Patents

Literature

41results about How to "Improve hot melt efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

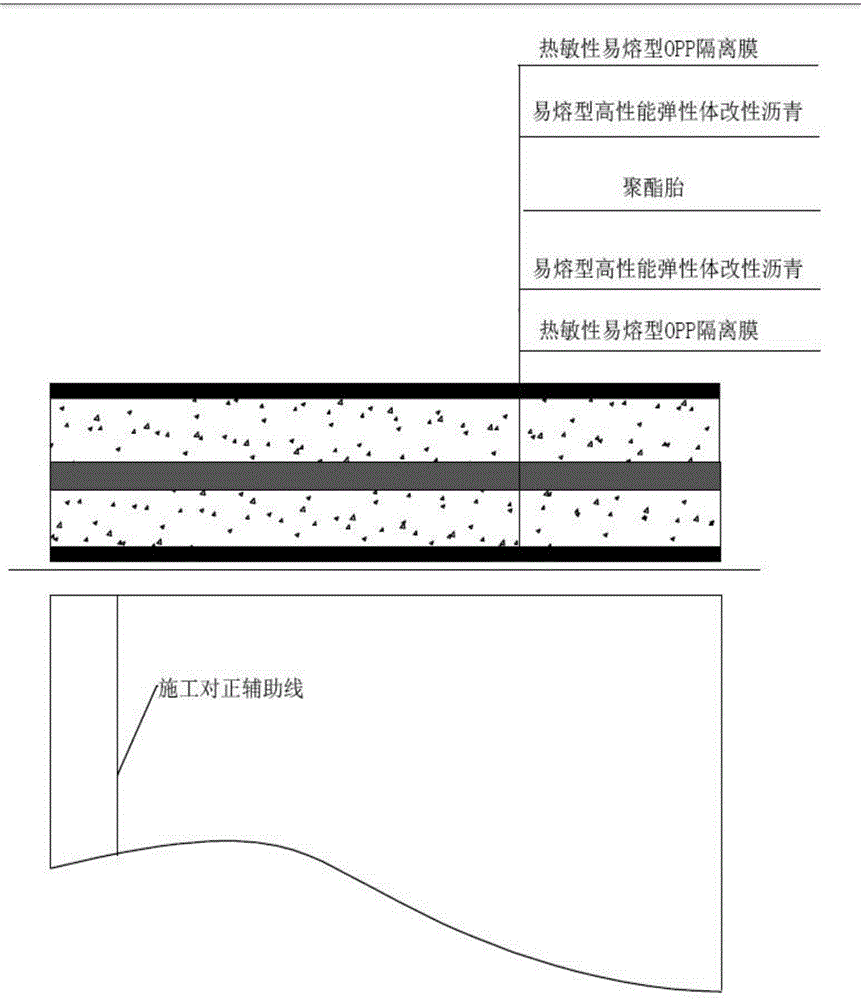

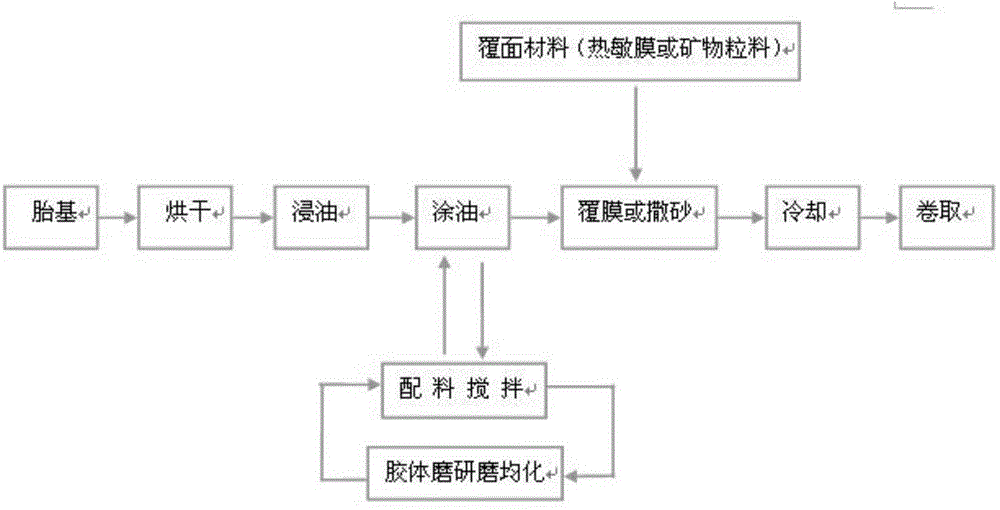

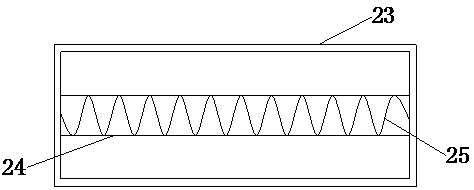

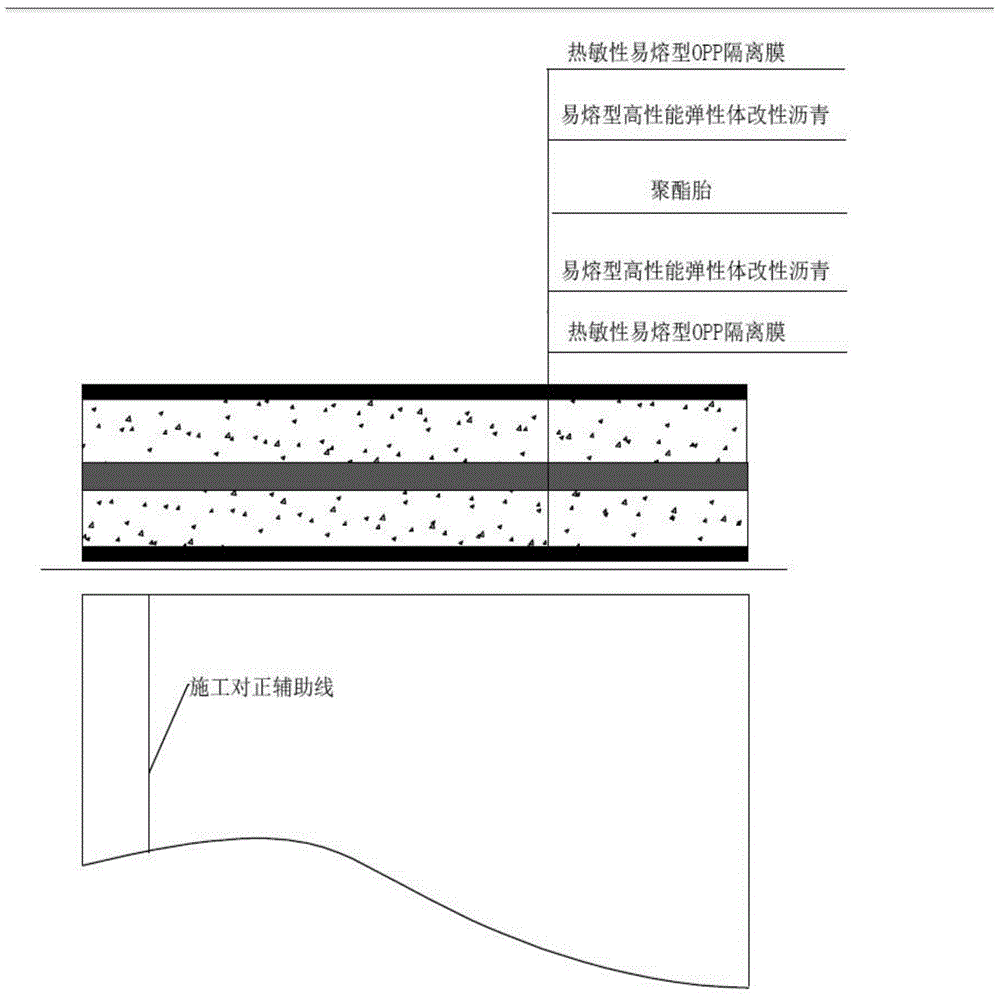

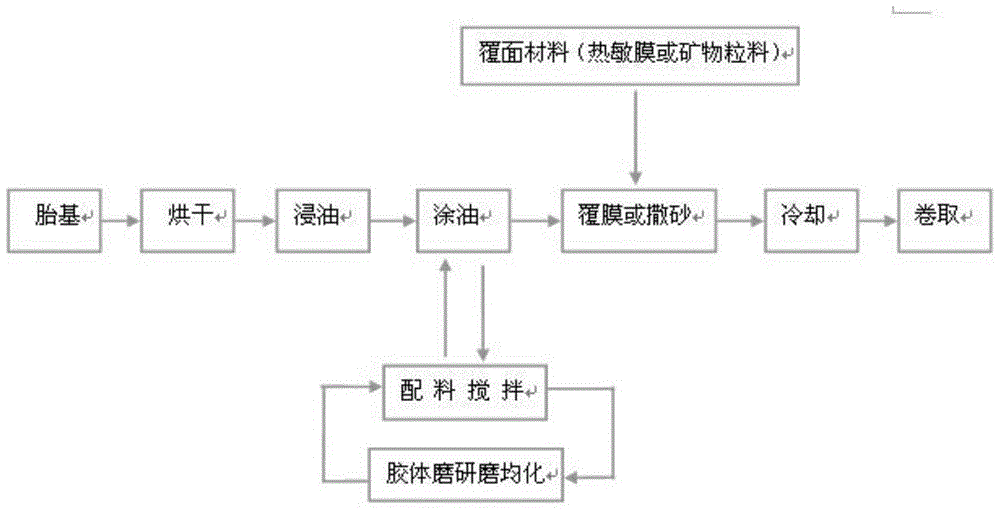

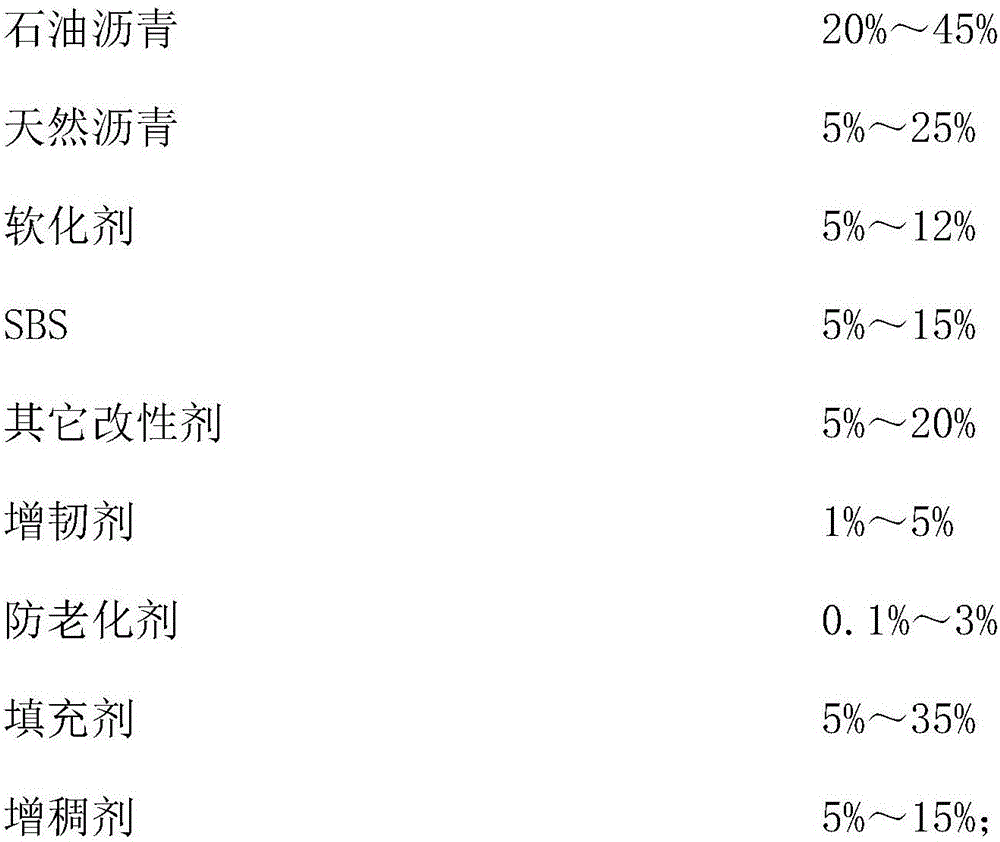

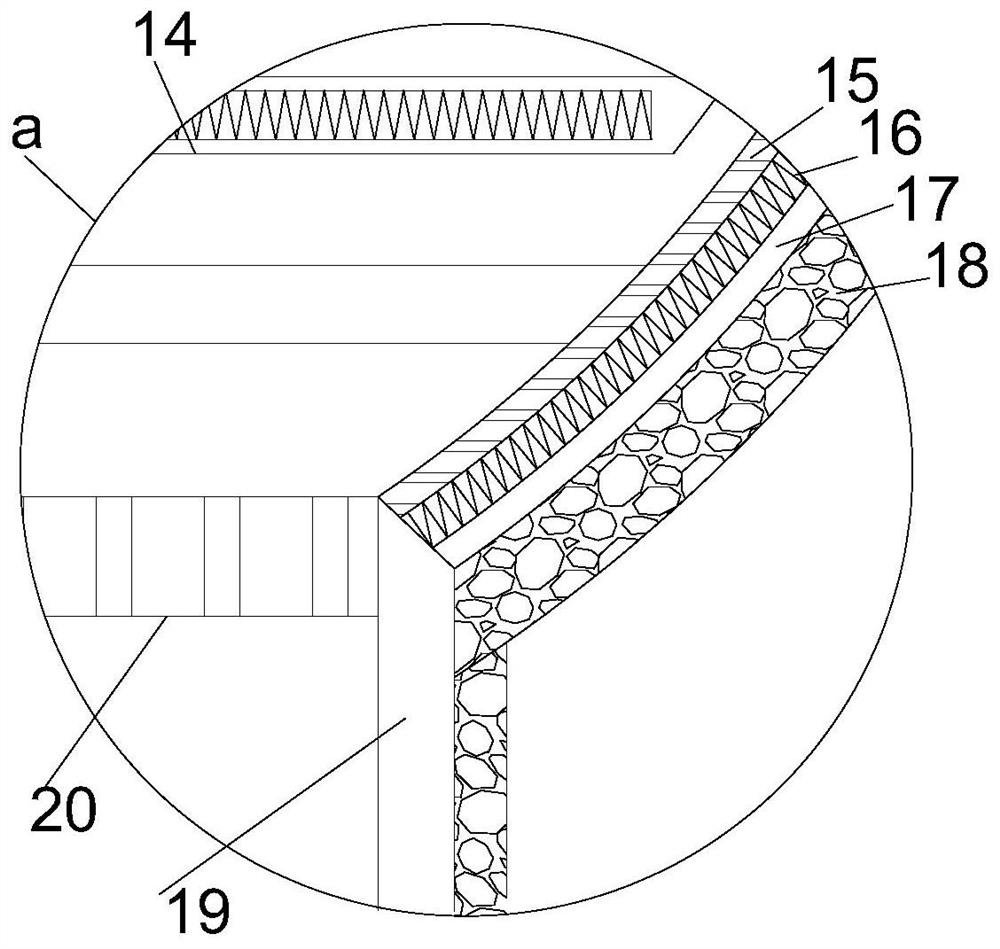

Fusible high-performance elastomer modified asphalt waterproof roll

ActiveCN104553130AImprove construction rateExtended service lifeSynthetic resin layered productsBituminous layered productsSocial benefitsElastomer

The invention discloses a fusible high-performance elastomer modified asphalt waterproof roll. The fusible high-performance elastomer modified asphalt waterproof roll sequentially comprises a heat-sensitive fusible OPP (o-phenylphenol) isolating membrane, a fusible elastomer modified asphalt, a polyester reinforcement, fusible elastomer modified asphalt and a heat-sensitive fusible OPP isolating membrane from top to bottom. When the fusible high-performance elastomer modified asphalt waterproof roll is applied, the construction efficiency can be improved, the energy consumption is reduced, and the waterproof roll is energy-saving, environment-friendly and long in service life and has good economic benefits and social benefits. The experiment proves that the fusible high-performance elastomer modified asphalt waterproof roll disclosed by the invention has the advantage that the construction rate can be improved by 10-20 percent.

