively overcomes various defects during the traditional carst region double-arch road tunnel construction.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

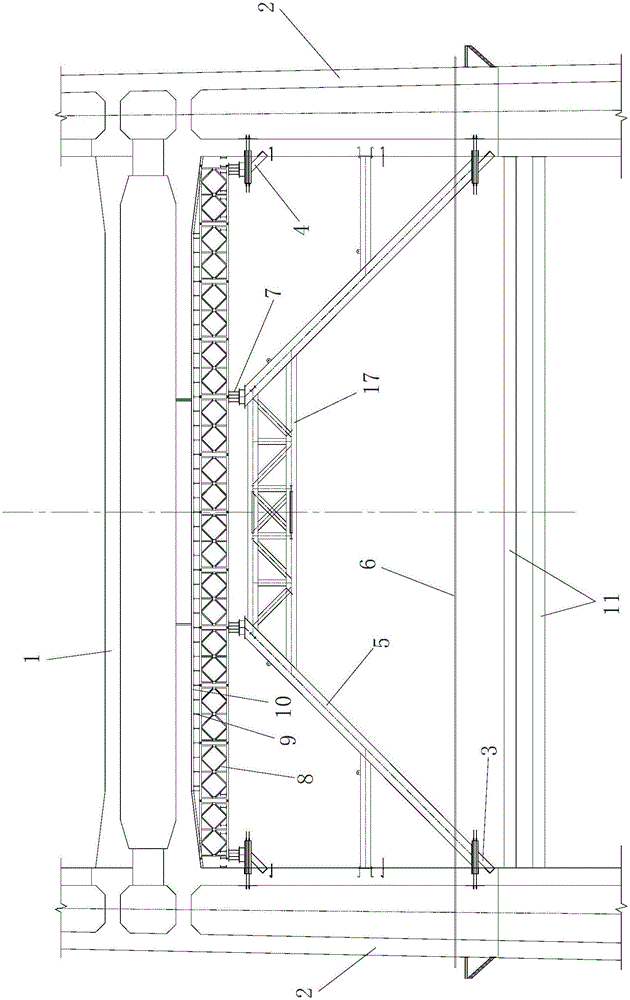

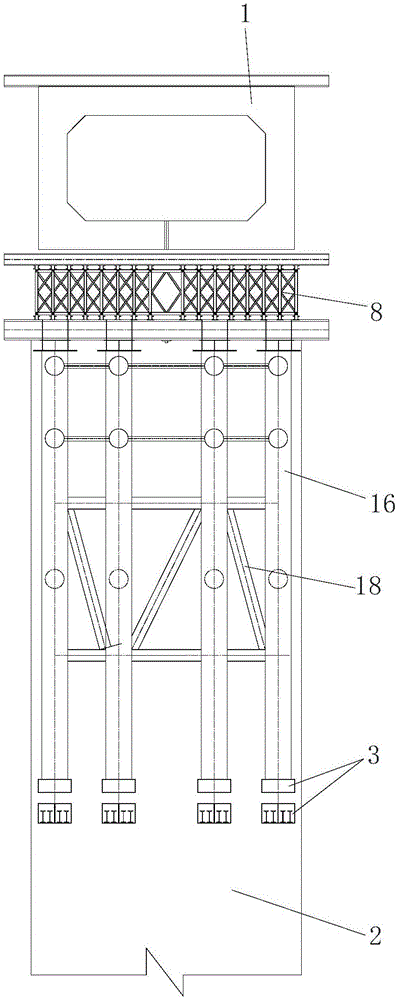

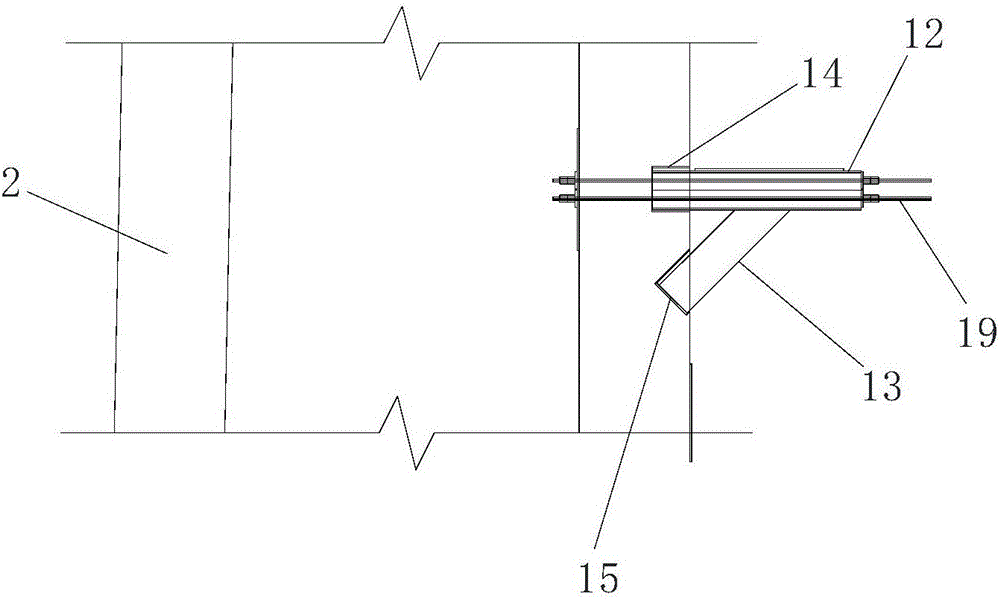

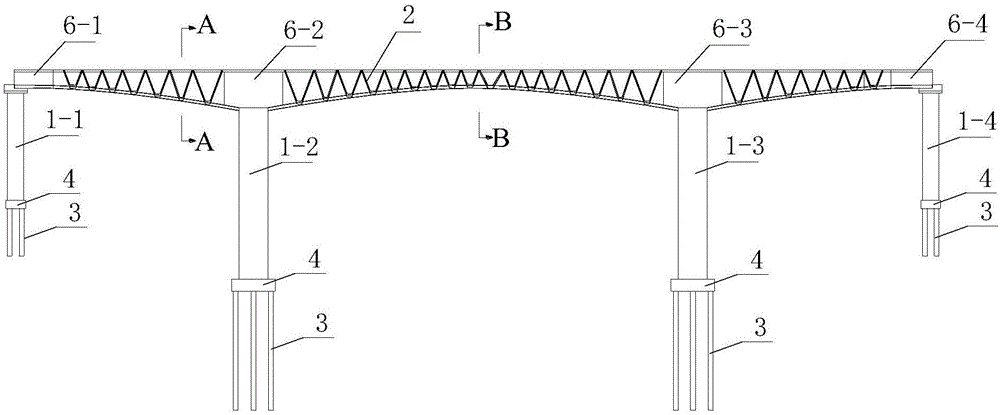

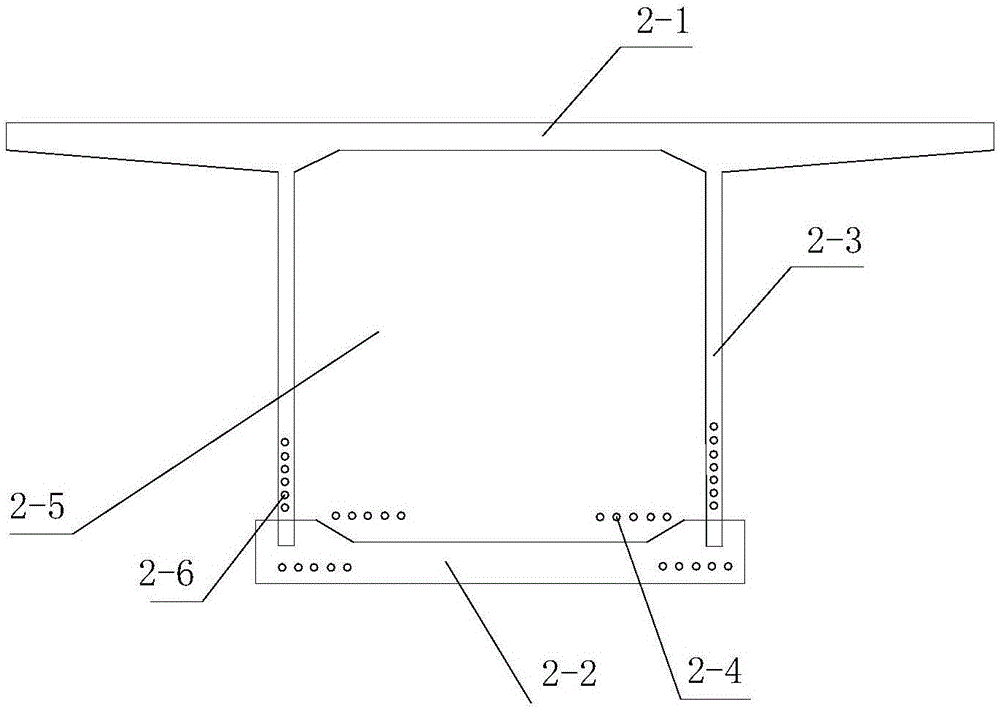

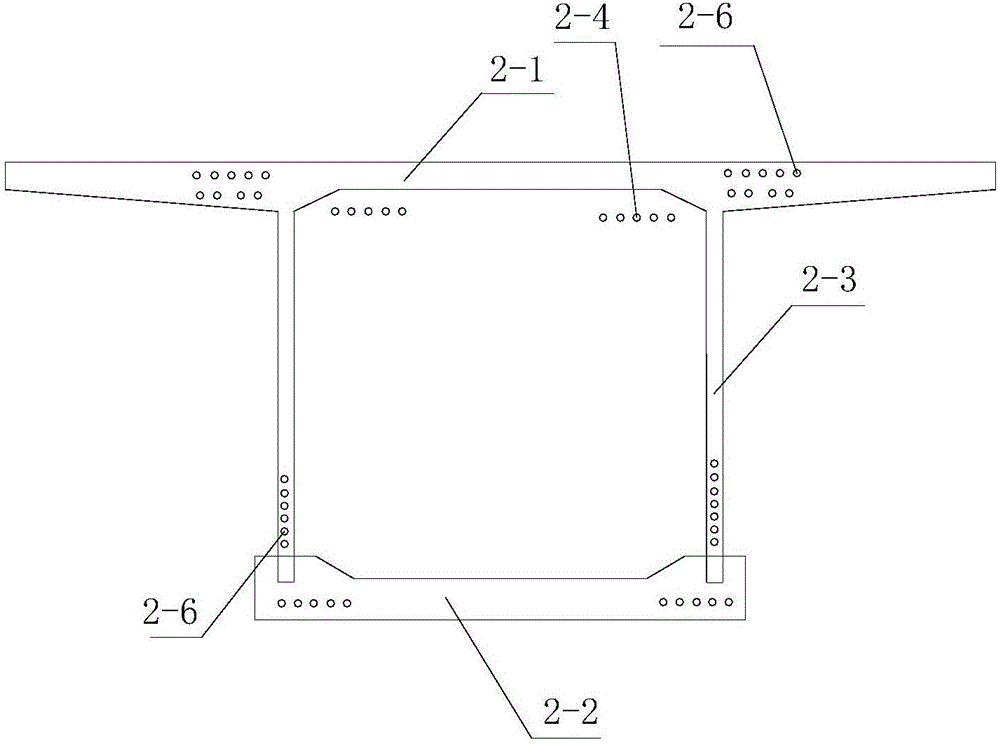

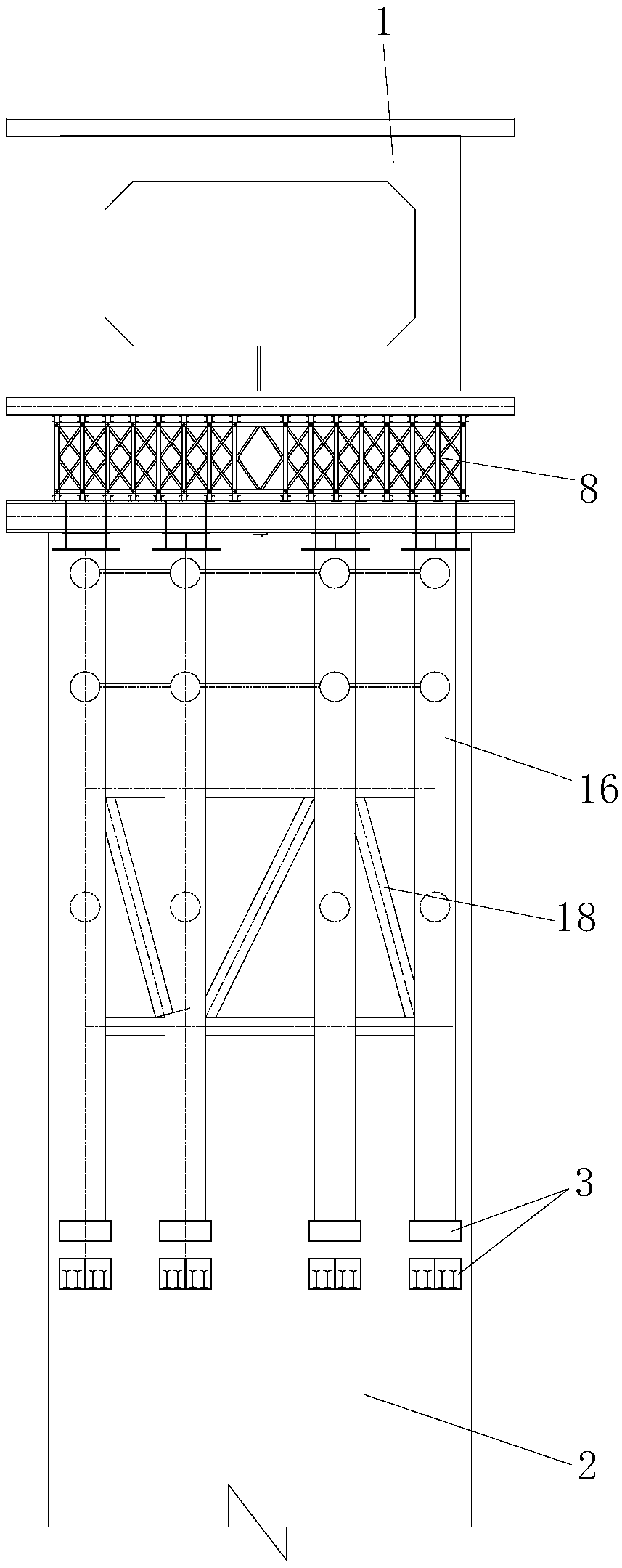

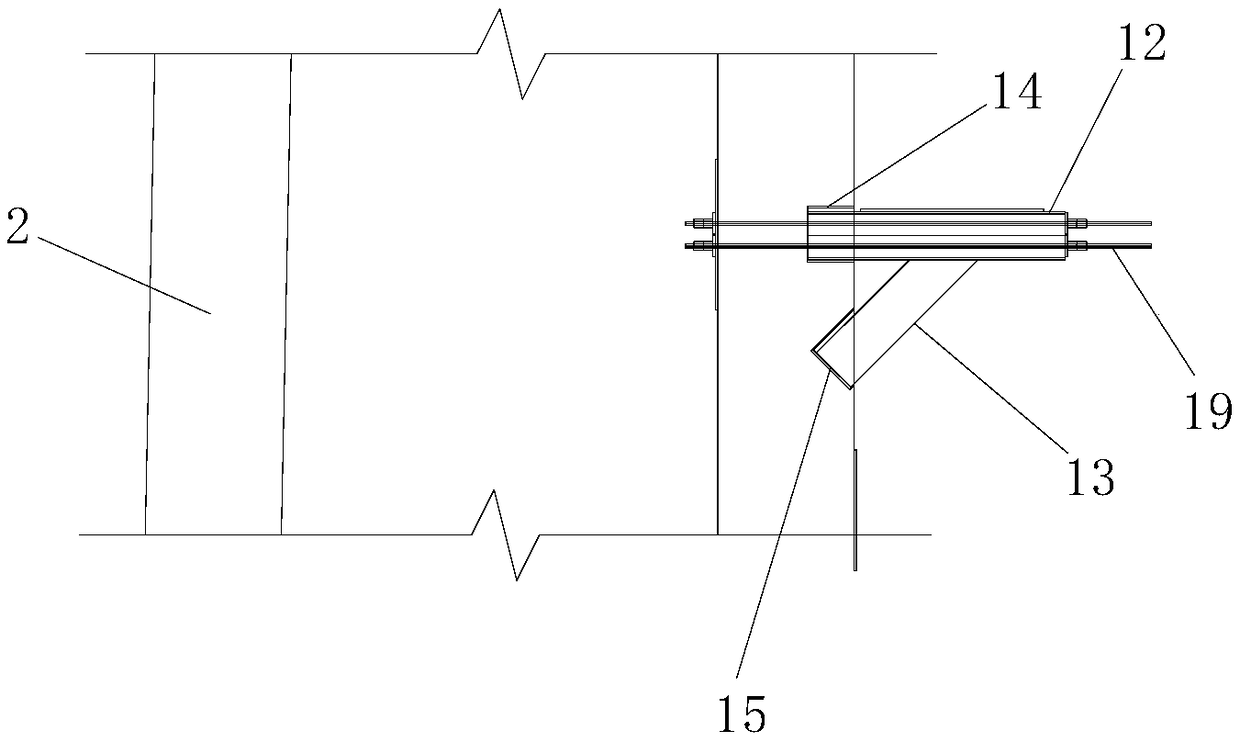

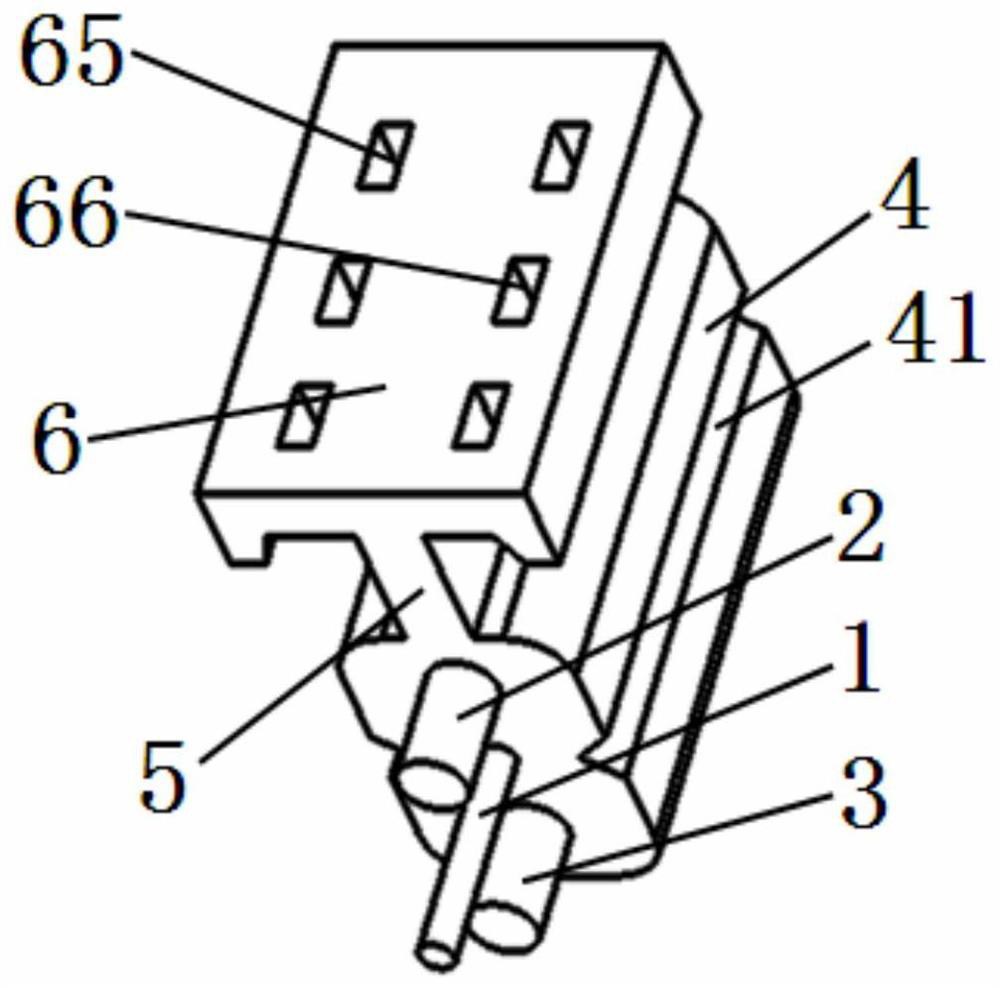

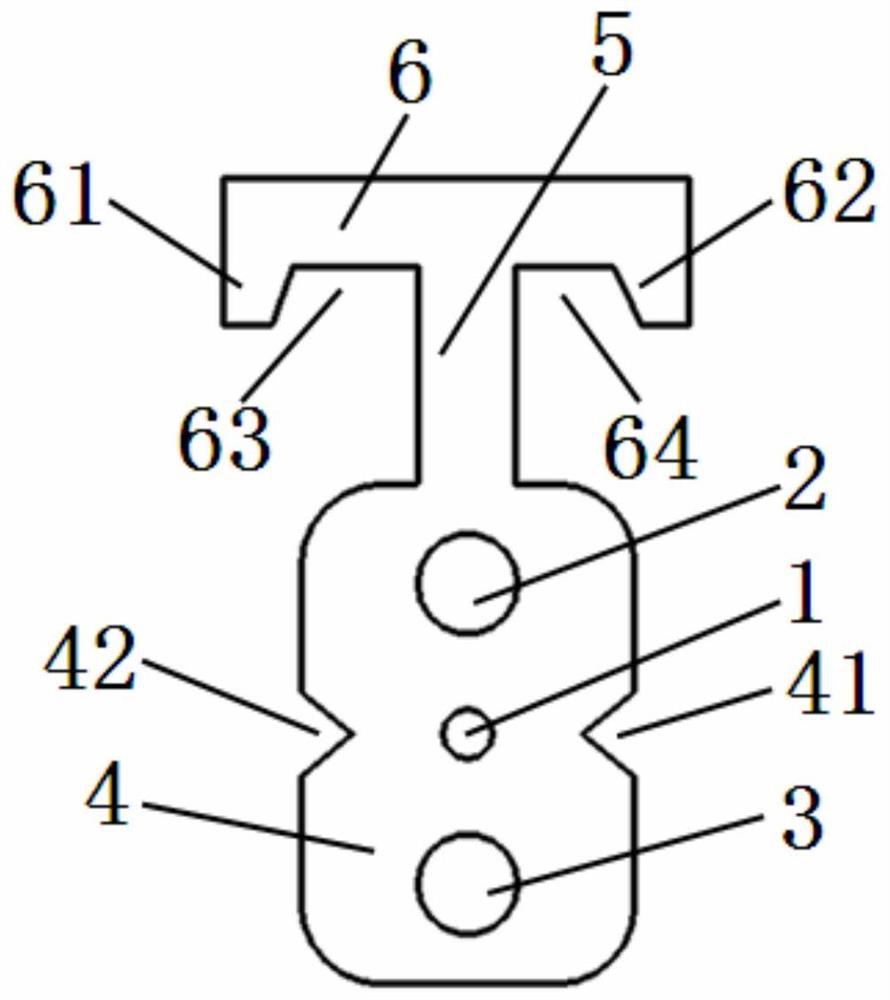

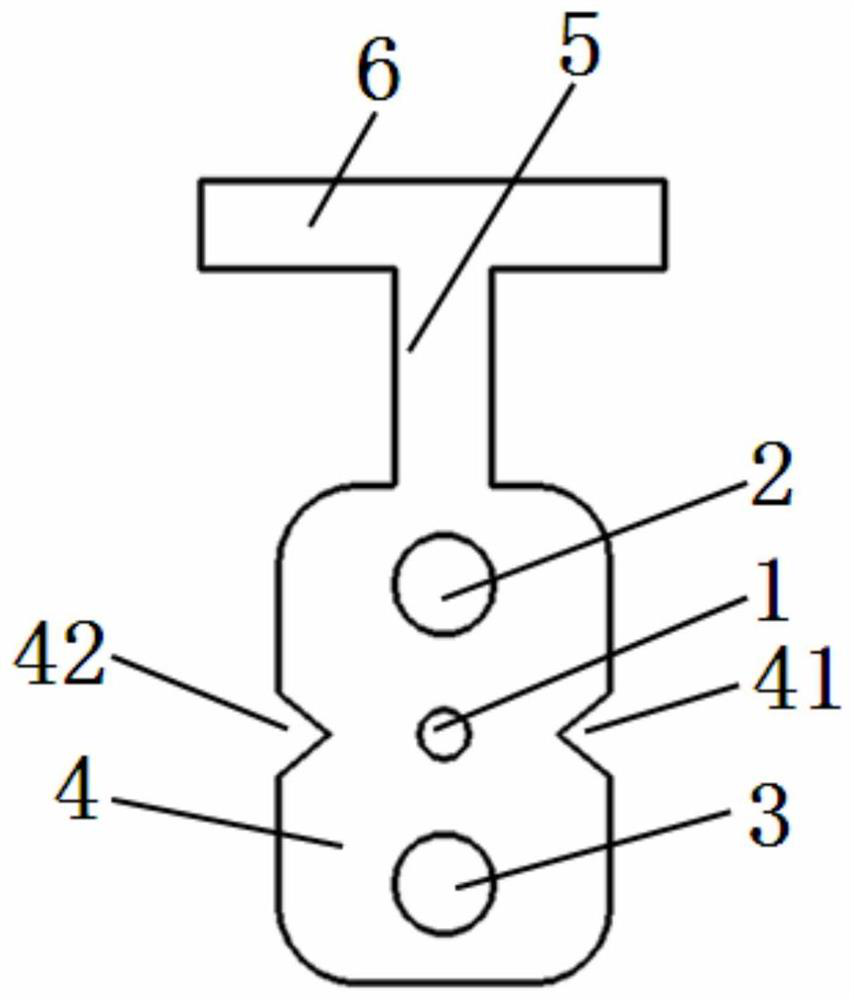

Construction support and method for overhead large-span heavy-duty cross beam

ActiveCN106677070ASimple structureEasy to processBridge erection/assemblySupporting systemPipe support

The invention discloses a construction support and method for an overhead large-span heavy-duty cross beam. The construction support comprises a lower bracket supporting structure, an upper bracket supporting structure located above the lower bracket supporting structure, and a middle supporting structure with the bottom supported on the lower bracket supporting structure. The top face of the upper bracket supporting structure is flush with the top face of the middle supporting structure, and the upper bracket supporting structure and the middle supporting structure form a temporary supporting platform for supporting the cross beam to be constructed. A load bearing structure is erected on the temporary supporting platform. The construction method comprises the steps that firstly, the lower bracket supporting structure is installed; secondly, the upper bracket supporting structure and the middle supporting structure are installed; thirdly, the load bearing structure is erected; fourthly, the support is prepressed; fifthly, the upper cross beam is constructed; and sixthly, the support is removed. According to the construction support and method, design is reasonable, construction is easy and convenient, the using effect is good, and the problems that as for an existing floor steel pipe supporting system, cost is high, the erection process is complex, the construction period is long, the construction risk is high, the requirement for supporting stability is high, and the construction progress of the upper cross beam is affected can be effectively solved.

