A high-altitude large-span heavy-duty beam construction support and construction method

A large-span, cross-beam technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems affecting the construction progress of the upper cross-beam, high support stability requirements, and complicated erection process, so as to achieve easy guarantee of processing quality and satisfy Structural force requirements and the effect of shortening the total construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

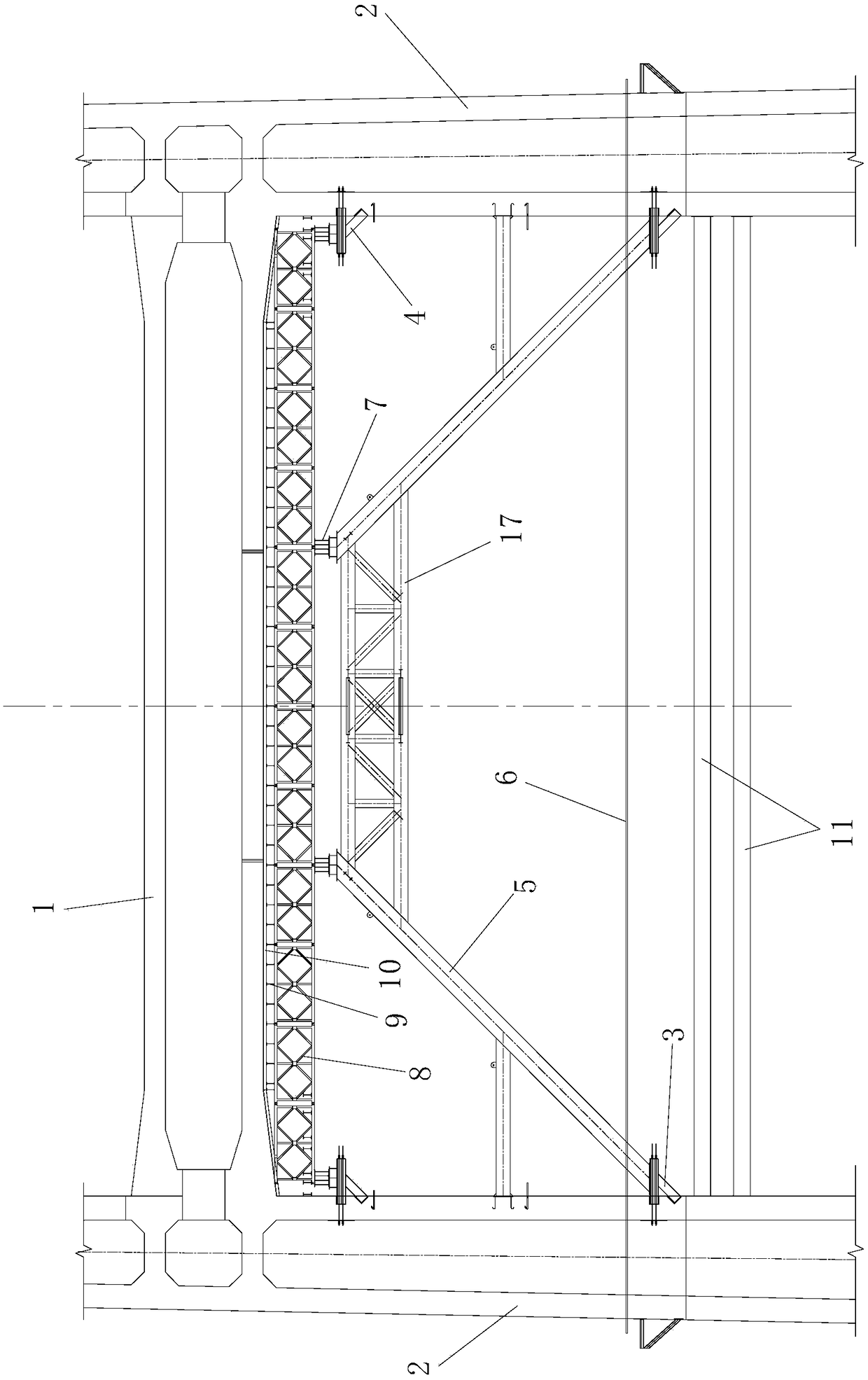

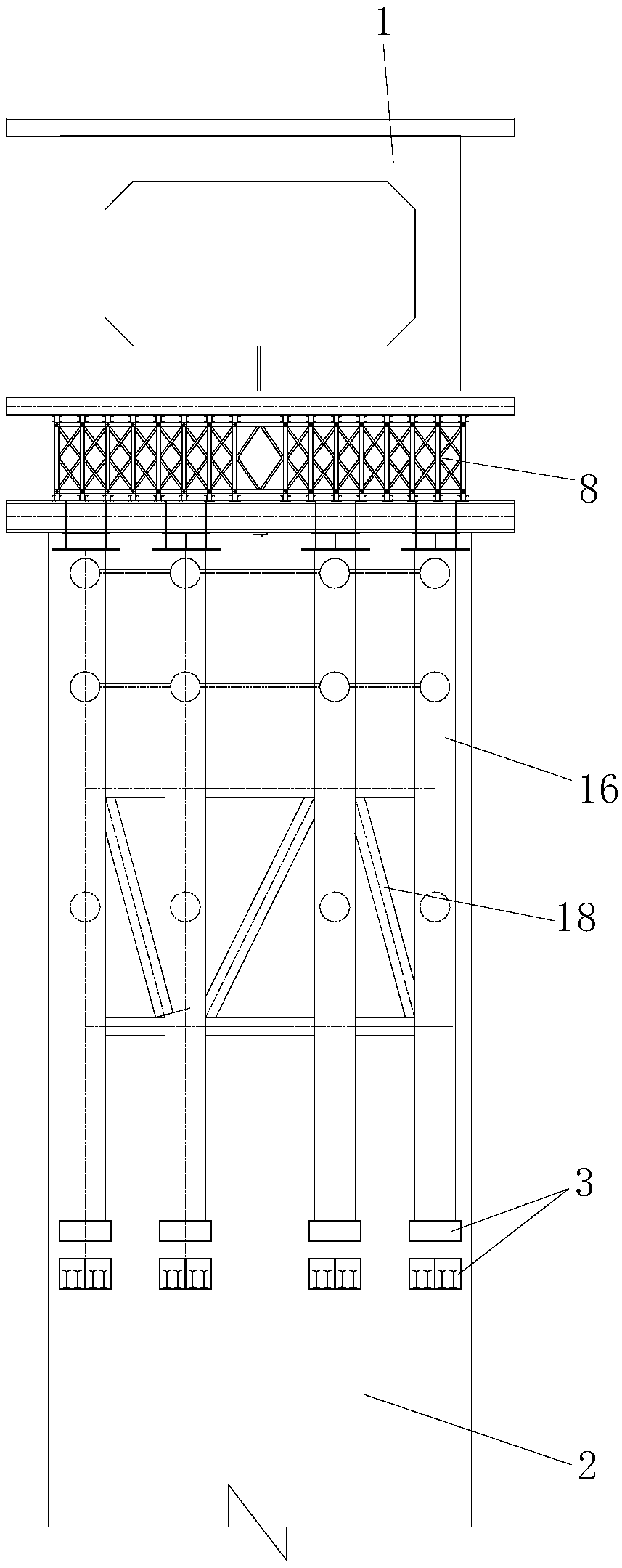

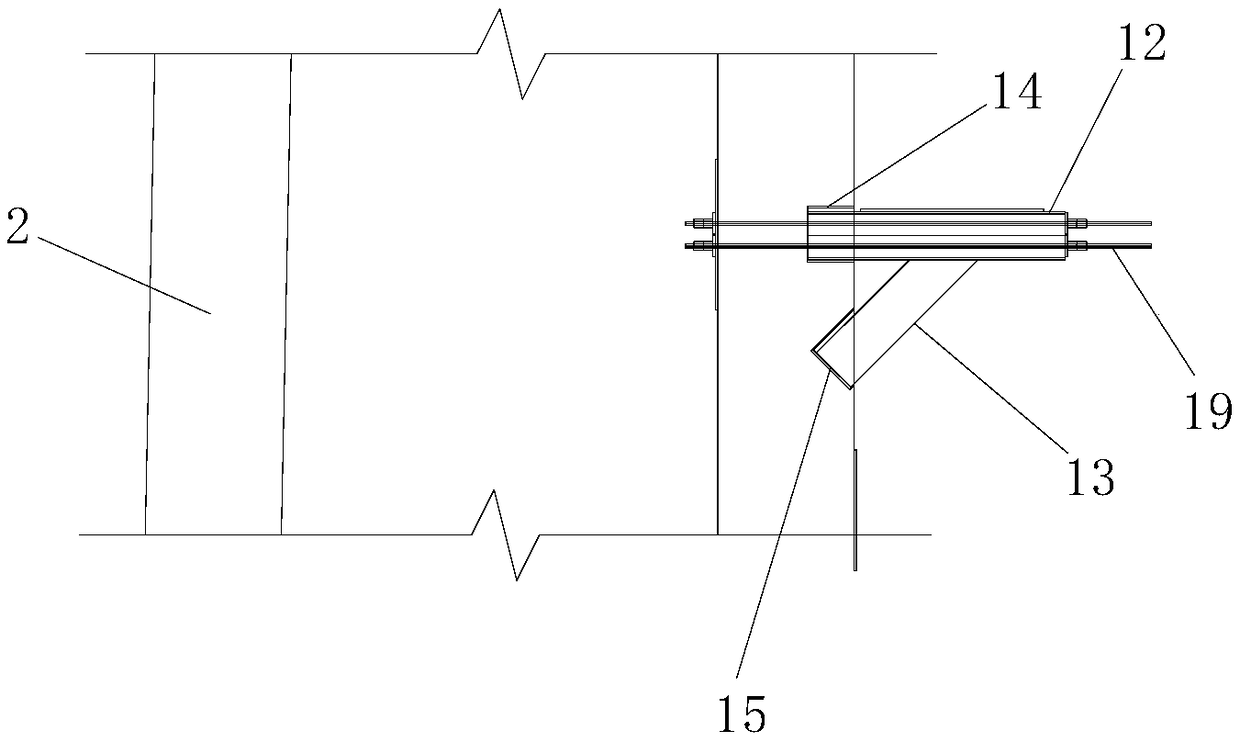

[0059] Such as figure 1 , figure 2 The shown high-altitude large-span heavy-load beam construction support includes a lower corbel supporting structure, an upper corbel supporting structure located above the lower corbel supporting structure, and a middle part of the bottom supported on the lower corbel supporting structure The supporting structure, the upper corbel supporting structure and the top surface of the middle supporting structure are flush, and the two constitute a temporary support platform for supporting the constructed beam. The constructed beam is the upper beam 1 of the cable-stayed bridge tower, The upper beam 1 is arranged horizontally and its two ends are respectively supported on the two tower columns 2 of the cable-stayed bridge tower, the upper beam 1 and the two tower columns 2 are both reinforced concrete structures; A load-bearing structure for horizontally supporting the upper beam 1 is built on the temporary support platform; the lower corbel support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com