Owner:TANGSHAN DONGFANG YUHONG WATERPROOF TECH CO LTD +2

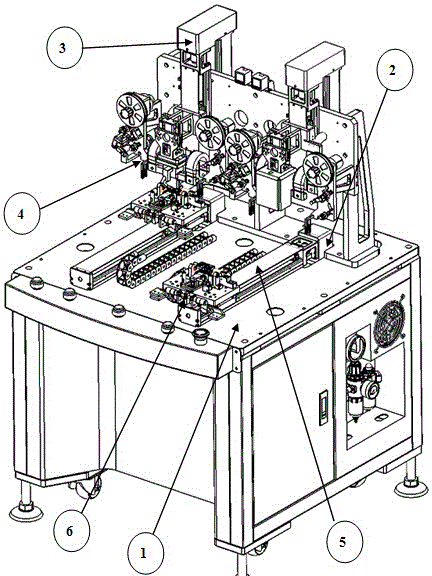

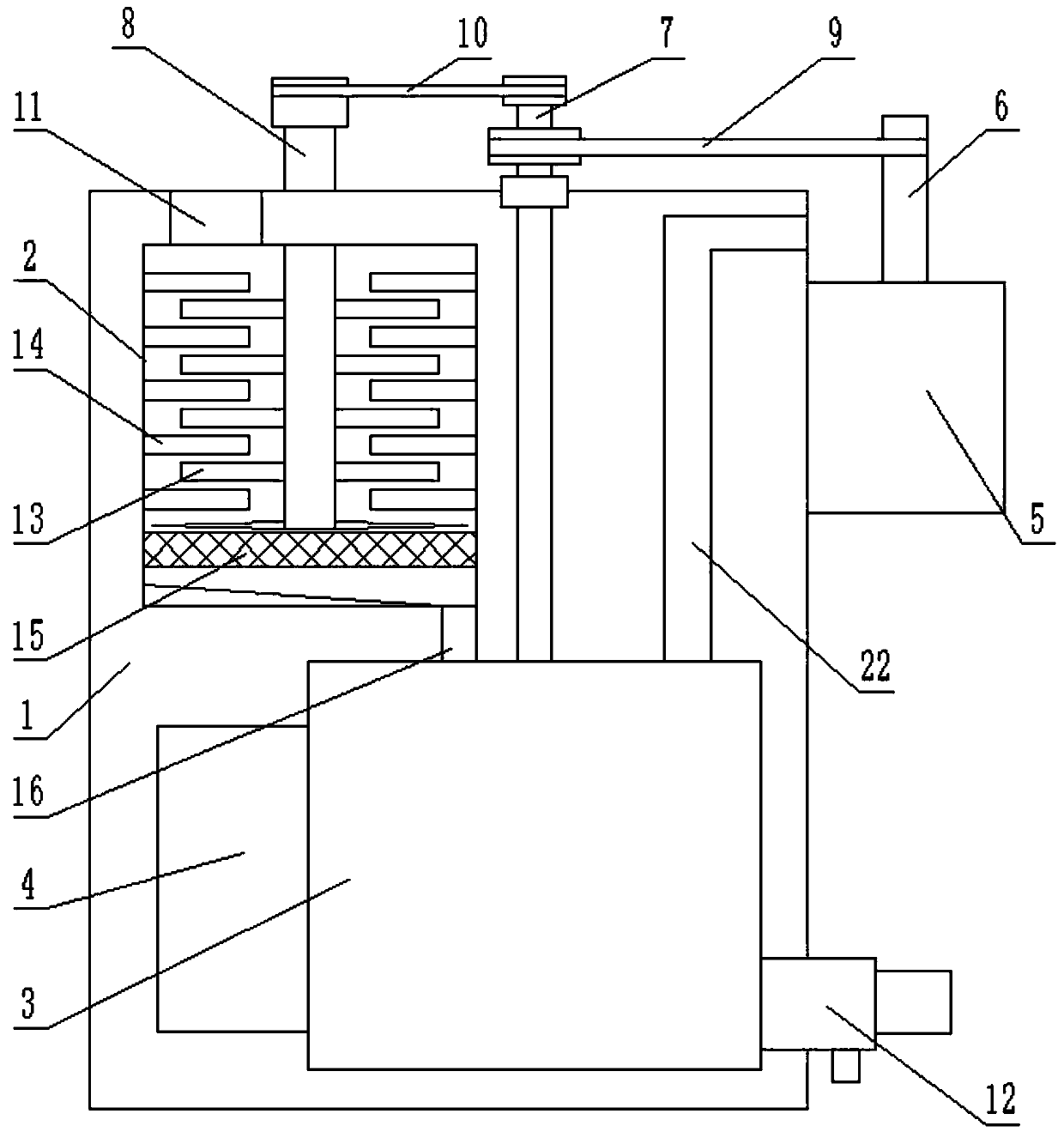

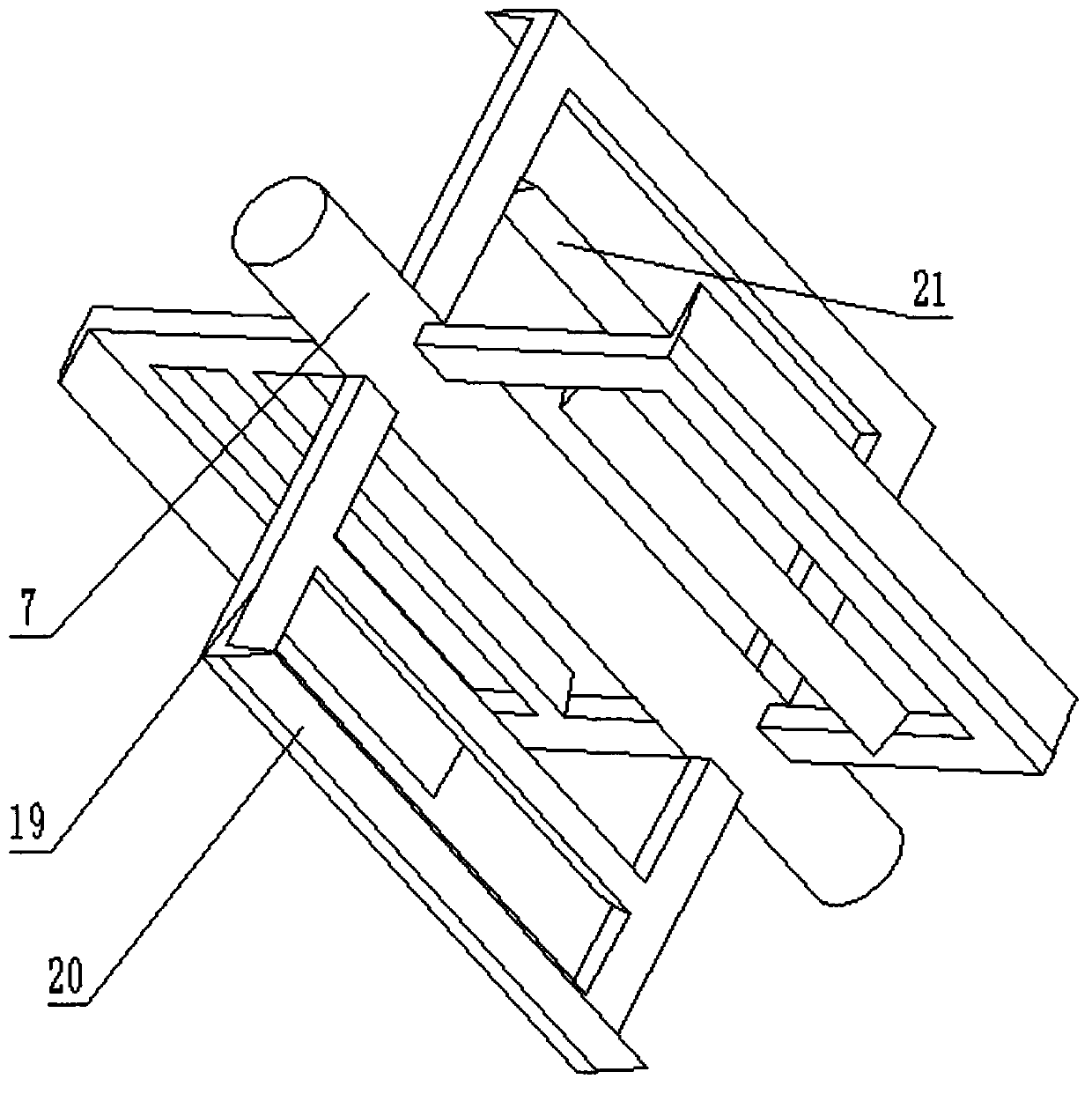

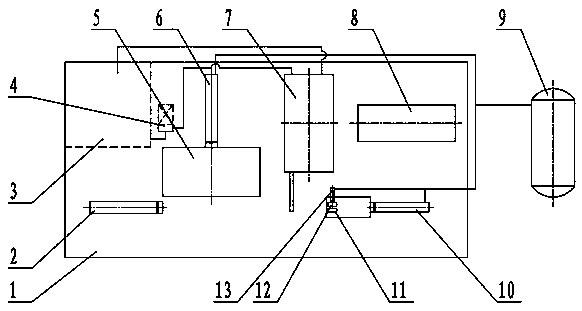

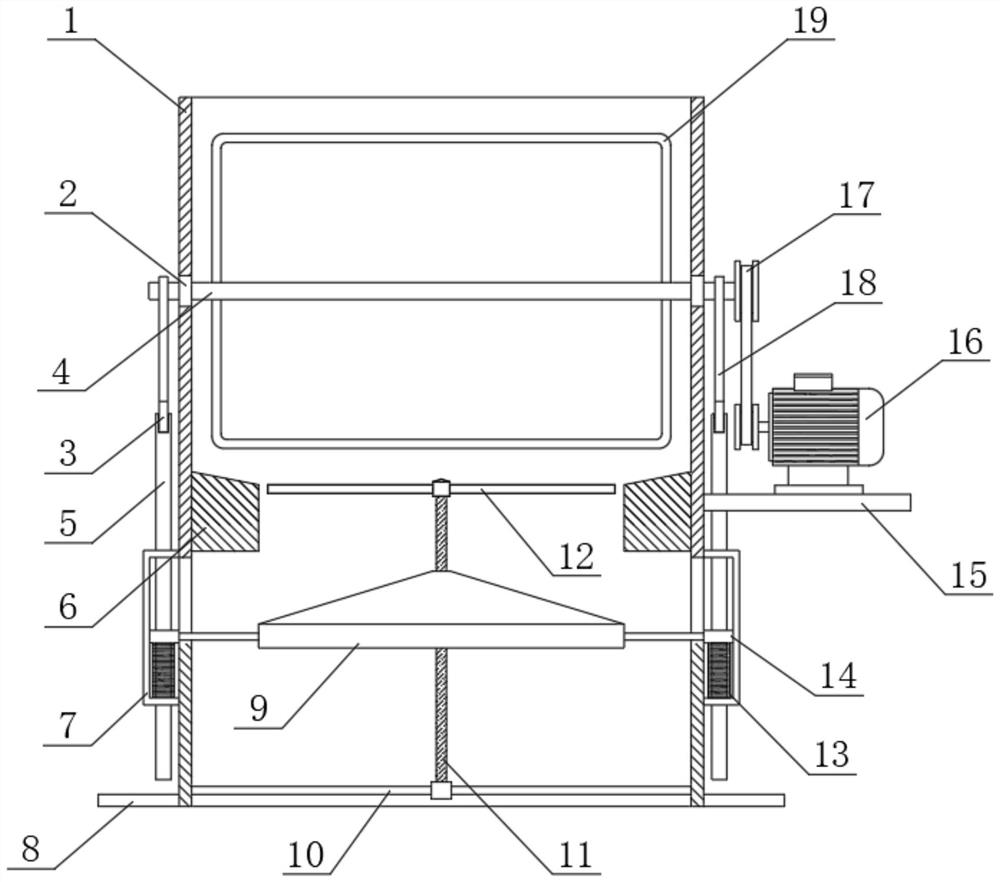

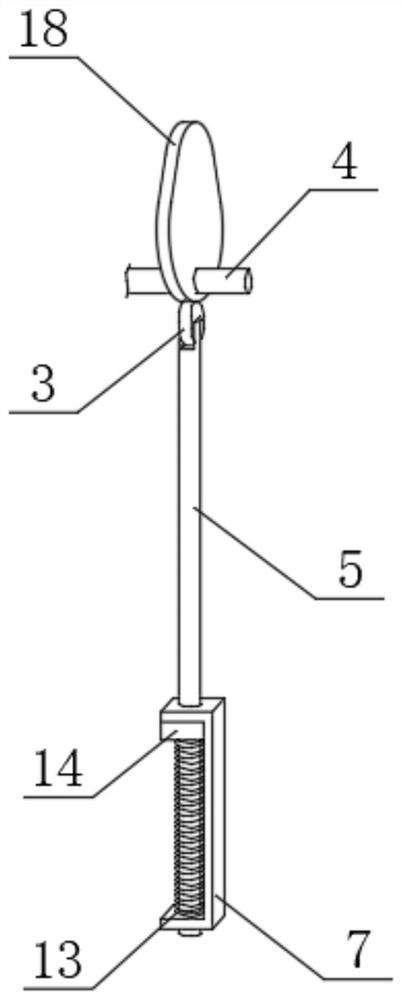

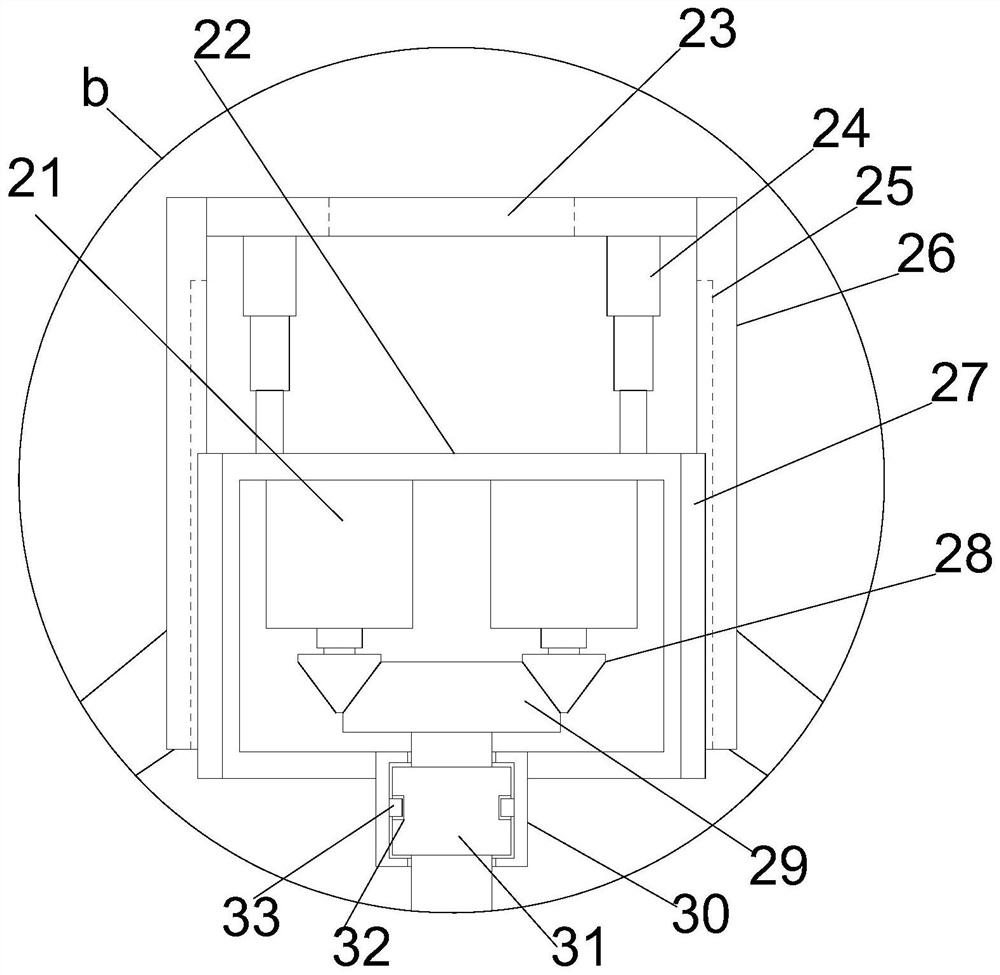

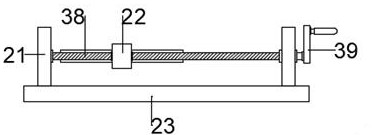

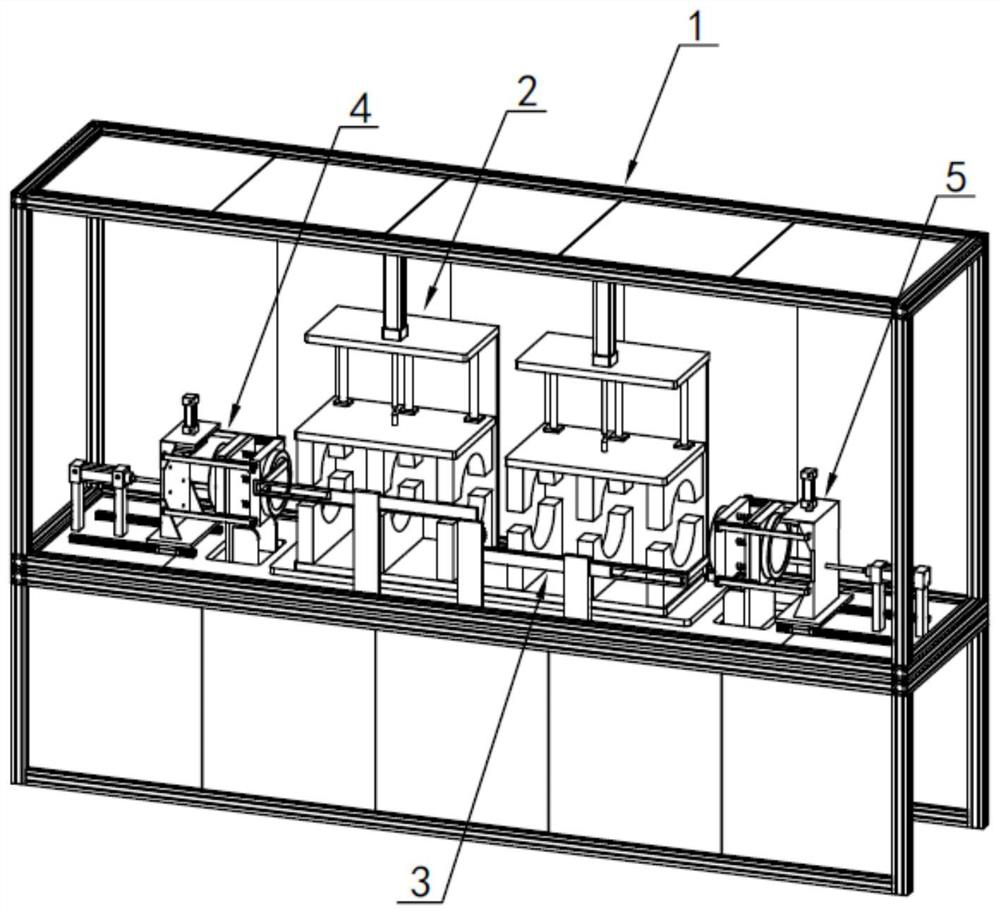

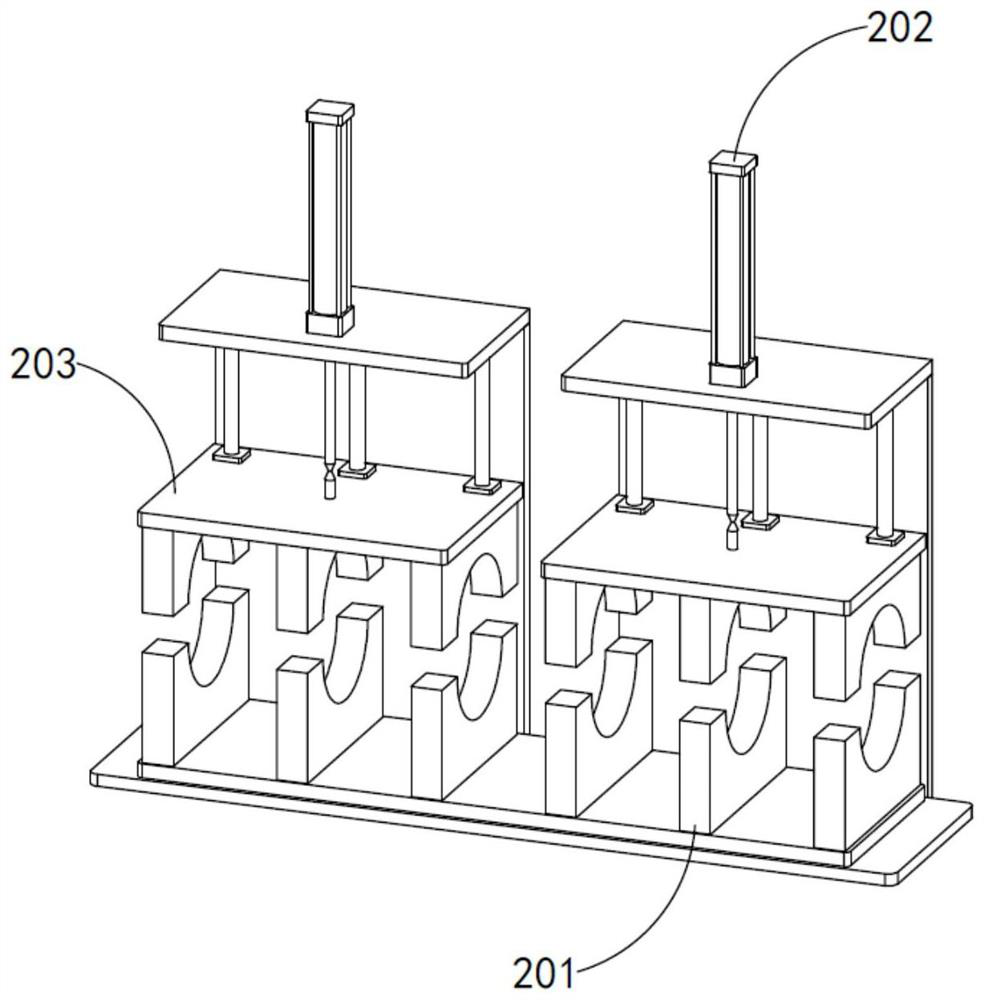

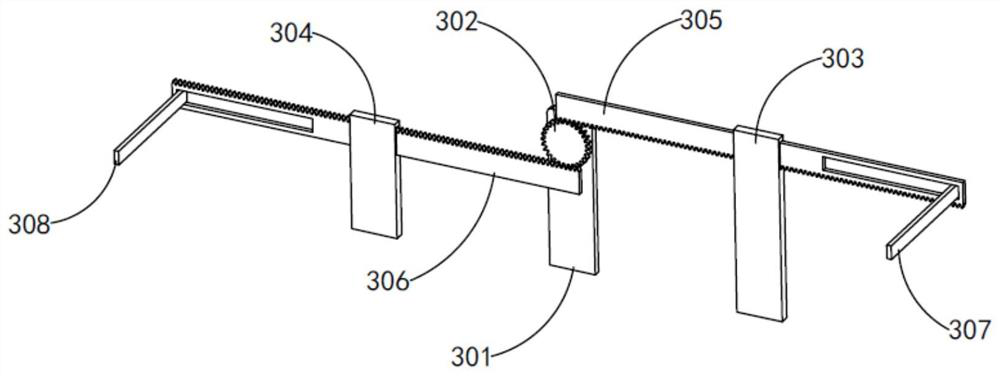

Automatic hot melting device

InactiveCN105014181ASimple structureEasy to useHeating appliancesMetal working apparatusMicrocomputerMicrocontroller

The invention relates to an automatic hot melting device. The automatic hot melting device comprises a machine frame, X-axis modules, Z-axis modules, hot melting mechanisms, Y-axis modules and flexible printed circuit positioning carriers, and is characterized in that the X-axis modules and the Y-axis modules are arranged on the machine frame; the Z-axis modules are arranged on the sides, close to the X-axis modules, of the Y-axis modules; the hot melting mechanisms are arranged on the Z-axis modules; and the flexible printed circuit positioning carriers are arranged on the Y-axis modules. In practical use, products are placed on the flexible printed circuit positioning carriers, the Y-axis modules drive the flexible printed circuit positioning carriers to move to the positions under the hot melting mechanisms, and then the Z-axis modules drive the hot melting mechanisms to move downwards to complete the hot melting action. Due to the fact that double stations alternately work and do not influence each other, the hot melting efficiency is improved. The automatic hot melting device can be connected with an appropriate single-chip microcomputer of electrical circuits of the X-axis modules, the Z-axis modules, the hot melting mechanisms and the Y-axis modules arranged in the machine frame, the pure automatic operation is achieved, and the hot melting pressure, the hot melting temperature and the hot melting time can be regulated at any time according to requirements of clients.