Owner:CHINA RAILWAY FIRST GRP CO LTD +2

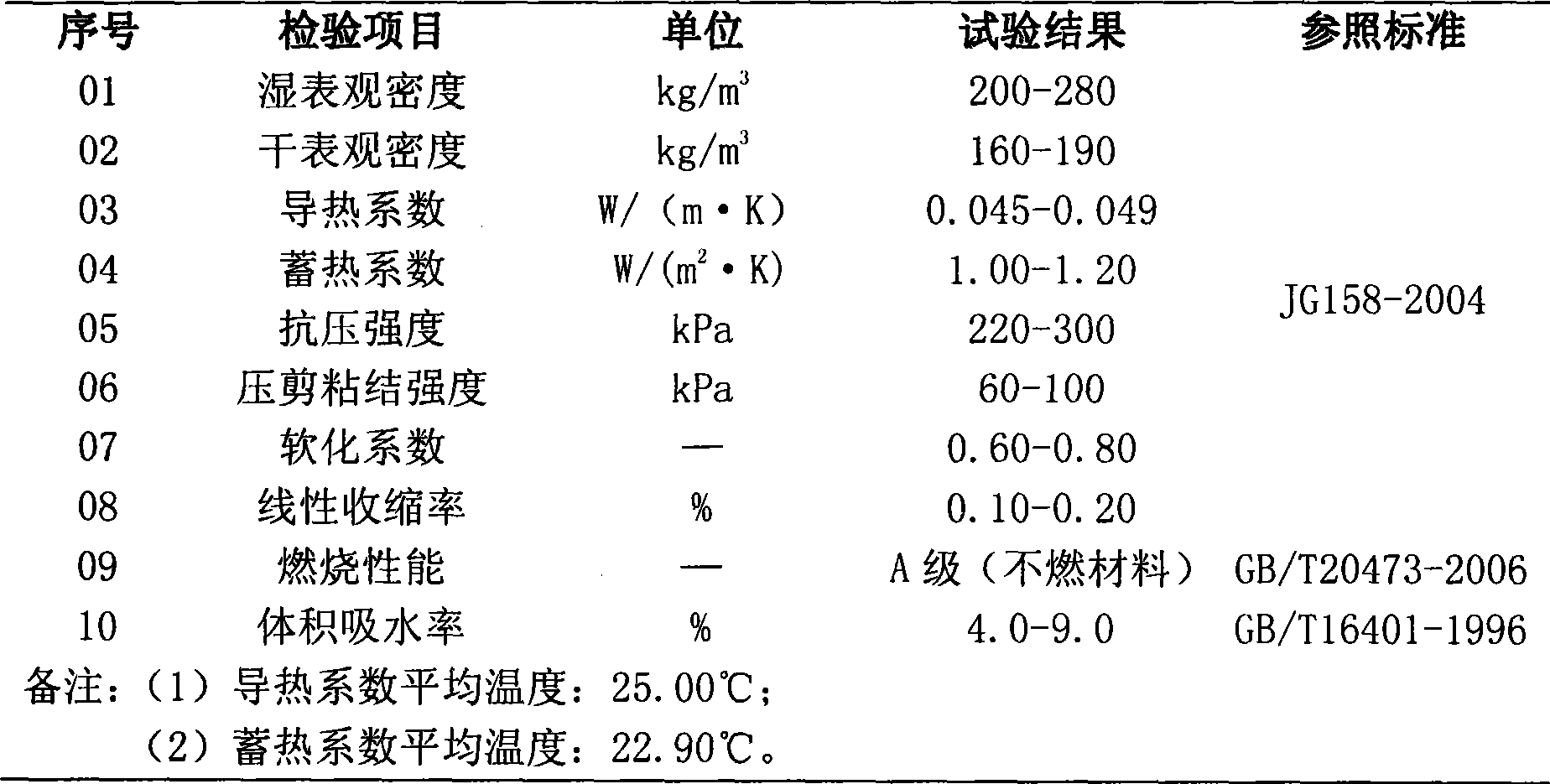

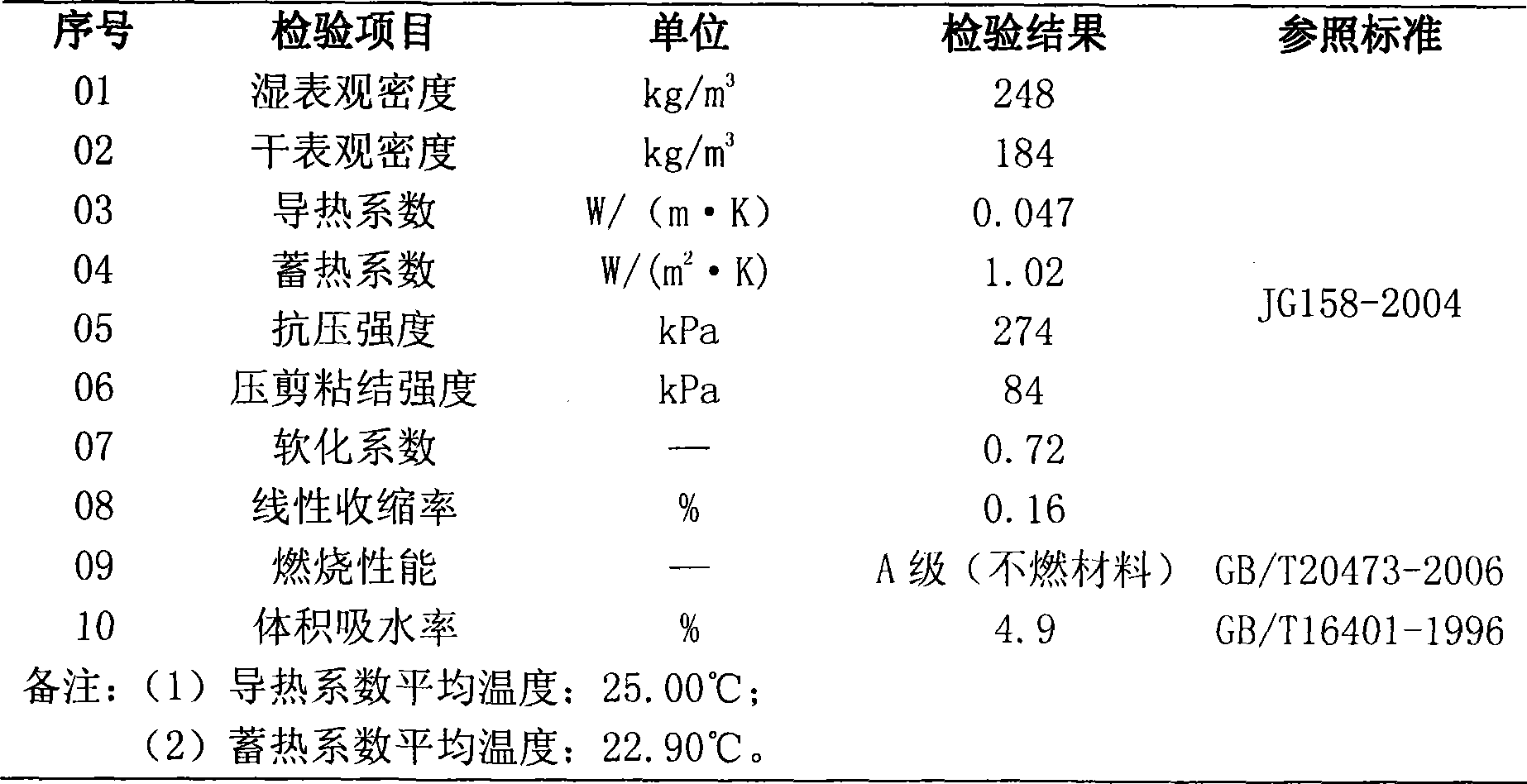

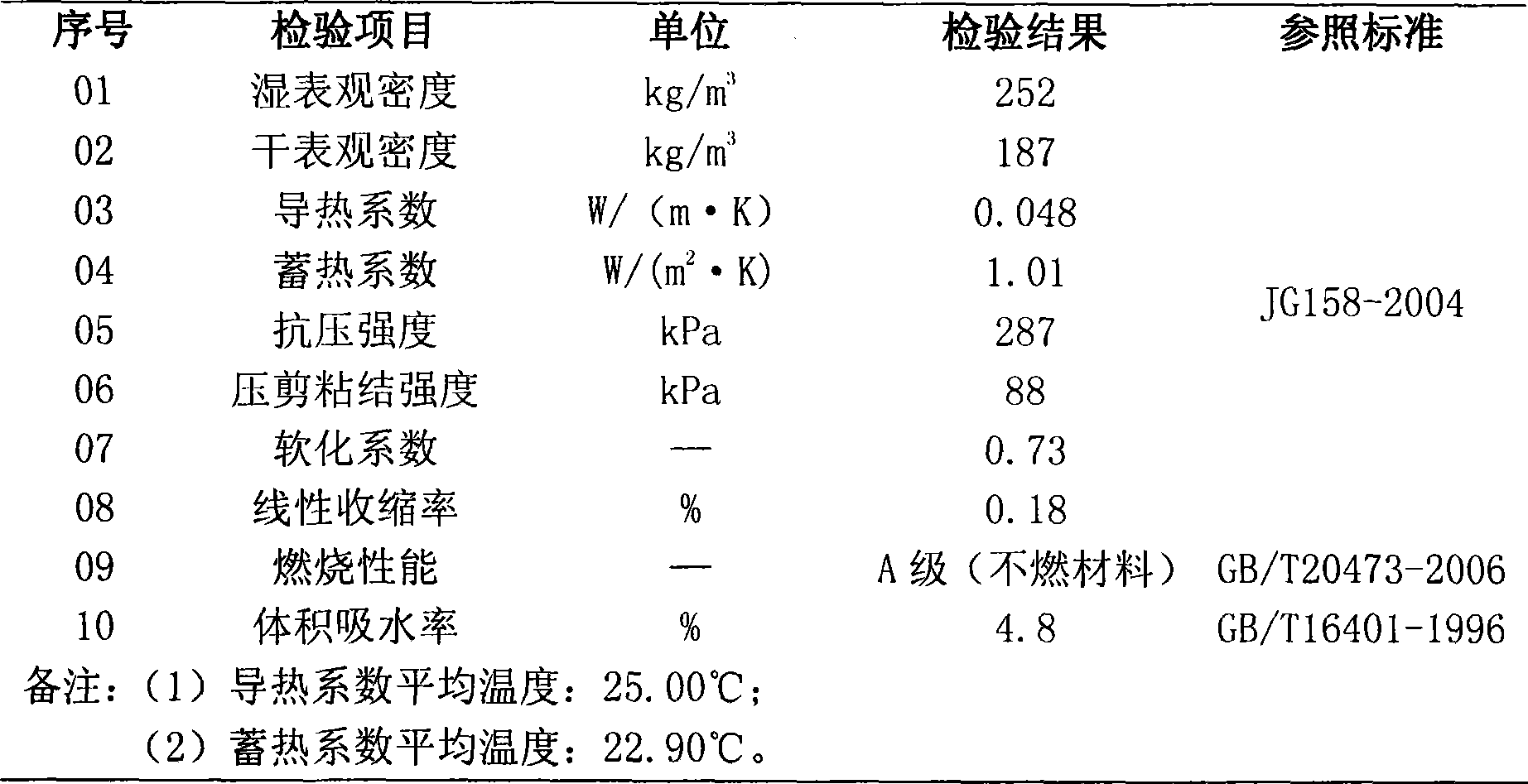

Building ecological heat-insulation mortar and preparation method thereof

The invention relates to a building ecological heat-insulation mortar and a preparation method of the heat-insulation mortar, belonging to the technical field of buildings heat-insulation mortar materials. The preparation method mainly comprises the steps of organically combining phase change material, material for regulating environment humidity and adsorbing harmful gas, and foaming heat-insulation inorganic cementing material, and fully building an ecological environment of human and buildings. The raw materials are cheap and easily available, thus being conducive to waste recovery, environment friendliness and energy conservation. The product is convenient to produce, package, store, transport and construct. Heat-insulation inner wall mortar, heat-insulation outer wall mortar, heat-insulation building mortar, heat-insulation floor heating mortar and heat-insulation wall pouring mortar can be prepared by regulating different formulas. The construction modes include manual scraping, pouring and mechanical spraying.

Owner:武汉优特斯节能建材研究所

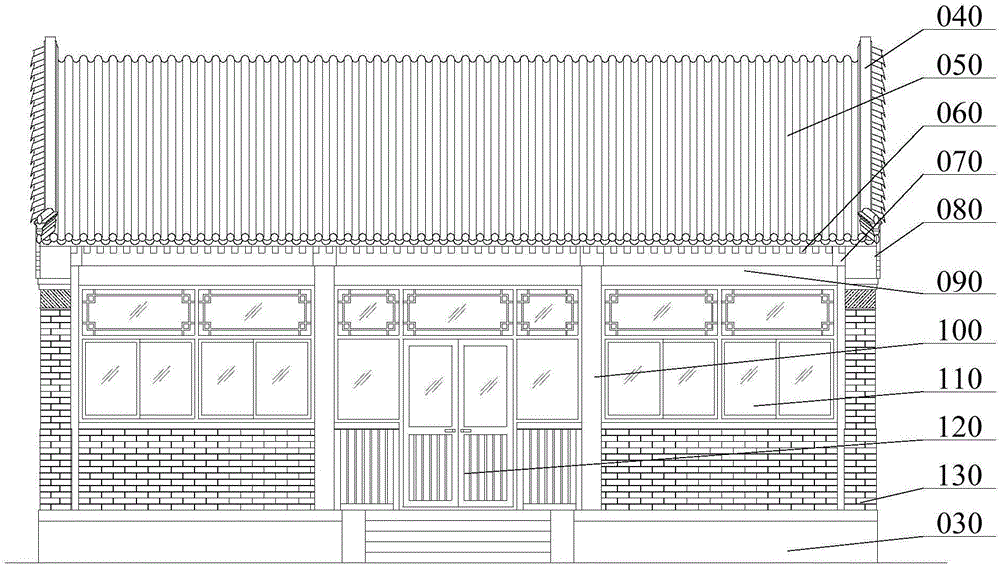

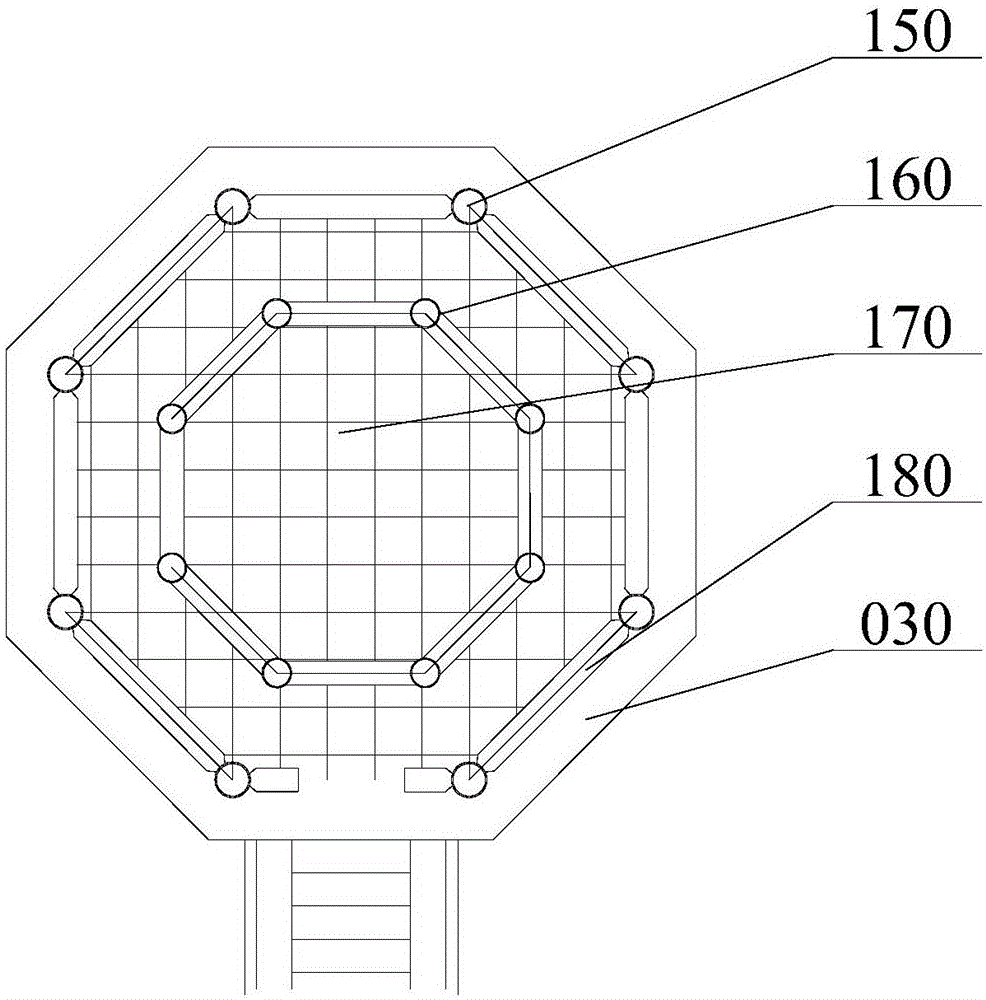

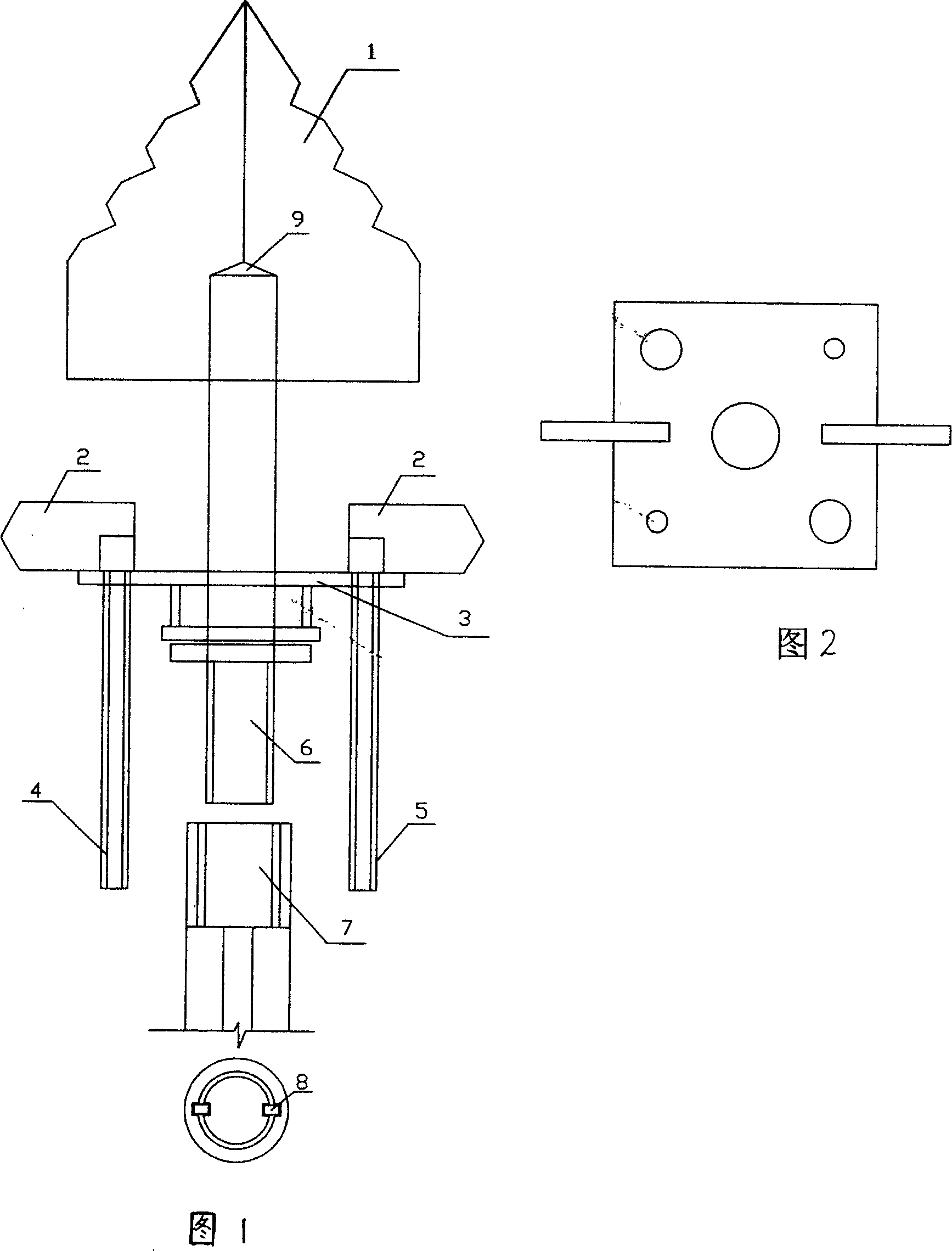

Archaistic building and manufacturing method thereof

ActiveCN106382023AConstruction rationalizationStable physical propertiesBuilding roofsRoof covering using tiles/slatesWater seepageBuilding construction

The invention provides an archaistic building and a manufacturing method thereof, relating to the technical field of manufacturing of historic buildings. The archaistic building comprises a ground foundation, a main body steel structure, archaistic upright pillars and archaistic joint tiles, wherein the archaistic joint tiles and the archaistic upright pillars are made of modified cement and are factory prefabricates with lifelike forms and excellent assembling and archaistic effects. Besides, the steps of the manufacturing method are simple, and the manufactured archaistic joint tiles are scientific in physical dimension design and reasonably butted and have the advantages that water seepage and rain leakage are avoided, the texture is real, the durability is good, and the appearance and the proportion are accordant with traditional tiles. According to the manufacturing method, the technical problems of long construction cycle and short service life in the prior art are solved, the construction of the archaistic building is relatively reasonable, and the application of the archaistic building is relatively wide.

Owner:BEIJING JUXING COMPOSITE MATERIAL TECH DEV

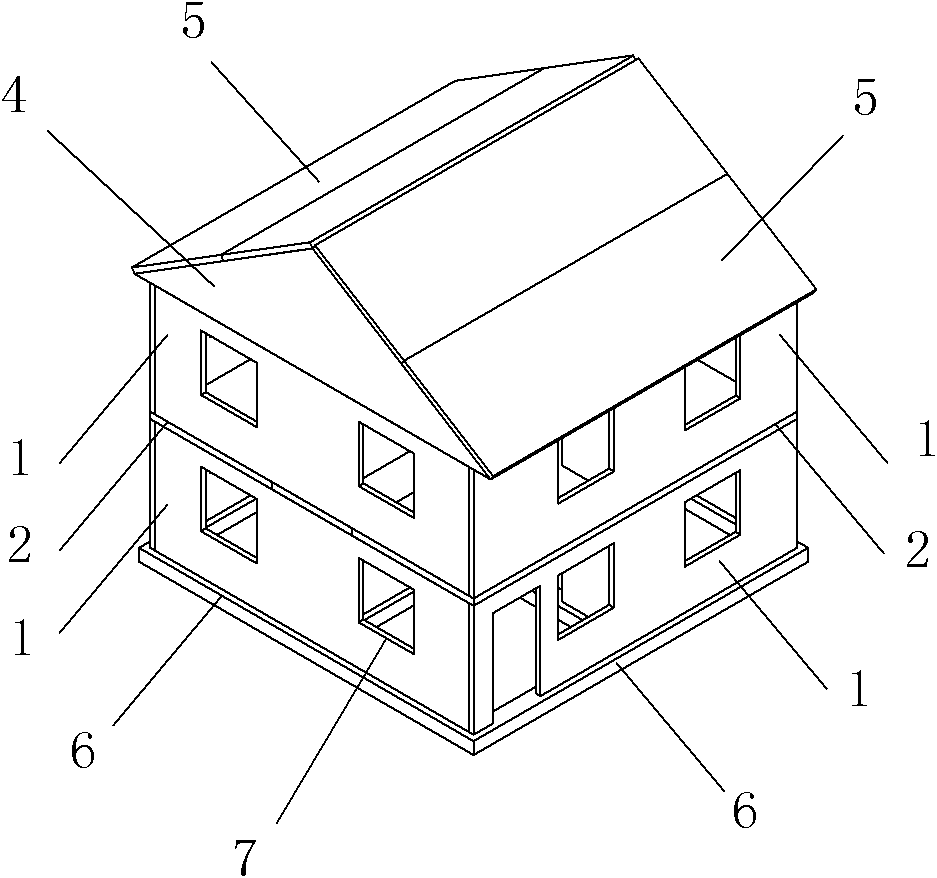

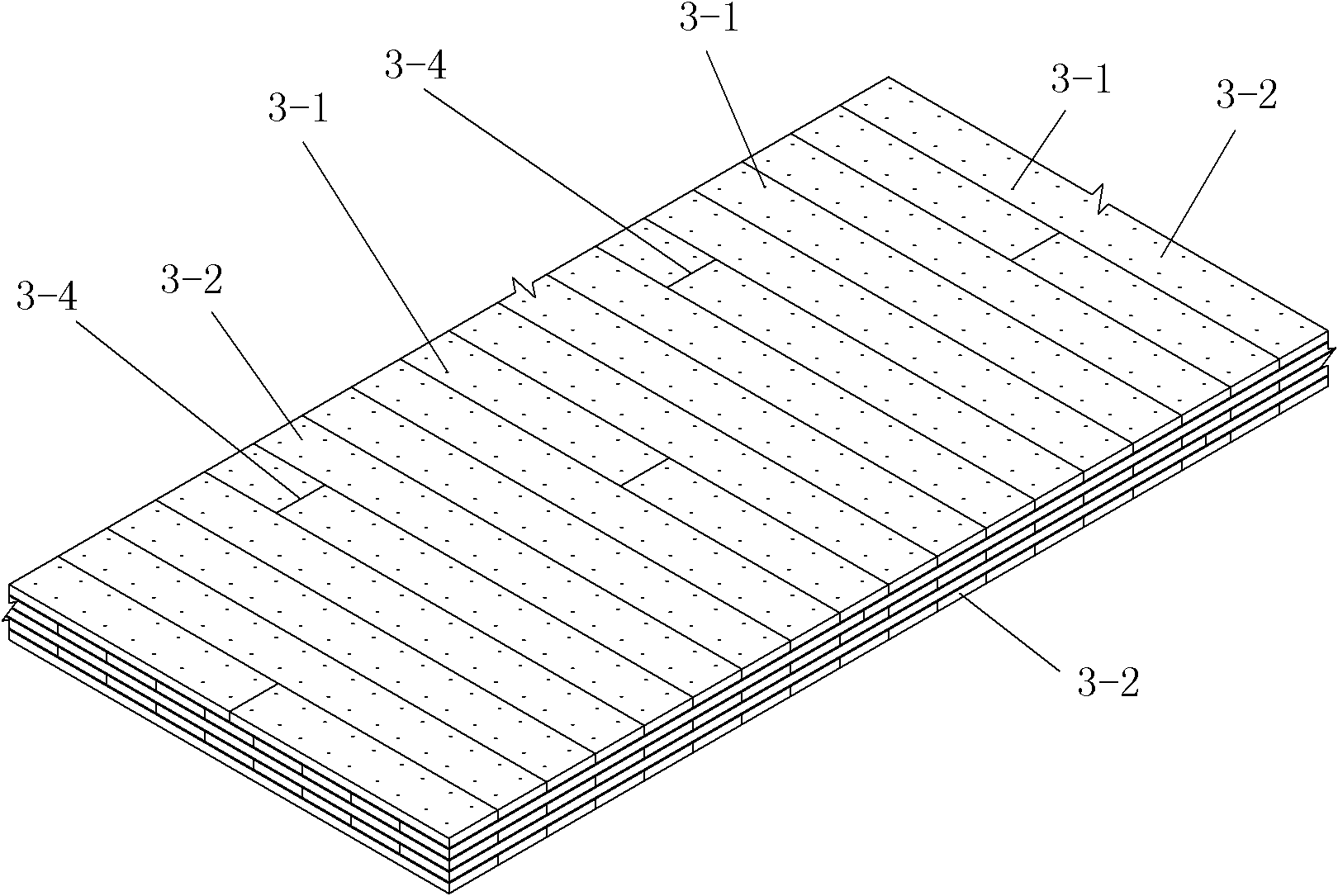

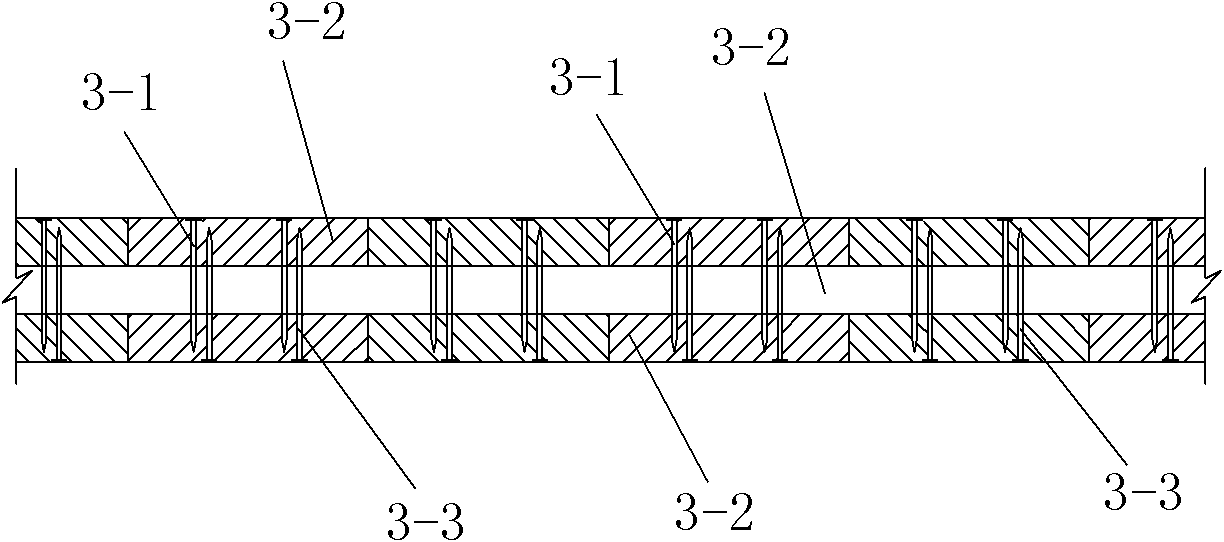

Wooden structure house and building process thereof

InactiveCN102174859ASimple structureClear mechanical propertiesRoof covering using slabs/sheetsBuilding roofsBasementOn board

The invention discloses a wooden structure house and a building process thereof. The wooden structure house comprises a house main body structure and a roof structure, wherein every floor of the house main body structure comprises a plurality of wall bodies 1; the adjacent floors are separated by a floor plate; the wall bodies 1 and the floor plate are an integrated composite board or are formed by splicing a plurality of composite boards arranged on the same plane; the integrated composite board is formed by piling a plurality of layers of wooden boards with same shapes and sizes; and the wooden board is formed by splicing a plurality of wooden plate strips which are arranged on the same plane. The building process comprises the following steps of: 1, on-site constructing foundation and basement, factory-prefabricating and transporting the integrated composite boards; and 2, using the prefabricated composite boards to assemble the wooden structure house on the spot. The wooden structure house in the invention is simple in construction process, controllable in construction quality, low in input investment, rational in structural stress of the built house, beautiful in shape, wide in application range and convenient for prefabricating the integrated boards and suspending on the spot.

Owner:杨岳华

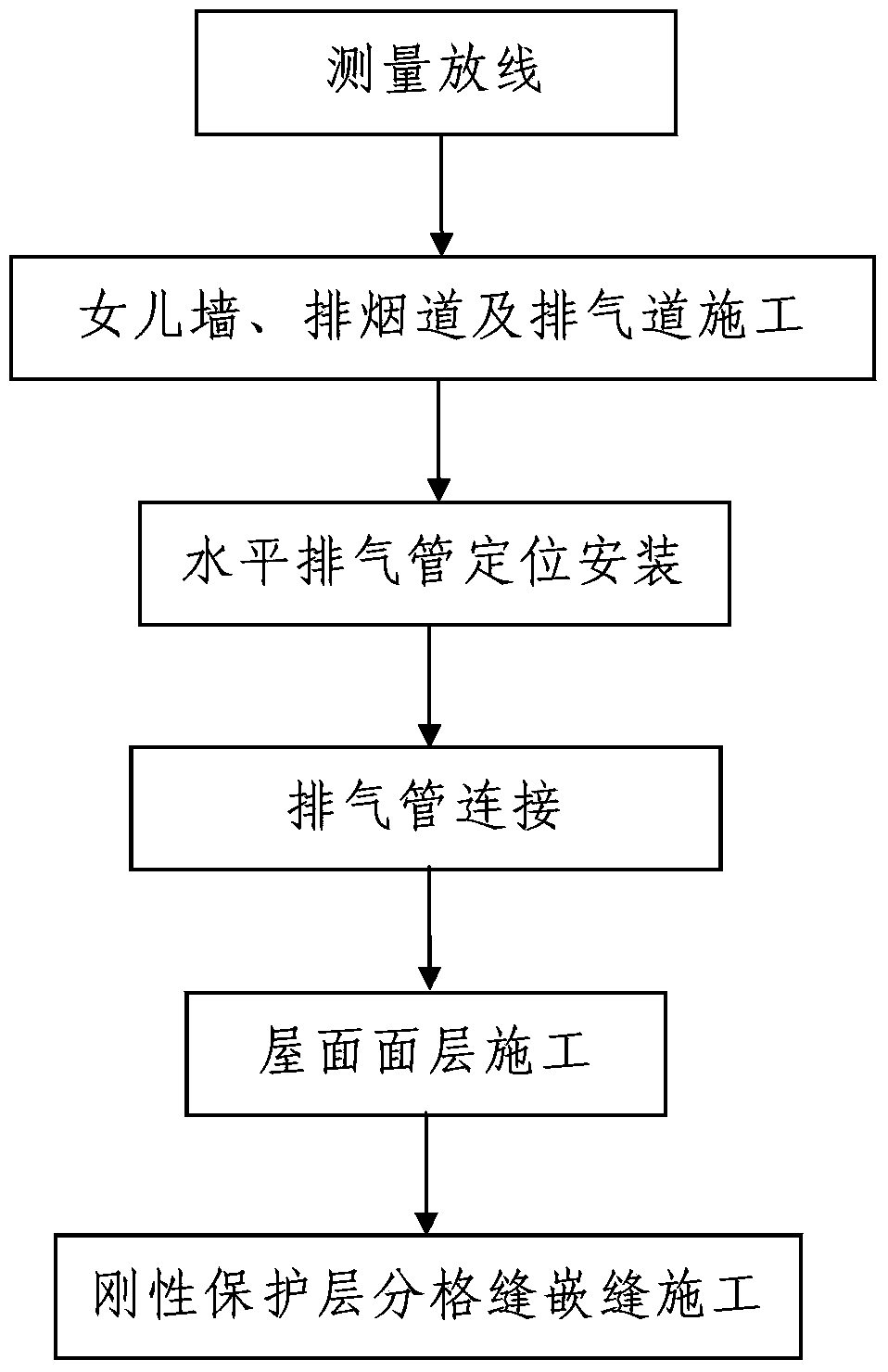

Building roof construction process

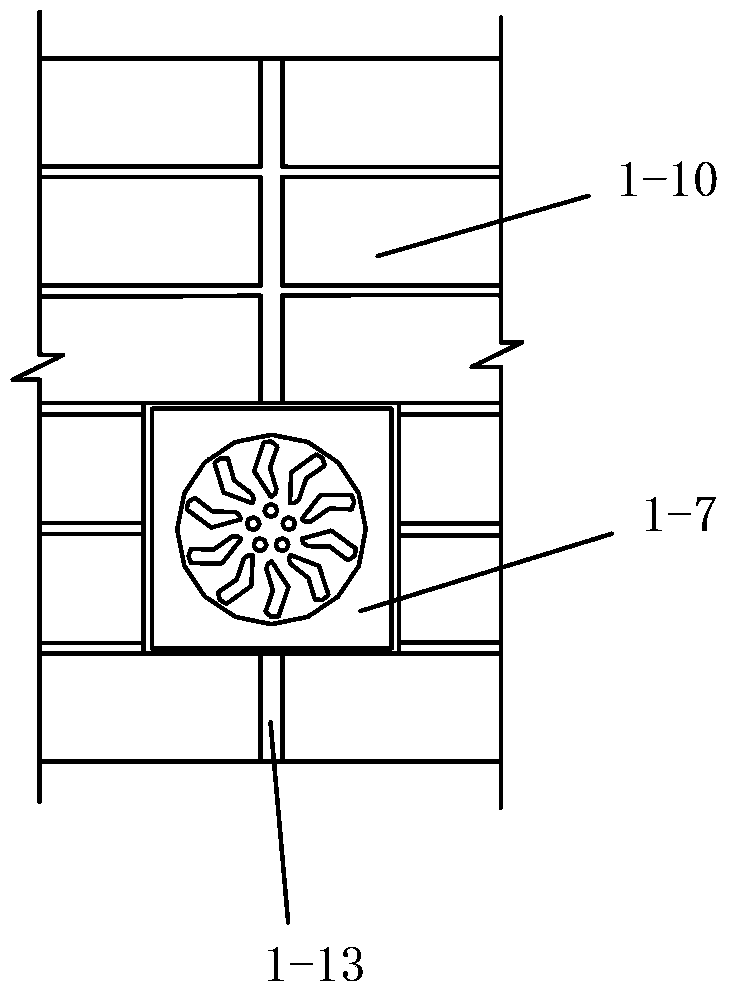

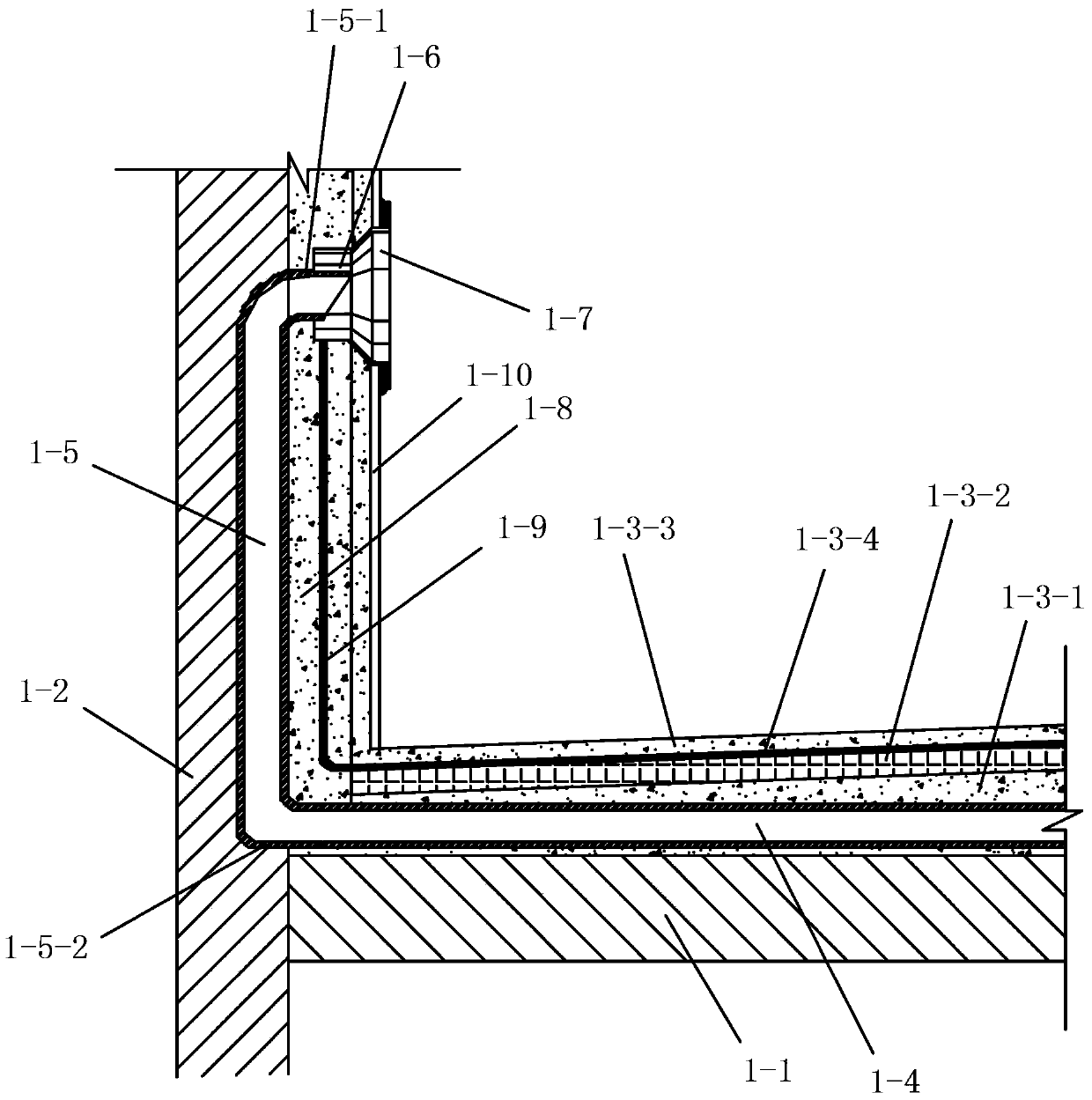

InactiveCN103362254ASimple stepsReasonable designLighting and heating apparatusBuild-up roofsInsulation layerSurface layer

The invention discloses a building roof construction process. A construction roof comprises a roof structure plate, a parapet wall and a roof surface layer, wherein the parapet wall is arranged above the roof structure plate, the roof surface layer is paved on the roof structure plate, a roof exhaust system is arranged on the construction roof and comprises a plurality of first horizontal exhaust pipes, the first horizontal exhaust pipes are respectively laid in a slope finding layer or a heat insulation layer in the roof surface layer, two ends of each first horizontal exhaust pipe are respectively connected with a vertical exhaust pipe, and the vertical exhaust pipes are embedded in the side walls of the parapet wall and a discharge flue or the side wall of an exhaust passage. The construction process of a construction roof comprises the steps of 1, surveying and setting out; 2, parapet wall, discharge flue and exhaust passage construction; 3, horizontal exhaust pipe positioning installation; 4, exhaust pipe connection; 5, roof surface layer construction; and 6, rigid protecting layer mesh division and caulking construction. The construction process has the advantages that the steps are simple, the operability is high, the realization is convenient, in addition, the work efficiency is high, the construction effect is good, and the construction quality of the construction forming building roof can be effectively ensured.

Owner:陕西建工集团有限公司 +1

High performance polymer cement foam material and preparation thereof

InactiveCN101412610AImprove closureImprove insulation effectSolid waste managementCeramicwareFiberPolymer science

The invention relates to a high performance polymer cement foam material and a method for preparing the same. The high performance polymer cement foam material comprises the following components in weight portion: 500 to 1,000 portions of sulphate aluminium cement, 500 to 0 portion of admixture, 20 to 100 portions of polymer, 20 to 100 portions of foaming agent, 5 to 20 portions of composite additive, 0 to 20 portions of fiber, and 500 to 900 portions of water. The method for preparing the high performance polymer cement foam material comprises the following steps: firstly, preparing the foaming agent and the water into a foaming solution according to the ratio of 1 to 10, and preparing the foaming solution into tiny, even and stable foams through a compressed air foaming machine; secondly, simultaneously stirring the cement, the admixture, the polymer, the composite additive, fiber, and the remaining water to prepare a polymer neat cement paste, then inputting the foams and the polymer neat cement paste into a slurry agitator for agitation,, and evenly mixing the materials into a slurry; and thirdly, casting, molding and natural curing on the slurry to obtain the high performance polymer cement foam material. The high performance polymer cement foam material overcomes the disadvantages that an inorganic foam material has heavy brittleness, high water absorption rate, and poor heat insulation effect, and avoids the defects that an organic heat insulating material is easy to burn and has poor weathering resistance; besides, the high performance polymer cement foam material has the advantages of light weight, heat insulation, economy, environmental protection, waste recycling, innocuity, endurance, and same service life as a building, and can be applied to heat insulations of roofing, wall body, and floor (floor warming).

Owner:建筑材料工业技术监督研究中心

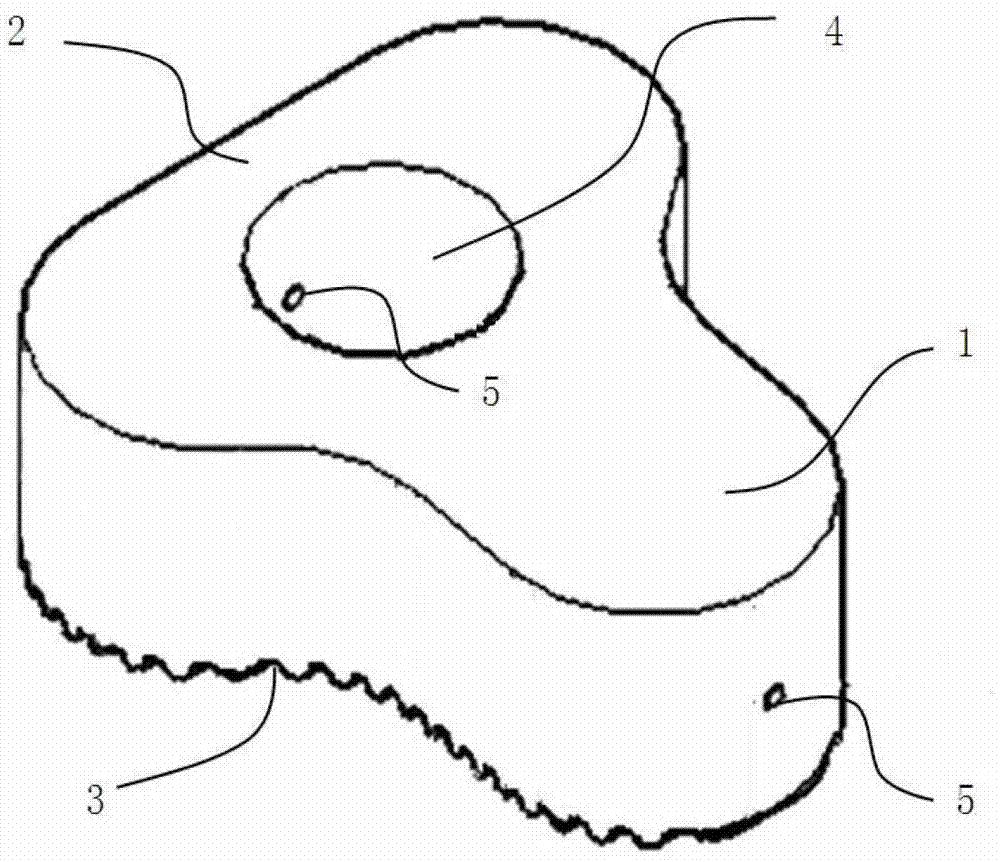

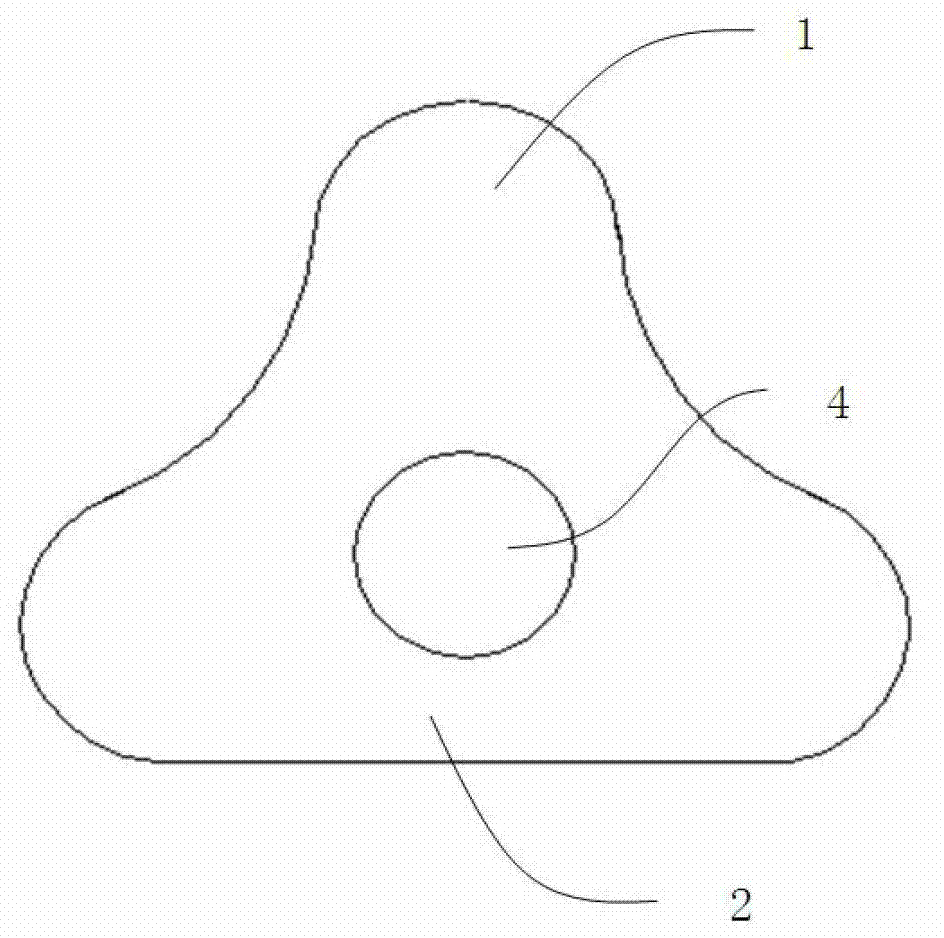

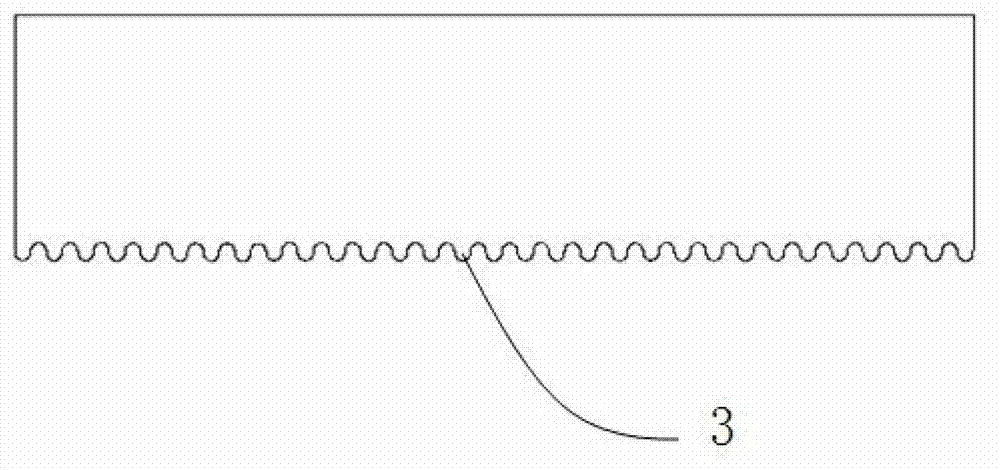

Anti-skid ecological building block and application thereof

InactiveCN103114559AImprove skid resistanceConstruction safetyCoastlines protectionExcavationsEngineeringEcological Building

The invention discloses an anti-skid ecological building block which is in a special shape similar to a triangle. The anti-skid ecological building block comprises a building block top and a building block bottom, wherein the building block top is an arc-shaped protrusion, the building block bottom is provided with two arc-shaped protrusions in horizontal symmetry, the bottom of the building block is provided with an anti-skid groove, and the building block is provided with a planting hole penetrating through the building block. The invention further discloses application of the ecological building block in construction of ecological revetments. The ecological building block is good in anti-skid effects, safe in construction, material-saving, light in weight and convenient to construct. Construction forms of the ecological revetments are flexible, the built ecological revetments are attractive in appearance, and firmness of the ecological revetments can be improved through fixing and additional arrangement of anchor bars.