Owner:SUZHOU SECOTE PRECISION ELECTRONICS CO LTD

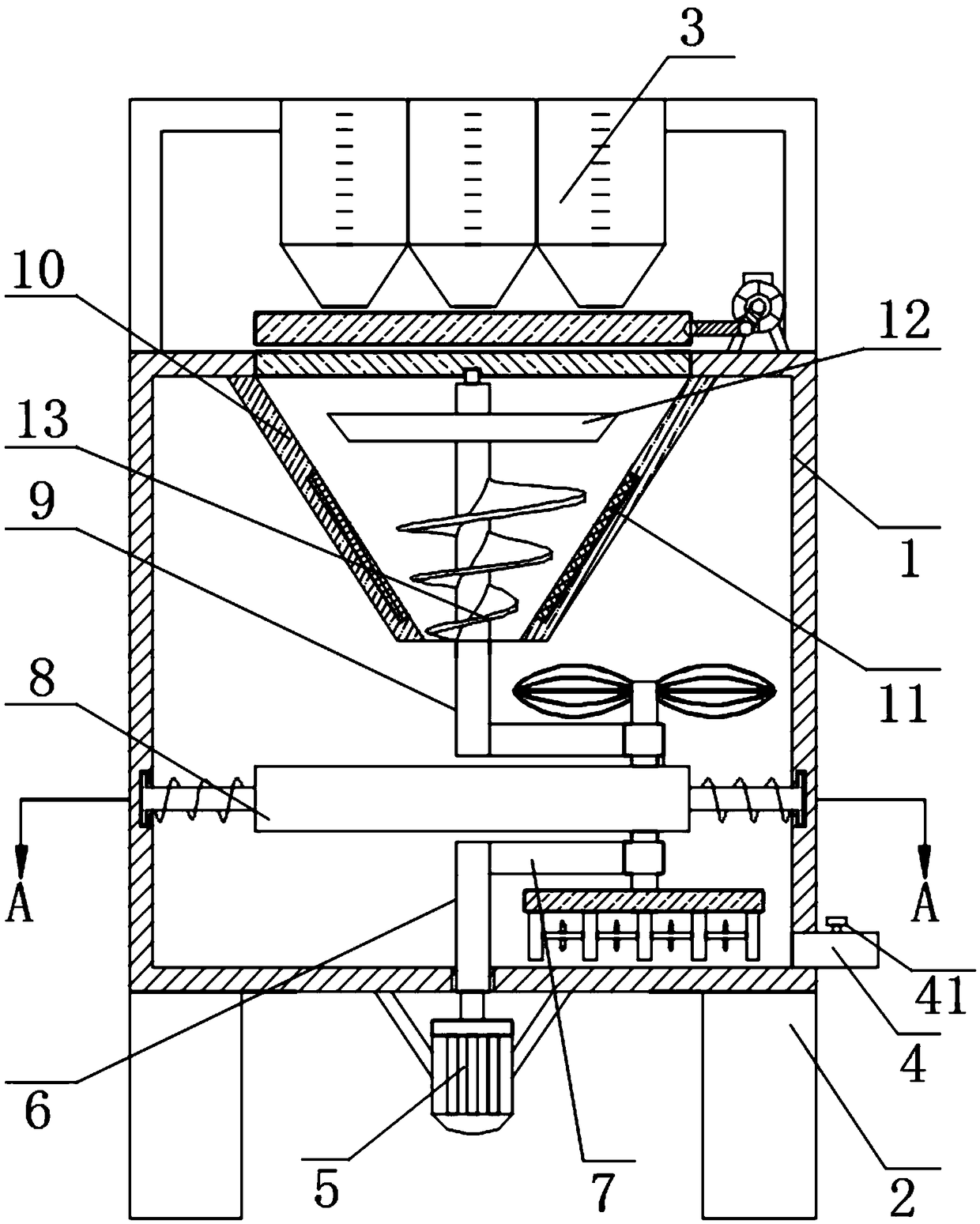

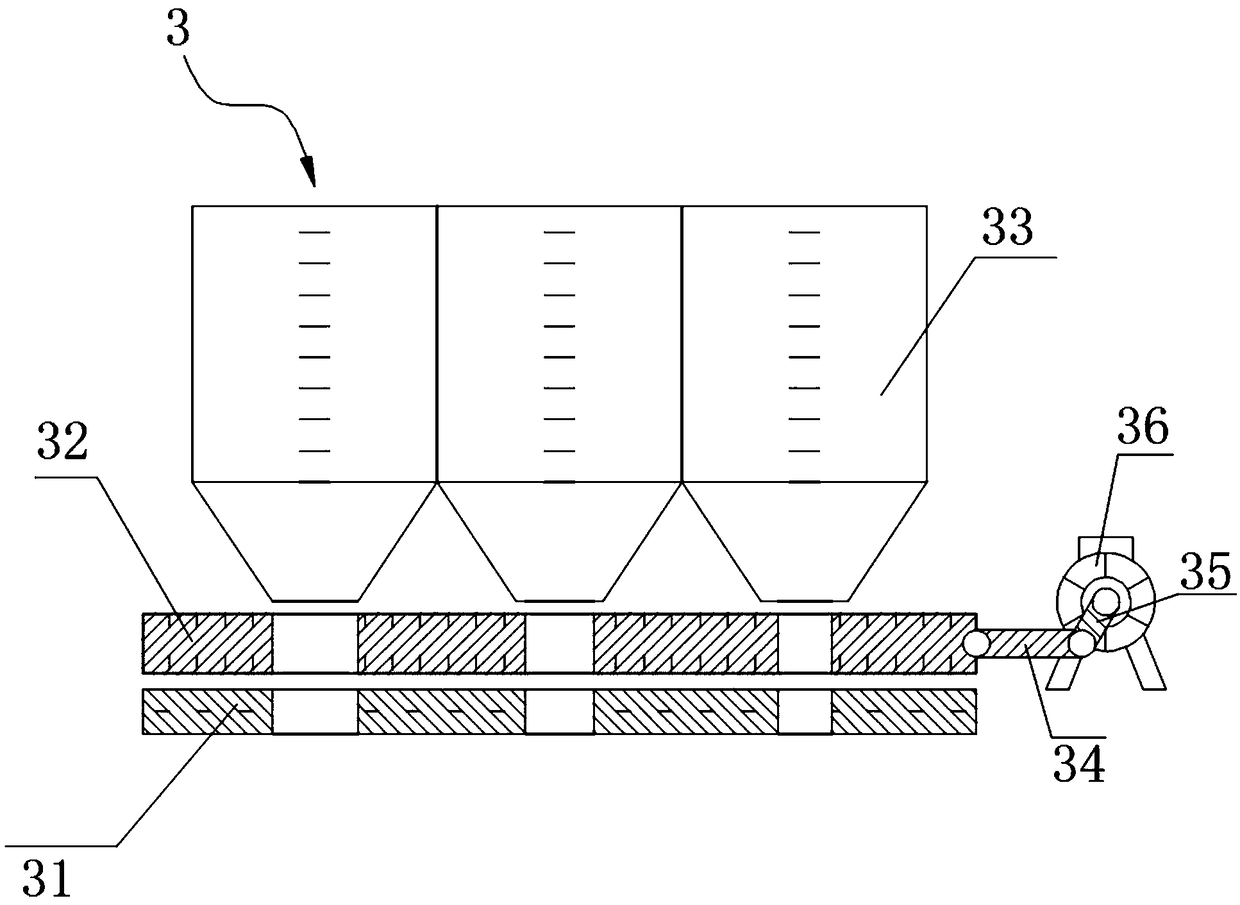

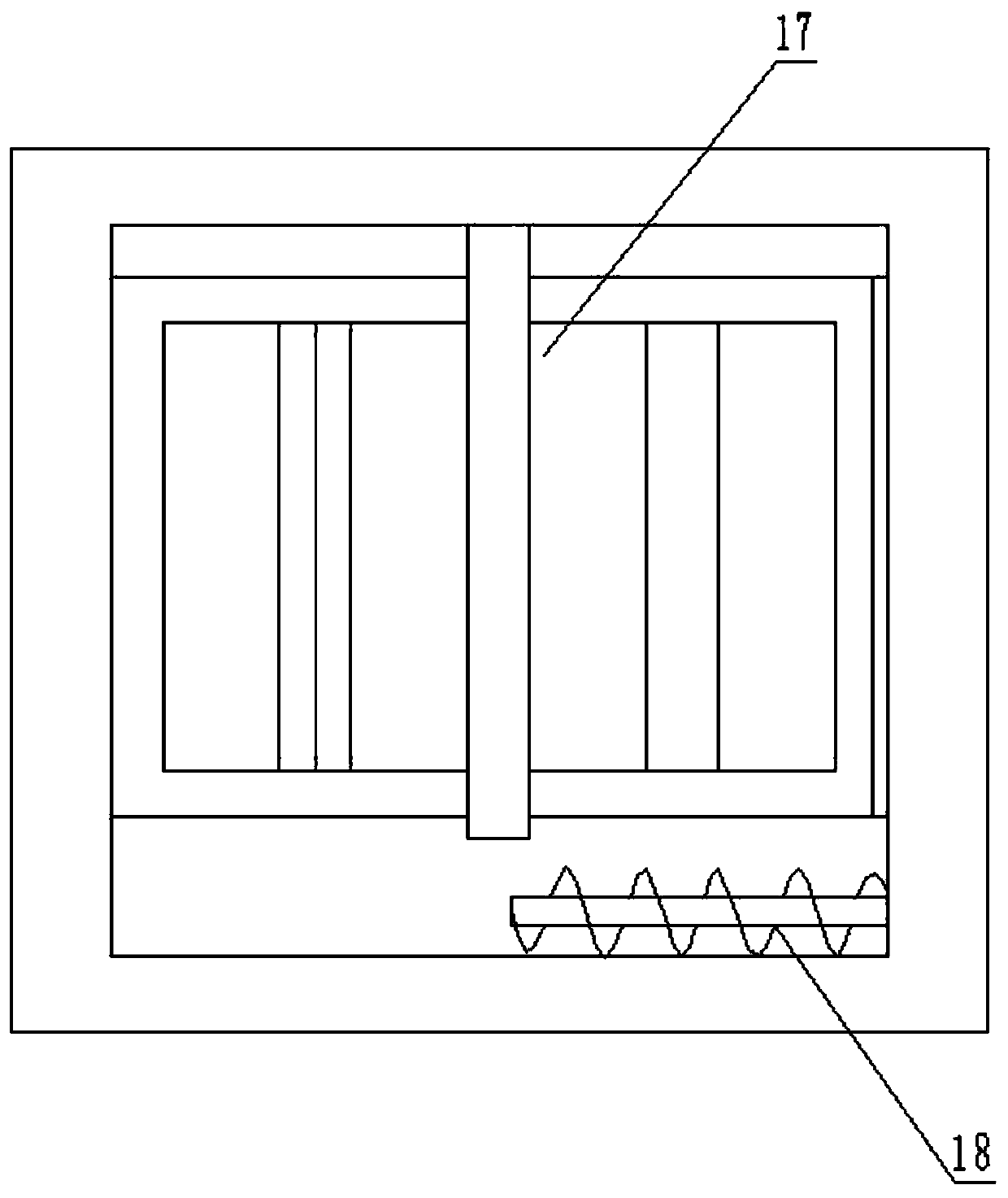

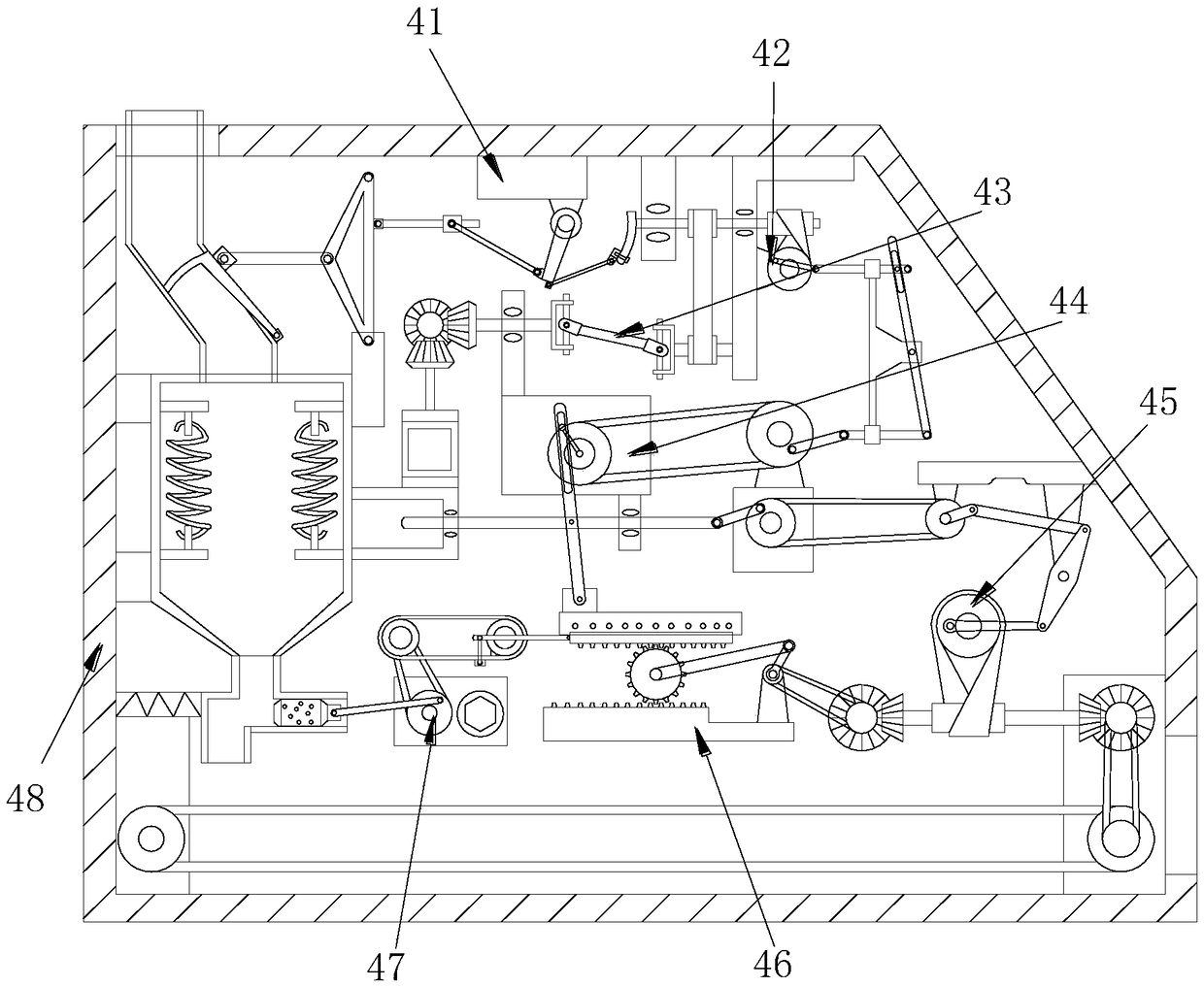

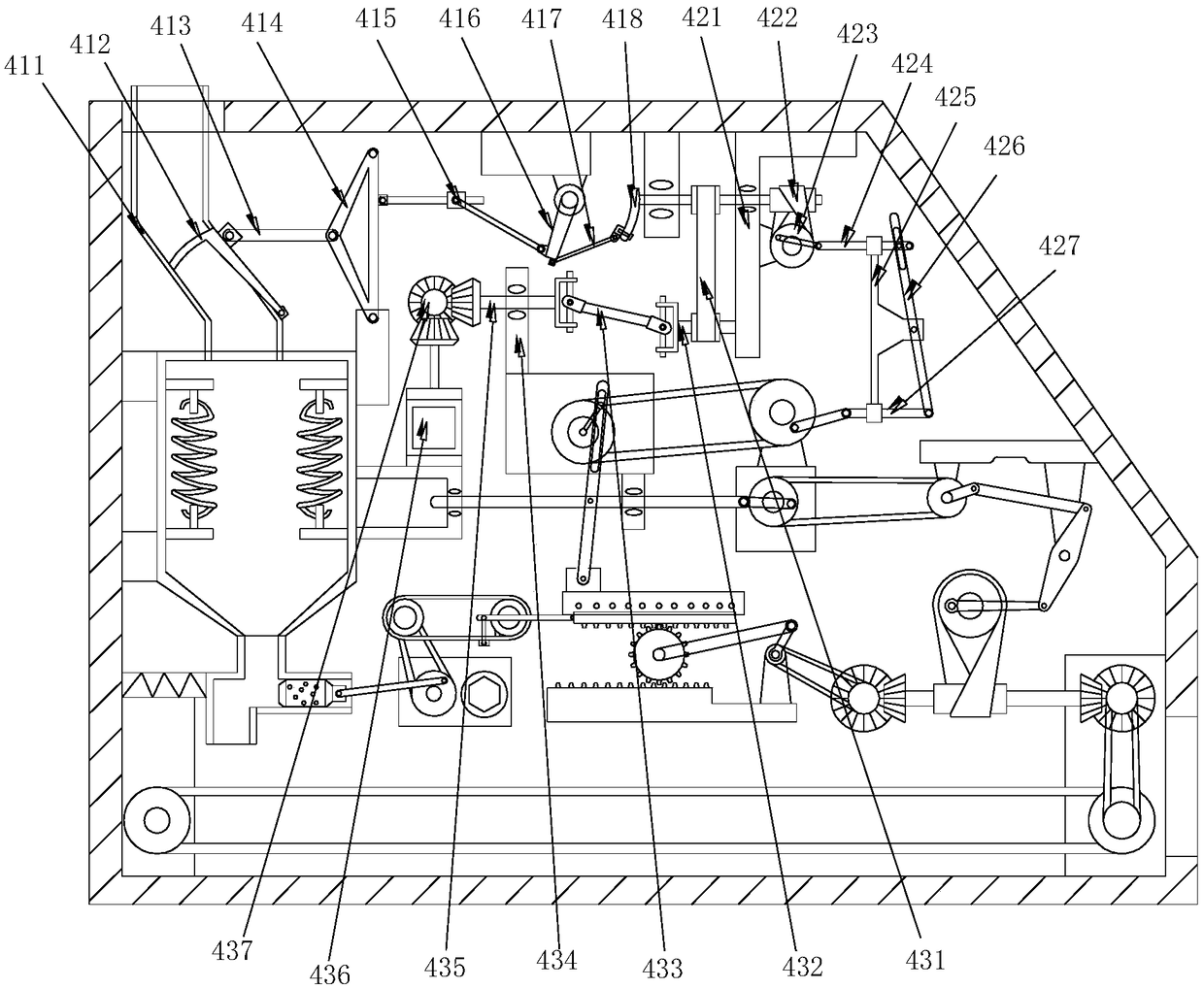

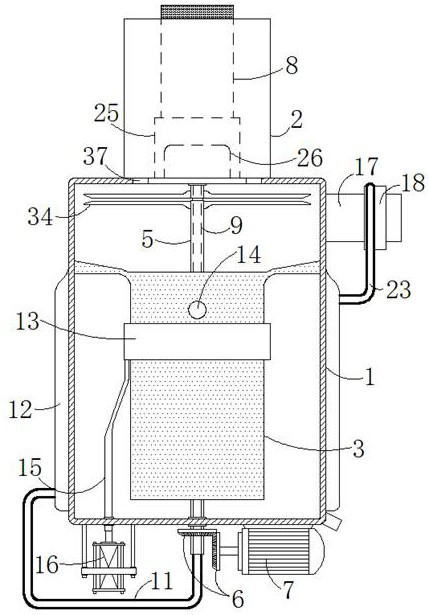

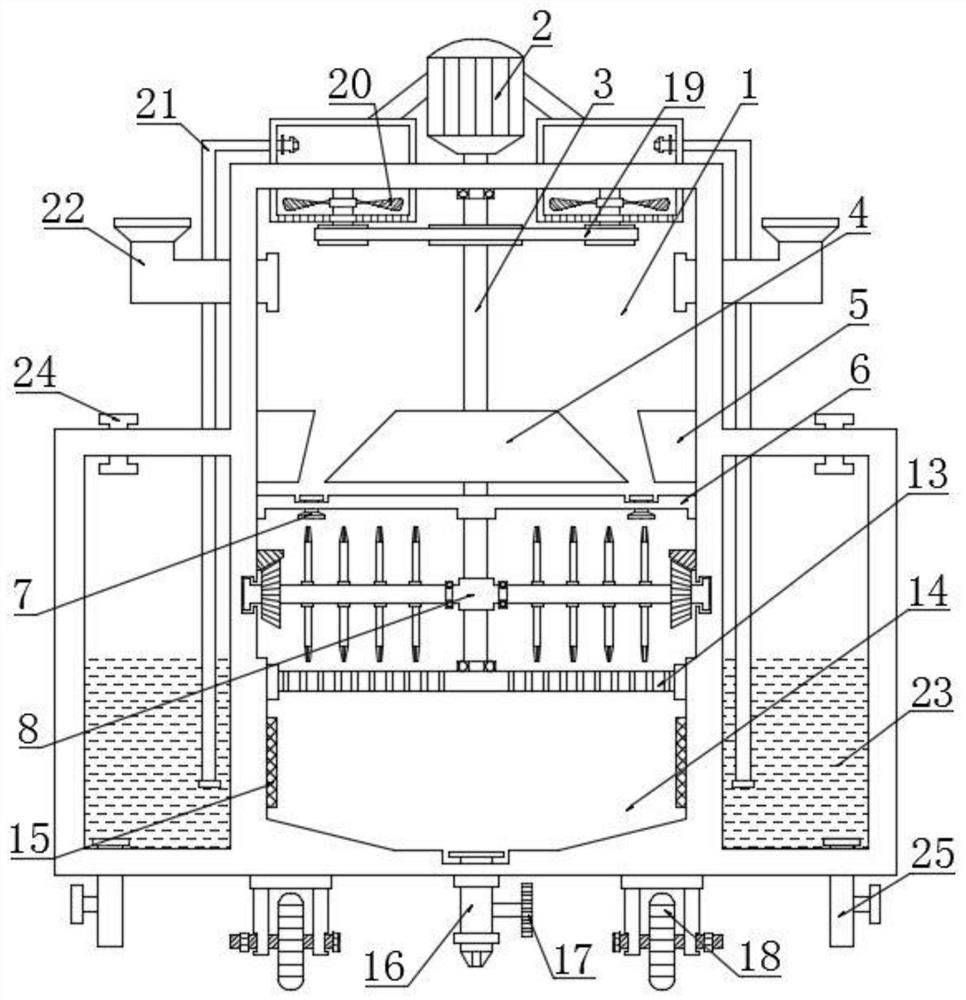

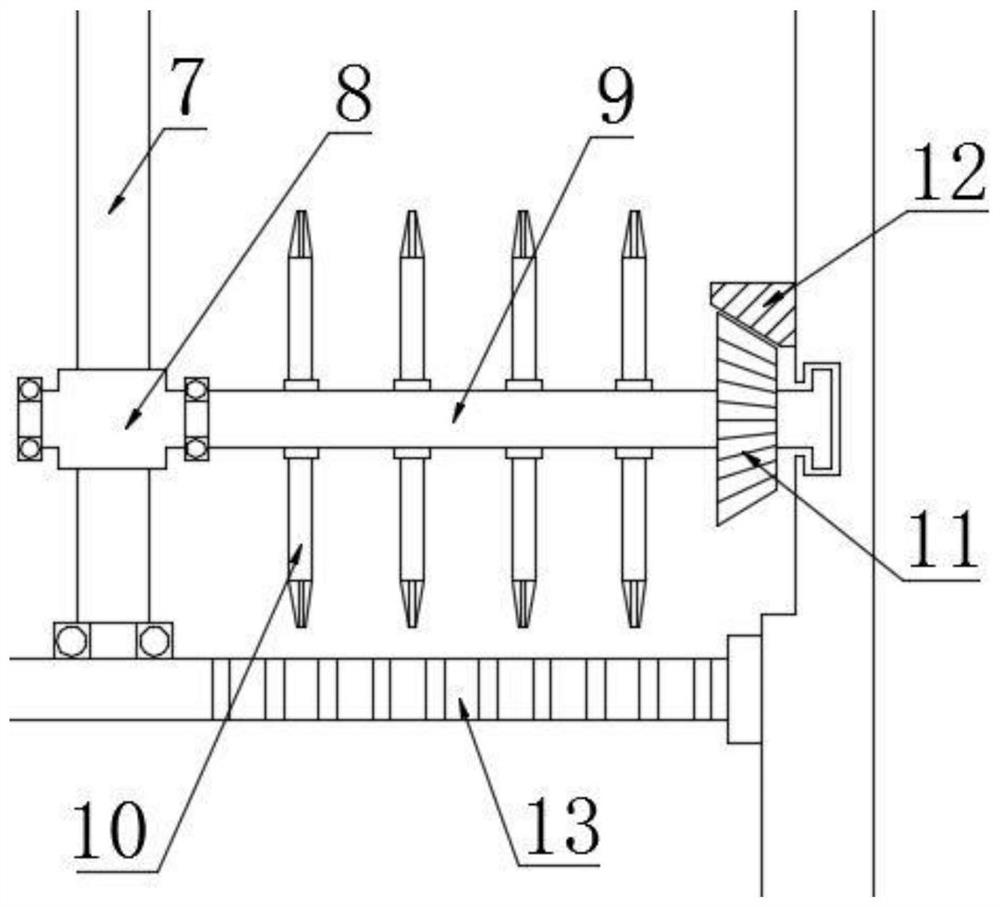

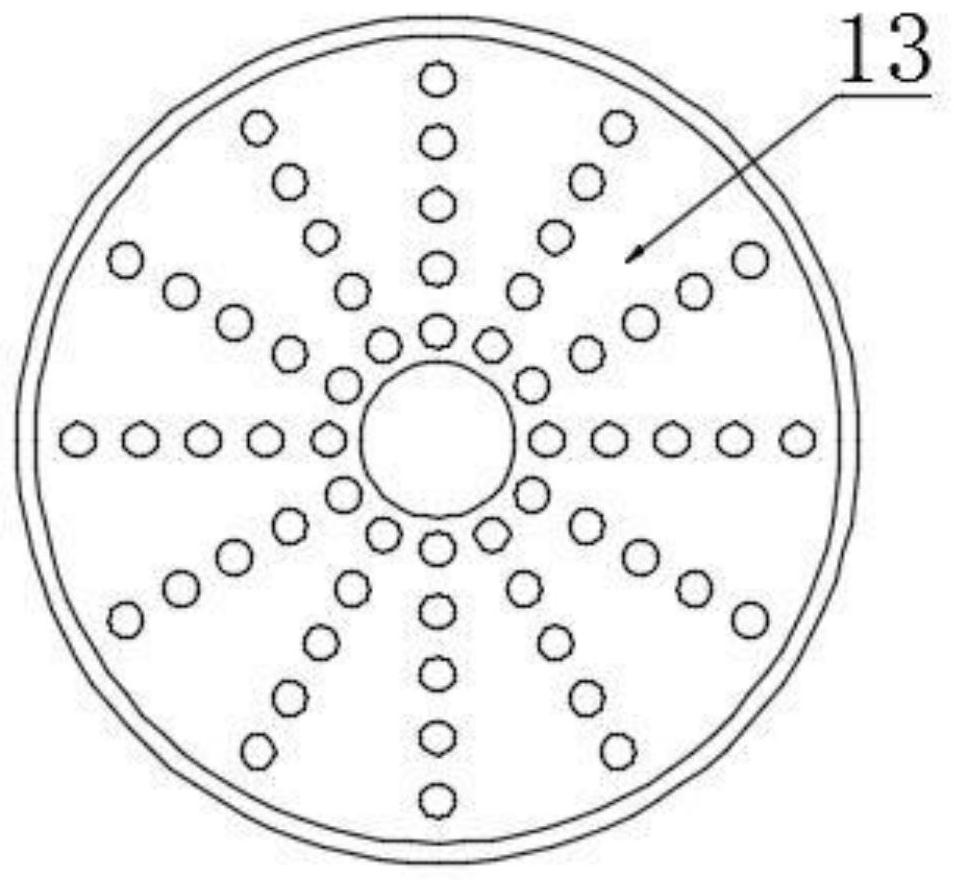

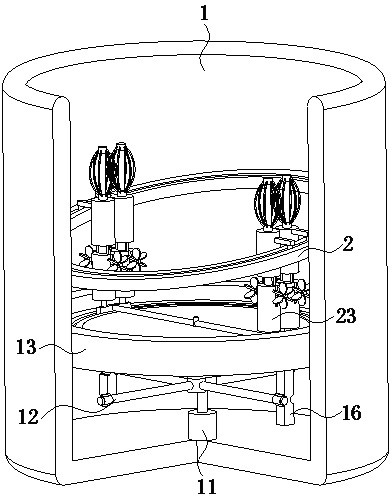

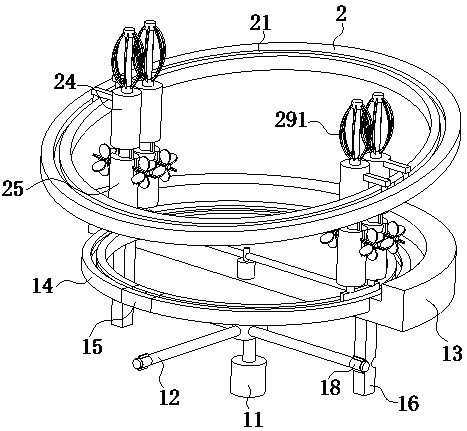

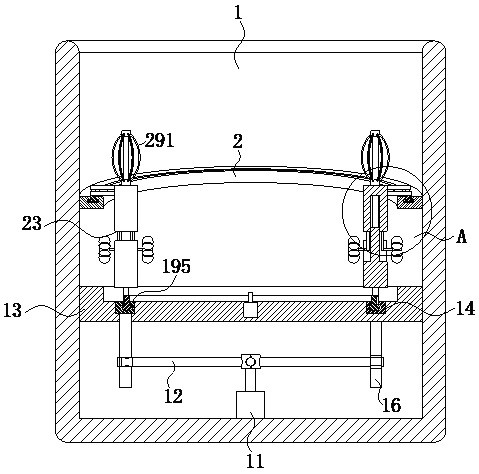

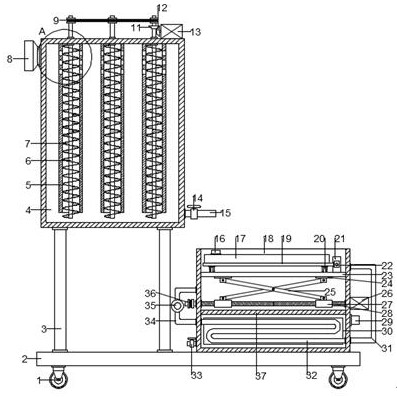

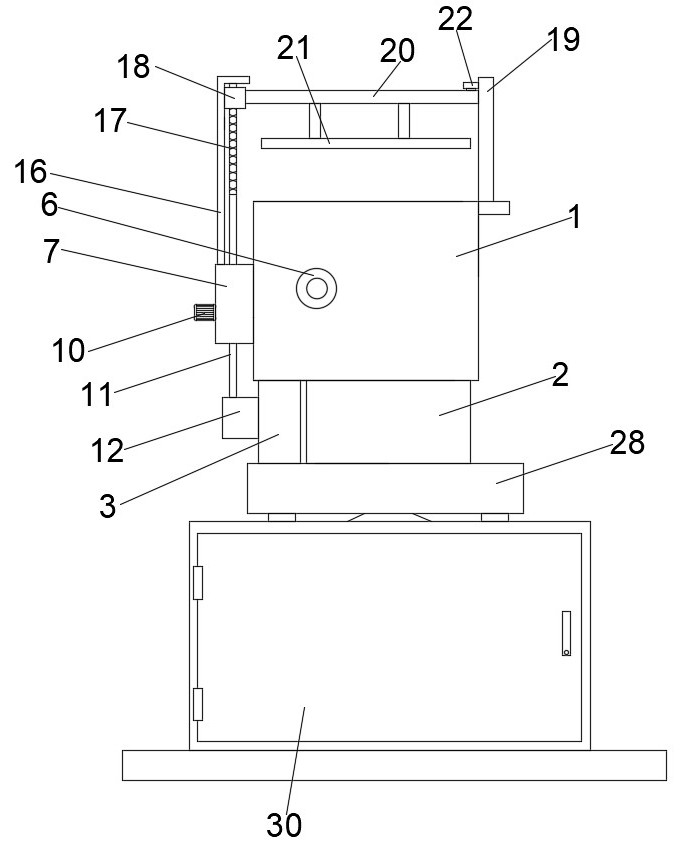

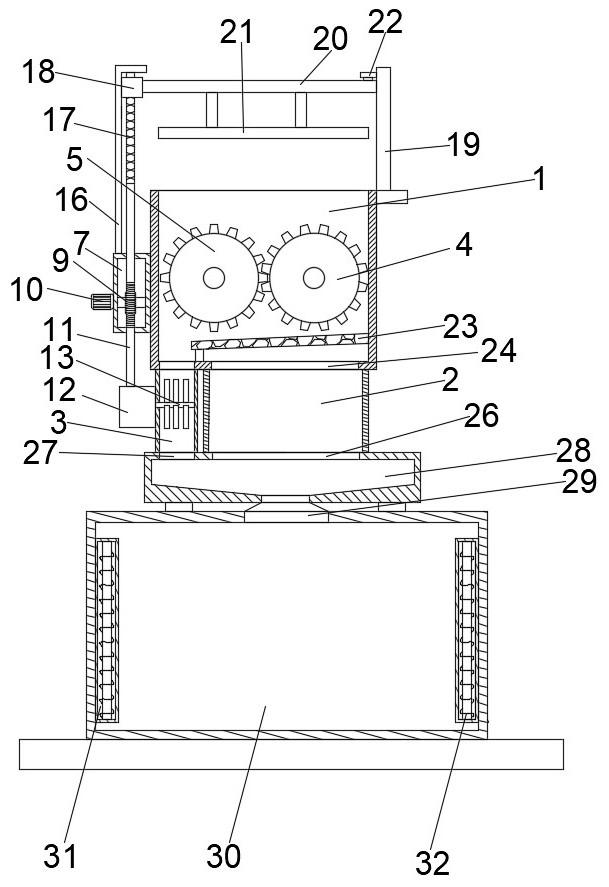

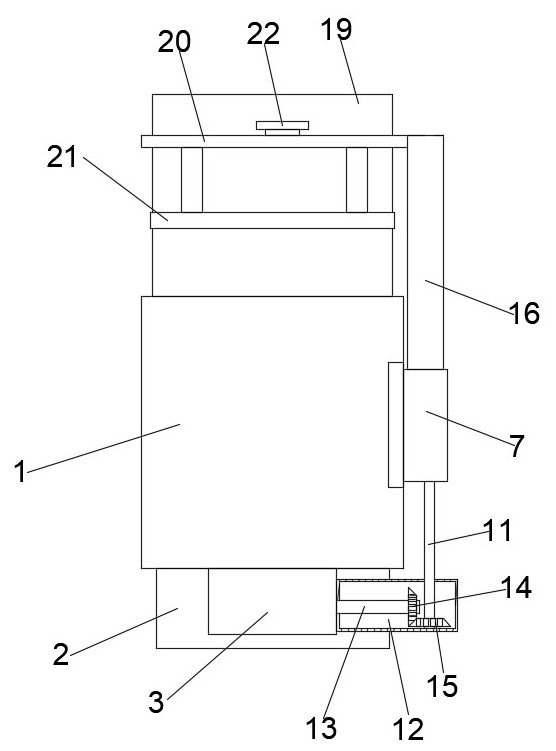

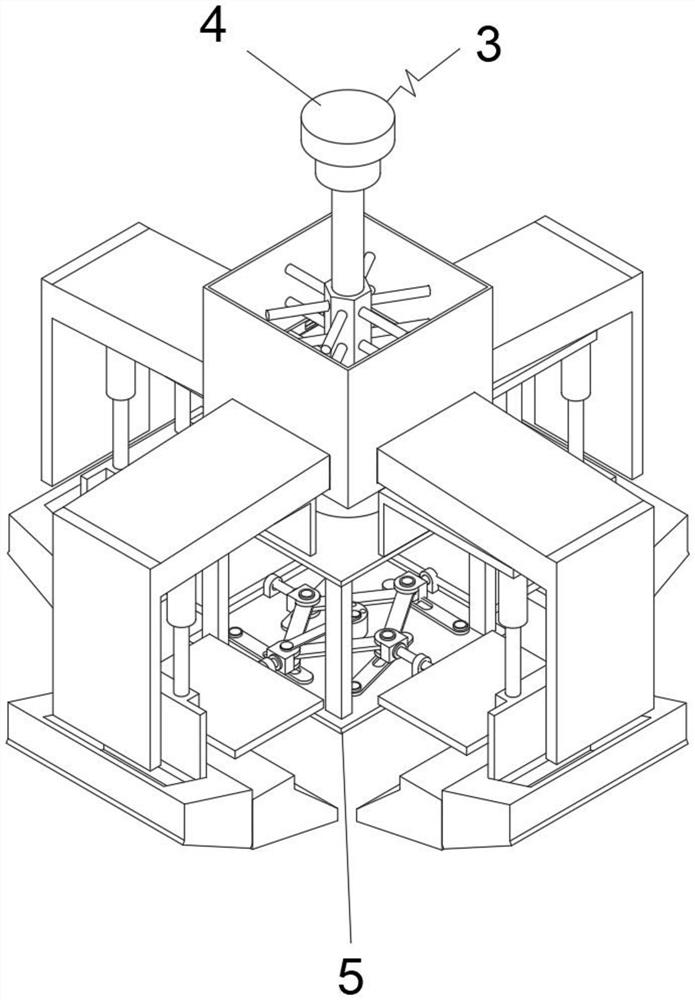

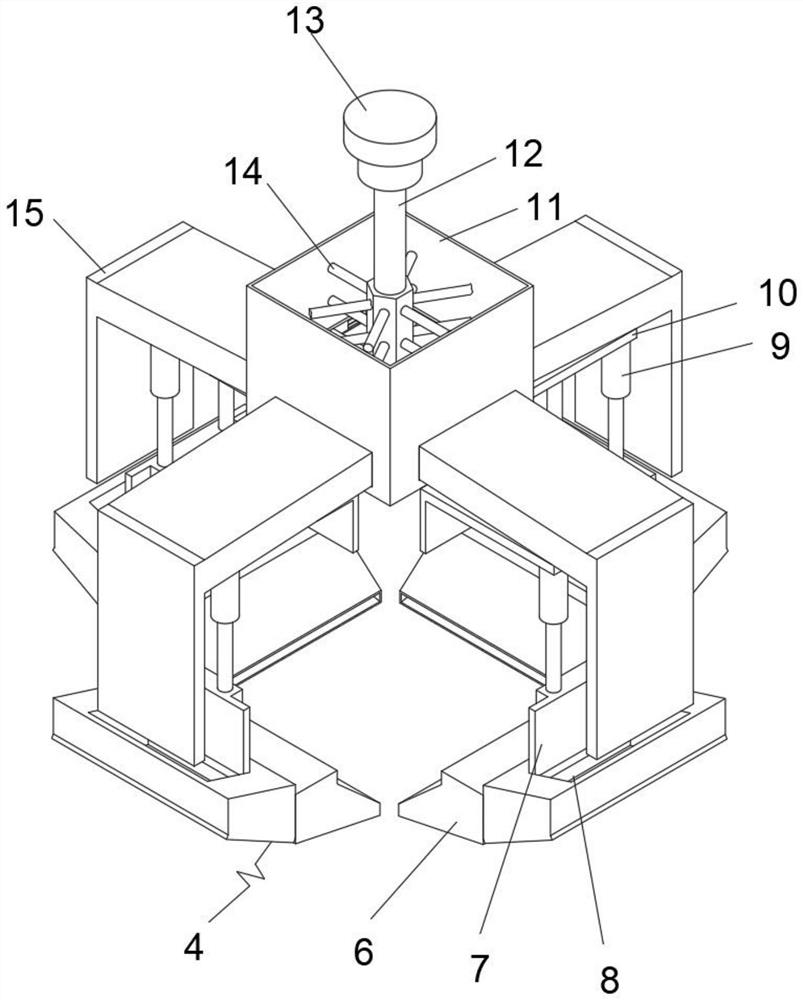

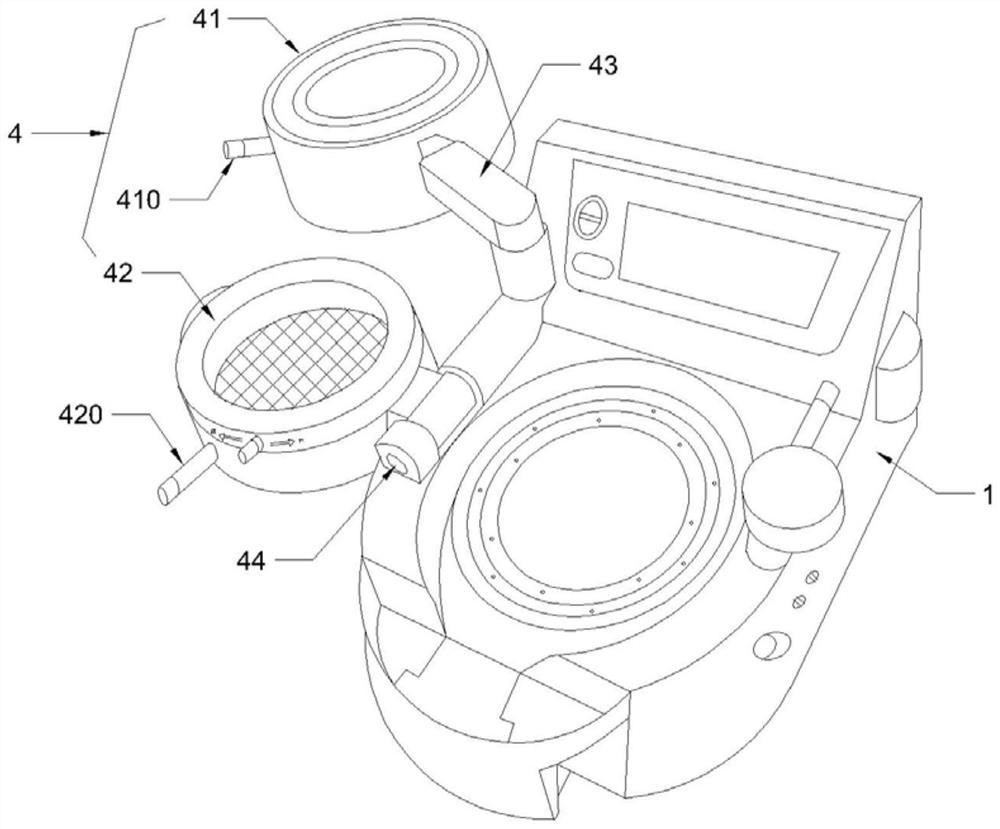

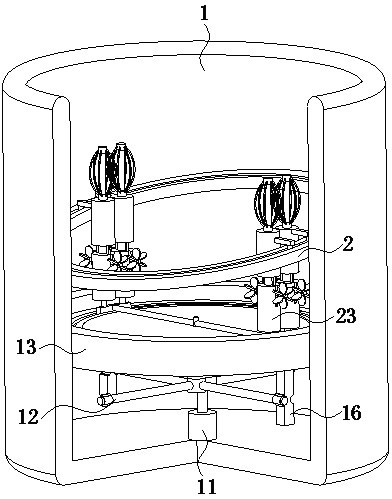

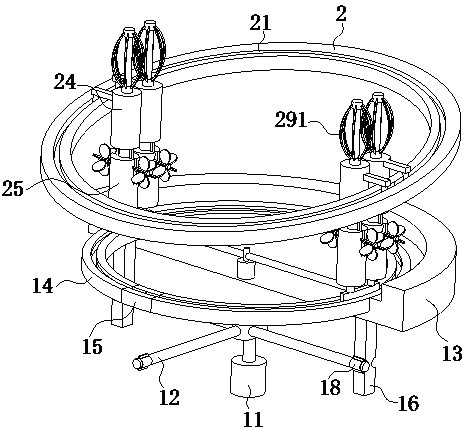

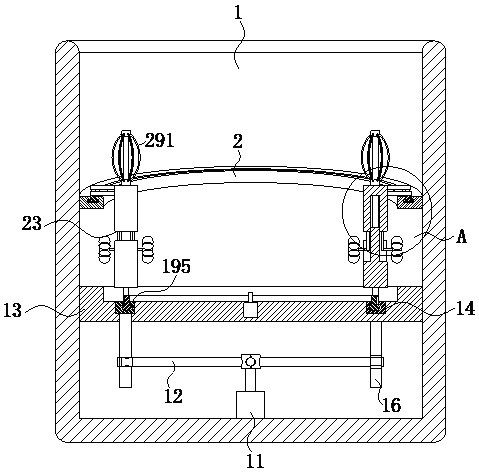

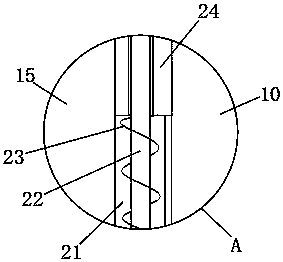

High-efficiency hot melt stirring device for processing of plastic product

The invention discloses a high-efficiency hot melt stirring device for processing of a plastic product. The high-efficiency hot melt stirring device for the processing of the plastic product has the advantages that the structure is simple; different plastic particles are quantitatively added into a plurality of transparent charge tanks according to scale lines on the transparent charge tanks, a second motor drives a second connecting plate to move left and right, and the plastic particles are uniformly discharged according to a certain ratio; at the same time, a first motor drives a rotary disc and a rotary stirrer to rotate together, the rotary disc is rotated to mix the multiple types of plastic particles, the rotary stirrer is rotated to drive the multiple types of plastic particles touniformly move down, the plastic particles are in tighter contact with an annular heating plate, and the hot melting efficiency of the plastic particles is accelerated; a core shaft drives a net-shaped stirrer and a circular disc to rotate together and stir the melted plastic particles; by adopting multiple different stirring types, the stirring efficiency is improved.

Owner:新昌县明拓机械有限公司

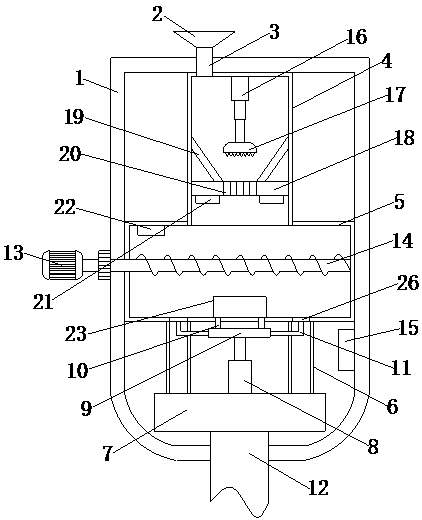

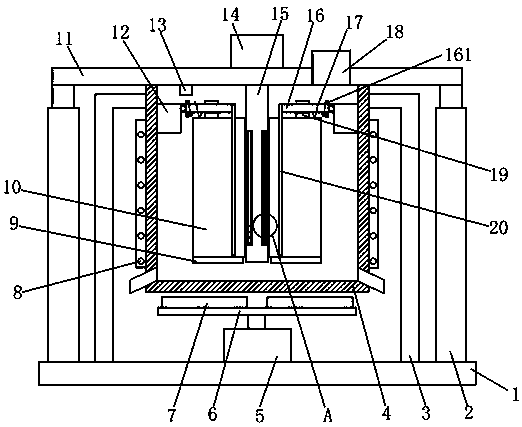

A hot-melt mechanism of injection molding machine for plastic mold processing

ActiveCN106273058BImprove hot melt efficiencyImprove production efficiencyTemperature controlEconomic benefits

The invention provides a hot melting mechanism of an injection molding machine for processing plastic molds, and relates to the field of plastic mold processing. The hot melting mechanism of the injection molding machine for processing the plastic molds comprises a shell. A feed hopper is arranged on the top of the shell, one end of a feed pipe is communicated with the bottom of the feed hopper, the other end of the feed pipe penetrates the shell and extends into the shell to be communicated with the top of a smashing machine, the top of the smashing machine is fixedly connected with the top of the inner wall of the shell, the bottom of the smashing machine penetrates a melting machine and extends into the melting machine, connecting pipes are arranged on two sides of the bottom of the melting machine, and the other end of each connecting pipe is communicated with the top of a connecting block. The hot melting mechanism of the injection molding machine for processing the plastic molds has the advantages that the hot melting efficiency can be greatly improved, excellent temperature control effects can be realized, the time can be saved to a great extent, the product manufacturing efficiency can be improved, the production cost of products can be reduced, and accordingly economic benefits can be increased for enterprises.

Owner:天津市佰盟科技发展有限公司

A Fusible Elastomer Modified Asphalt Waterproof Membrane

ActiveCN104553130BImprove construction rateExtended service lifeSynthetic resin layered productsBituminous layered productsSocial benefitsPolyester