Owner:HOHAI UNIV

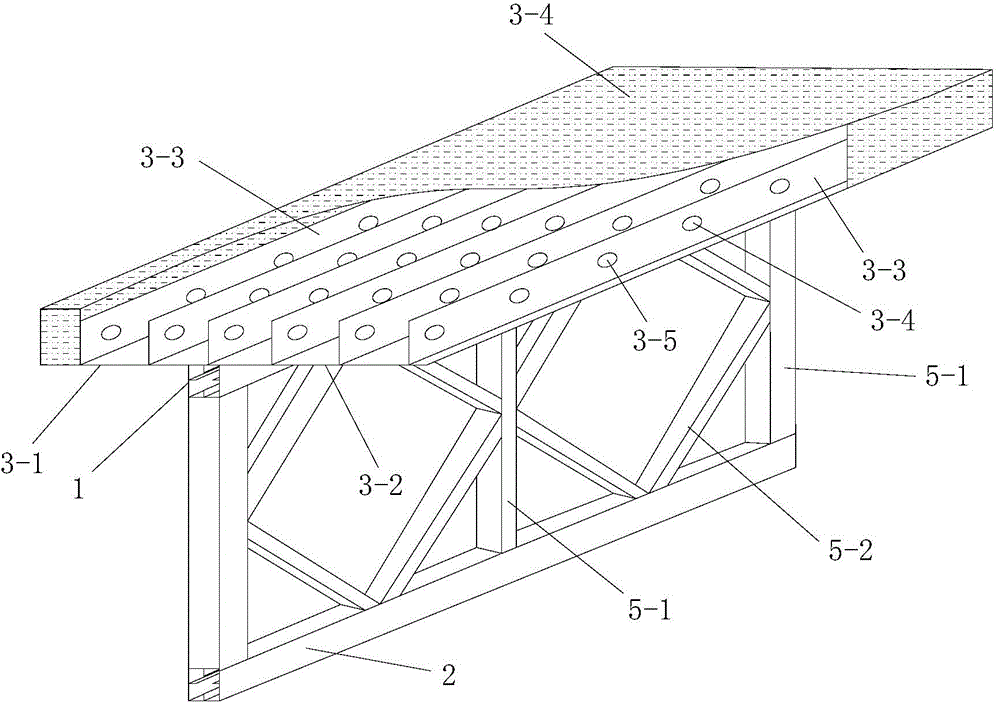

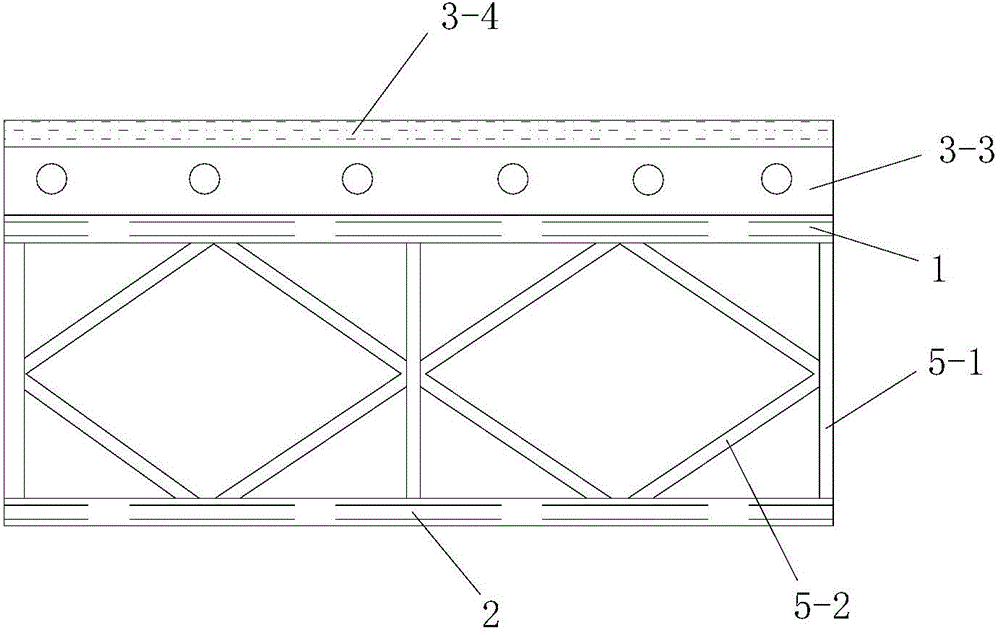

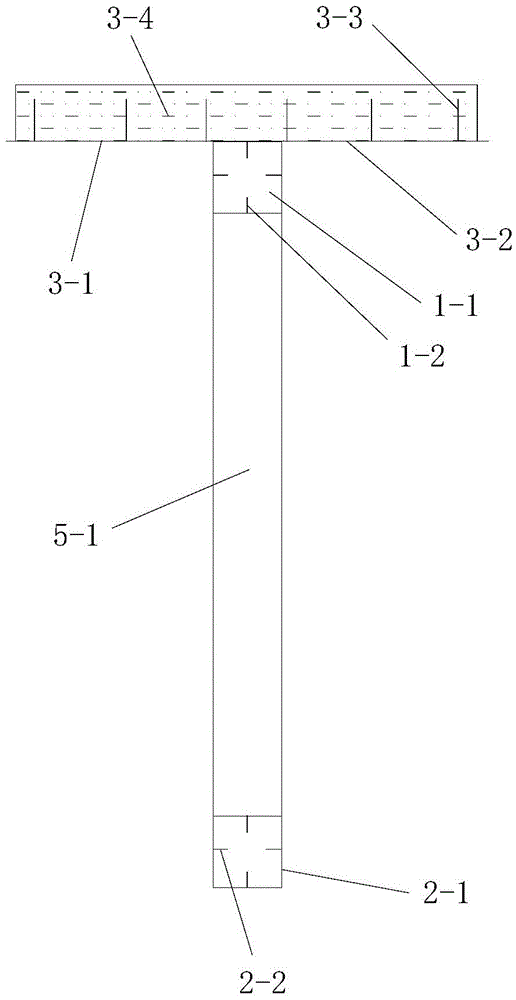

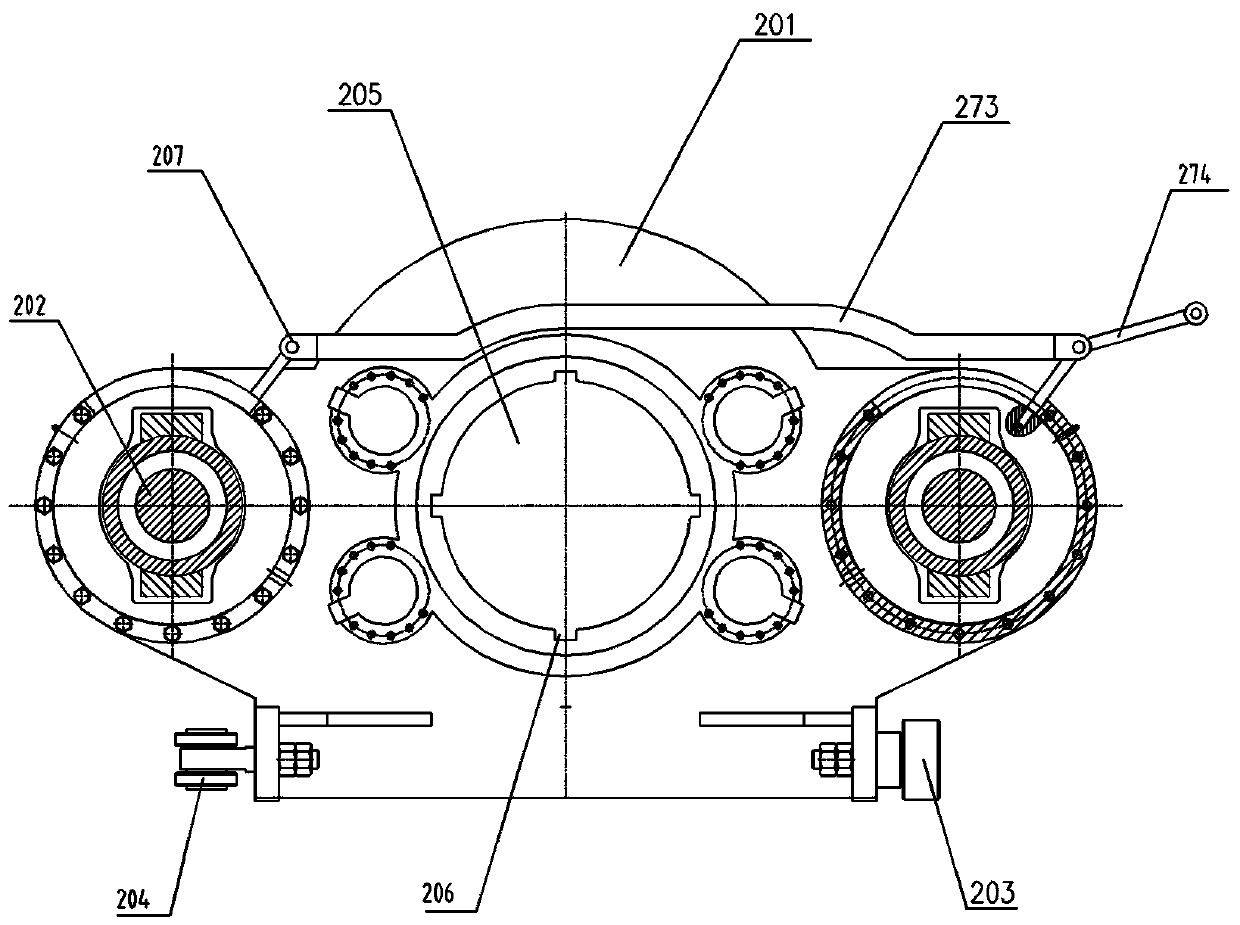

T-shaped plate girder segment prefabricating unit based on steel truss and combined bridge deck slab

InactiveCN104088221ASimple structureReasonable designBridge structural detailsSheet steelBridge deck

The invention discloses a T-shaped plate girder segment prefabricating unit based on a steel truss and a combined bridge deck slab. The T-shaped plate girder segment prefabricating unit comprises a lower force bearing structure and the combined bridge deck slab arranged on the lower force bearing structure, and the combined bridge deck slab and the lower force bearing structure are both arranged in the longitudinal bridge direction; the lower force bearing structure is a planar truss composed of an upper chord rod, a lower chord rod and a web rod, the upper chord rod comprises a first rectangular steel tube, and the lower chord rod comprises a second rectangular steel tube; the combined bridge deck slab comprises a bottom supporting steel plate, a plurality of upper longitudinal ribs arranged on the bottom supporting steel plate, and a concrete bridge deck slab arranged on the bottom supporting steel plate in a pouring mode, the upper longitudinal ribs are arranged in the concrete bridge deck slab in a pouring mode, and the upper longitudinal ribs are long-strip-shaped steel plates with the middles provided with a plurality of through holes; the bottom supporting steel plate is a rectangular supporting steel plate formed by connecting a left extension steel plate, a right extension steel plate and a first rectangular steel tube. The T-shaped plate girder segment prefabricating unit is simple in structure, reasonable in design, easy and convenient to construct, good in overall mechanical property and capable of improving the structure accuracy and construction convenience of a steel and concrete combined bridge.

Owner:CHANGAN UNIV

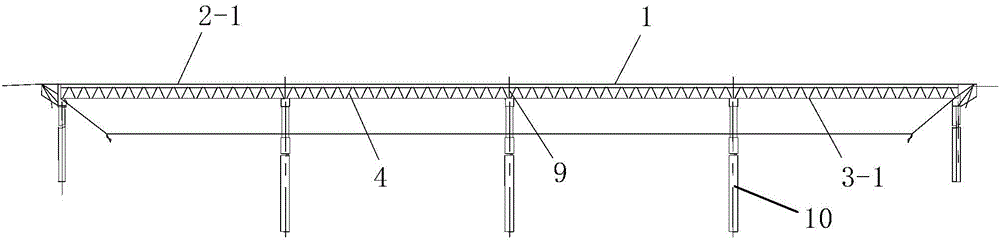

Assembly type rectangular concrete-filled steel tube composite truss girder bridge and construction method thereof

ActiveCN106223183ASimple structureEasy on-site constructionTruss-type bridgeBridge structural detailsSteel tubeGirder bridge

The invention discloses an assembly type rectangular concrete-filled steel tube composite truss girder bridge and a construction method thereof. The truss girder bridge comprises girder lower supporting structures, an assembly type girder and a prefabricated bridge panel which is connected with the assembly type girder through a shear key. The assembly girder is a rectangular concrete-filled steel tube composite truss and is formed by splicing a plurality of longitudinal trusses. Each longitudinal truss is composed of an upper chord member, a lower chord member and a web member. A horizontal bridge direction supporting structure composed of two inclined struts arranged in a crossed mode is arranged over each girder lower supporting structure, and the rectangular concrete-filled steel tube composite truss is formed by assembling a plurality of truss sections. The construction method comprises the first step of construction of the girder lower supporting structures, the second step of erecting of the assembly type girder, and the third step of mounting of the prefabricated bridge panel. The assembly type rectangular concrete-filled steel tube composite truss girder bridge is reasonable in design, easy and convenient to construct, good in using effect, capable of fully performing the advantage of the combination of steel and concrete materials, good in stress performance, high in construction speed, low in construction cost, capable of achieving the standard and batch production of the girder and the bridge panel.

Owner:CHANGAN UNIV

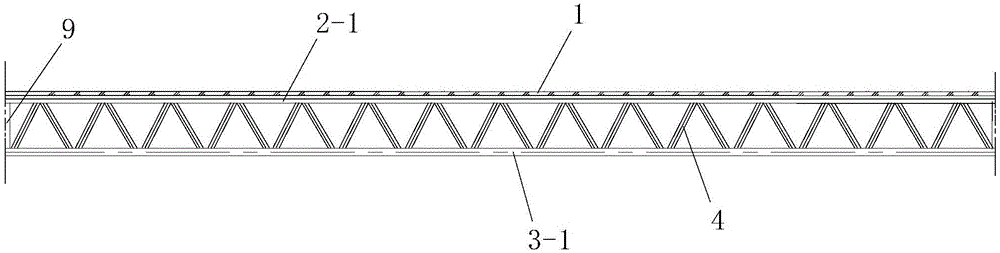

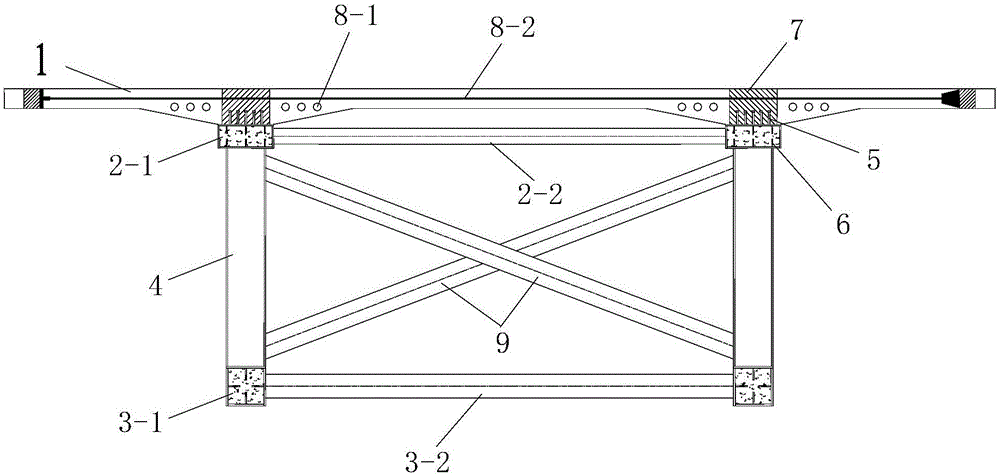

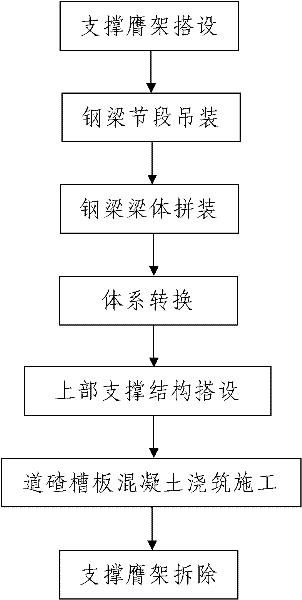

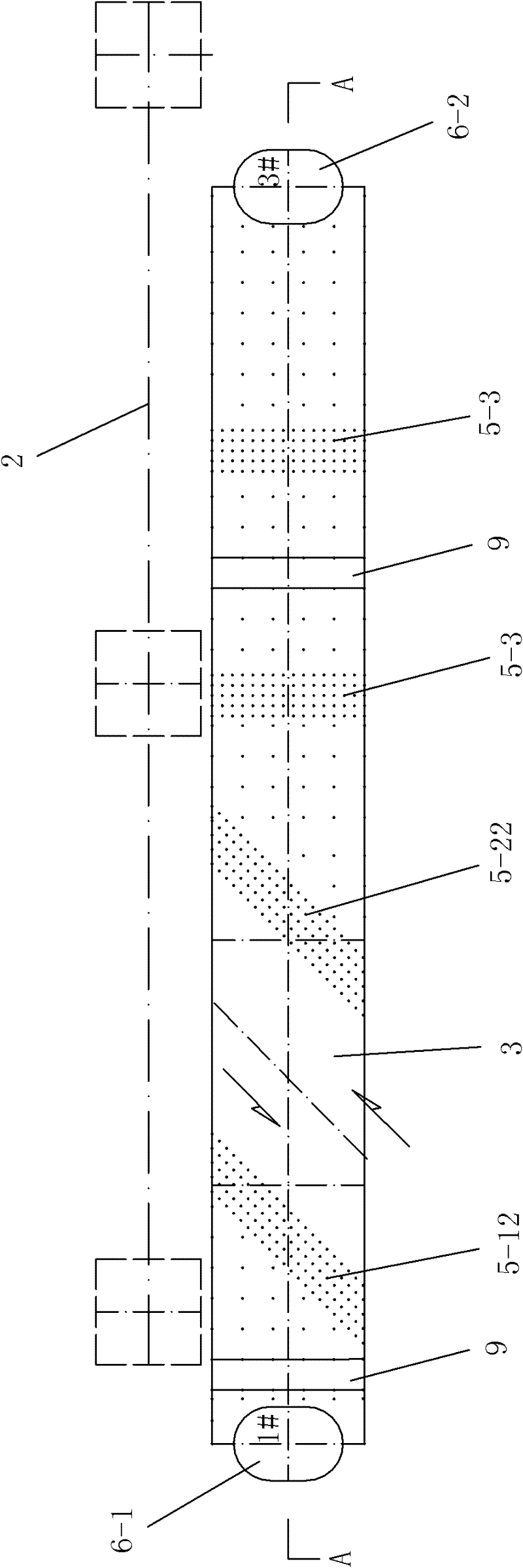

Steel-concrete composite girder construction technology striding current lines and being parallel to existing lines

InactiveCN102220741AReasonable designSimplify construction stepsBridge erection/assemblyButtressFalsework

The invention discloses a steel-concrete composite girder construction technology striding over current line and being parallel to existing lines, which comprises the flowing steps: firstly, erecting a supporting falsework, wherein the supporting falsework comprises a plurality of temporary buttresses which are distributed between two buttresses from left to right, and the distribution positions of the plurality of temporary buttresses respectively correspond to the connection position of two adjacent steel grinder sections of a steel grinder body in a construction steel-concrete composite girder; secondly, hoisting the steel grinder sections, wherein a plurality of steel grinder sections constituting the steel grinder body are hoisted in place one by one; thirdly, splicing the steel grinder body, wherein splicing is conducted on the steel grinder body after linetype adjustment and camber adjustment; fourthly, converting the system; fifthly, conducting concrete pouring construction on a ballast channel plate; and sixthly, detaching the supporting falsework. The steel-concrete composite girder construction technology has reasonable design, convenience in the construction, low investment cost, good using effect, high construction efficiency, short construction period and low safety risk, and the adopted supporting falsework has a simple structure and high satiability and is economical and practical.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