The invention discloses a fusible high-performance elastomer modified asphalt waterproof roll. The fusible high-performance elastomer modified asphalt waterproof roll sequentially comprises a heat-sensitive fusible OPP (o-phenylphenol) isolating membrane, a fusible elastomer modified asphalt, a polyester reinforcement, fusible elastomer modified asphalt and a heat-sensitive fusible OPP isolating membrane from top to bottom. When the fusible high-performance elastomer modified asphalt waterproof roll is applied, the construction efficiency can be improved, the energy consumption is reduced, and the waterproof roll is energy-saving, environment-friendly and long in service life and has good economic benefits and social benefits. The experiment proves that the fusible high-performance elastomer modified asphalt waterproof roll disclosed by the invention has the advantage that the construction rate can be improved by 10-20 percent.

Owner:TANGSHAN DONGFANG YUHONG WATERPROOF TECH CO LTD +2

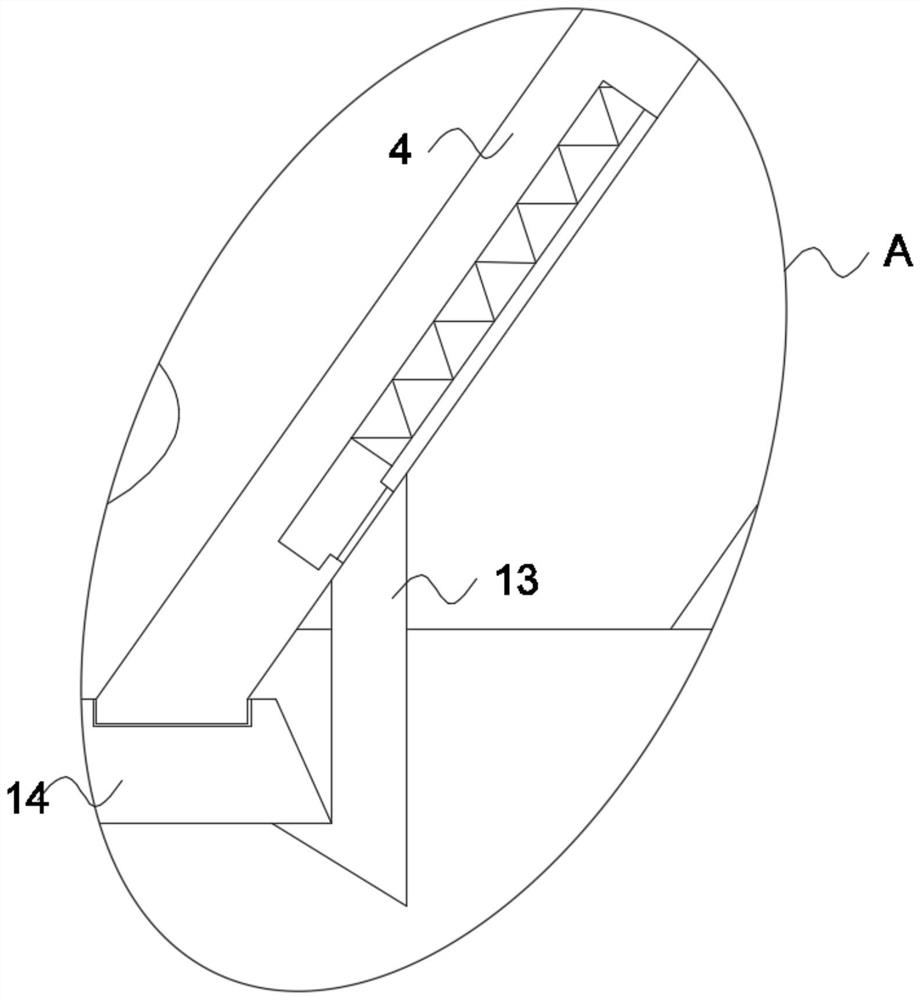

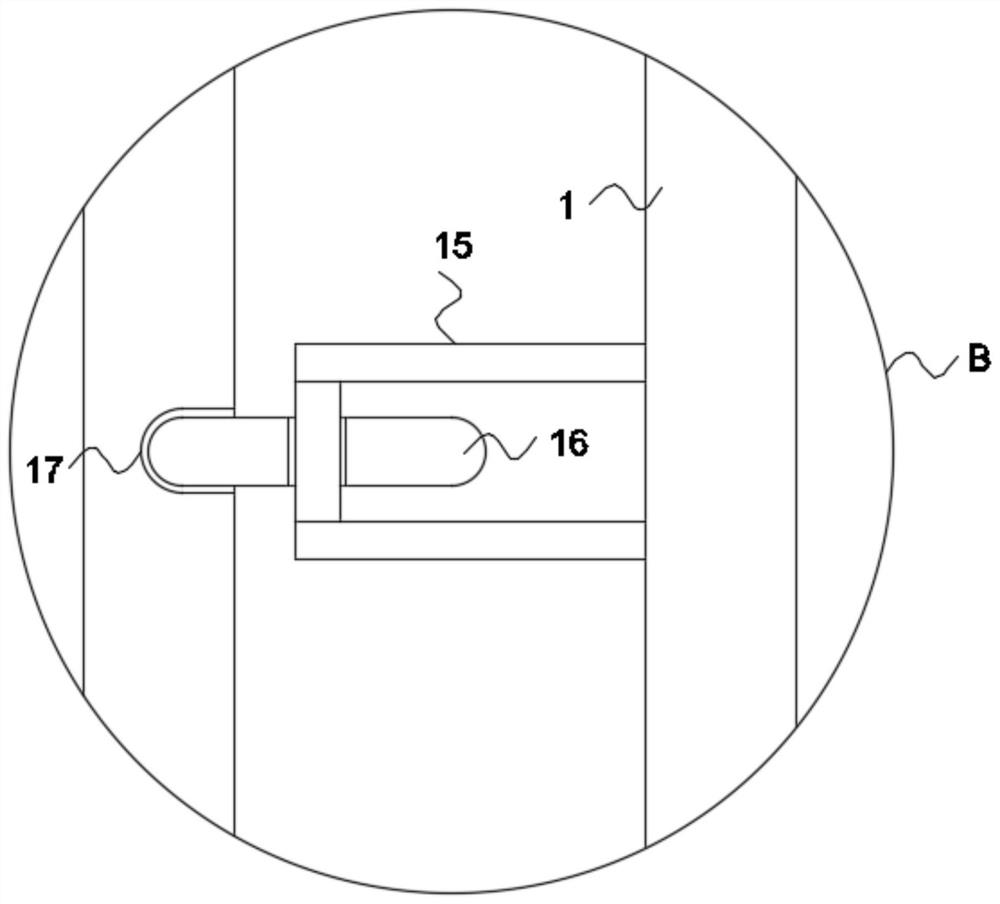

Raw material hot-melting device for plastic toy production

The invention discloses a raw material hot-melting device for plastic toy production. The raw material hot-melting device comprises a rack; a hot-melting box and a heater are arranged in the rack andare arranged in parallel; a crushing box is further arranged in the rack and is located on the inclined upper side of the hot-melting box; a feeding opening is formed in the top of the crushing box; aconnecting pipe connected with the hot-melting box is arranged at the bottom of the crushing box; the hot-melting box is cylindrical; a stirrer is arranged in the hot-melting box and comprises a first driven shaft and multiple square frames; and the square frames are fixed to the first driven shaft and are arranged in the circumferential direction of the outer wall of the first driven shaft at equal intervals. According to the device, during hot melting, the first driven shaft is driven by a driving motor to rotate, raw materials are stirred by the square frames, thus the raw materials are prevented from being heated unevenly, and the hot-melting efficiency is improved; besides, a scraping plate is arranged, the raw materials adhering to the inner wall of the hot-melting box during hot melting are scraped down, the raw materials adhering to the inner wall of the hot-melting box are prevented from being burnt, and the quality of the hot-melted raw materials is guaranteed.

Owner:宁波正时科技咨询有限公司

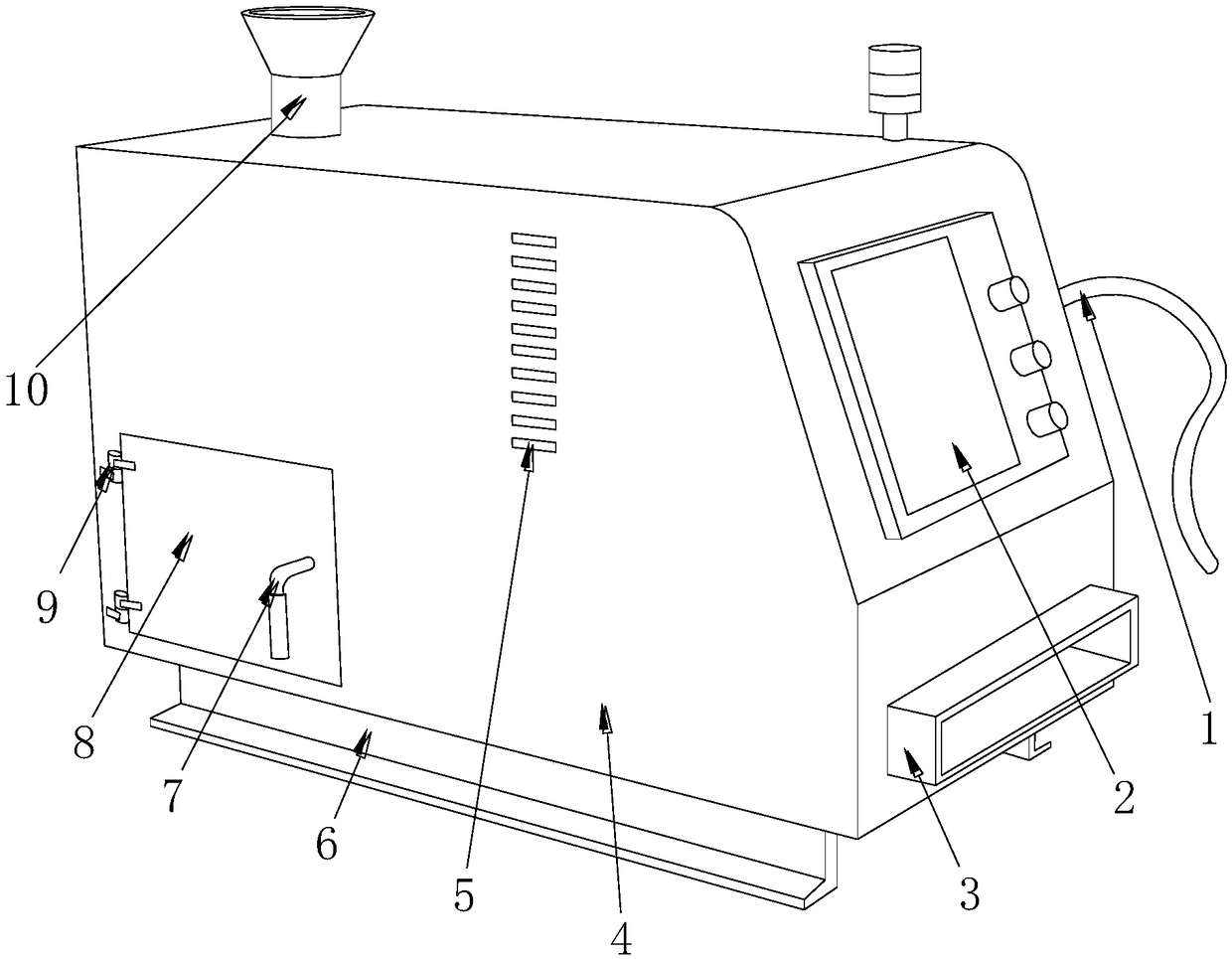

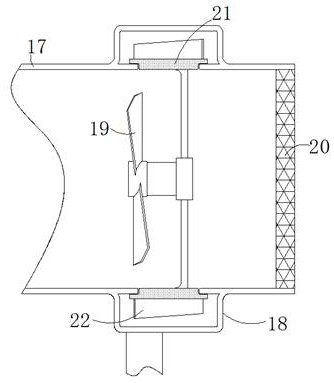

Device for supplying unmelted hot melt adhesive pieces

InactiveCN108855786AShorten melting timeAvoid material breakLiquid surface applicatorsCoatingsThermal insulationHot melt

The invention discloses a device for supplying unmelted hot melt adhesive pieces. The structure of the device comprises a power cord, a control panel, a feedwell, a preheating thermal insulation device, an air vent, a steel backing plate, a handle, an opening and closing door, a plug pin, and a feeding funnel, wherein the feeding funnel is embedded in the left end of the upper surface of the preheating thermal insulation device, the steel backing plate is welded with the lower end of the preheating thermal insulation device, the air vent is embedded in the upper end of the front side of the preheating thermal insulation device, the plug pin is welded with the left end of the opening and closing door, and the opening and closing door is hinged to the left end of the front side of the preheating thermal insulation device by the plug pin. The device for supplying unmelted hot melt adhesive pieces heats the hot melt adhesive pieces firstly through the preheating thermal insulation device when supplying the hot melt adhesive pieces to make the temperature of the hot melt adhesive pieces between the freezing point and the melting point, so that the hot melt adhesive pieces can quickly reach the melting point temperature when entering a melting box of a hot melt adhesive machine, thereby shortening the melting time of the hot melt adhesive pieces, improving the hot melt efficiency, ensuring the adhesive supply speed, and avoiding feeding interruption of the hot melt adhesive machine during the adhesive application.