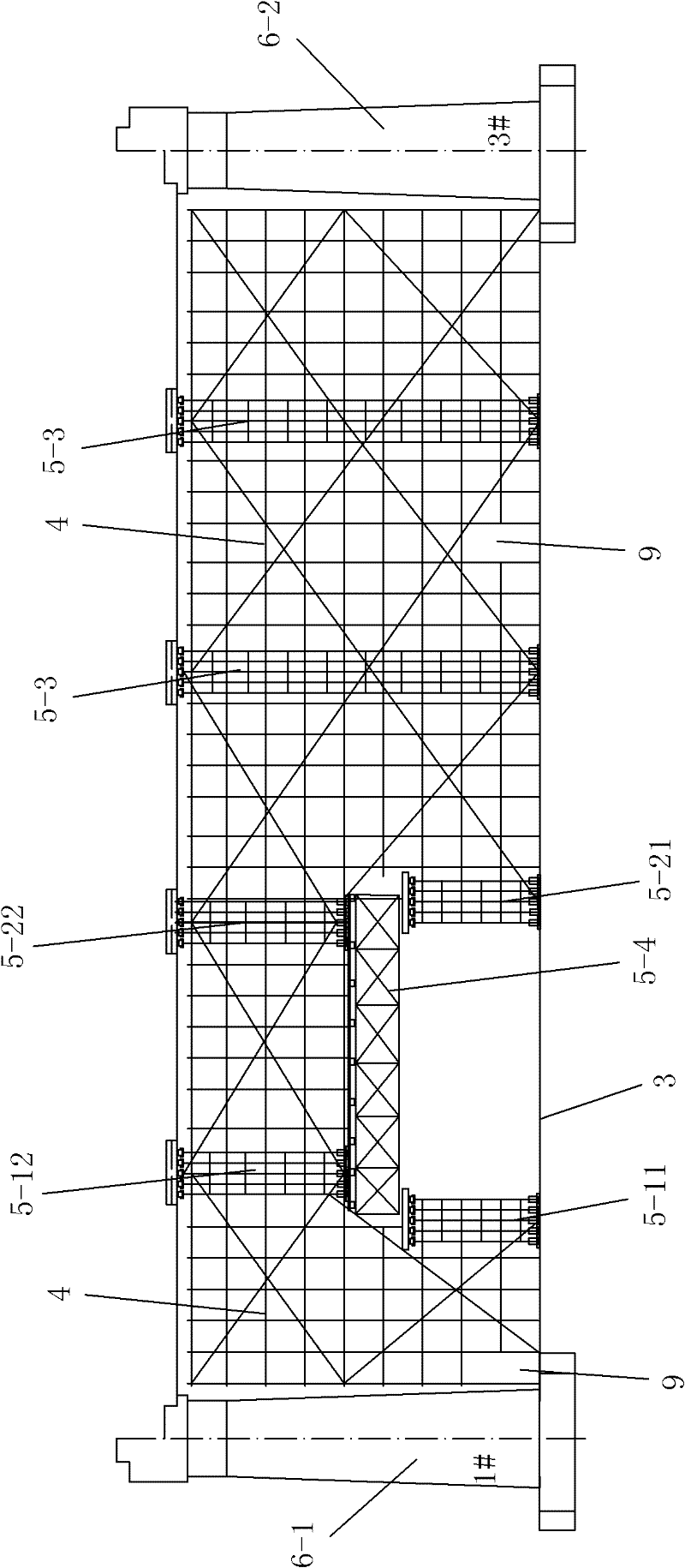

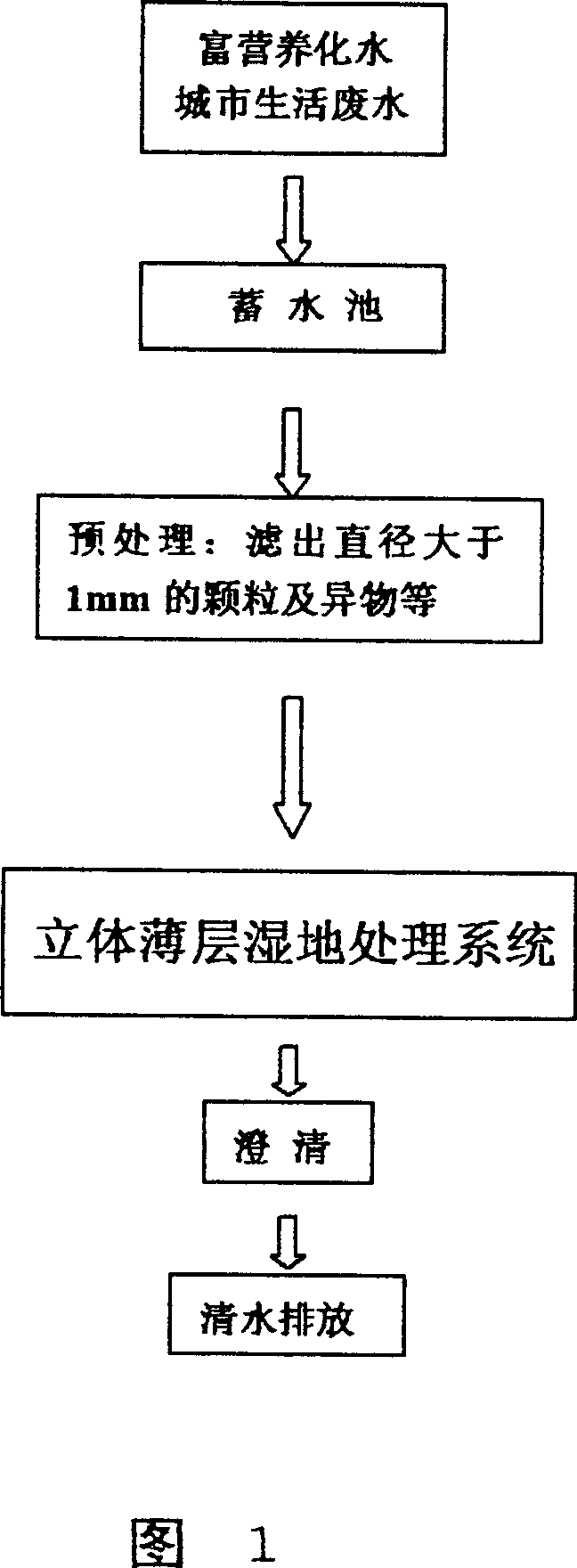

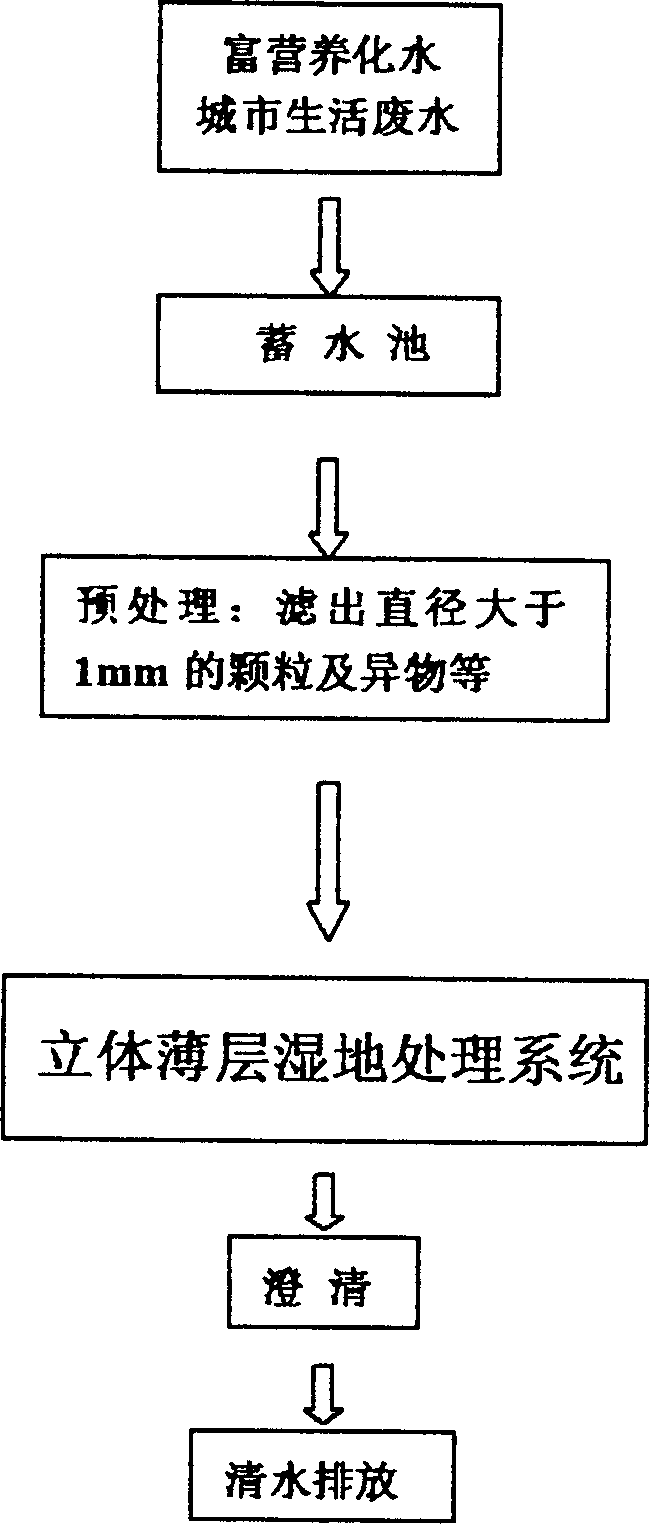

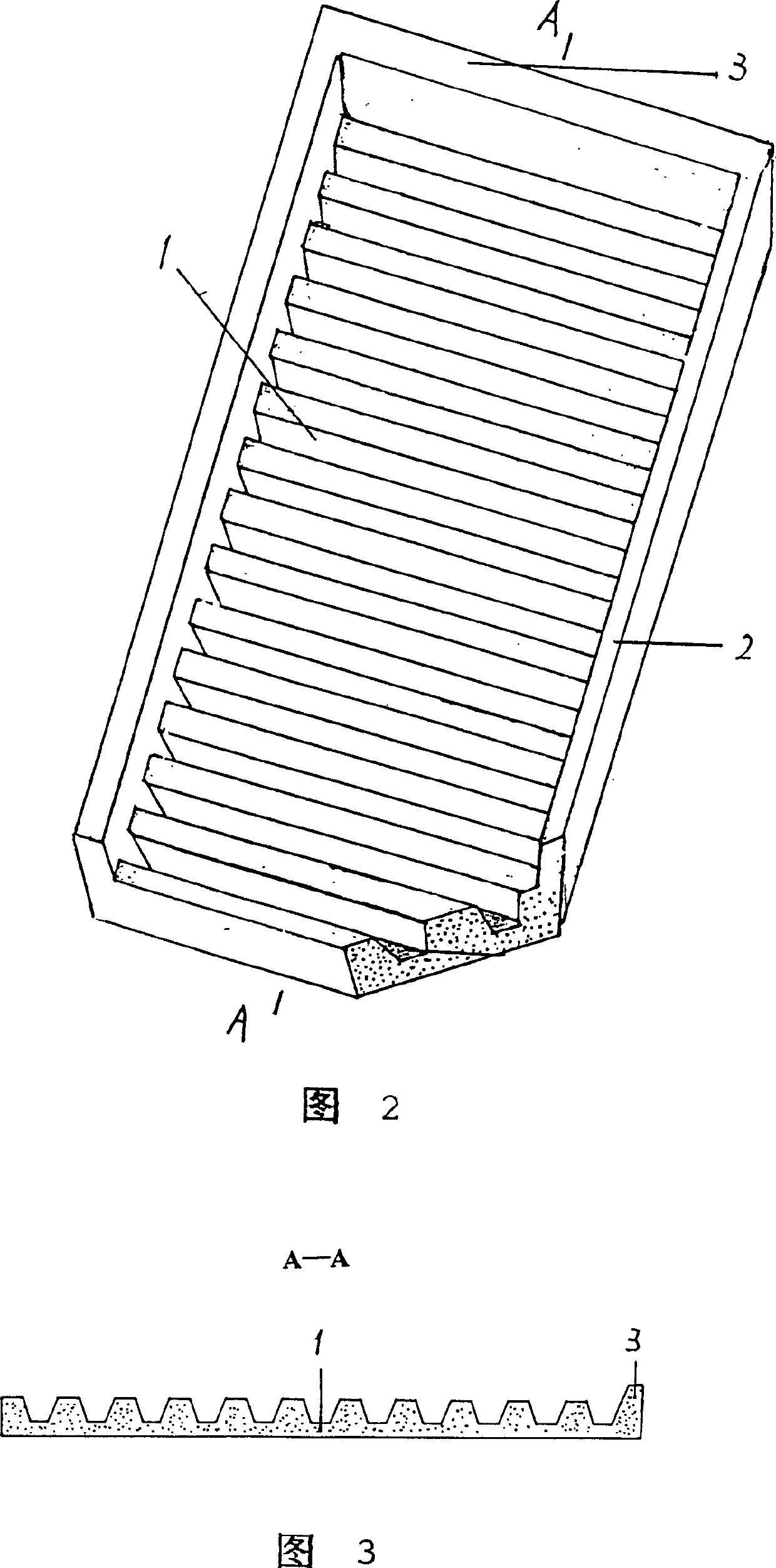

Stereo-thin-layer wet land technique for treating eutrophication water and its filtering block

InactiveCN1443714AIncrease the greenhouse effectEasy to makeWater/sewage treatment bu osmosis/dialysisEnergy based wastewater treatmentRough surfaceEutrophication

Said invention adopts the expanded pearlite with rich micropores and makes it into filter block with rough surface, every filter block has several recessed grooves on its transverse direction, two sides of its longitudinal direction and its back side are equipped with water-retention walls, and lower front end of its bottom portion is equipped with a water-receiving groove. Several filter blocks are connected, and made into a filter unit with inclined step-like structure from bottom to top, and the inclined angle of the filter unit alpha is greater than or equal to 10 deg.C or less than or equal to 30 deg.C, on the filter block the wetland economic plant is planted, the eutrophicated water or urban domestic water water can be slowly flowed through filter block to form membrane phase effect so as to clean water quality.

Owner:申光华

Occlusive pile construction method

InactiveCN103967002AFast crossingReduce processing difficultyBulkheads/pilesReinforced concreteRebar

An occlusive pipe construction method comprises the following steps: constructing reinforced concrete piles in advance; constructing full-plain concrete piles by using a manual construction mode among piles after the reinforced concrete piles are solidified to a certain strength, wherein the full-plain concrete piles and the reinforced concrete piles are mutually occluded. According to the method, the reinforced concrete piles are constructed in advance, then the full-plain concrete piles are constructed manually without cutting the bodies of the reinforced concrete piles, and the constructing processes of the reinforced concrete piles and the full-plain concrete piles are relatively independent of each other and do not interact; in addition, strict requirements on time can be avoided as the construction of the reinforced concrete piles can be carried out without judging the forming states of the full-plain concrete piles first; the technology difficulty is greatly reduced, and the construction of manual hole shaping is free of strict shape requirements; construction manners can be flexibly changed when a rocky stratum is encountered during construction, the rocky stratum can be rapidly penetrated, the hole shaping quality can be controlled conveniently, and the occlusive effect is better than that of the traditional construction manner.

Owner:SHENZHEN GEOTECHN INVESTIGATION & SURVEYING INST

Soil body anchor rod construction process and anchor rod member thereof

InactiveCN101096849AGuarantee the construction qualityGuaranteed workmanshipExcavationsBulkheads/pilesHigh pressureCement mortar

The invention discloses a working craft of solid body anchor bar, which comprises the following steps: A, drilling with anchor bar machine; feeding water through self high pressure of drilling rod; reaching to high pressure on the drilling place for water flow; forming cutting for soil layer; B, setting the drill as zigzag type; connecting the drill and prestressed hank anchor solid end with common bearing or pressure bearing; supplementing a slip casting pipe; drilling into designing depth as the drill; C, taking up the drilling rod; leaving the prestressed hank anchor solid end, slip casting pipe and drill at the bottom of the drilling hole; proceeding slip casting or cement paste or cement sand paste through the casting pipe; reaching the designing demand; forming the inherent stress anchor rod. This method can increase efficiency and decrease cost, which can be used to breast, continuous wall under floor and so on working craft.

Owner:于艳芳

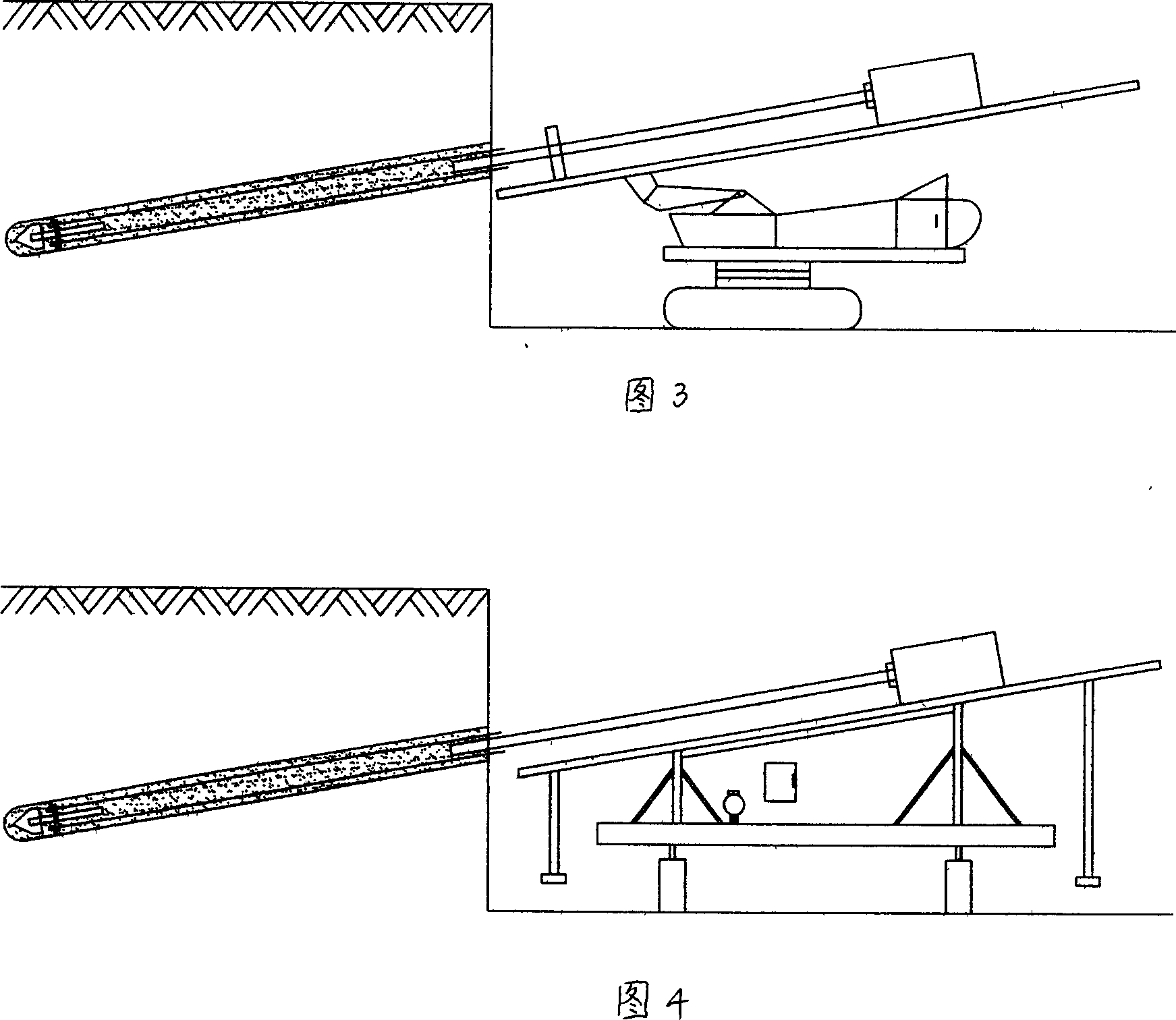

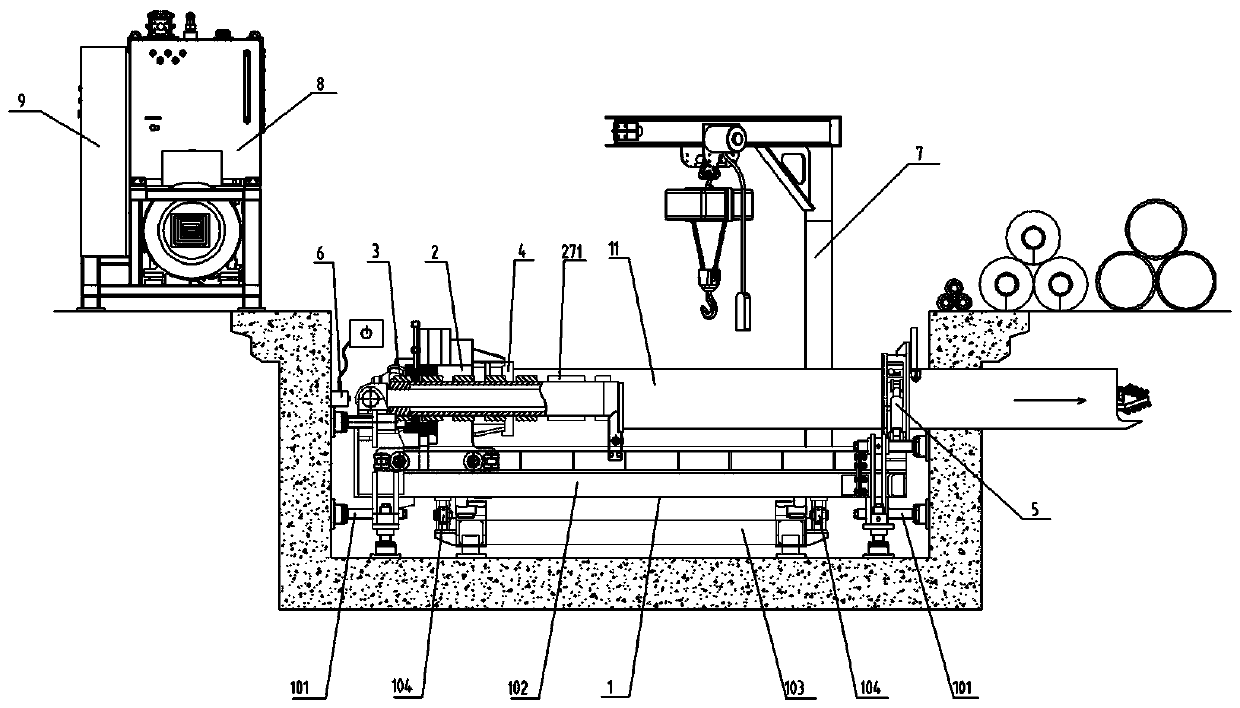

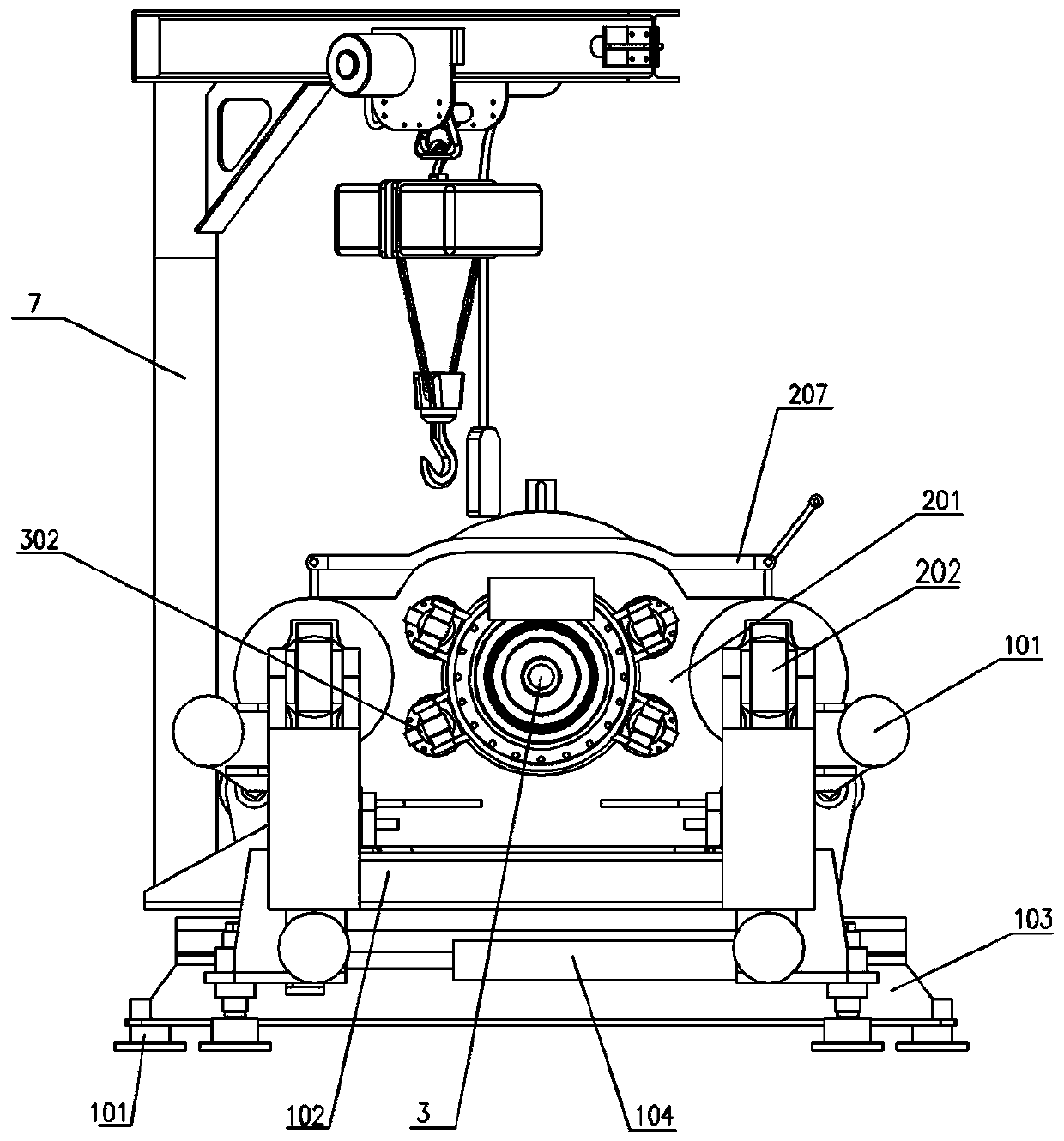

High-precision multifunctional horizontal spiral drilling rig

ActiveCN106761405AFunctional diversityEasy and safe operation controlDrilling rodsConstructionsShortest distanceFunctional diversity