Owner:芜湖启邦电力技术服务有限公司

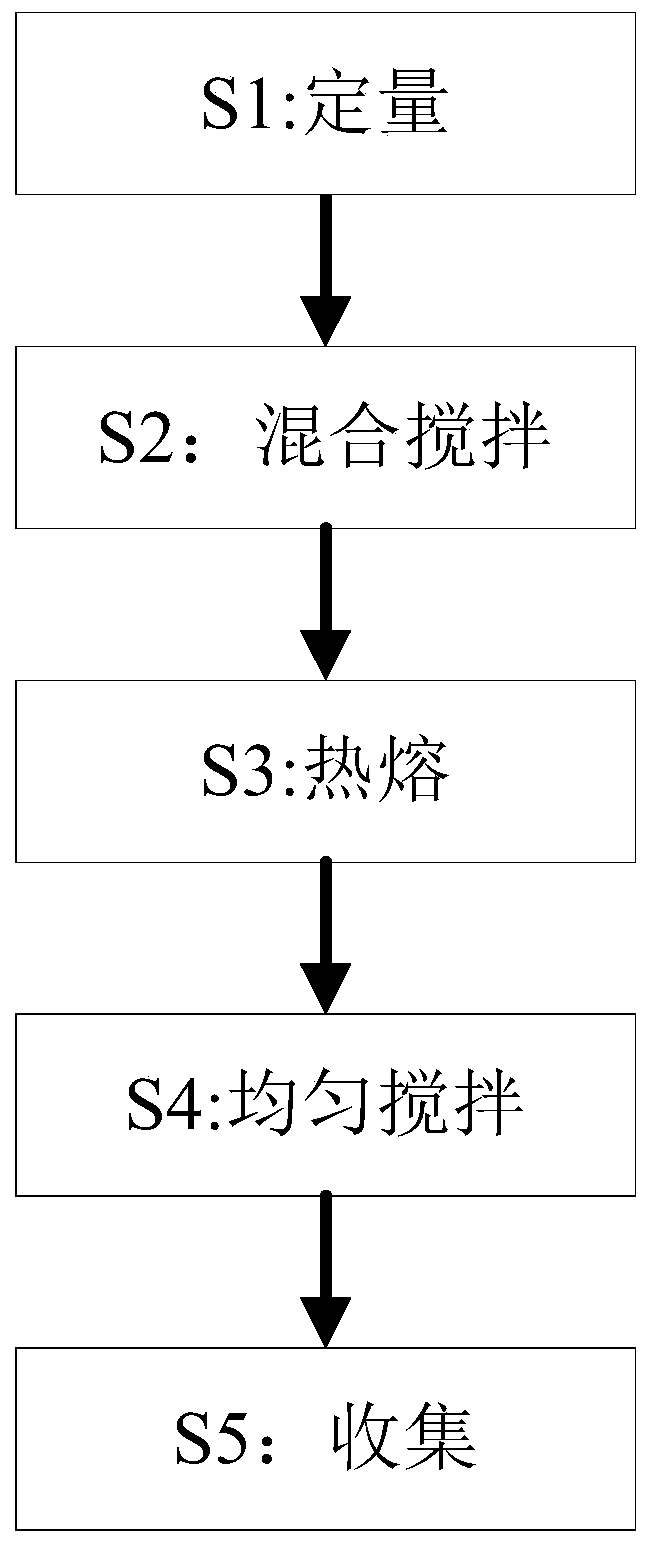

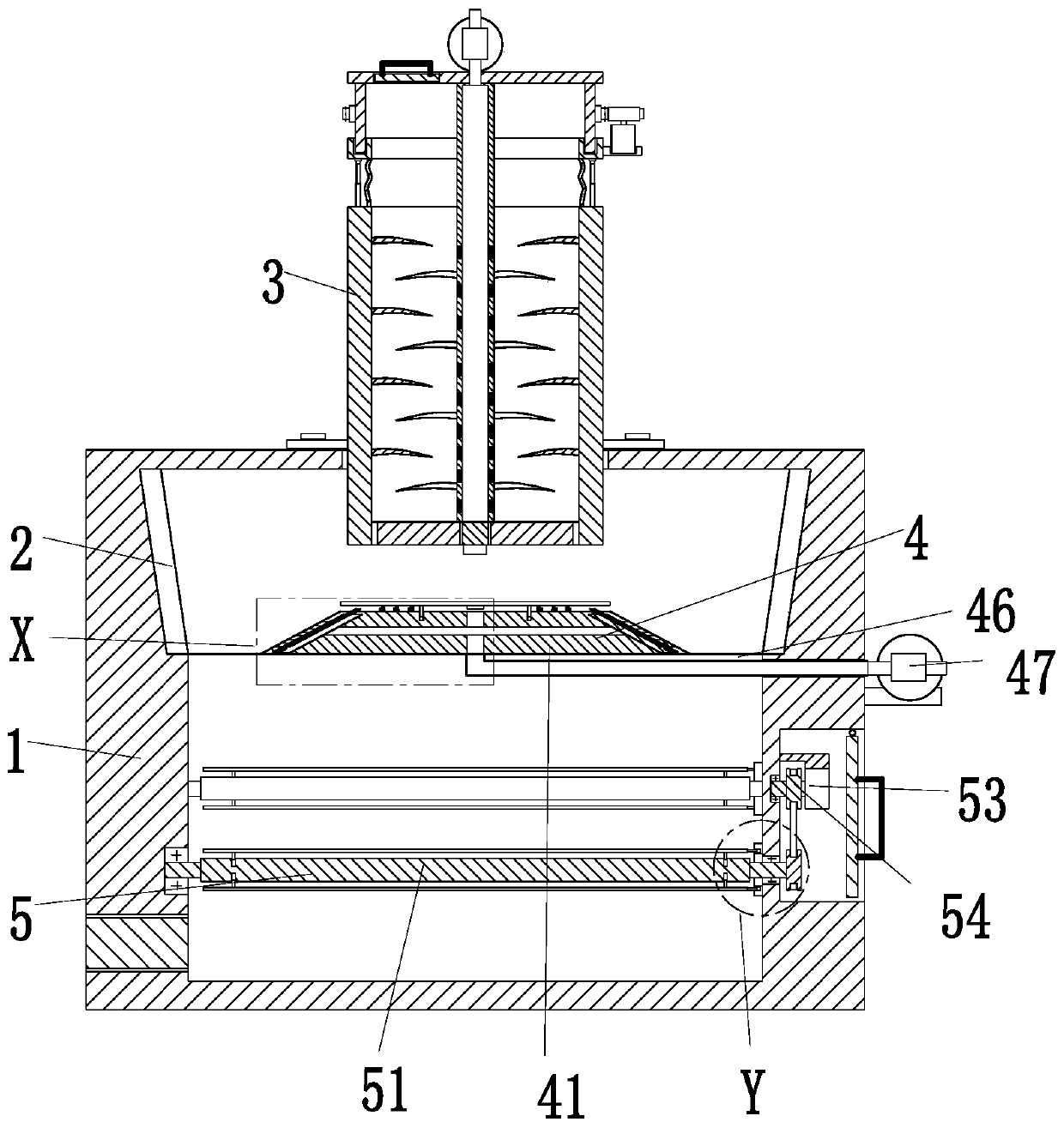

Pretreatment method for raw materials of plastic fresh-keeping film

The invention provides a pretreatment method for raw materials of a plastic fresh-keeping film. A frame body, an annular heating plate, a mixed hot melting device, a blowing device and a stirring device are matched to complete the operation, and the method can solve the problems that plastic particles begin to perform hot melting treatment without thorough mixing due to the fact that stirring andheating are simultaneously performed during existing hot melting and stirring, the mixing efficiency is reduced, and a part of the plastic particles are not subjected to sufficient hot melting due toa large amount of stirred plastic particles, so that part of the residual particles are mixed in a hot melt fluid after hot melting, the hot melting efficiency is reduced and the like.

Owner:侯哲宇

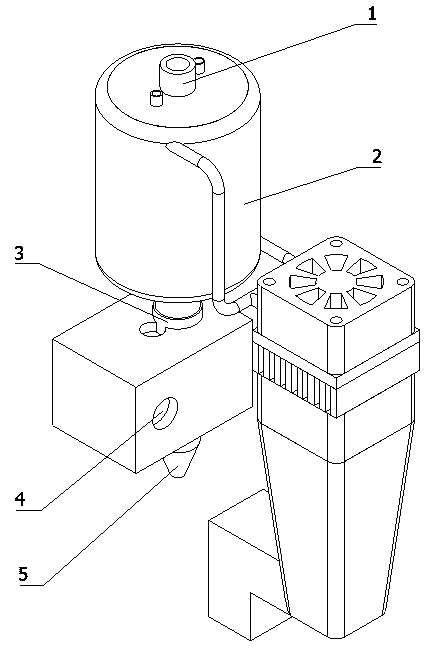

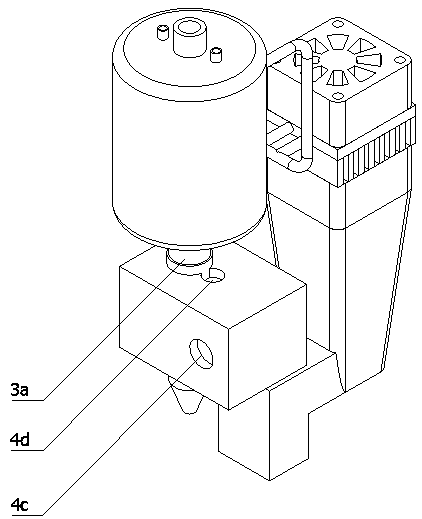

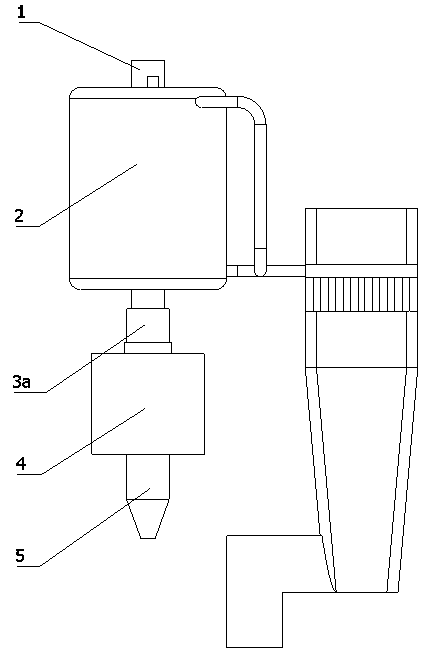

High-temperature 3D printing head

InactiveCN111113890AGuaranteed patencyImprove hot melt effectManufacturing heating elements3D object support structuresThermodynamicsComputer printing

The invention relates to the technical field of 3D printing and particularly relates to a high-temperature 3D printing head. The high-temperature 3D printing head comprises a material guide pipe, a heat dissipating assembly, a heat insulation assembly, a heating assembly and a discharging spray nozzle. The initial end of the material guide pipe is fixedly installed on a printer body and communicates with a feeding mechanism, the heat dissipating assembly is connected to the outer wall of the material guide pipe in a sleeving mode, the heat insulation assembly, the heating assembly and the discharging spray nozzle are connected with the material guide pipe in sequence, and the material guide pipe is made of a PTFE material. According to the technical scheme, the problem that an existing 3Dprinting head is prone to blockage is solved, the hot melting effect is good, the smoothness of the printing head is better ensured, the heat dissipating effect is good, blockage caused by expansion deformation of a wire in the printing head is avoided, and the manpower consumed for cleaning the printing head is reduced.

Owner:浙江高米网络科技有限公司

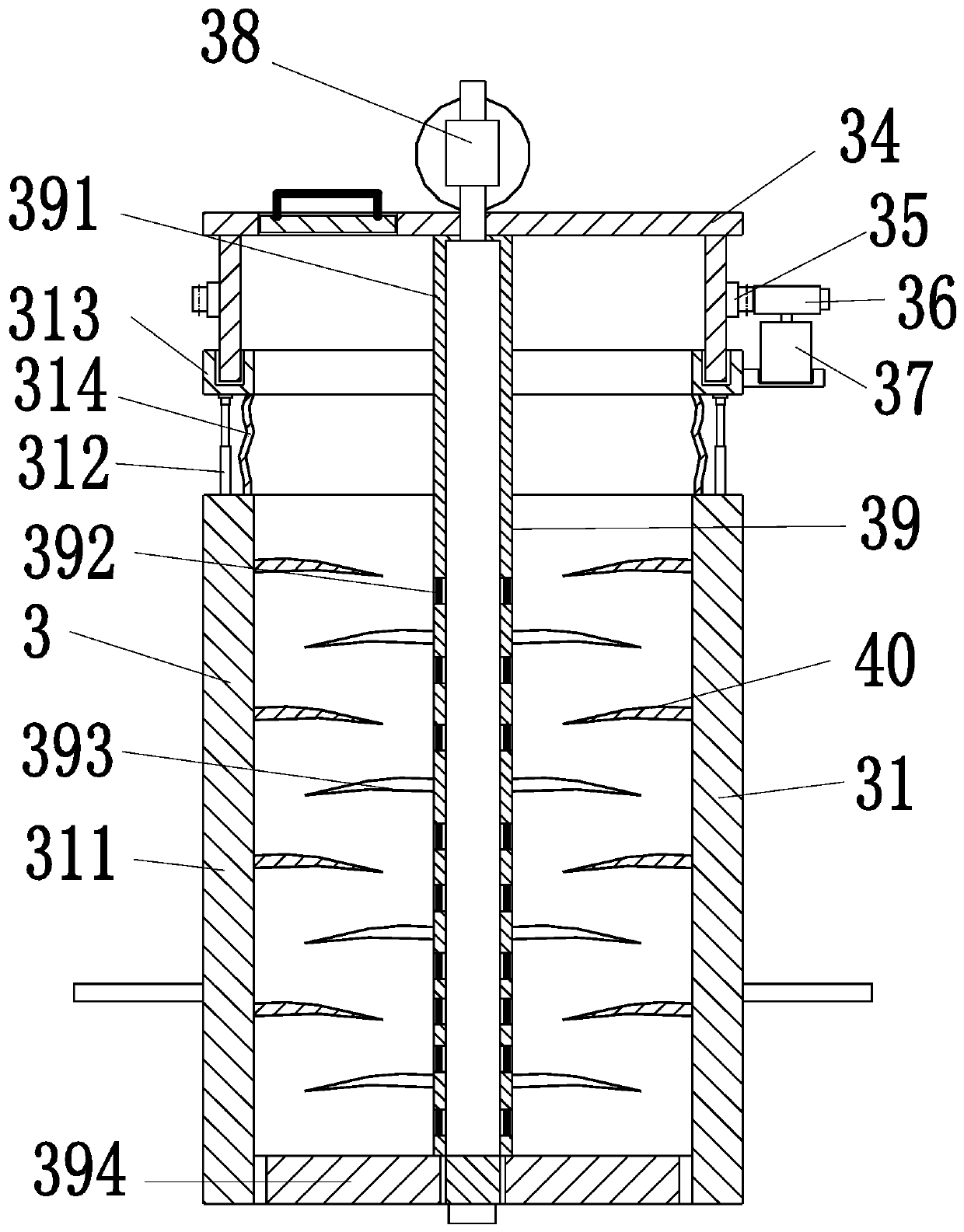

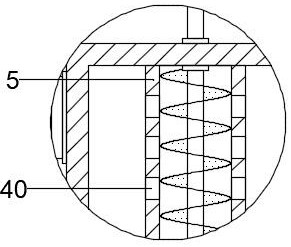

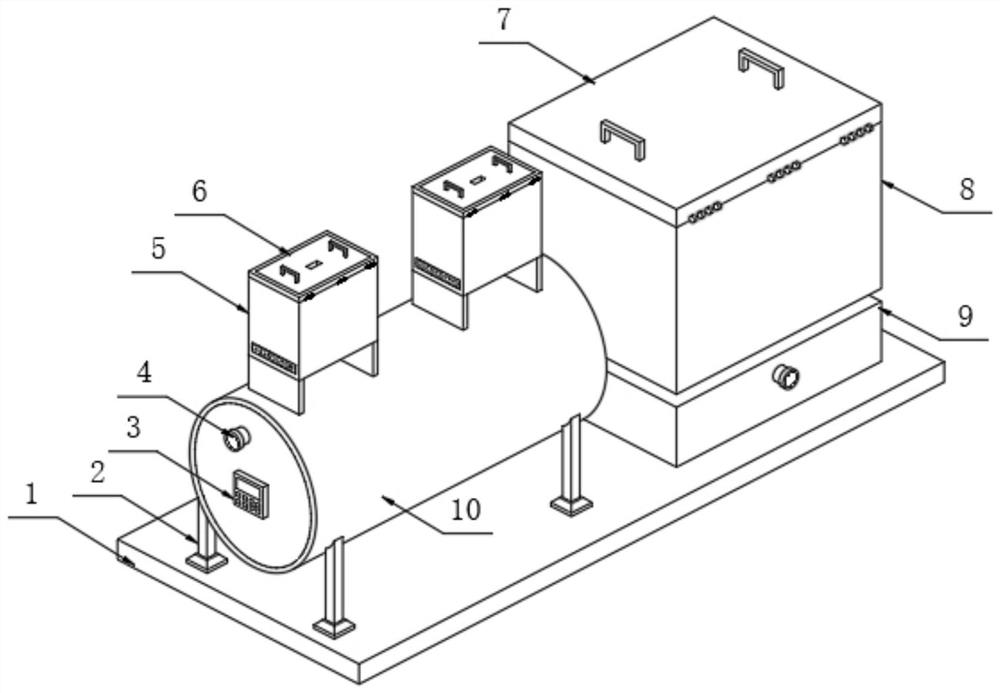

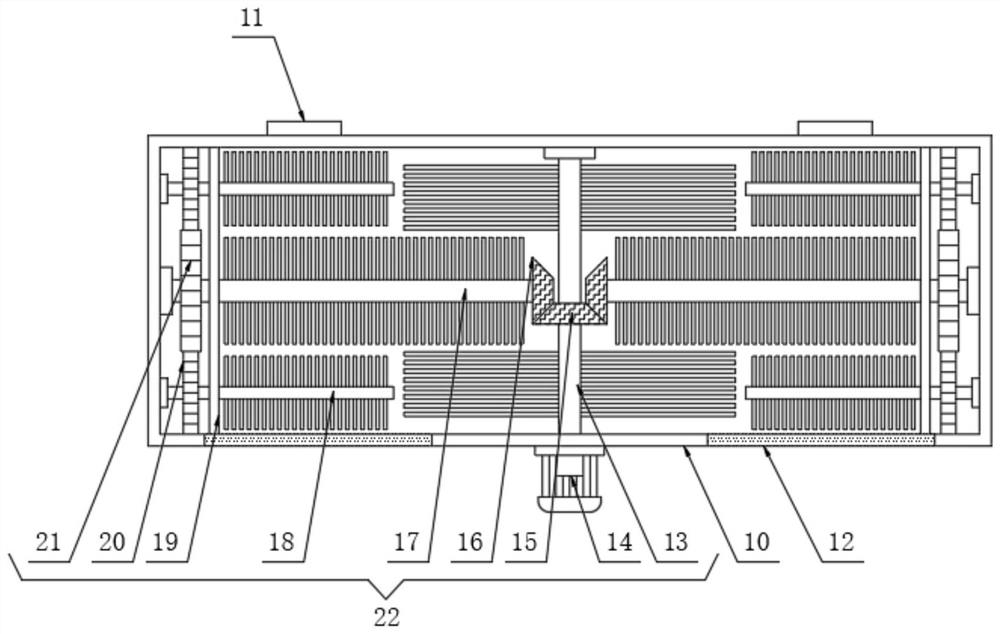

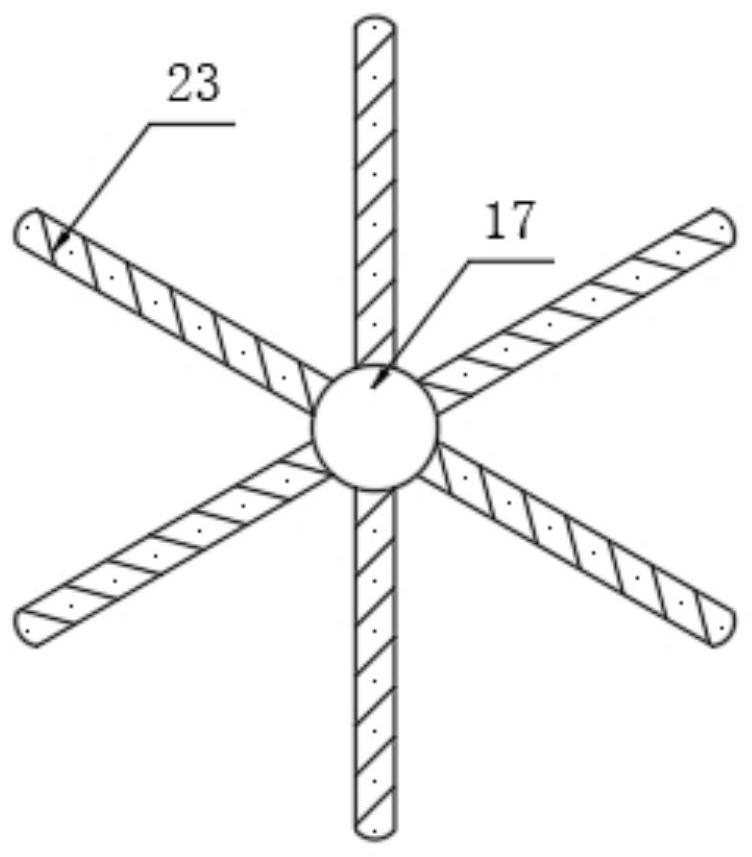

Slicing and melting integrated processing system for mask non-woven fabrics

ActiveCN113771370AIncrease heatRealize active exportDispersed particle filtrationMetal working apparatusProcess engineeringNonwoven fabric

The invention discloses a slicing and melting integrated processing system for mask non-woven fabrics. The slicing and melting integrated processing system comprises a shell, a feeding opening, an auger plate and a material hole, the feeding opening is formed in the top end of the shell, a molten material discharging opening is formed in the bottom end of the shell, a circulating barrel is fixedly installed in the shell, the auger plate rotatably conveys materials in the circulating barrel downwards, and a material hole is formed in the top end of the shell. According to the slicing and melting integrated processing system for the mask non-woven fabrics, the conduction effect of each cavity structure is utilized, so that hot oil can synchronously flow in materials accumulated on the outer wall of the shell and in the center of the interior, it is ensured that the outer side and the center area of the materials can be well heated, and the hot melting efficiency is improved; and meanwhile, double-blade opposite slicing and active guiding-out of waste gas in the melting process can be achieved through flowing of the hot oil, the structure is reasonable, and more energy saving and environmental protection are achieved.