The invention relates to the field of single-foundation-pit short-distance pipeline excavation tunnel construction, in particular to a bilayer translation rack, a jacking walking device, a driving power device, a rotation device and a pipe-paving direction adjusting device and further comprises an optical guide device, a hoisting device, a hydraulic pump station and an electric appliance cabinet. Stability of the whole drilling rig is improved, structure of the whole drilling rig is improved, and jacking movement tracks are more accurate; the driving power device can be used for driving a drilling stem to rotate and can be used for efficient connection among sleeves, so that pipe paving efficiency is improved; the drilling rig is flexible in construction and high in construction accuracy; the drilling rig is suitable for various strata, diverse in function, convenient and safe to operate and control, low in equipment manufacturing cost, economical and practical.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

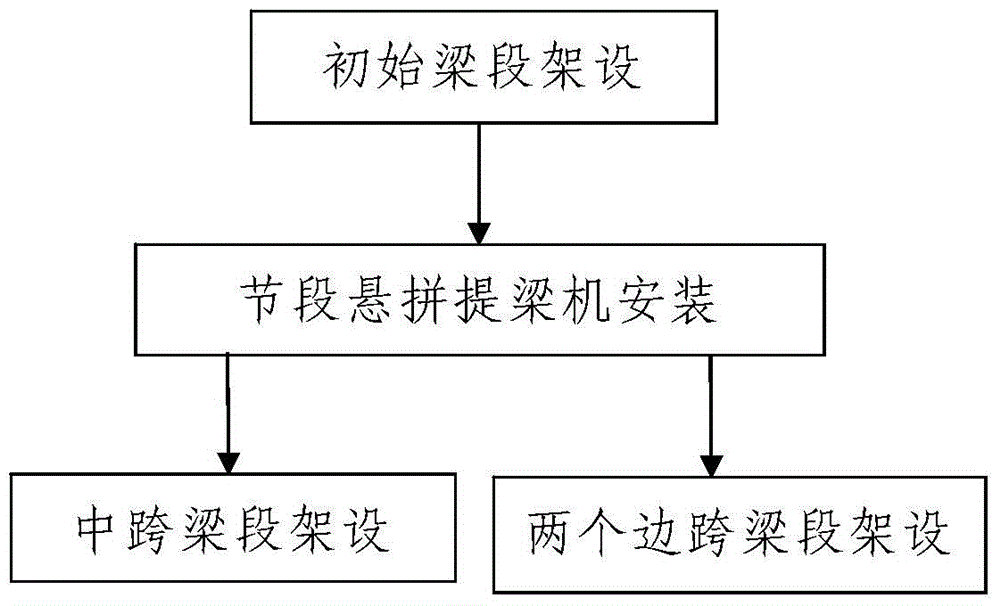

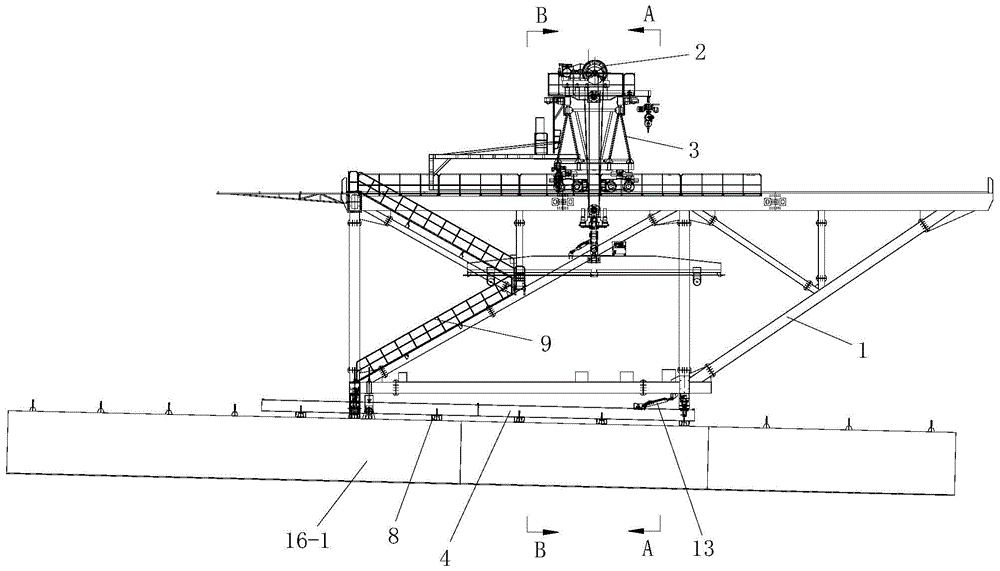

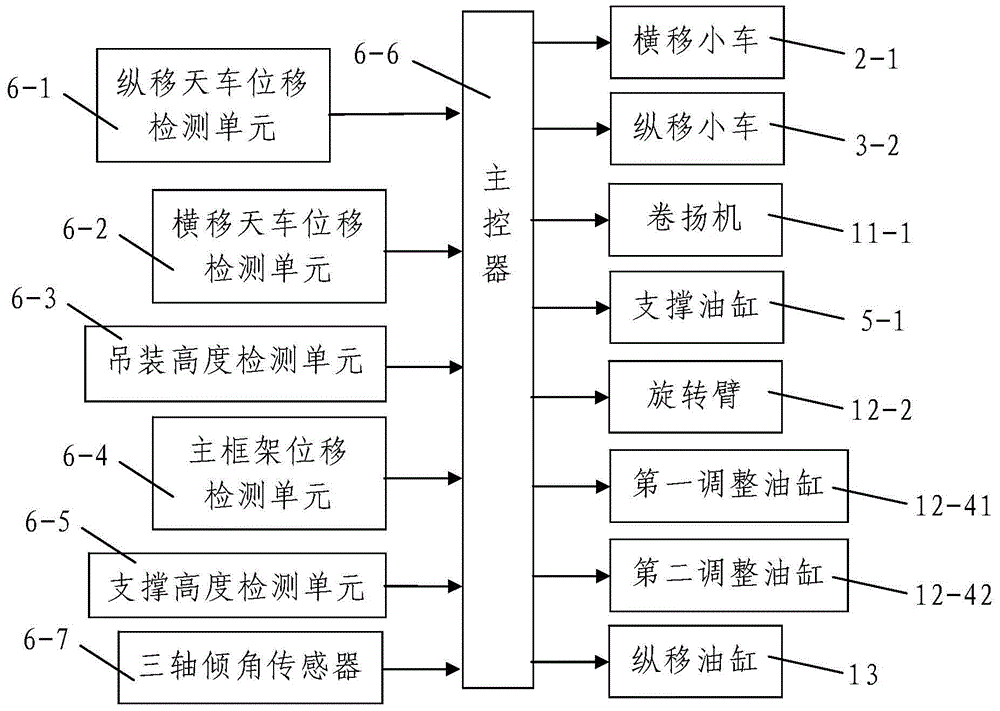

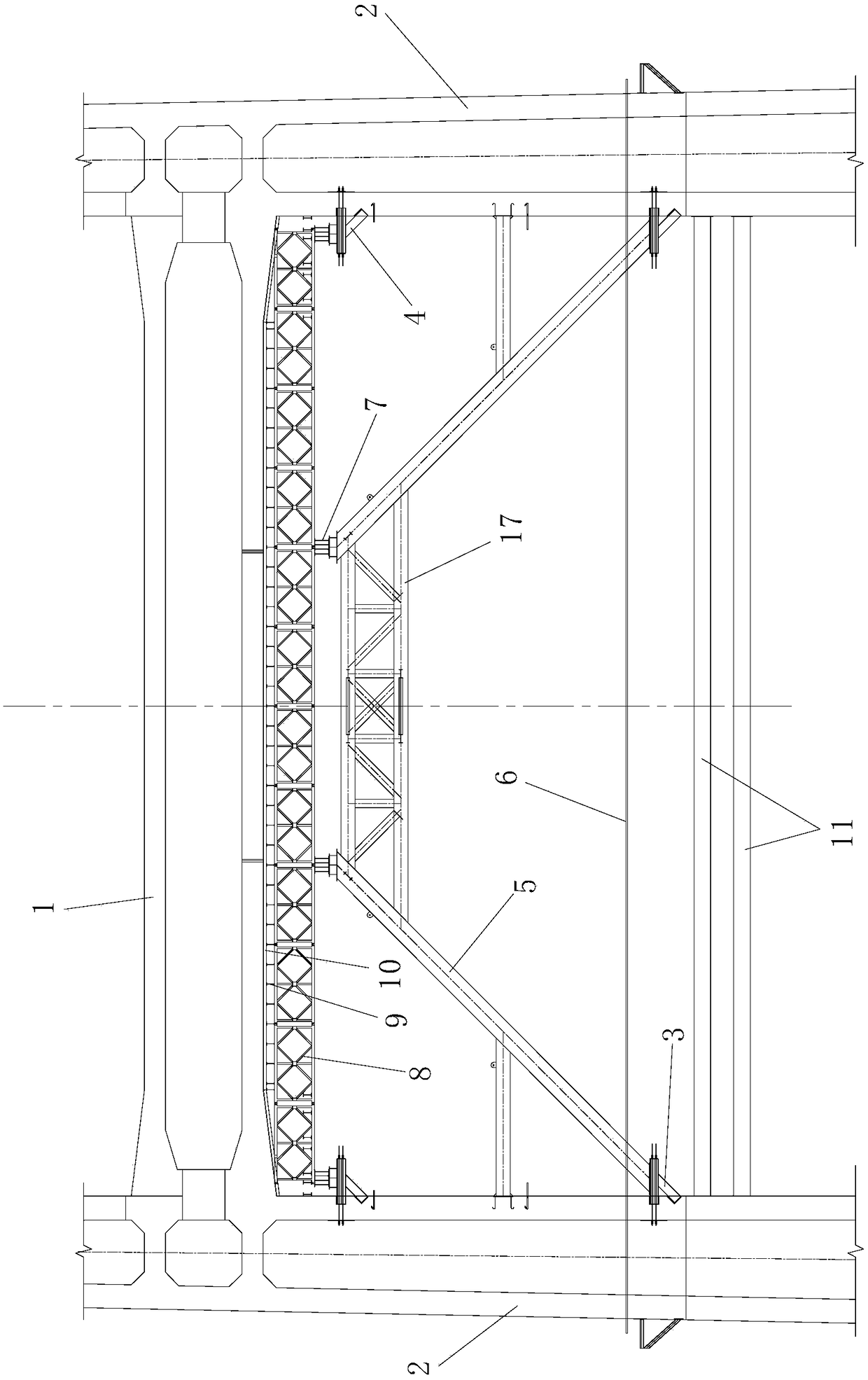

Erecting construction process for large-span steel-concrete combination beam

The invention discloses an erecting construction process for a large-span steel-concrete combination beam. The constructed steel-concrete combination beam comprises a main beam body and a concrete bridge deck slab paved on the main beam body. The main beam body is a steel beam body and comprises a mid-span beam section and two side-span beam sections. The mid-span beam section and the two side-span beam sections are connected through initial beam sections. The erecting construction process for the steel-concrete combination beam comprises the steps that 1, the initial beam sections are erected; and 2, the mid-span beam section and the two side-span beam sections are erected, specifically, the mid-span beam section and the two side-span beam sections are erected through section suspended splicing beam lifters; when erected, the mid-span beam section is erected through the two section suspended splicing beam lifters from the two sides to the middle till the mid-span beam section is closed; when erected, the two side-span beam sections are erected through the two section suspended splicing beam lifters correspondingly. According to the erecting construction process for the large-span steel-concrete combination beam, the steps are simple, the design is reasonable, construction is easy and convenient, and the using effect is good; the erecting process of the steel-concrete combination beam can be easily, conveniently and rapidly competed through the section suspended splicing beam lifters.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

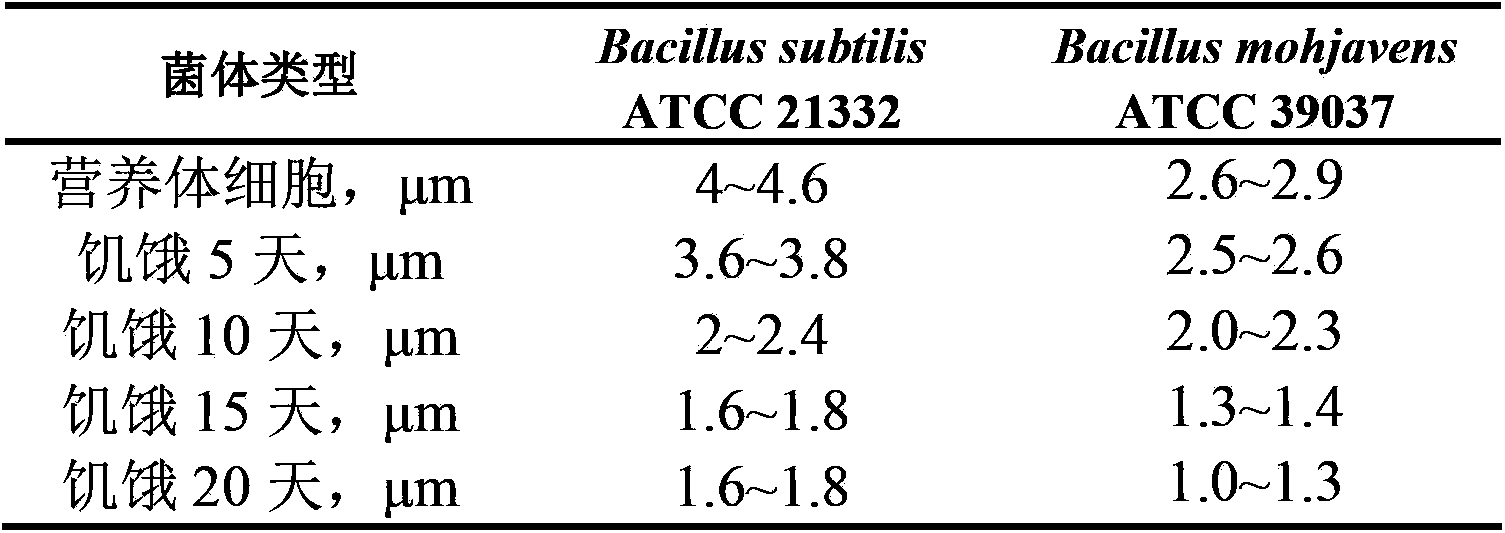

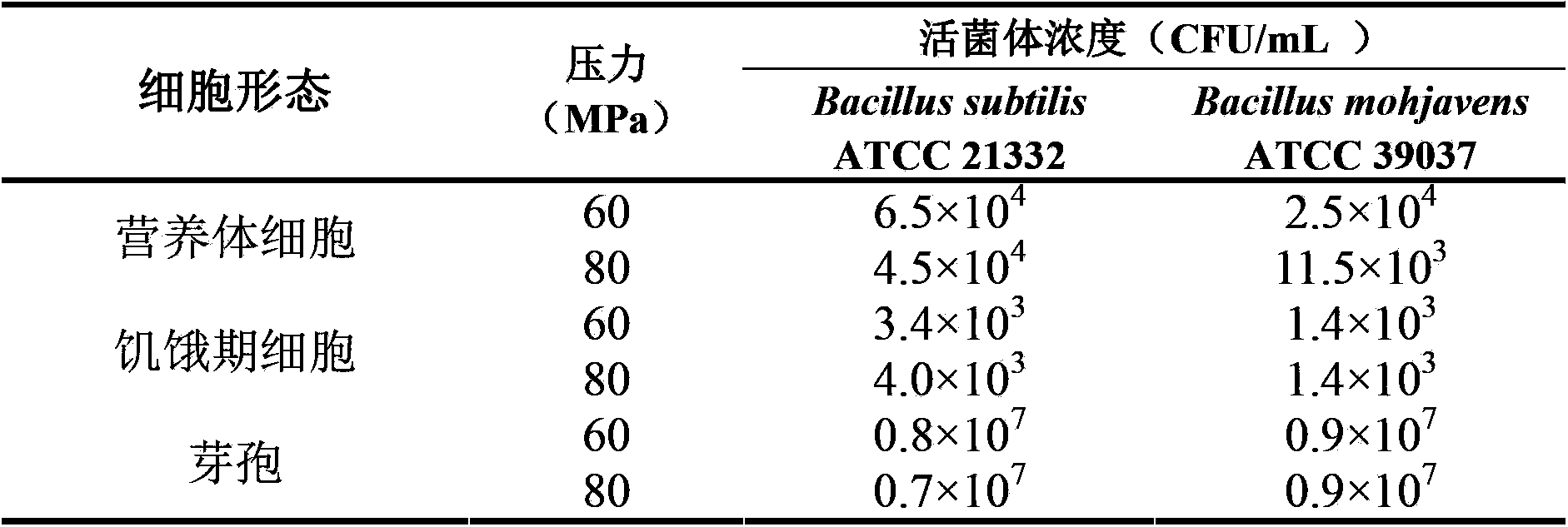

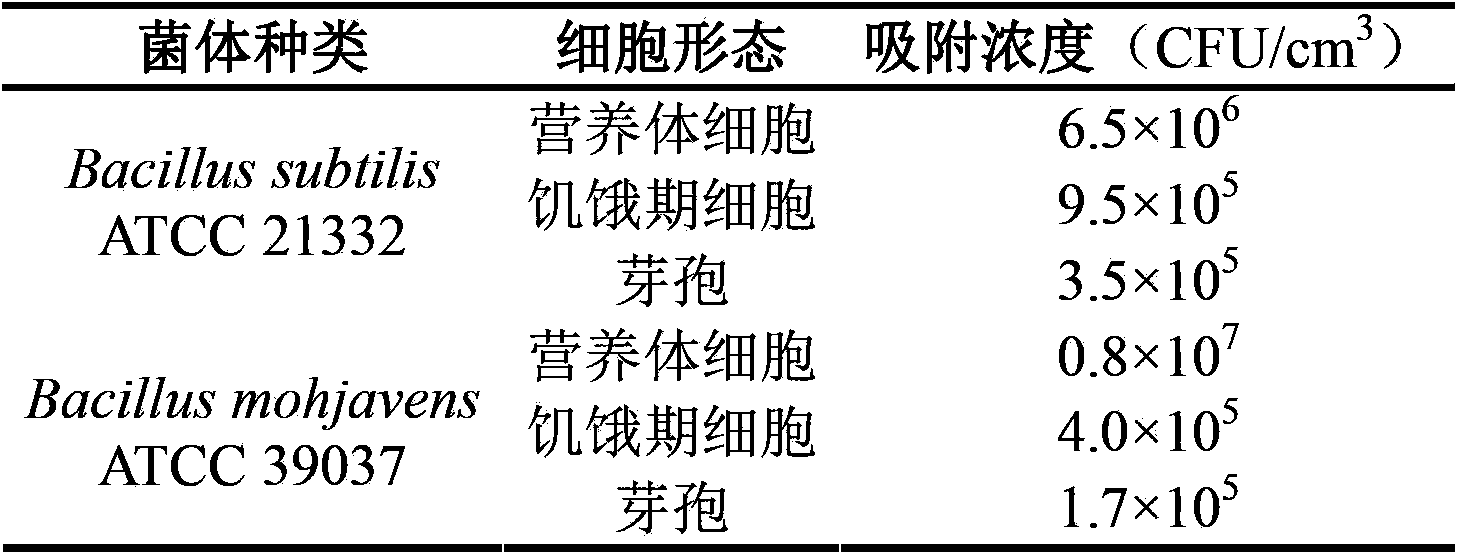

Method for conveying microorganisms to stratum

InactiveCN103912249AFlexible construction methodsImprove efficiencyFluid removalRecovery factorsEnhanced oil recovery

The invention provides a method for conveying microorganisms to a stratum. The method is characterized in that microorganisms are carried in a viscous fluid and then go into the stratum by use of a hydraulic fracturing technology, wherein the microorganisms are pretreated so that the microorganisms are in at least one of the following existence forms: a vegetative cell suspension, a starvation-stage cell suspension and a spore suspension. The method realizes carrying the microorganisms deep into the stratum by use of the hydraulic fracturing technology; the microorganisms are appropriately pretreated so that higher conveying efficiency is achieved, and therefore, the microorganisms are enabled to be better in pressure resistance and migration capability, and higher in survival rate. The provided method is advantageous for guaranteeing that related engineering technical operations can be carried out deep into the stratum by using the microorganisms, and especially advantageous for utilizing the microorganisms in the fields of improving the production capacity of a fractured well, improving the oil recovery factor and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flame-retardant single-component moisture-cured silicone rubber and its construction method and application

ActiveCN107033599BExtended shelf lifeImprove electrical insulation strengthRubber materialPolymer science

The invention provides a flame-retardant single-component moisture-curable silicone rubber and a preparation method and application thereof and belongs to the field of organic silicon rubber materials. The preparation method of the flame-retardant single-component moisture-curable silicone rubber is characterized in that alpha,omega-hydroxyl-terminated polydimethylsiloxane serves as a basic resin, alkoxy silane serves as a cross-linking agent, organic tin serves as a catalyst, meanwhile reinforcing filler, increment filler, a fire retardant, hydroxyl scavenging agent and other components are adopted for matching, and the silicone rubber is obtained through vacuum kneading and mixing, extrusion and lamination and vacuum package. The silicone rubber is a single-component band-shaped or flaky material, is stable in appearance, has a certain initial strength and flexibility, and has good insulativity, weather resistance, heat resistance, acid-base resistance and flame retardant properties after moisture curing. The silicone rubber has good appearance and plasticity, can be attached in a planar mode, wound and bound, or be plugged, blocked and filled in joints and has the wide application prospect in the fields of cable damage repairing, insulated protection of exposed electrical connecting points and the like. The flame-retardant single-component moisture-curable silicone rubber is simple in preparation process and is especially suitable for industrial production, and the raw materials are wide in source.