Owner:徐州市康农消毒技术研究院有限公司

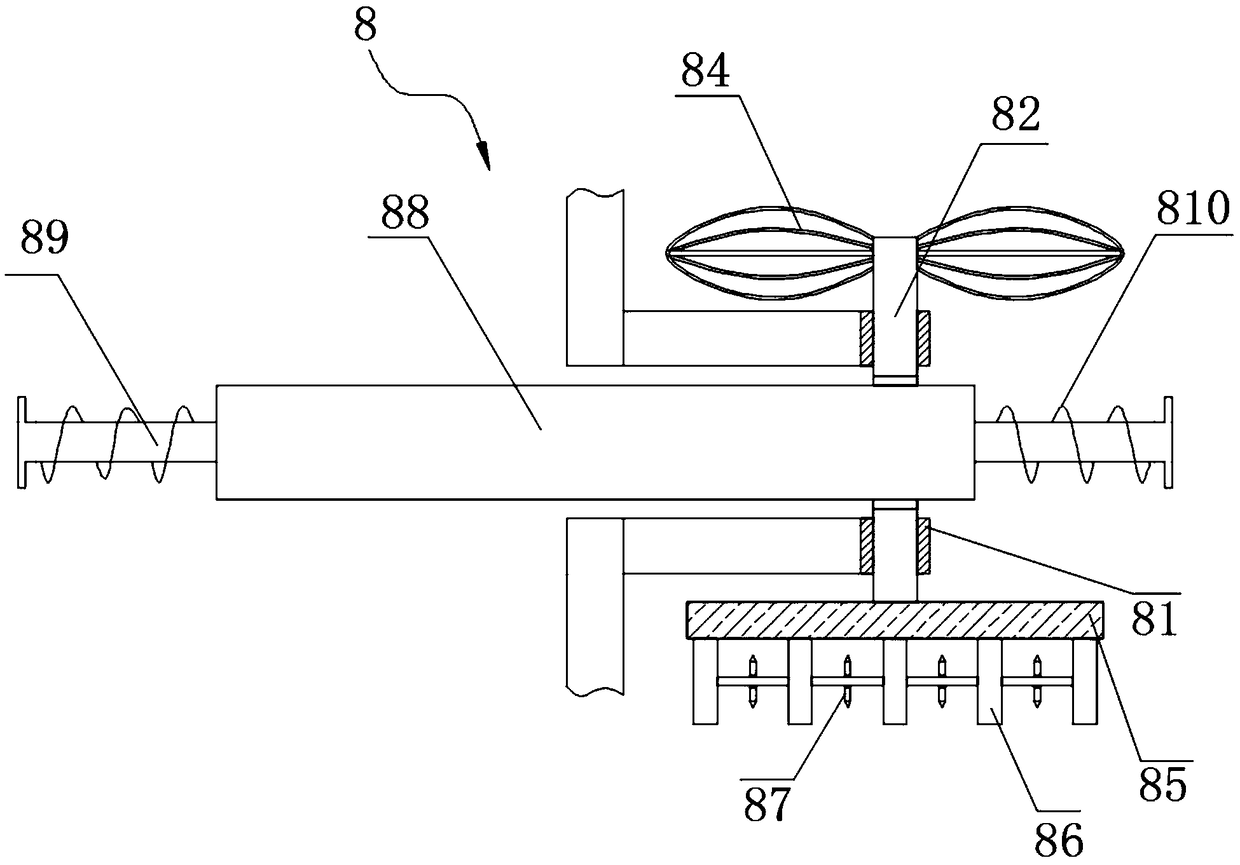

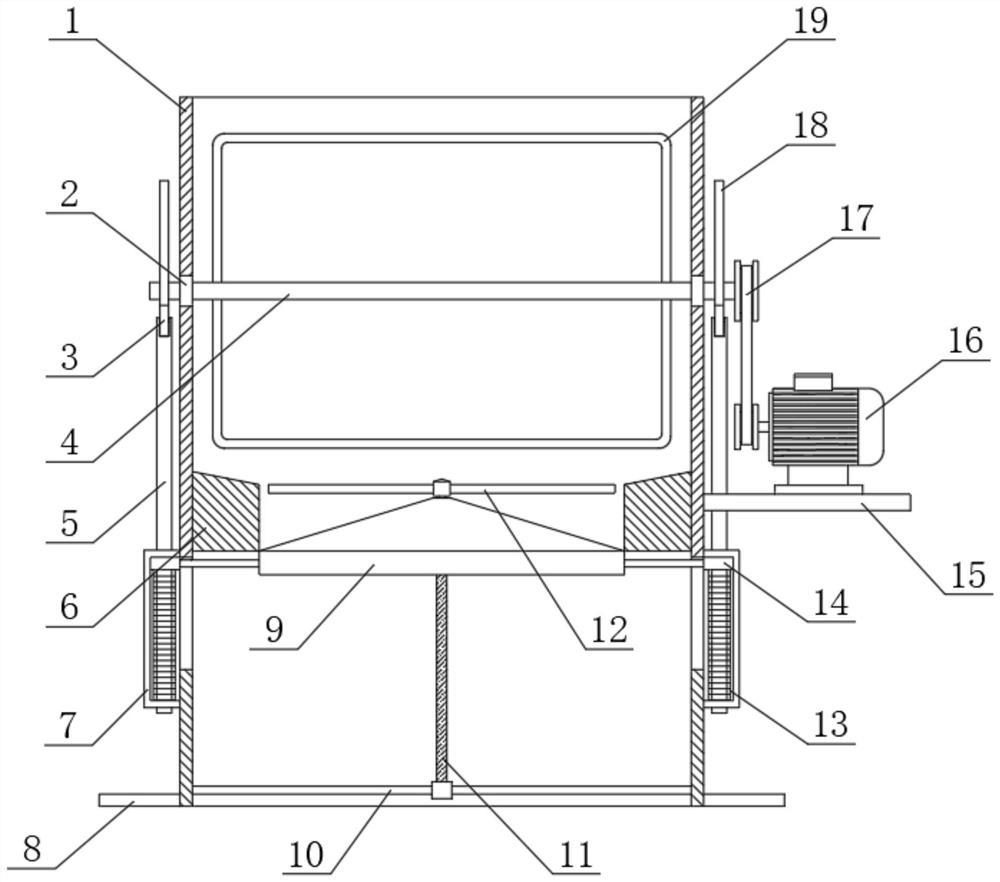

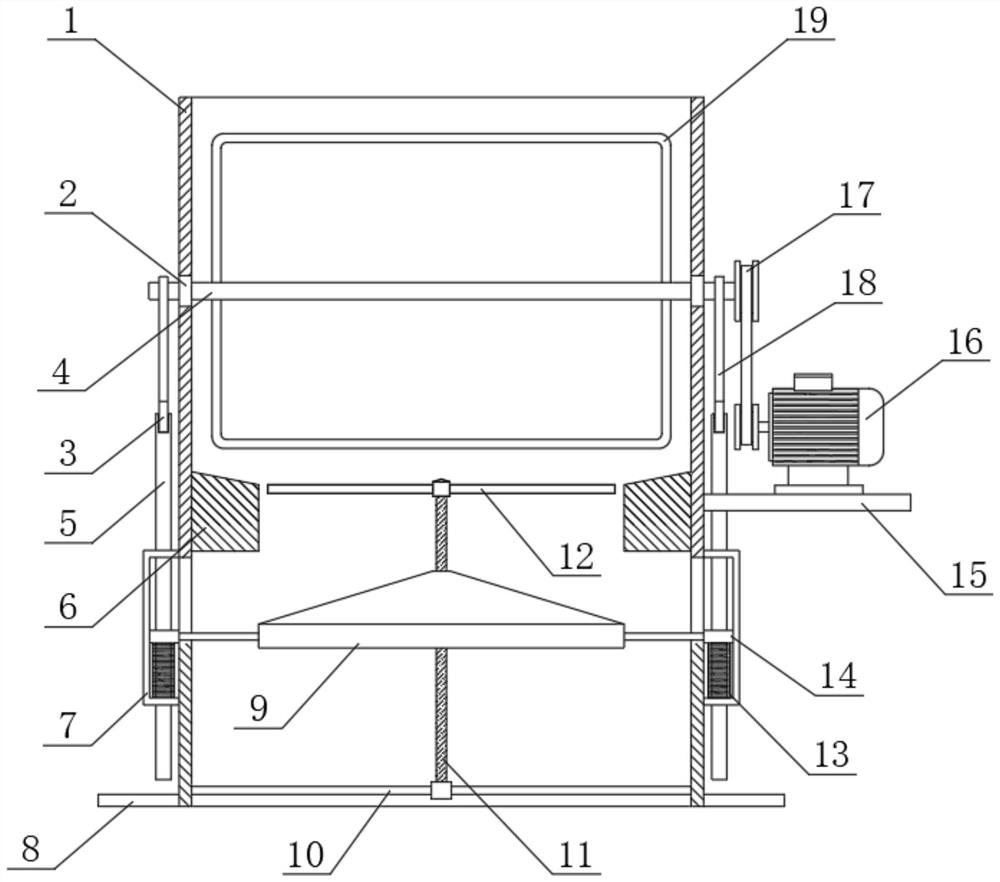

Raw material hot melting device for educational toy production

InactiveCN113183350AReduce the impactResidue reductionDomestic articlesElectric machineryEngineering

The invention discloses a raw material hot melting device for educational toy production. The raw material hot melting device comprises an outer box, wherein a plurality of hoppers fixedly communicate with the outer box; a motor is fixedly mounted on the outer box; a supporting rod is fixedly mounted at the driving end of the motor; an inner box is fixedly mounted on the supporting rod; and a rolling mechanism is mounted between the inner box and the outer box. The raw material hot melting device has the advantages that liquid plastic adhered to the side wall of the inner box can be scraped off, and the operation of scraping off the liquid plastic by using a scraper is not required, so that the labor intensity of workers is greatly reduced, the efficiency of the scraper is improved, the plastic residue on the side wall of the inner box is reduced, the utilization rate of the plastic is improved, and the influence of residual plastic solidification on the inner wall of the inner box is reduced; the inner box is driven to rotate through the rotation of the motor, and in the high-speed rotation process, plastic raw materials in the inner box can be adhered to the side wall of the inner box under the action of centrifugal force; and as the temperature on the side wall is higher than that in the inner box, the hot melting efficiency of the plastic raw materials can be greatly improved.

Owner:金溪县金港实业有限公司

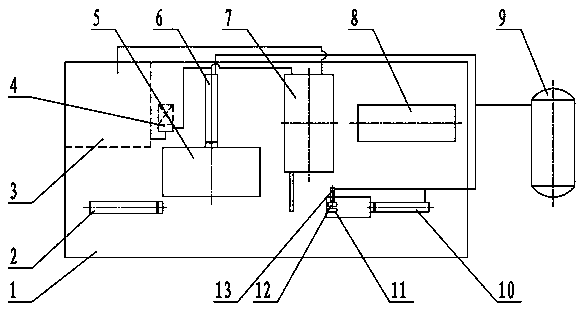

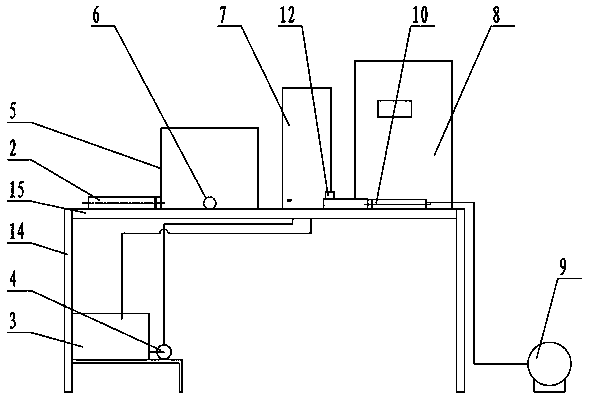

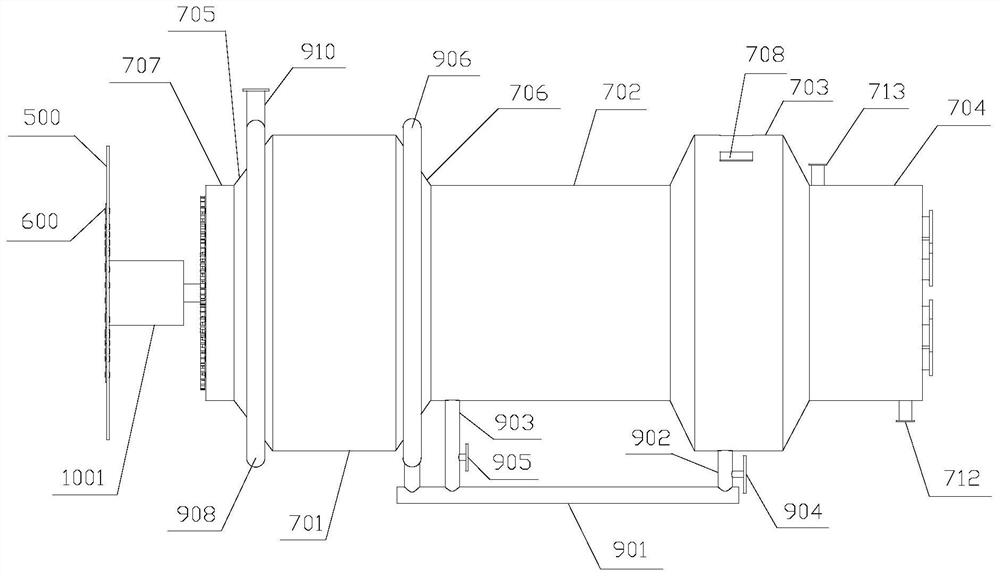

Automatic injection pipe production device

InactiveCN109703042ARealize automatic productionRealized production costNumerical controlCirculator pump

The invention belongs to the technical field of an injection pipe production device, and particularly relates to an automatic injection pipe production device. The device can achieve automatic injection pipe production through automatic feeding, and hot melting abut joint. The device comprises a worktable, and further comprises a high-frequency hot melt machine, a discharging feeding device, a pneumatic linkage device, a computer numerical control device, a cooling circular pump, a water tank and an air pump. The aim that according to the injection pipe production device, through automatic feeding and hot melting abut joint, injection pipe automatic production is achieved can be achieved.

Owner:山东新雪矿井降温科技有限公司

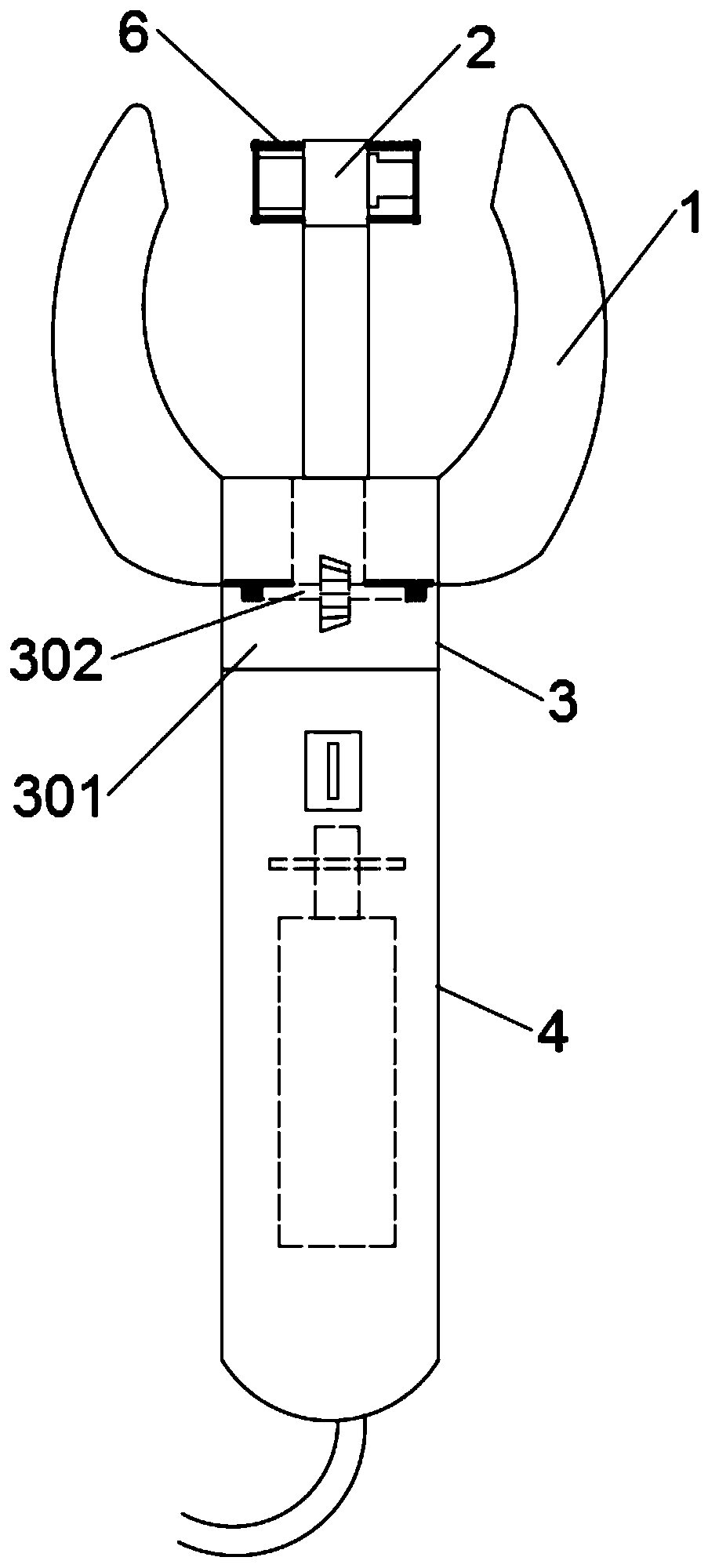

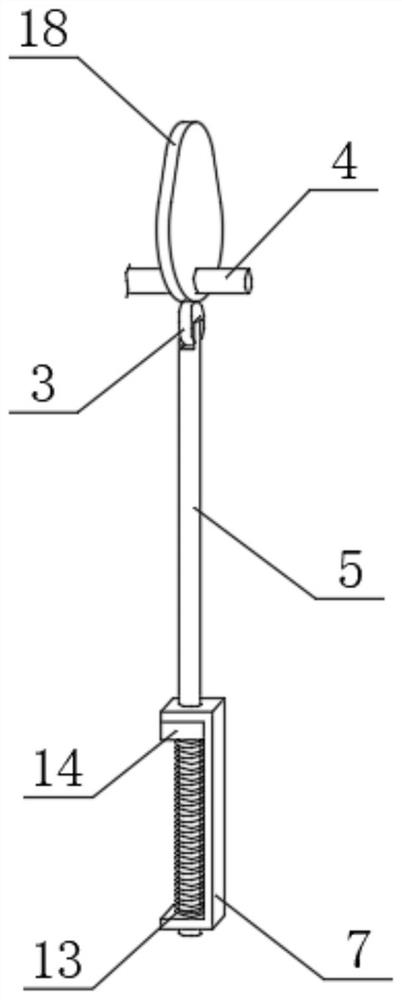

Automatic hot melting device

The invention discloses an automatic hot melting device which comprises pipe fitting chucks, an ironing head, a power cabin and a holding handle, wherein the holding handle can be conveniently held bya worker; a built-in motor as a power source is arranged in the holding handle; a reversing switch for controlling the built-in motor is mounted on the holding handle; the power cabin is mounted at one end of the holding handle; the other end of the holding handle is connected with a power supply through a supply lead; the pipe fitting chucks are arranged on the two sides of the power cabin; theironing head is arranged between the pipe fitting chucks; the power cabin is used for controlling action of the pipe fitting chucks and the ironing head; the pipe fitting chucks are used for clampingpipe fittings; adjustable pipe clamps are arranged on the pipe fitting chucks; the ironing head is used for hot melting of the pipe fittings; the pipe fitting chucks clamp the pipe fitting and a pipeseparately, and then, the pipe fitting chucks are controlled to move towards the ironing head so as to carry out hot melting on the pipe fitting and the pipe, so that the problem in the prior art thatthe hot melting device is inconvenient to operate is effectively solved.

Owner:谢明金

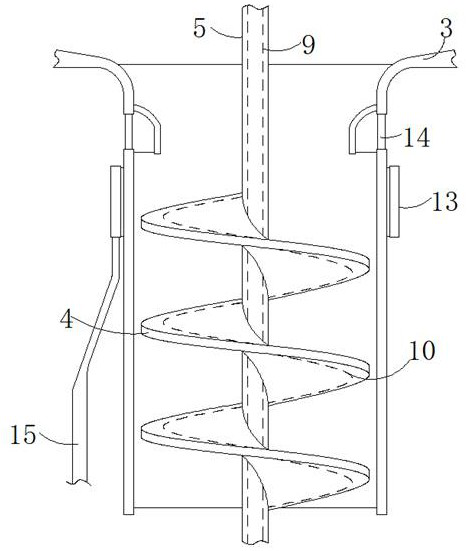

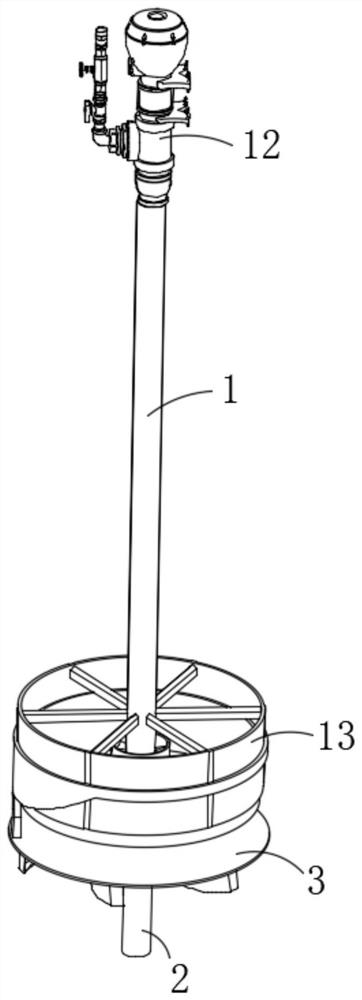

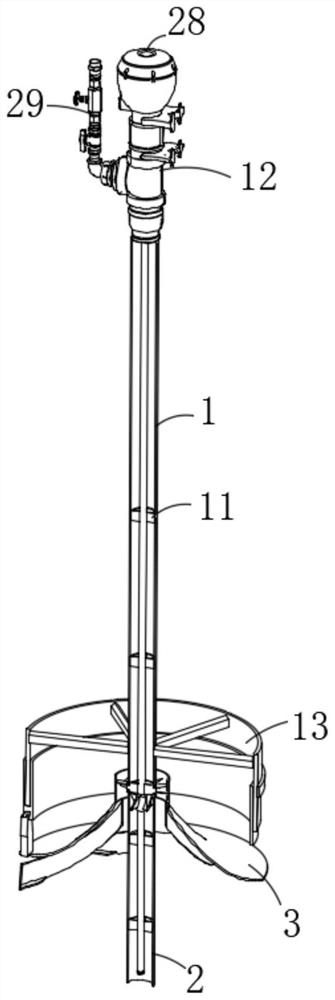

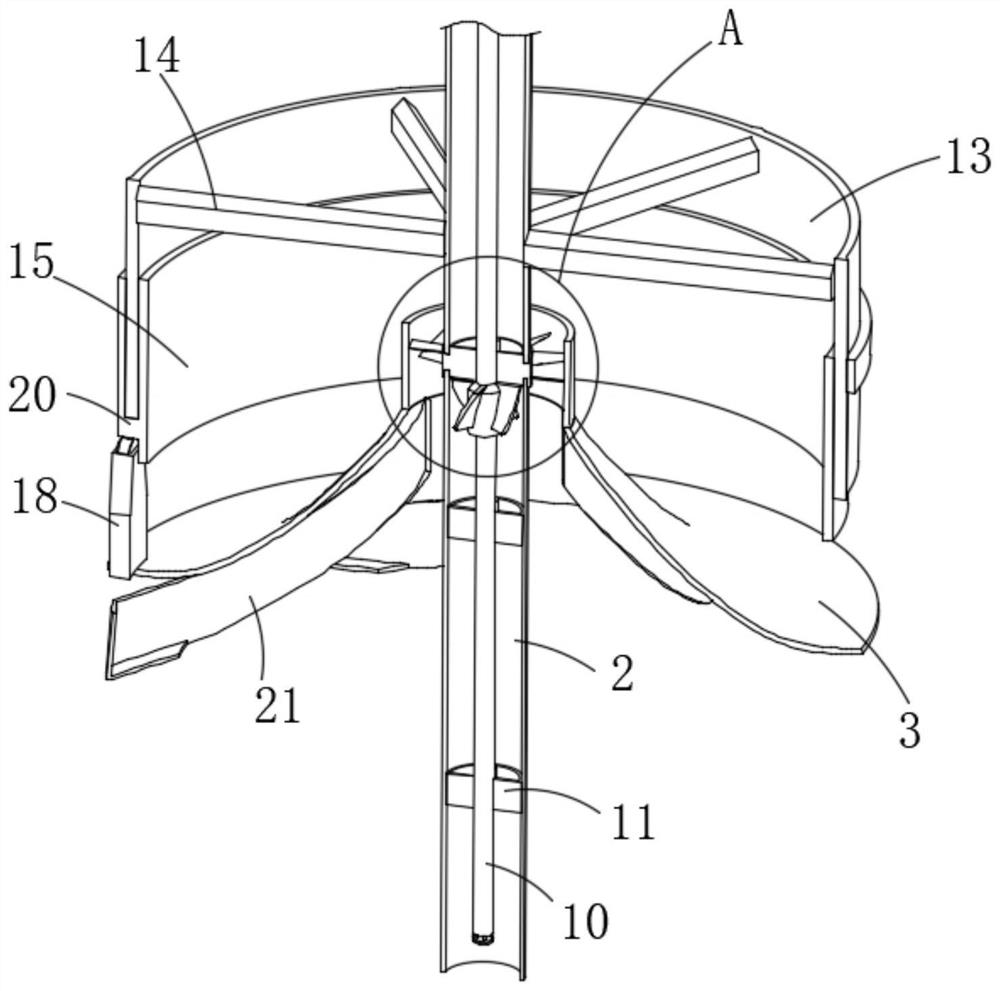

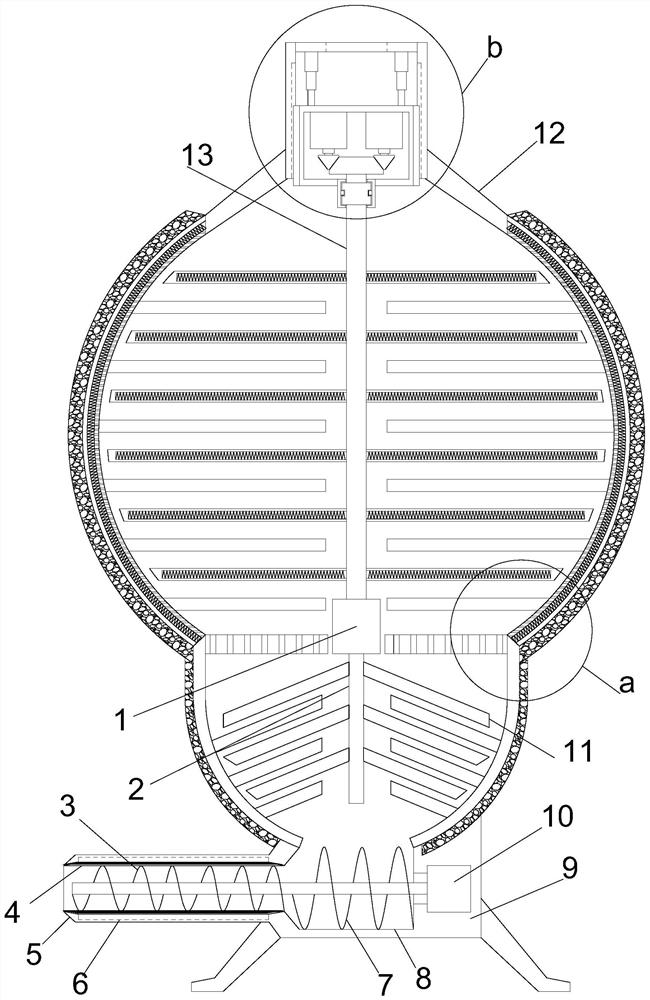

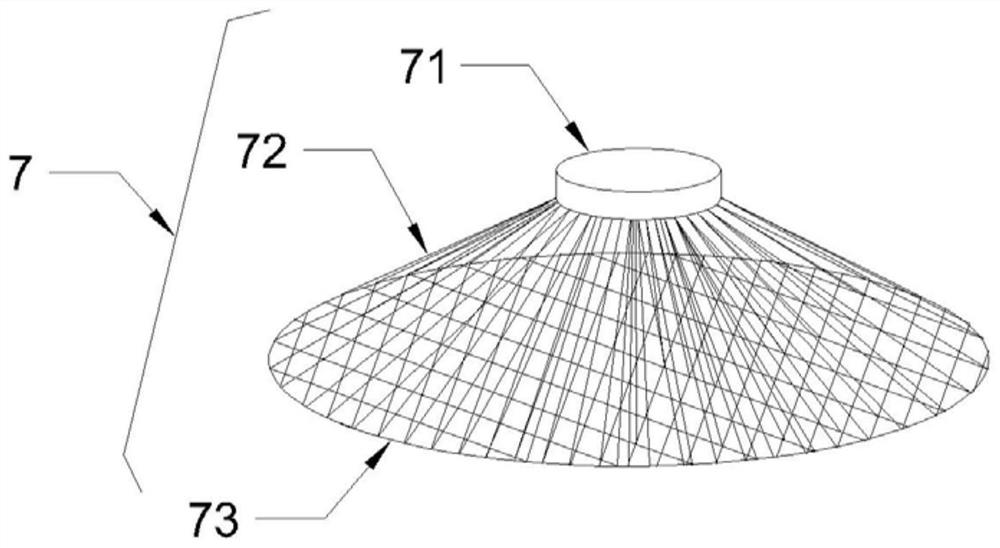

An asphalt heating device for municipal road maintenance

ActiveCN108265588BEvenly heatedImprove hot melt efficiencyRoads maintainenceElectric machineDrive shaft

The invention discloses an asphalt heating device for municipal road maintenance. A tapered roller is fixedly connected to the middle of a driving shaft, a ring wall is arranged on the outer side of the tapered roller and fixedly connected with the inner wall of a device body, charging holes are fixedly connected to the two sides of the upper end of the device body and communicated with the interior of the device body, a driving motor is electrically connected with a power supply and a switch, a partition panel is arranged at the lower end of the tapered roller and fixedly connected with the device body, discharging holes are symmetrically formed in the circumference of the partition panel, the partition panel sleeves a driving shaft, and a fixed block is arranged at the lower end of the partition panel. According to the device, asphalt materials are crushed continuously through the tapered roller and the ring wall, after crushing, the crushed asphalt materials are heated and melted through a heating wire, in the melting process, a driven shaft which revolves both around a driving shaft and on its own axis stirs asphalt on a filter plate, the asphalt is heated uniformly, and melting is accelerated; meanwhile, generated harmful gas in the heating process is purified through a water purification box. The device is reasonable and applicable in structure, the asphalt hot melting efficiency is greatly improved, and the phenomenon that the ambient air is polluted is avoided.