Owner:HUNAN AEROSPACE SANFENG SCI & TECH CO LTD

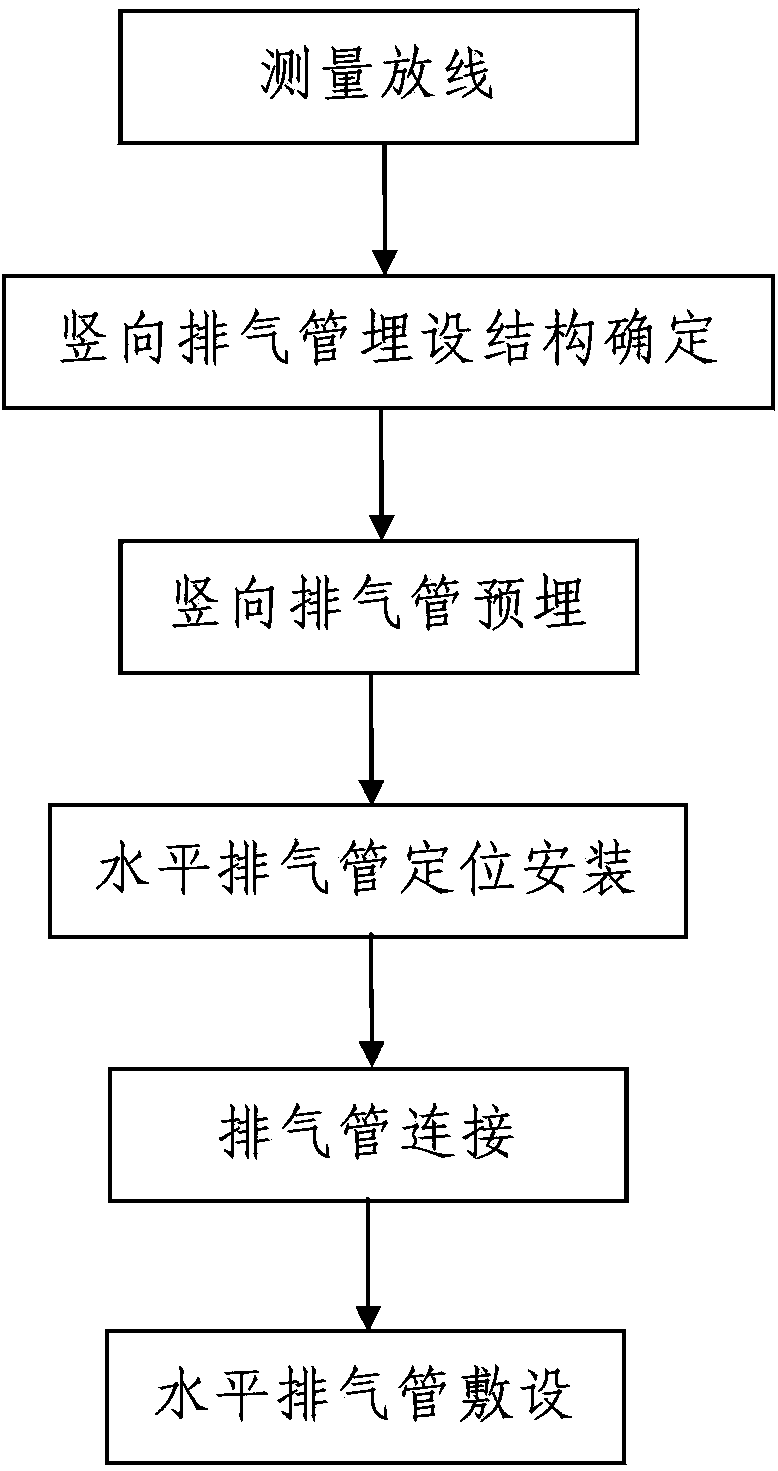

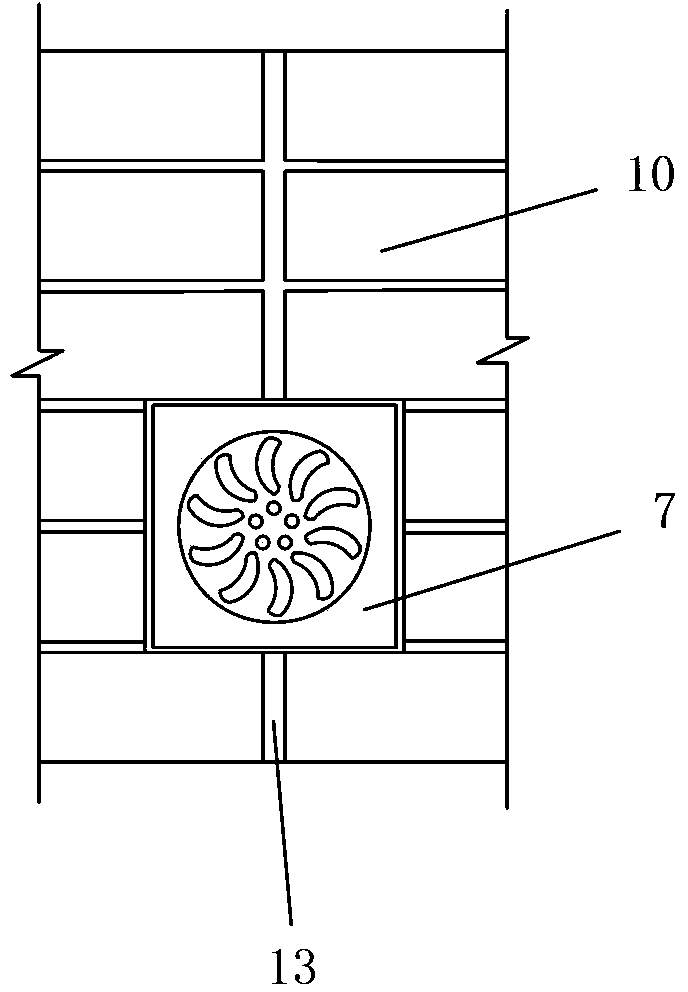

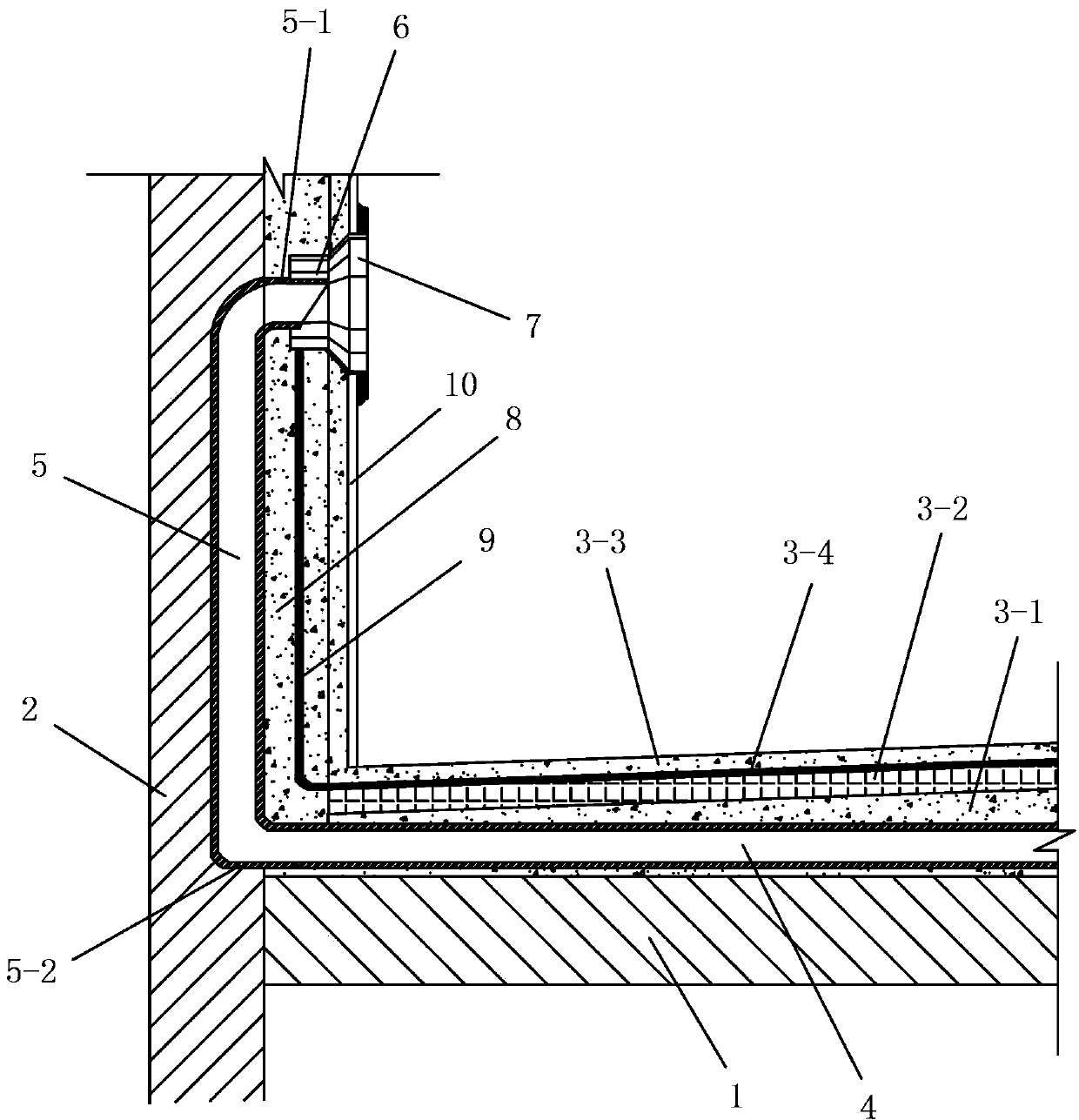

Construction process of concealed roofing exhaust hole

InactiveCN103362257AGuarantee the construction qualityConstruction quality is easy to controlLighting and heating apparatusRoof covering ventilationsReinforced concreteRebar

The invention discloses a construction process of concealed roofing exhaust holes, wherein a roofing exhaust system is arranged on a constructed roofing, the roofing exhaust system comprises sloping layers which are uniformly laid in a roofing layer or a plurality of first horizontal exhaust pipes which are uniformly laid in a heat-insulating layer; both ends of each first horizontal exhaust pipe are respectively connected with a vertical exhaust pipe; and the vertical exhaust pipe is buried into a parapet, the lateral wall of a discharge flue or the lateral wall of an exhaust passage, and the parapet, the discharge flue and the exhaust passage are all of reinforced-concrete structures. The construction process of the concealed exhaust holes comprises the following steps of 1, measuring and releasing lines; 2, determining the buried structures of the vertical exhaust pipes; 3, pre-burying the vertical exhaust pipes; 4, positioning and installing the horizontal exhaust pipes; 5, connecting the exhaust pipes; and 6, laying the horizontal exhaust pipes. The construction process of the concealed roofing exhaust holes has the advantages of simple process step and reasonable design, the using effect of the molded roofing exhaust system through construction is good, and the problems of easy blockage, easy damage, unsmooth exhaust, poorer exhaust effect and the like existing in the existing exposed mode of the exhaust holes can be solved.

Owner:陕西建工集团有限公司 +1

Continuous beam structure provided with V-shaped webs and construction method of continuous beam structure

InactiveCN106192726ASimple structureReasonable designBridge structural detailsBridge erection/assemblySupporting systemContinuous beam

The invention discloses a continuous beam structure provided with V-shaped webs and a construction method of the continuous beam structure. The continuous beam structure provided with the V-shaped webs comprises a bridge lower part support system and a combination box beam erected on the bridge lower part support system, wherein the combination box beam comprises a top plate, a bottom plate located below the top plate as well as a left V-shaped web and a right V-shaped web which are symmetrically connected between the top plate and the bottom plate; the top plate and the bottom plate are concrete slabs formed by casting UHPC (ultra-high performance concrete), each V-shaped web comprises a plurality of V-shaped precast slabs and is arranged in the longitudinal bridge direction, and the V-shaped precast slabs are V-shaped precast concrete slabs formed by casting UHPC. The construction method comprises the following steps: 1, constructing the bridge lower part support system and prefabricating the V-shaped precast slabs; 2, constructing the combination box beam. The continuous beam structure provided with the V-shaped webs and the construction method of the continuous beam structure have the advantages that the design is reasonable, the construction is simple and convenient, the using effect is good, the top plate and the bottom plate made of the UHPC are combined with the V-shaped webs made of the UHPC, and the stress performance and the durability of a bridge are improved effectively.

Owner:XIAN HIGHWAY INST

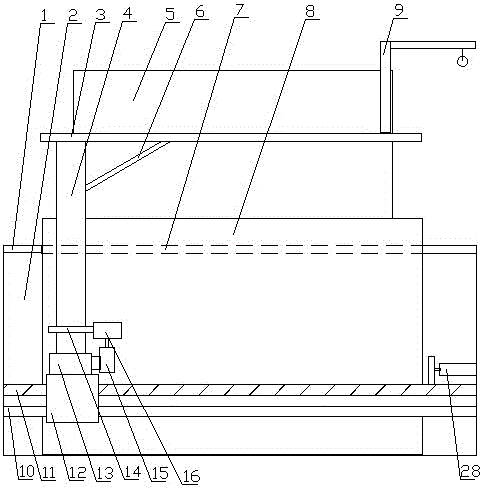

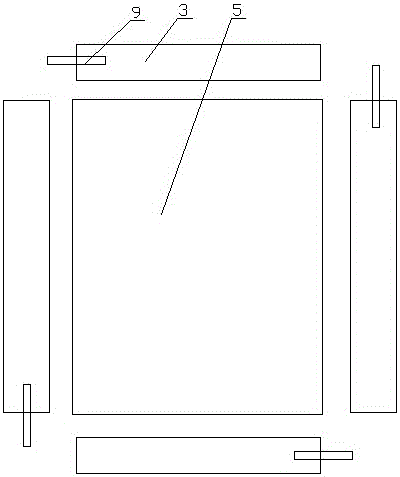

Integrated multifunctional movable construction equipment

InactiveCN103707420ARealize mobile constructionFlexible construction methodsMixing operation control apparatusMixing operation plantControl systemProcess engineering

The invention provides integrated multifunctional movable construction equipment, which can independently finish transportation, preparation and construction works of casting materials such as concrete, mortar and neat paste. The equipment comprises the following 7 parts: a movable carrier, a power system, a material system, a delivery system, a stirring system, a control system and an auxiliary tool module, wherein a vehicle and a ship are used as the movable carrier; a combined movable engine capable of meeting the power requirements of the equipment is used as the power system; the material system is used for feed, storage and preparation of powdery materials, granular materials, lumpish materials, fibrous materials and liquid materials; the delivery system is used for sequentially adding materials in a stock bin into the stirring system according to a proportion and also regulating the temperature of the materials; the stirring system can be used for adding trace materials and compulsively stirring the materials uniformly; the control system is used for controlling the modules to achieve an integral function according to requirement and sequence; the auxiliary tool module mainly comprises a power supply interface and simple construction equipment, and the construction equipment can be flexibly selected and matched.

Owner:SHENZHEN ACAD OF AEROSPACE TECH

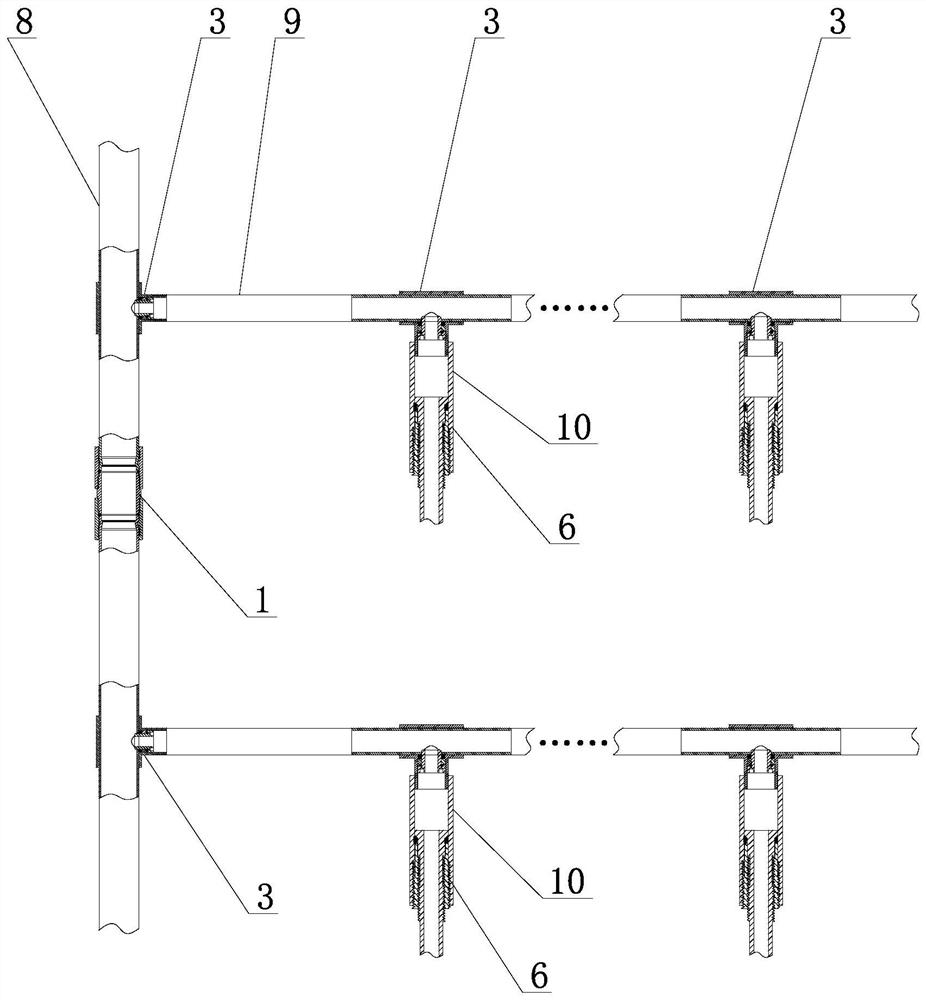

A high-altitude large-span heavy-duty beam construction support and construction method

ActiveCN106677070BSimple structureEasy to processBridge erection/assemblySupporting systemPipe support

The invention discloses a construction support and method for an overhead large-span heavy-duty cross beam. The construction support comprises a lower bracket supporting structure, an upper bracket supporting structure located above the lower bracket supporting structure, and a middle supporting structure with the bottom supported on the lower bracket supporting structure. The top face of the upper bracket supporting structure is flush with the top face of the middle supporting structure, and the upper bracket supporting structure and the middle supporting structure form a temporary supporting platform for supporting the cross beam to be constructed. A load bearing structure is erected on the temporary supporting platform. The construction method comprises the steps that firstly, the lower bracket supporting structure is installed; secondly, the upper bracket supporting structure and the middle supporting structure are installed; thirdly, the load bearing structure is erected; fourthly, the support is prepressed; fifthly, the upper cross beam is constructed; and sixthly, the support is removed. According to the construction support and method, design is reasonable, construction is easy and convenient, the using effect is good, and the problems that as for an existing floor steel pipe supporting system, cost is high, the erection process is complex, the construction period is long, the construction risk is high, the requirement for supporting stability is high, and the construction progress of the upper cross beam is affected can be effectively solved.

Owner:CHINA RAILWAY FIRST GRP CO LTD +2

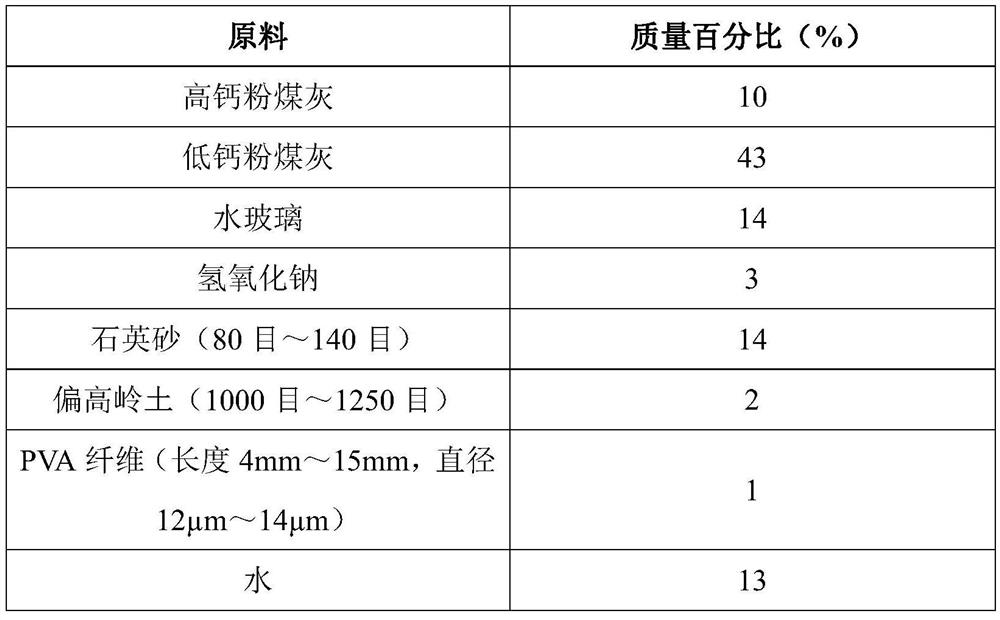

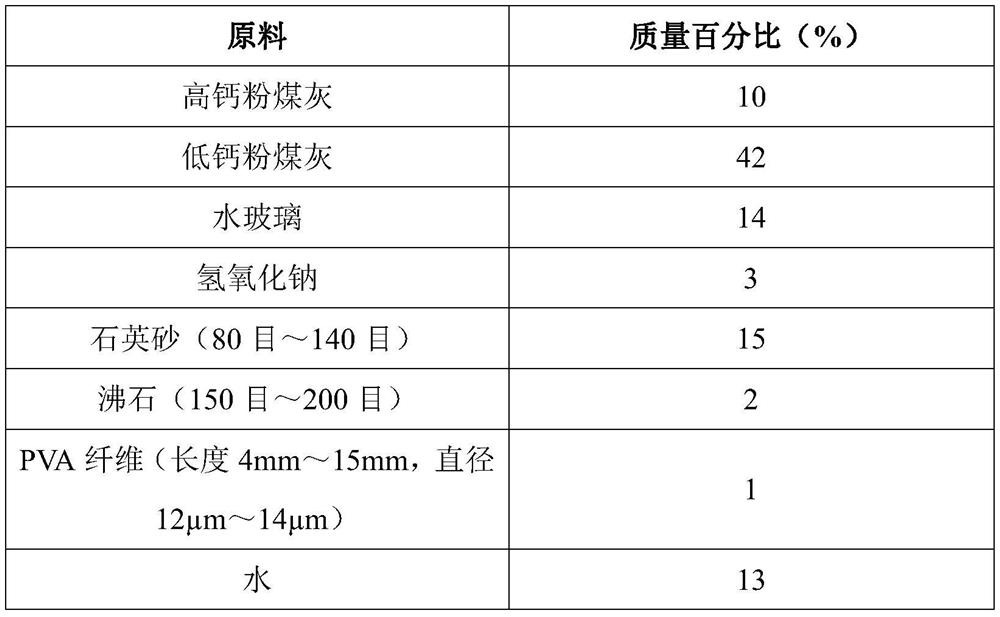

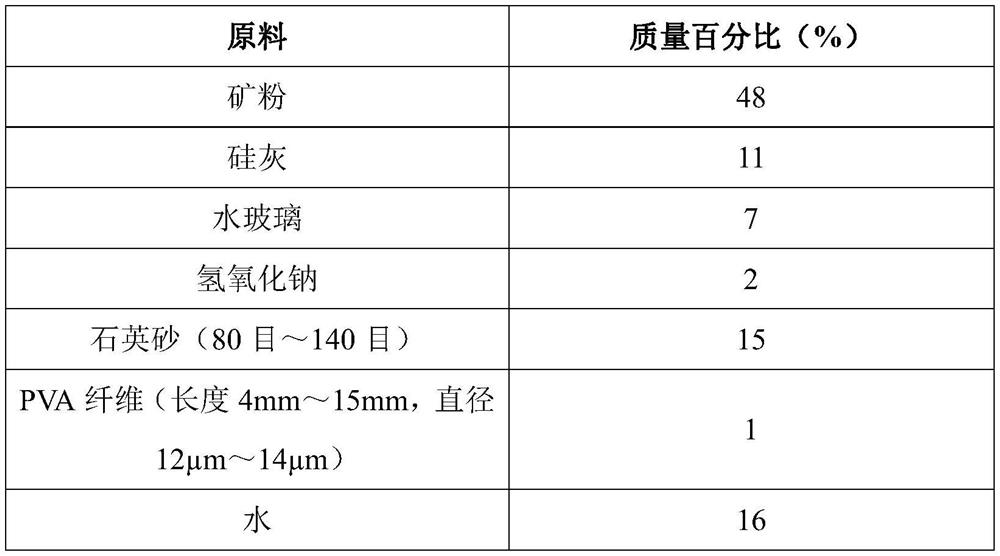

Building coating and preparation method thereof

The invention discloses a building coating and a preparation method thereof. The building coating is composed of a cementing material, water glass, sodium hydroxide, quartz sand, metakaolin, zeolite, fibers and water. The preparation method comprises the following steps: mixing the cementing material, the quartz sand, the metakaolin and the zeolite, stirring, adding the water glass, the sodium hydroxide and the water, stirring, adding the fibers, and stirring to obtain the building coating. A coating layer formed by the building coating has ultrahigh toughness and excellent strain hardening characteristics, can still provide protection for a structure or a component matrix after being subjected to large deformation, is high in anti-permeability grade and excellent in bonding performance, and can be widely applied to surface protection of various building structures and components thereof; and the coating can also be used for reinforcing and maintaining aged and damaged building structures.