Owner:广东道衡建设工程有限公司

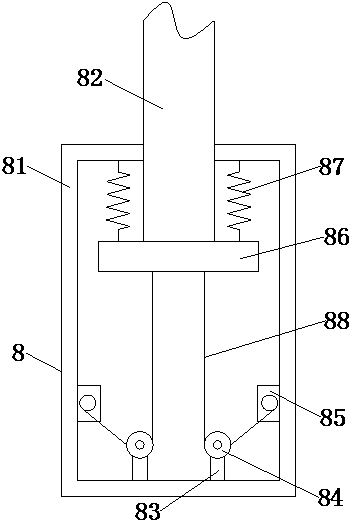

Automatic feeding device for rubber machine

The invention discloses an automatic feeding device for a rubber machine. The device comprises a feeding trough, wherein an elliptical rotating block is driven by a rotating rod to rotate to drive a rotating wheel to move up and down so as to push a groove supporting round bar and a fixed block to move up and down, and meanwhile, a telescopic spring shrinks to work to lift intermittently. When thefixed block moves up and down to work, a cone-shaped seat device will be driven to move up and down, so that a lead screw will be driven to rotate to work and a stirring rod device will be driven tostir, thus, a phenomenon that rubber particles plug is avoided. Meanwhile, by the cone-shaped connecting seat device, the rubber particles are uniformly divided, so that the rubber particle hot melting efficiency is improved. In addition, through the rotating rod which drives the concave stirring round bar to rotate, the concave stirring round bar will mix the rubber particles, and meanwhile, stirs the rubber particles at the feeding port, so that the plugging phenomenon is avoided.

Owner:郑叶芳

Direct-current ore-smelting electric furnace with variable loop

ActiveCN111928665AAvoid wear and tearAffect positive and negative polesElectric heating for furnacesElectrical connectionEngineering

The invention belongs to the technical field of direct-current ore-smelting electric furnaces, in particular to a direct-current ore-smelting electric furnace with a variable loop. The direct-currentore-smelting electric furnace comprises a furnace body; the inner surface of the furnace body is fixedly connected with a servo motor at the bottom of the furnace body, and the servo motor is electrically connected with a controller through a wire; four uniformly-arranged conduction columns are fixedly connected to a drive shaft of the servo motor; the electrodes of the left and right conduction columns are a negative electrode and a positive electrode respectively; the electrodes of the front and rear conduction columns are a negative electrode and a positive electrode respectively; and electrode disks which are uniformly arranged are fixedly connected in the inner wall of the supporting plate. The direct-current ore-smelting electric furnace is mainly used for solving the problems that in the working process of an existing ore-smelting electric furnace, the calorific value of a positive electrode anode area is larger than that of a negative electrode cathode area, smelting current isa main heat energy source for electrode roasting, roasting near an electrode holder is similar under the condition that the pressing-down speed is equal, and but due to the fact that anode electrodeconsumption is relatively high and heating of the anode by an end head is more serious, and soft and hard electrode breakage accidents often occur.

Owner:贵州金源锰业股份有限公司

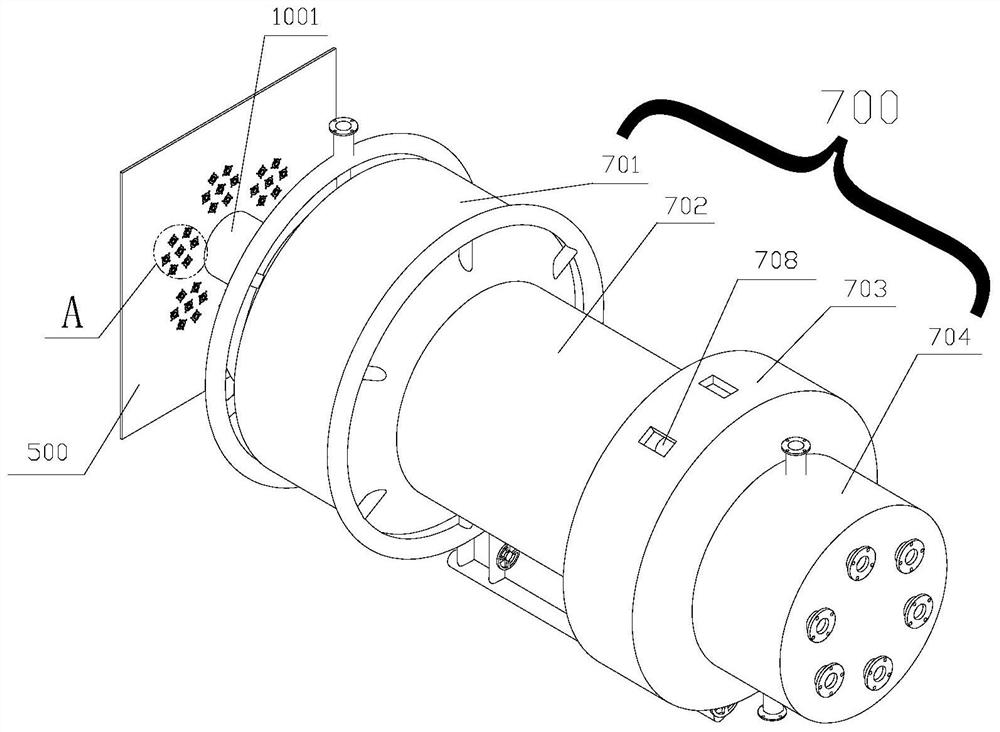

An adjustable oxygen supply system and method for an oxygen-enriched smelting furnace

ActiveCN113532111BHot melt fastSmooth feedingMaintainance of heating chambersCrucible furnacesEngineeringMechanical engineering

The present invention relates to the field of smelting furnace supply systems, in particular to an adjustable oxygen supply system for an oxygen-enriched smelting furnace. A spray pipe extending along the direction of the central axis is fixedly connected, and a rotating frame is connected to the close port of the air spray pipe and the protruding pipe. The lower end of the rotating frame is fixedly connected to a connecting sleeve, and the connecting sleeve The outer surface is provided with a number of swirl vanes, the connecting sleeve and the rotating frame are both movably sleeved on the outer surface of the spray pipe, and the outer surface of the rotating frame is provided with a connecting cylinder, and an oxygen-enriched melting furnace is also provided. Adjusting the oxygen supply method, the present invention is used in the Aisa smelting process, aiming at the smelting of the crushed flake metal scraps during copper metal recovery, the lower end of the pipe extending into the smelting process is no longer directly inserted into the hot melt material, It is conducive to the rapid hot-melting of flake scrap materials, ensuring uniform feeding of scrap materials, and improving hot-melt efficiency.

Owner:黄石市泓义城市矿产资源产业研究院有限公司

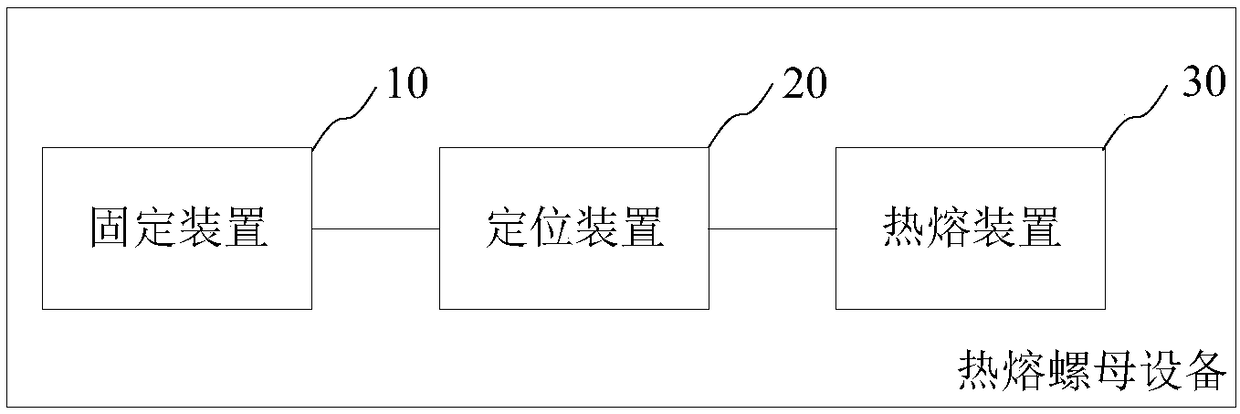

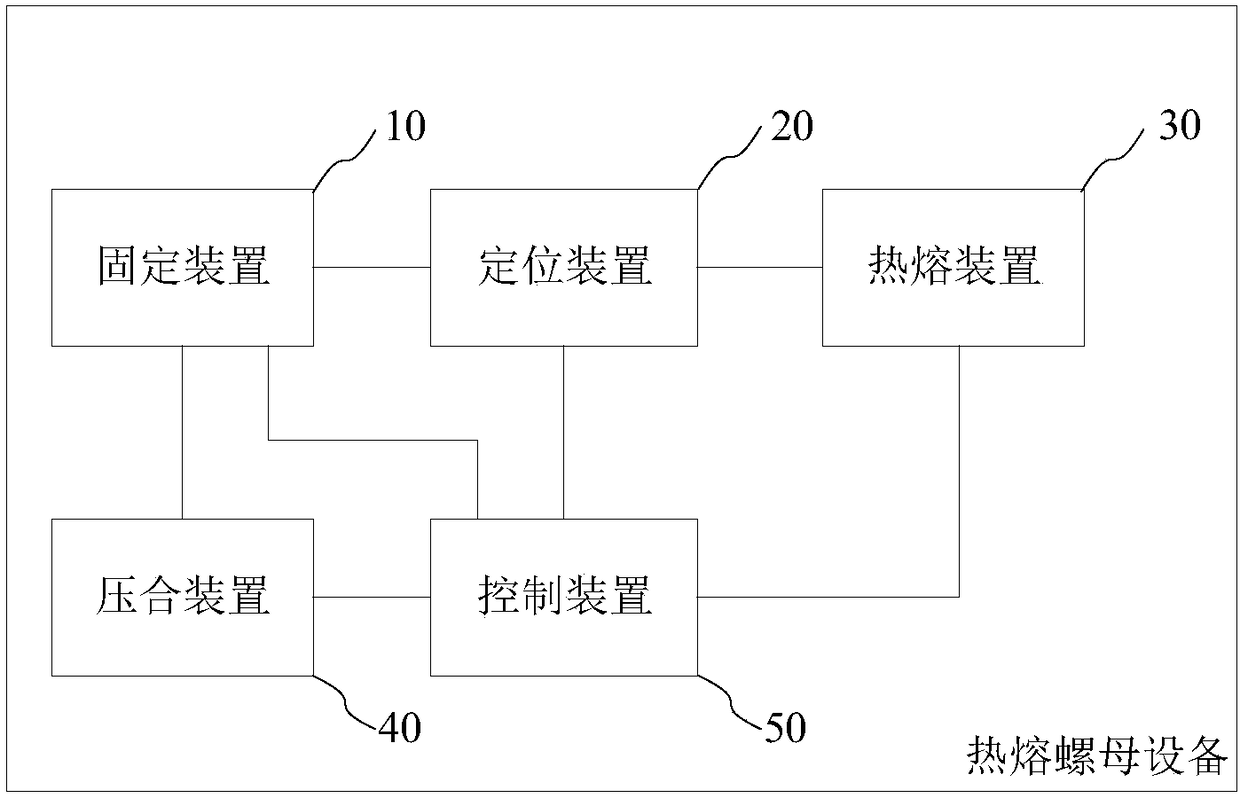

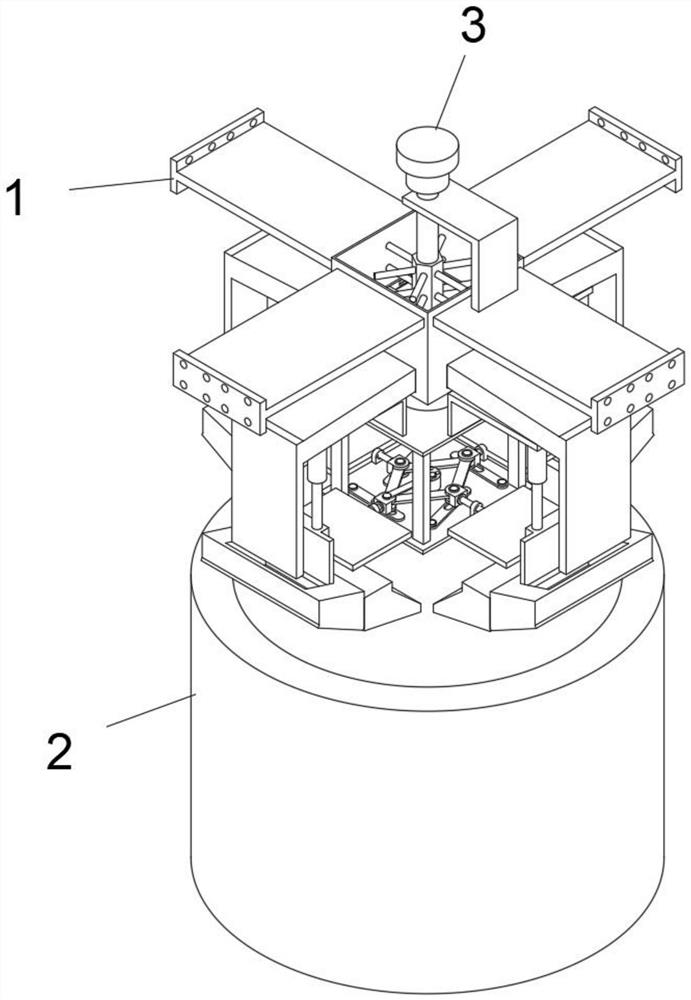

Heat staking insert equipment and method for inserting heat staking insert

The invention relates to heat staking insert equipment and a method for inserting a heat staking insert. The heat staking insert equipment comprises a fixing device used for fixing a workpiece to be subjected to heat staking inserting, a positioning device used for positioning the center of an insert hole in the workpiece, a heat staking device used for heat staking inserting of the insert into the workpiece according to a positioning result. By means of the heat staking insert equipment and the method for inserting the heat staking insert, the center of the insert hole is accurately positioned, the concentricity of the insert is effectively improved, the accuracy of the insert after heat staking is improved greatly, the complexity of workpiece assembly is further simplified, and the product quality is improved.

Owner:SHANGHAI TRANSSION CO LTD

Mixing device for electronic packaging high-thermal-conductivity material

ActiveCN112705094AQuick mixImprove hot melt efficiencyGlass furnace apparatusTransportation and packagingSurface mountingHeat losses

The invention relates to the field of electronic packaging material production, particularly to a mixing device for an electronic packaging high-thermal-conductivity material. The mixing device comprises a vertically arranged cambered surface mounting cylinder, wherein a spherical surface mounting cylinder is vertically arranged in the middle of the lower end of the cambered surface mounting cylinder, a support mounting plate is horizontally arranged at the lower end of the spherical surface mounting cylinder, supporting mounting columns are arranged at the four corners of the lower end of the support mounting plate correspondingly, a material guiding mounting groove is formed in the upper end of the support mounting plate and matched with a spherical surface mounting cylinder, a supporting mounting cylinder is vertically arranged over the cambered surface mounting cylinder, and a lifting transmission cylinder is vertically arranged in the supporting mounting cylinder. According to the invention, by matching synchronous transmission with hot melting, mixing and stirring, raw materials can be quickly mixed; by matching with a heat preservation structure, heat loss is reduced, the hot melting efficiency of the raw materials is remarkably improved, and the mixing efficiency and quality are improved; and through lifting adjustment, the device can adapt to mixing of the raw materials of different sizes, the adaptability adjusting performance of the device is remarkably improved, and material guiding is smoother.

Owner:HEBEI NORTH UNIV

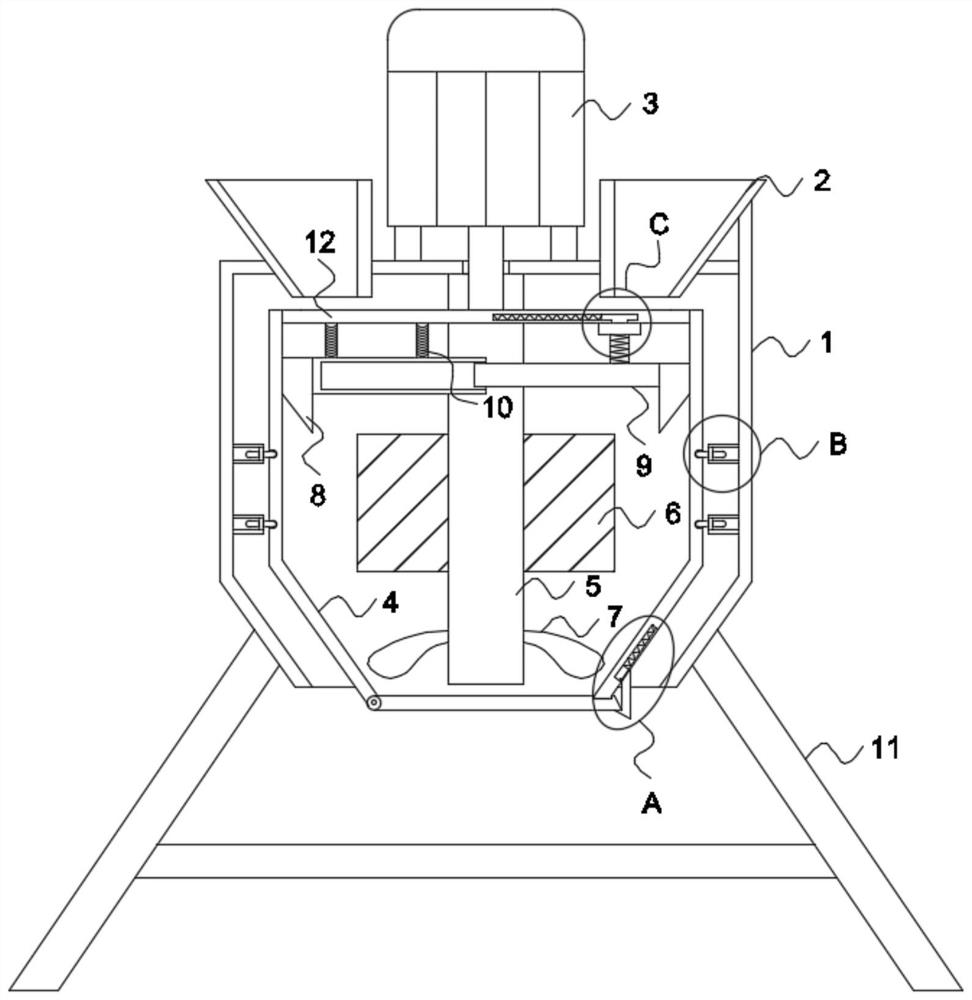

Lead-free alloy new material alloy pipe preparation device for food mechanical part

PendingCN112846103AImprove hot melt efficiencyShort cooling timeFoundry mouldsFoundry coresAlloyCooling pipe

The invention discloses a lead-free alloy new material alloy pipe preparation device for a food mechanical part. The lead-free alloy new material alloy pipe preparation device comprises a base, a melting box and a box body, wherein the melting box is fixedly arranged above the base through a plurality of supporting rods, the upper portion of the box body is open, and the box body is fixedly arranged on the base; a stirring assembly used for efficiently and evenly stirring various metal raw materials in the melting box to promote the melting efficiency of the metal raw materials is arranged in the melting box, the interior of the box body is divided into a water storage bin and a cooling bin through a sealing partition plate, a lifting plate is arranged in the water storage bin in an up-down moving manner, and a bearing table is arranged above the lifting plate; and a plurality of pipe molds are arranged on the bearing table at equal intervals from front to back, a cooling pipe is fixedly arranged in the cooling bin, and the cooling pipe is of a snakelike winding structure. The lead-free alloy new material alloy pipe preparation device can effectively improve the hot melting efficiency of various metal raw materials and reduce the cooling time consumption of the poured pipe molds, greatly improves the preparation efficiency of a novel lead-free alloy material alloy pipe, and has good economic benefits and practical significance.

Owner:SUZHOU RICHMOND ADVANCED MATERIAL TECH TRANSFER CO LTD

Waste foam fuse machine

PendingCN112706326ARaise smashAvoid enteringPlastic recyclingMechanical material recoveryProcess engineeringMechanical engineering

The invention discloses a waste foam fuse machine, and relates to the technical field of waste foams. The waste foam fuse machine comprises a crushing box, the bottom of the crushing box is fixedly connected with a first discharging cylinder, the side, away from the first discharging cylinder, of the bottom of the crushing box is fixedly connected with a second discharging cylinder, and the interior of the crushing box is rotatably connected with a first crushing roller. According to the waste foam fuse machine, a second smashing roller, the first smashing roller and a first servo motor are arranged, the output end of the first servo motor drives the second smashing roller to rotate, the second smashing roller drives the first smashing roller to rotate through teeth, foam is smashed through the second smashing roller and the first smashing roller, large foam can be smashed, large foam is prevented from entering a hot melting box, the volume in the hot melting box cannot be reasonably utilized due to the fact that gaps between the foam are large, the volume in the hot melting box can be reasonably utilized by the machine, and therefore the hot melting efficiency of the fuse machine is improved.

Owner:曹璐

Energy-saving and environment-friendly efficient treatment device for urban garbage

InactiveCN113183361AImprove cleaning efficiencyReduce pollutionPlastic recyclingPressesWater storageProcess engineering

The invention relates to the technical field of urban garbage treatment, and discloses an energy-saving and environment-friendly efficient treatment device for urban garbage. The energy-saving and environment-friendly efficient treatment device is characterized in that the outer side of a cleaning box is fixedly connected with a controller and a water injection port, a cleaning mechanism is installed inside the cleaning box, an extrusion mechanism is further installed above a feeding port, a hot melting box is installed at the top of a water storage box, a protective shell is hinged to the top of the hot melting box, and an adjusting mechanism is installed inside the water storage box. Plastic garbage in the cleaning box can be cleaned through the cleaning mechanism, and a transverse cleaning brush and a longitudinal cleaning brush can be driven to rotate at the same time, so that the cleaning efficiency of the plastic garbage in the cleaning box is improved, and the cleaning mechanism can complete the cleaning task in a short time; and the plastic garbage in an extrusion box can be extruded through the extrusion mechanism so that the occupied area of the plastic garbage can be reduced, a residual liquid in the plastic garbage can further be automatically extruded, and subsequent deep processing is facilitated.

Owner:扬州润中信息科技有限公司

Hot melting equipment for PVC (polyvinyl chloride) pipe processing

InactiveCN113696363AConvey evenlyUneven distributionGrain treatmentsPolyvinyl chlorideProcess engineering

The invention relates to the technical field of hot melting for PVC pipe processing, in particular to hot melting equipment for PVC pipe processing. According to the technical scheme, the technical problems that in the using process of existing hot melting equipment for PVC pipe processing, particles in a material body are large, so that hot melting is inconvenient, and the feeding speed and position are inconvenient to adjust are solved. The hot melting equipment for PVC pipe processing comprises four fixed support plates, a hot melting box and a feeding control mechanism, wherein the feeding control mechanism is located over the hot melting box; and the four fixed support plates are fixedly connected to the upper end of the feeding control mechanism. According to the technical scheme, the hot melting equipment has the beneficial effects that the positions of raw material particles falling into the hot melting box and the discharging speed of fed materials can be controlled through the feeding control mechanism, four conveying openings in the feeding control mechanism can be rapidly closed, and the material body cannot be conveyed into the hot melting box, so that the hot melting effect is excellent.

Owner:湖南意风环保科技有限公司

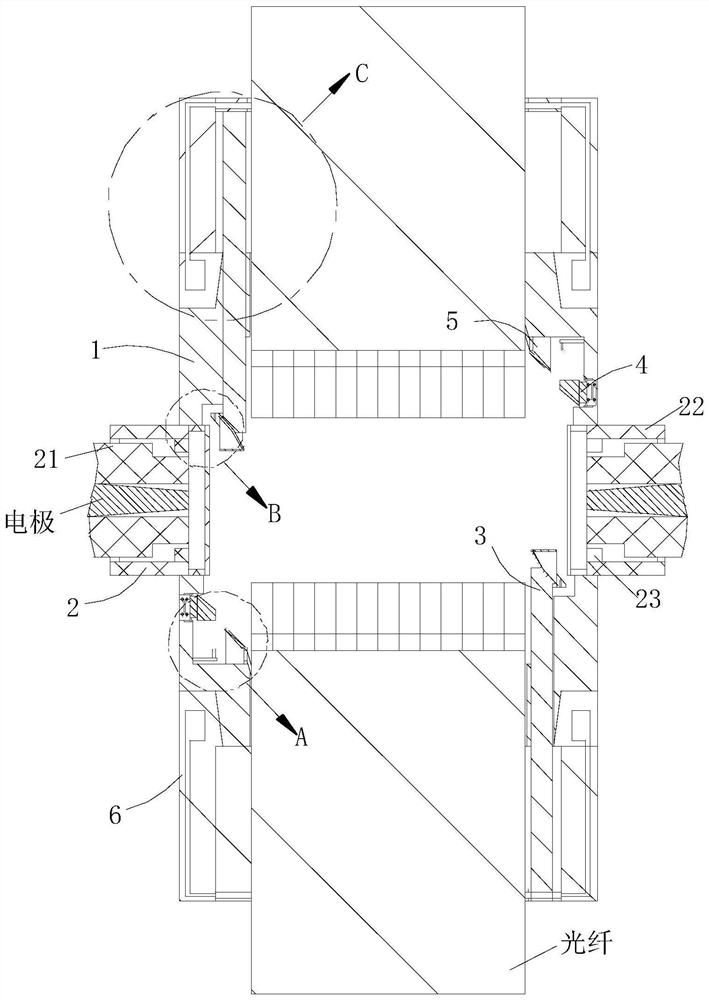

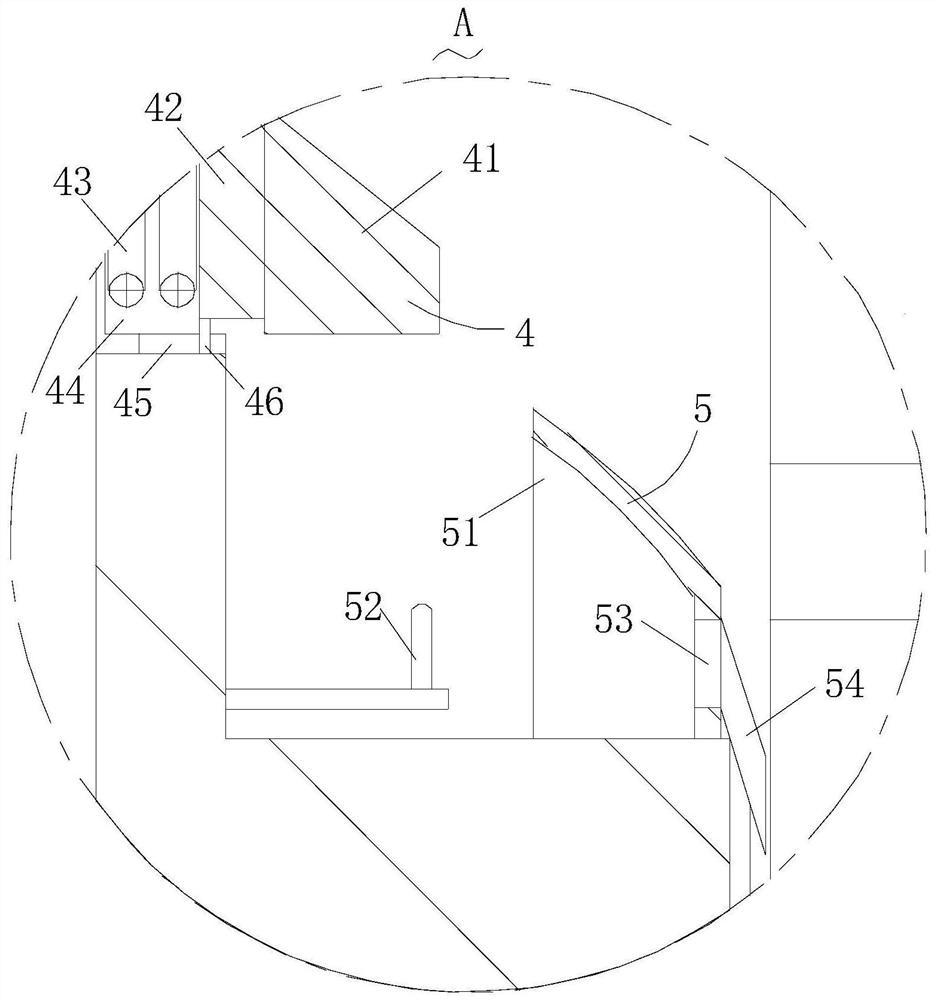

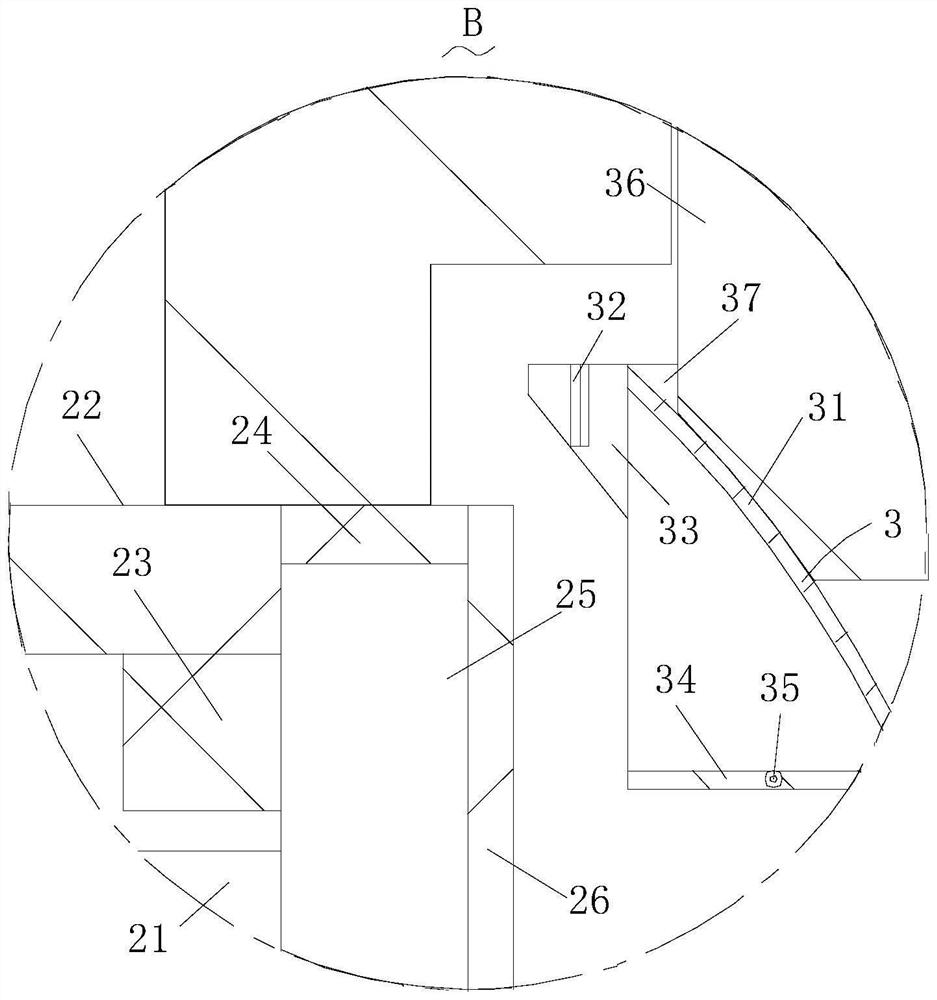

High-power output optical fiber coupler

InactiveCN114879308AFirmly connectedImprove sealingCoupling light guidesOptical fiber couplerMaterials science

The invention relates to the field of optical fiber couplers, in particular to a high-power output optical fiber coupler which comprises a shell, a hot melting mechanism is arranged on the shell, the hot melting mechanism abuts against a splitting mechanism, the splitting mechanism is arranged in the shell, and the hot melting mechanism abuts against the splitting mechanism. According to the optical fiber hot melting device, an optical fiber powder material in the hot melting mechanism can be detached through the arranged detaching mechanism, so that the optical fiber powder material enters the interior of the shell, when the hot melting mechanism carries out hot melting, the hot melting efficiency can be rapidly improved, and connection of optical fiber contact points after hot melting is firmer; the optical fiber surface and the shell are sealed more firmly, a good sealing effect is achieved, the surface of the optical fiber can be sealed through the arranged fastening mechanism, the fastening mechanism can further extrude the surface of the optical fiber while fastening the optical fiber, and therefore the fastening mechanism and the optical fiber are sealed.

Owner:鲍立新

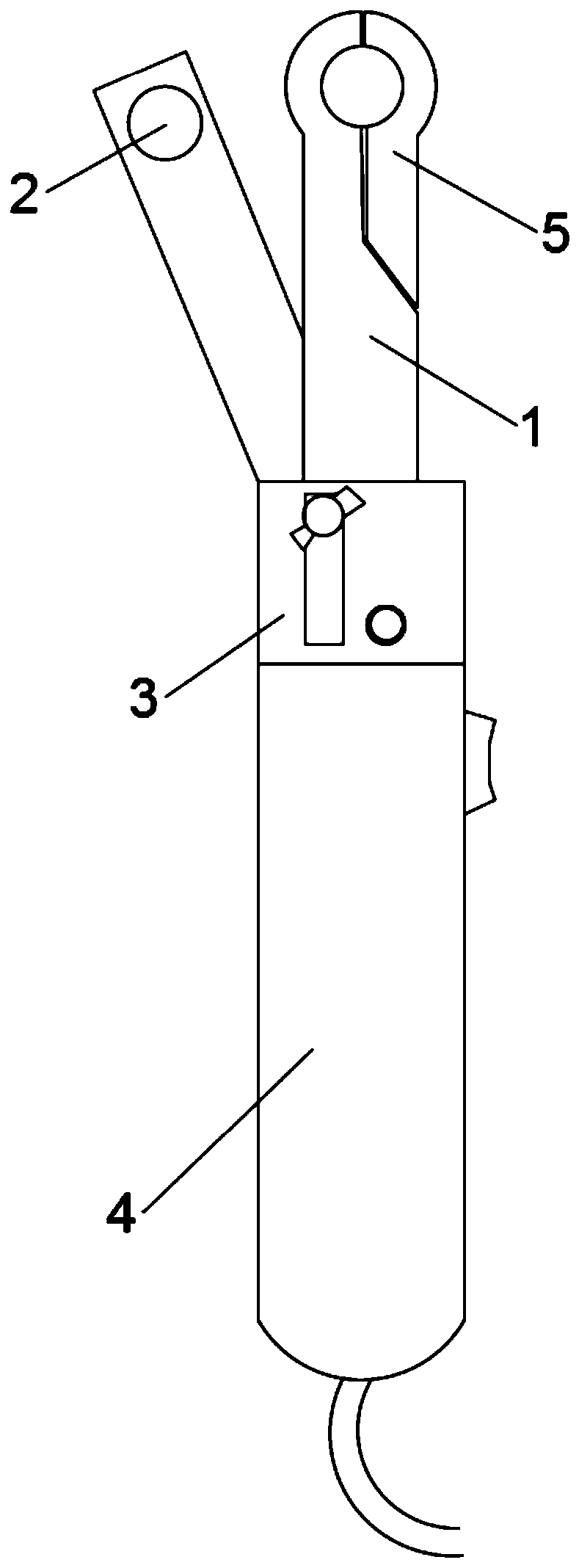

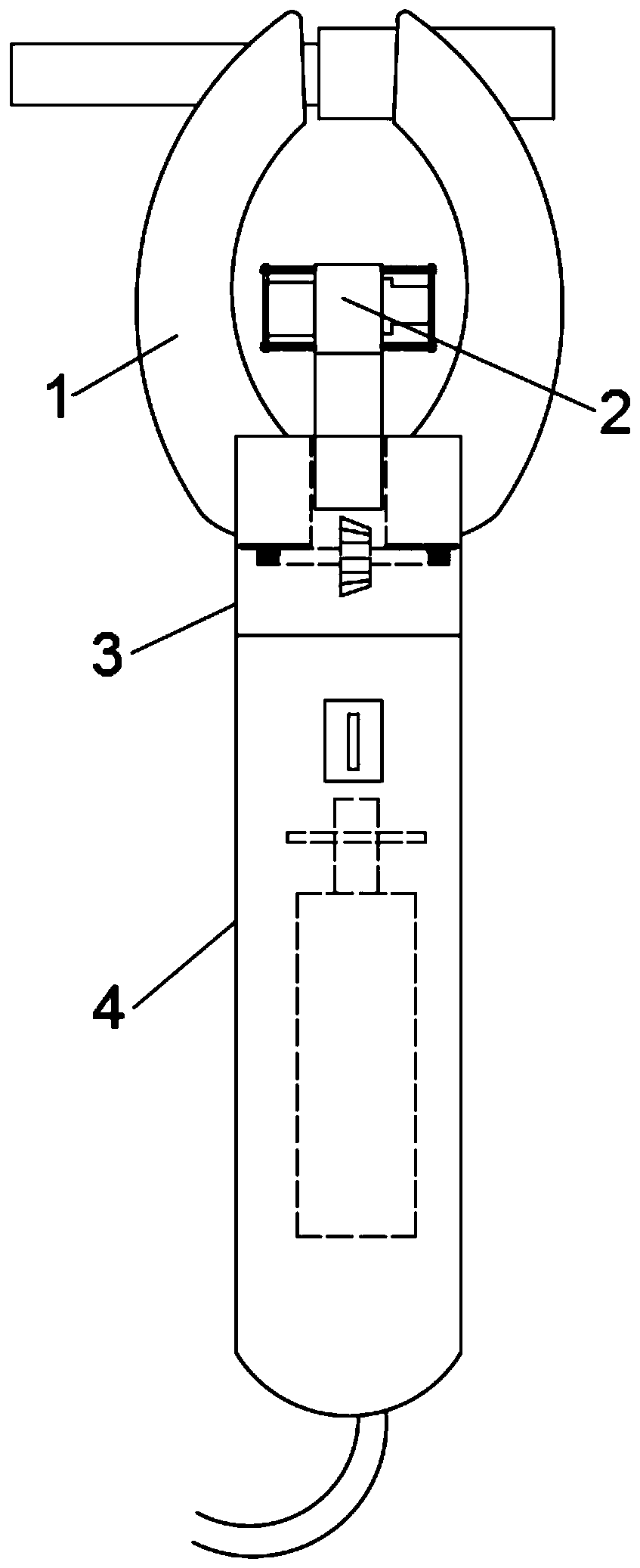

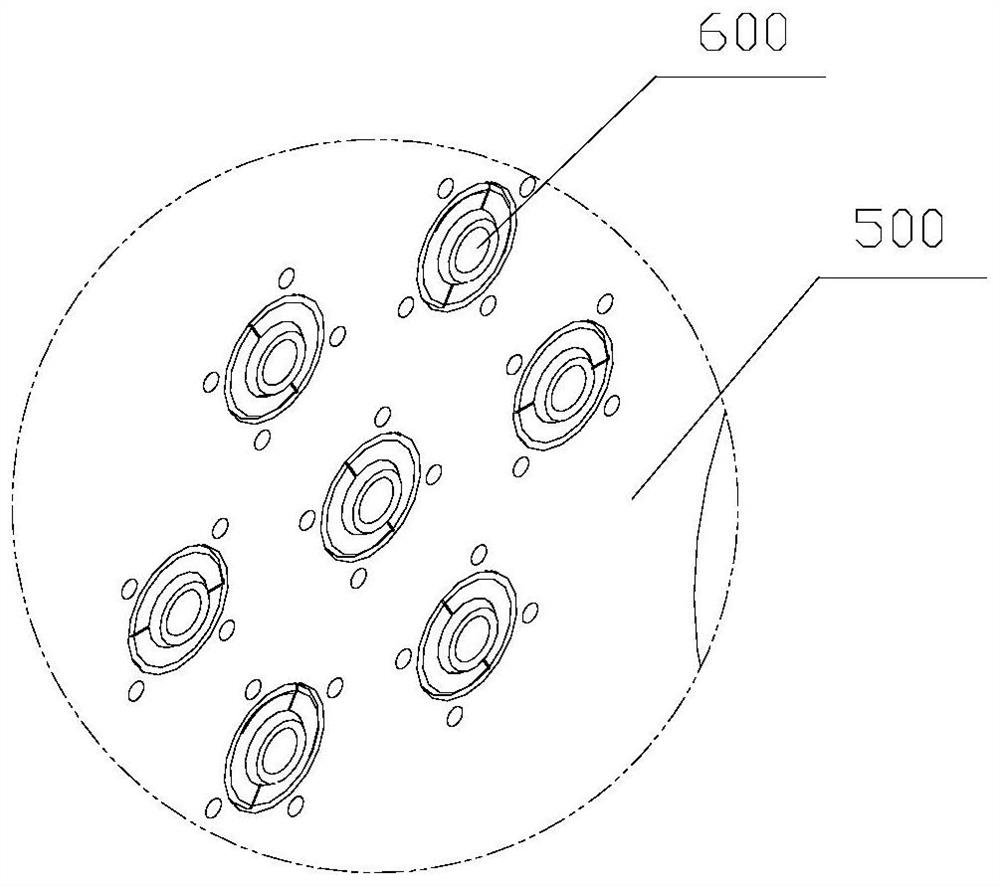

Automatic welding machine for ultrafiltration membrane column and end cover

PendingCN113442445AHigh degree of automationEliminate the disadvantages of stainless steel hoop connectionButt weldingEngineering

The invention discloses an automatic welding machine for an ultrafiltration membrane column and an end cover. The automatic welding machine for the ultrafiltration membrane column and the end cover comprises a clamping mechanism arranged on a machine frame, the clamping mechanism is used for carrying out clamping and fixing on the ultrafiltration membrane column, a limiting mechanism is arranged on the front side of the clamping mechanism, the limiting mechanism is used for carrying out limitation on the two ends of the ultrafiltration membrane column in the clamping mechanism, a hot melting mechanism and a fixing mechanism which are matched with each other are further arranged on the two sides of the clamping mechanism, the hot melting mechanism comprises a first hot melting assembly and a second hot melting assembly, the first hot melting assembly and the second hot melting assembly carry out hot melting treatment on the end cover and an end opening of the ultrafiltration membrane column respectively, and the fixing mechanism comprises a pushing and pressing assembly and a pushing assembly. The pushing and pressing assembly fixes the end cover in a vertical downward pushing and pressing mode, the pushing assembly pushes the end cover to be close to the first hot melting assembly and simultaneously drives the second hot melting assembly to be close to the end opening of the ultrafiltration membrane column to complete hot melting treatment of the end cover and the end opening of the ultrafiltration membrane column, and after hot melting of the end cover is completed, the end cover horizontally moves towards the direction of the ultrafiltration membrane column to complete butt welding with the end opening, and therefore the defect that stainless steel hoops are adopted for connection in the prior art is overcome, and the manufacturing cost is reduced.

Owner:浙江英普智能制造有限公司

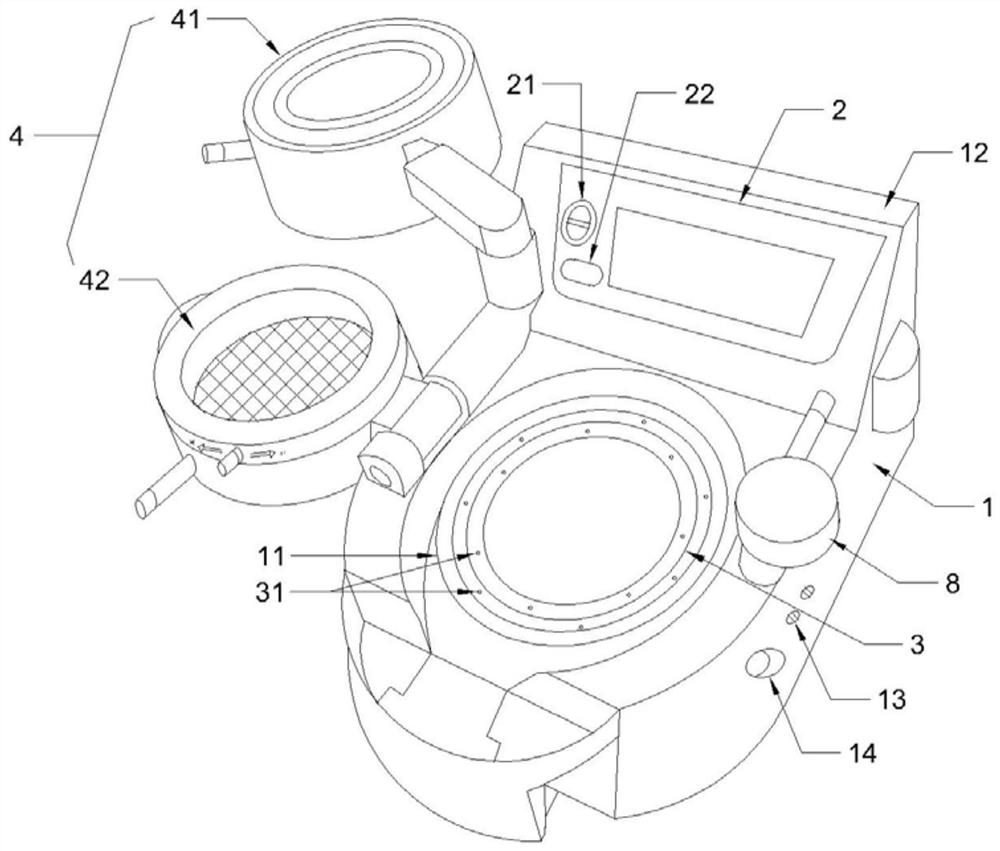

Dental brace film pressing machine

The invention discloses a dental brace film pressing machine, and belongs to the technical field of dental brace film pressing machine structures. According to the structure, a film can be uniformly heated in an electric control timing manner, then the heated film can be conveniently bonded to a dental cast, the hot melting effect is good, bonding is uniform, and bubbles are not prone to being generated. The dental brace film pressing machine comprises a film pressing machine body, the film pressing machine body is provided with a hot melting assembly used for film hot melting and a pressurizing assembly used for pressurizing, and the film pressing machine body is further provided with a touch screen used for adjusting parameters; the hot melting assembly comprises a hot melting cover and a hot melting base which are connected in a matched manner, and the film pressing machine body is provided with a cooling groove connected with the hot melting base in a matched manner; the pressurizing assembly comprises a pressurizing pump and a pressurizing protrusion, multiple air holes communicating with the pressurizing pump are formed in the pressurizing protrusion, and the pressurizing protrusion is arranged in the cooling groove; and the touch screen comprises a touch unit, a central processing unit and a control unit.

Owner:绍兴市上虞龙马机电有限公司

Preparation method and production equipment of skin-core composite fiber with high melt index and fiber rod thereof

ActiveCN113322542BImprove hot melt efficiencyFlow fastFilament/thread formingConjugated synthetic polymer artificial filamentsFiberMasterbatch

The invention provides a preparation method and production equipment for a skin-core composite fiber with a high melt index and its fiber rod, wherein the fiber includes a skin layer and a core layer arranged from outside to inside, and the skin layer is made of PE material and PP cooling masterbatch The PP cooling masterbatch accounts for 10% of the skin layer, the core layer is made of PP material, and the melting point of the skin layer is lower than the melting point of the core layer; the skin layer in the present invention is made of PE The material is made of PP cooling masterbatch. Based on PP cooling masterbatch, it has the characteristics of lowering the extrusion temperature (that is, lowering the melting point temperature) and increasing the resin melt index, so the temperature difference between the skin layer and the core layer increases, so that when preparing fibers When sticking, the hot-melt efficiency of the cortex at the same temperature will be higher than that of the cortex without adding PP cooling masterbatch in the prior art. It ensures the uniformity of the internal capillary structure after setting and curing, thus ensuring the capillary water absorption effect of the fiber rod.

Owner:GUANGDONG XINQIU NEW MATERIAL TECH CO LTD

A DC Submerged Thermal Electric Furnace with Variable Circuit

ActiveCN111928665BAvoid wear and tearAffect positive and negative polesElectric heating for furnacesElectrical connectionEngineering

The present invention belongs to the technical field of direct current submerged thermal furnace, specifically a variable circuit direct current submerged thermal electric furnace; it includes a furnace body; the inner surface of the furnace body is fixedly connected with a servo motor at the bottom of the furnace body, and the servo motor is connected to the furnace through wires. The controller is electrically connected; the servo motor drive shaft is fixedly connected with uniformly arranged conductive columns, and the number of conductive columns is four; the electrodes of the left and right conductive columns are negative and positive respectively; the electrodes of the front and rear conductive columns are respectively Negative electrode and positive electrode; the inner wall of the support plate is fixedly connected with an evenly arranged electrode disk; the present invention is mainly used to solve the problem that the heat generated by the anode area of the positive electrode is higher than the heat generated by the cathode area of the negative electrode during the working process of the current submerged arc furnace. Large, the smelting current is the main source of heat energy for electrode roasting, and the roasting near the electrode holder is similar when the pressing speed is equal, but because the anode electrode consumption is relatively fast, and the heating of the anode is more serious at the end, the electrode is often soft and hard problem of accidents.

Owner:贵州金源锰业股份有限公司

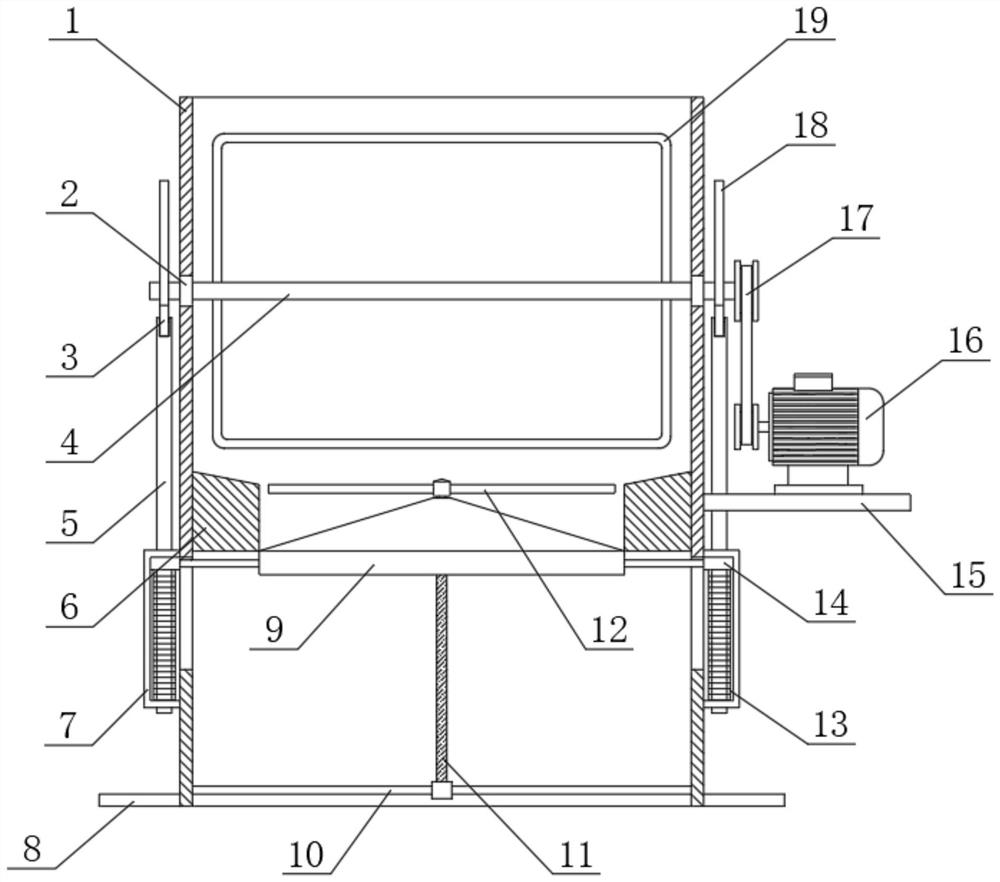

Novel material hot melting device

Owner:ZHEJIANG ACHEN NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com