Owner:SOUTH CHINA UNIV OF TECH

Auxiliary working platform of substation transformer

The invention discloses an auxiliary working platform of a substation transformer. The auxiliary working platform comprises a pit base, a transformer foundation arranged in the center of the pit base, a transformer arranged on the foundation, and a steel frame platform arranged above the pit base, wherein a groove body is arranged around the transformer; the groove body is provided with a cover plate mechanism; a lifting mechanism used for driving the cover plate mechanism is arranged below one end of the groove body; the lifting mechanism is arranged on a translation mechanism; and an L-shaped hoisting frame is movably arranged at the front end of the cover plate mechanism. When the transformer is overhauled, specific equipment or part can be hoisted and moved without other hoisting equipment to perform an auxiliary operation, so that potential safety hazard caused by movement of a large-scale hoisting apparatus in the transformer can be avoided; and therefore, the transformer can be overhauled and maintained by a staff more conveniently, and safety of the overhaul operation is also improved.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY +1

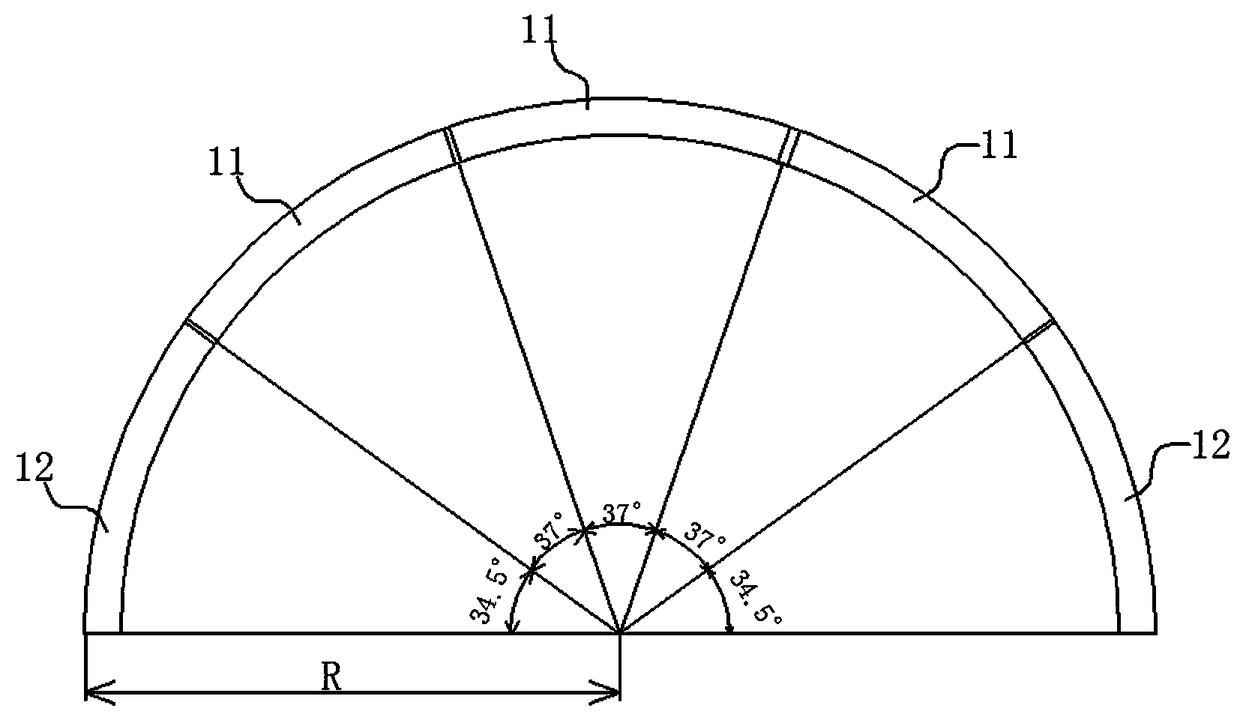

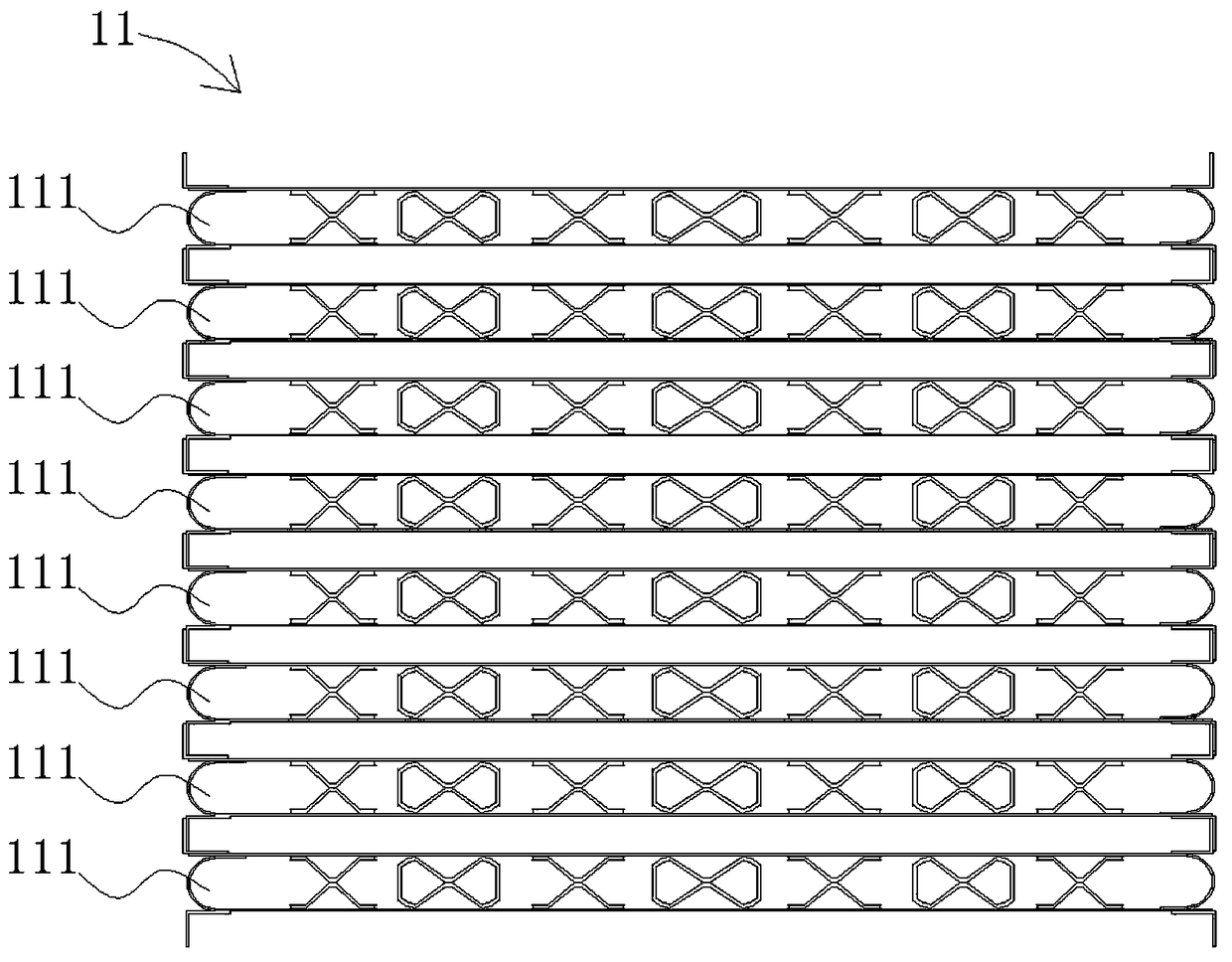

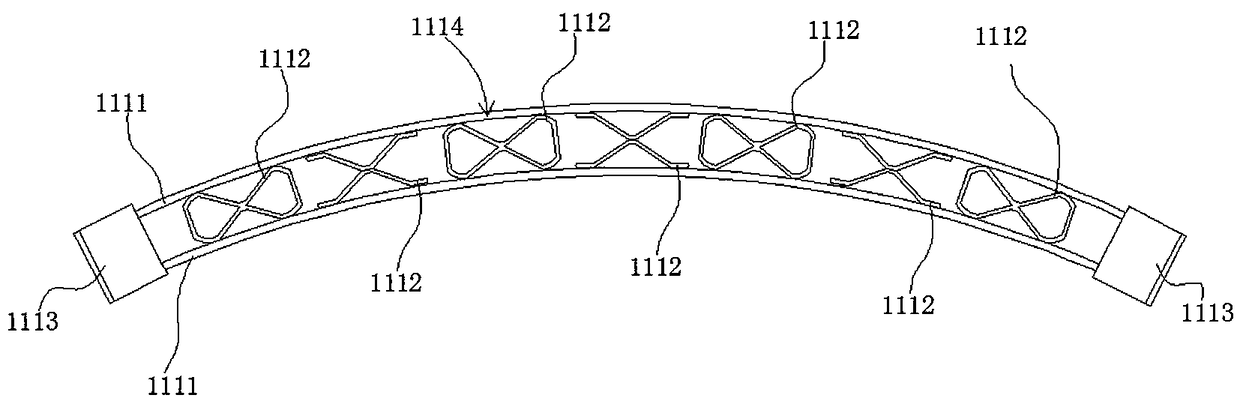

Grid steel frame, grid steel frame trial assembling device and grid steel frame manufacturing method

PendingCN108457679AFlexible construction methodsEasy to installUnderground chambersWelding/cutting auxillary devicesSteel frameMechanical engineering

The invention discloses a grid steel frame, a grid steel frame trial assembling device and a grid steel frame manufacturing method. The grid steel frame comprises a plurality of grid modules, the gridmodules are of cambered surface shape, each grid module is composed of a plurality of bracket units connected in front and rear, the left and right sides of each grid module are assembled into the grid steel frame, the grid steel frame is generally of 180-degree cambered surface shape, and when the grid steel frame is installed in a tunnel, the grid steel frame can be easily installed at the topof the tunnel as a support. The grid steel frame trial assembling device comprises a plurality of pedestals, the pedestals are arranged in an arc shape corresponding to the grid steel frame, left limit baffles and right limit baffles of each of the pedestals form an arc-shaped passage corresponding to the grid steel frame, whether or not the bracket units assembled together can be matched with thearc-shaped passage is observed to check whether the manufactured bracket units are qualified, and the qualification rate of the manufactured bracket units can be ensured.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Fire-fighting pipeline mounting system and construction method

PendingCN112370708AImprove construction efficiencyReduce on-site processingFire rescueBranching pipesPipeScrew thread

The invention relates to a fire-fighting pipeline mounting system and a construction method. The fire-fighting pipeline mounting system comprises a pipeline connecting mechanism, wherein the pipelineconnecting mechanism is used for pipeline series connection and comprises a pipe joint, locking nuts are connected to the two ends of the pipe joint respectively, a pipeline A is sleeved with the locking nuts, a sealing ring A is arranged between the pipeline A and the pipe joint, a limiting groove is formed in the outer wall of the pipeline A, and an elastic clamping piece is arranged on the inner wall of the pipe joint; a three-way connecting mechanism which comprises a pipe A and a pipe B which are perpendicularly connected, wherein the pipe A is arranged on a pipeline B in a sleeving mode,a through hole is formed in the position, corresponding to the pipe B, of the pipeline B, the diameter of the through hole is smaller than the inner diameter of the pipe B, a positioning pipe is in threaded connection in the pipe B, and a sealing piece is arranged between the positioning pipe and the pipe A; and a spraying height adjusting mechanism which comprises a height adjusting pipe, wherein the height adjusting pipe is in threaded connection with a pipeline C, a special-shaped spraying pipe is in threaded connection with the interior of the height adjusting pipe, and a sealing ring C is arranged on the special-shaped spraying pipe. The fire-fighting pipeline mounting system and the construction method have the advantages of reasonable structural design, fast pipeline connection, convenient tee joint connection, adjustable spraying pipe height, flexible construction process and the like.

Owner:速安云科技有限责任公司

Carst region double-arch road tunnel construction method

ActiveCN101864960BReasonable designSimplify construction stepsUnderground chambersTunnel liningTunnel constructionChannel inlet

The invention discloses a carst region double-arch road tunnel construction method, which comprises the following steps; 1. carrying out construction preparation; 2. carrying out construction at channel openings; 3. adopting a three-pilot-tunnel method for constructing the channel inlet opening section, and adopting a step digging method for digging during the three-pilot-tunnel method construction; 4. adopting a middle-pilot-tunnel method for constructing the middle communication section of the channel, and adopting a full cross section method for digging during the middle-pilot-tunnel method construction; 5. adopting the three-pilot-tunnel method or the middle-pilot-tunnel method for constructing the channel outlet opening section, adopting the step digging method for digging when the middle-pilot-tunnel method is adopted for digging construction of the channel outlet opening section, and synchronously carrying out secondary lining construction from the front part to the back part in the digging construction process of the channel inlet opening section, the middle communication section of the channel and the channel outlet opening section. The invention has the advantages of reasonable design, simple and convenient construction, safe and reliable construction process, flexible construction mode, short construction period and greatly simplified construction steps, and effectively overcomes various defects during the traditional carst region double-arch road tunnel construction.

Owner:CHINA RAILWAY 20 BUREAU GRP CORP LTD +3

Thermal repair material for carbon-free refined ladle base brick and preparation method thereof

The present invention discloses a carbon-free refined steel ladle base brick thermal-state repair material and a preparation method thereof. The repair material comprises 50-75 wt% of bauxite aggregate or corundum aggregate, 10-30 wt% of corundum fine powder, 4-10 wt% of magnesia fine powder, 4-10 wt% of spinel fine powder, 0.5-4 wt% of SiO2 micro-powder, 1-5 wt% of alpha-Al2O3 micro-powder, and 1-5 wt% of a binder. According to the production method, the repair material is adopted as a raw material, a water reducing agent accounting for 0.1-0.2 wt% of the repair material and a sintering agent accounting for 1-2 wt% of the repair material are added, the obtained mixture is placed into a stirrer, and complete and uniform stirring is performed to obtain the carbon-free refined steel ladle base brick thermal-state repair material. According to the present invention, the defects of the traditional base brick repair material are overcome; the preparation method is simple and easy to perform; the dry construction can be achieved, and the water can be added on the site to form the self-flowing material so as to construct; the construction is simple, safe and environment-friendly, and the quick base brick repair can be achieved; and the material has characteristics of low cost, excellent use performance, and flexible construction method.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Self-supporting butterfly-shaped leading-in optical cable convenient for construction

PendingCN112198612AFlexible construction methodsFast constructionFibre mechanical structuresMechanical engineeringOptics

The invention belongs to the technical field of communication optical cables, and particularly relates to a self-supporting butterfly-shaped leading-in optical cable convenient for construction. The self-supporting butterfly-shaped leading-in optical cable is provided with a butterfly-shaped leading-in unit, a connecting rib and a hanging body, and is characterized in that the upper surface of thehanging body is a plane, the left-right symmetrical plane of the connecting rib coincides with the left-right symmetrical plane of the hanging body, the left-right symmetrical plane of the connectingrib perpendicularly and equally divides the hanging body, the left-right symmetrical plane of the connecting rib coincides with the left-right symmetrical plane of the butterfly-shaped leading-in unit, a first downward-protruding part extending downwards is arranged at the left end of the hanging body, a second downward-protruding part extending downwards is arranged at the right end of the hanging body, a first hanging groove is formed among the first downward-protruding part, the hanging body and the connecting rib, and a second hanging groove is formed among the second downward-protrudingpart, the hanging body and the connecting rib. The self-supporting butterfly-shaped leading-in optical cable has the following main beneficial effects that the construction modes are flexible and diverse, the construction speed is high, products are easy to manufacture, and the percent of pass is high.

Owner:SUIZHOU POWER SUPPLY COMPANY STATE GRID HUBEI ELECTRIC POWER +1

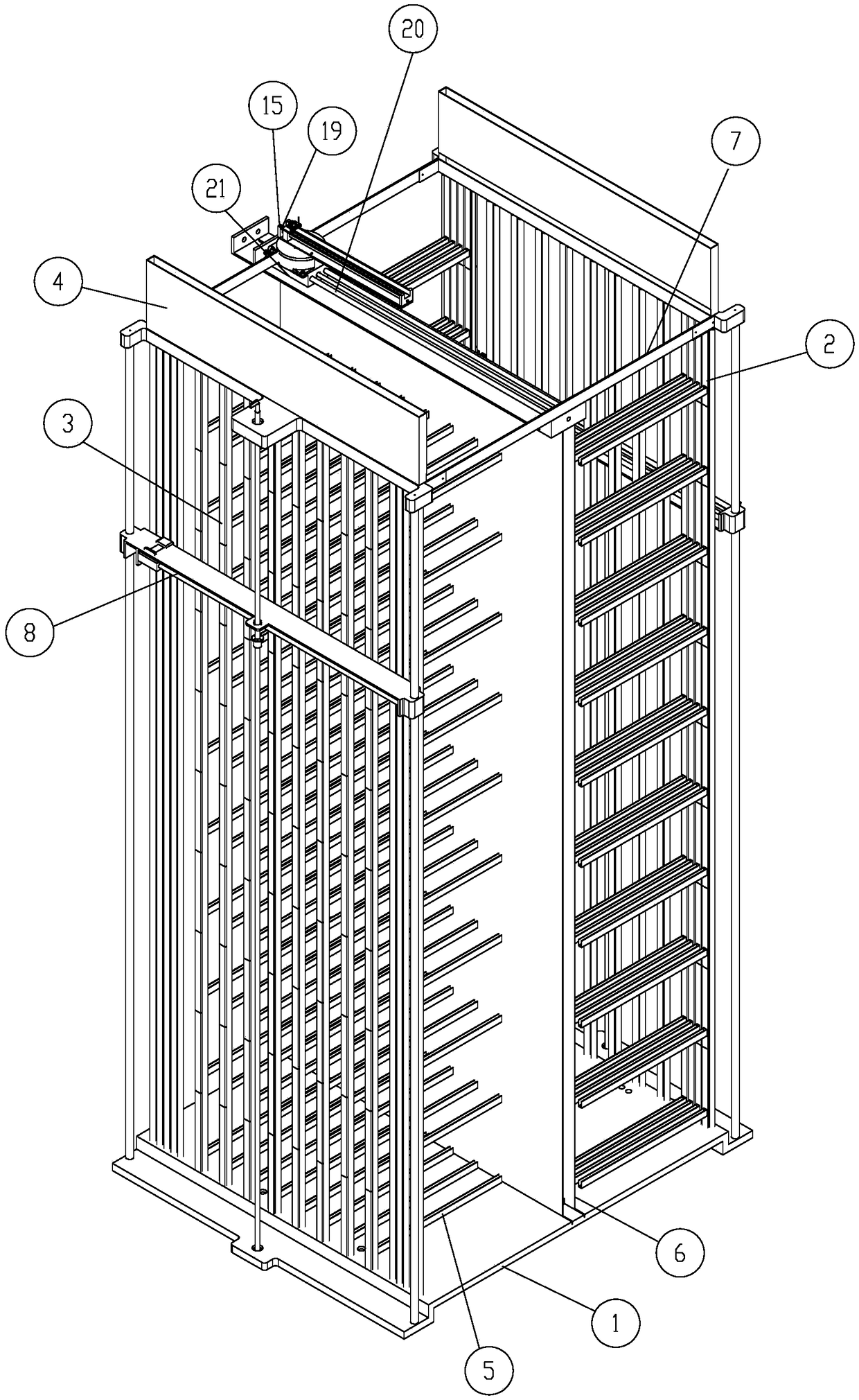

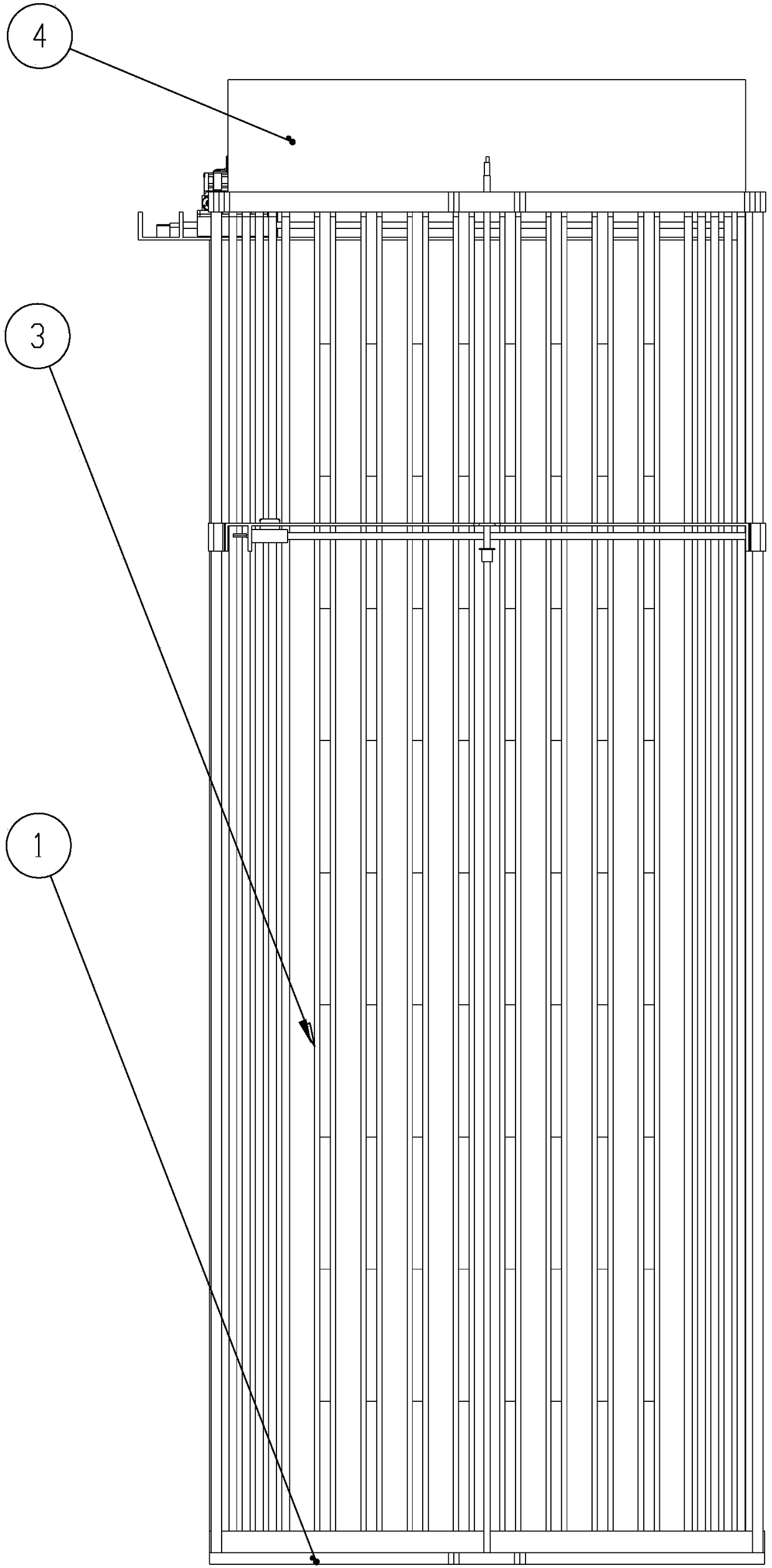

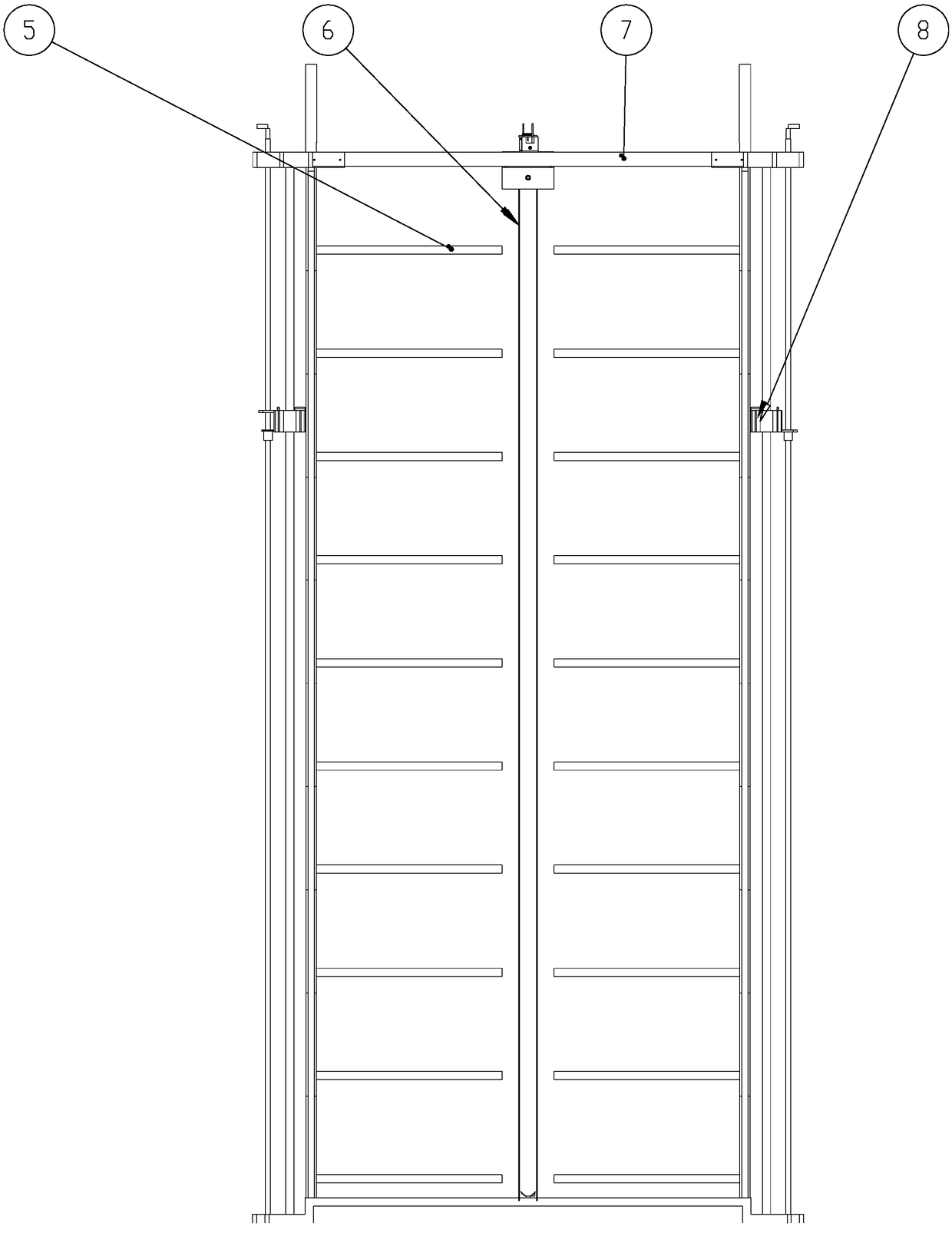

Stereo garage for shared bicycles

The invention discloses a stereo garage for shared bicycles. The stereo garage comprises a weighing board which is arranged horizontally, wherein a bicycle blocking board, a parking frame optical axisguide rail group and a storage unit are arranged on the upper board side of the weighing board in a manner of being vertical to the weighing board; the inner side of the parking frame optical axis guide rail group is provided with a parking frame in a manner of facing the bicycle blocking board; the inner side of the storage unit is provided with a bicycle guide frame in a manner of facing the bicycle blocking board; the bicycle blocking board and the parking frame optical axis guide rail group are arranged in parallel; the bicycle blocking board and the storage unit are arranged in parallel;the bicycle blocking board, the parking frame optical axis guide rail group and the upper end of the storage unit are arranged in a flush manner; a cross beam is erected at the upper ends of the bicycle blocking board, the parking frame optical axis guide rail group and the storage unit; the cross beam is arranged vertical to the bicycle blocking board; the beam ends of the cross beam are provided with the parking frame guide board in parallel to the bicycle blocking board; a transverse moving frame which can move in a reciprocating manner is arranged along the length direction of the cross beam; the cross beam frame comprises a transverse moving frame base which is vertical to the cross beam; a revolving device is arranged on the cross moving frame base.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com