Automatic welding machine for ultrafiltration membrane column and end cover

An automatic welding machine and ultrafiltration membrane technology, applied in the field of ultrafiltration water treatment, can solve the problems of high manufacturing cost, easy rust, easy water leakage, etc., and achieve the effect of ensuring accuracy, increasing the degree of automation, and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

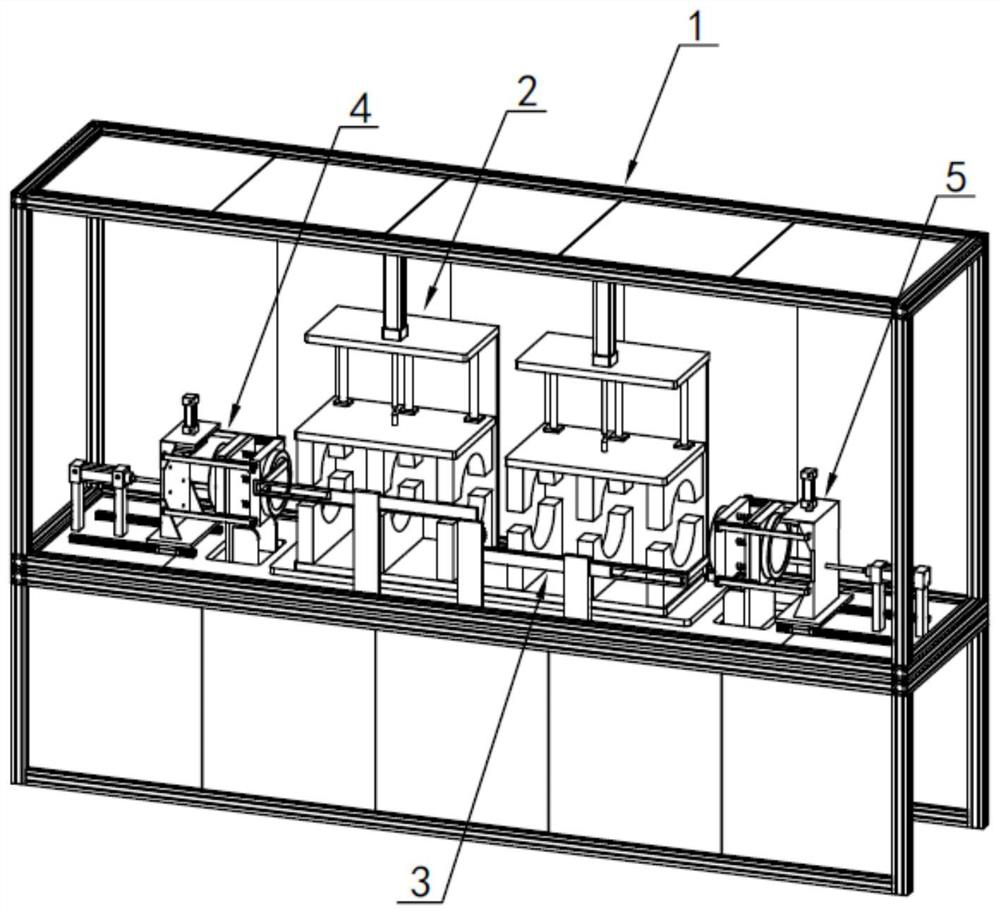

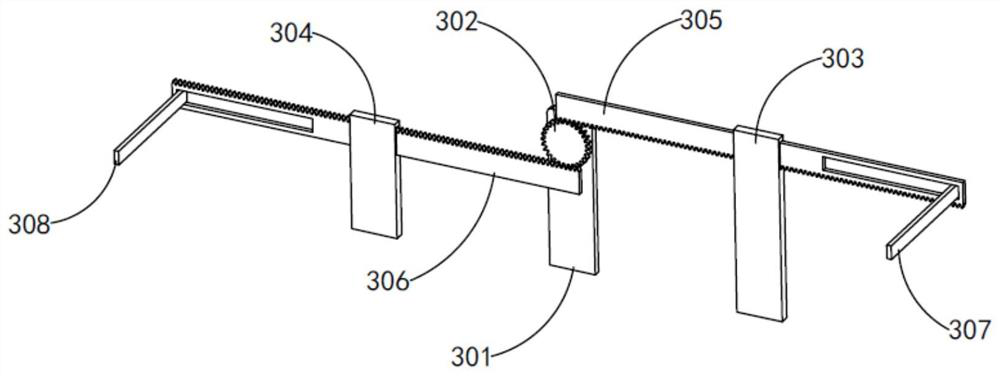

[0032] like Figure 1 to Figure 8 As shown, an automatic welding machine for an ultrafiltration membrane column and an end cap includes a clamping mechanism 2 arranged on a frame 1, and the clamping mechanism 2 is used to clamp and fix the ultrafiltration membrane column, and the The front side of the clamping mechanism 2 is provided with a limit mechanism 3, and the limit mechanism 3 is used to limit and correct the two ends of the ultrafiltration membrane column in the clamp mechanism 2, and the two sides of the clamp mechanism 2 are also sequentially A matching hot-melt mechanism 4 and a fixing mechanism 5 are provided. The hot-melt mechanism 4 includes a No. 1 hot-melt assembly 401 and a No. 2 hot-melt assembly 402. Carry out hot-melt treatment to the end cap and the port of the ultrafiltration membrane column respectively, and the fixing mechanism 5 includes a pressing assembly 501 and a pushing assembly 502, and the pressing assembly 501 fixes the end cap by pressing dow...

Embodiment 2

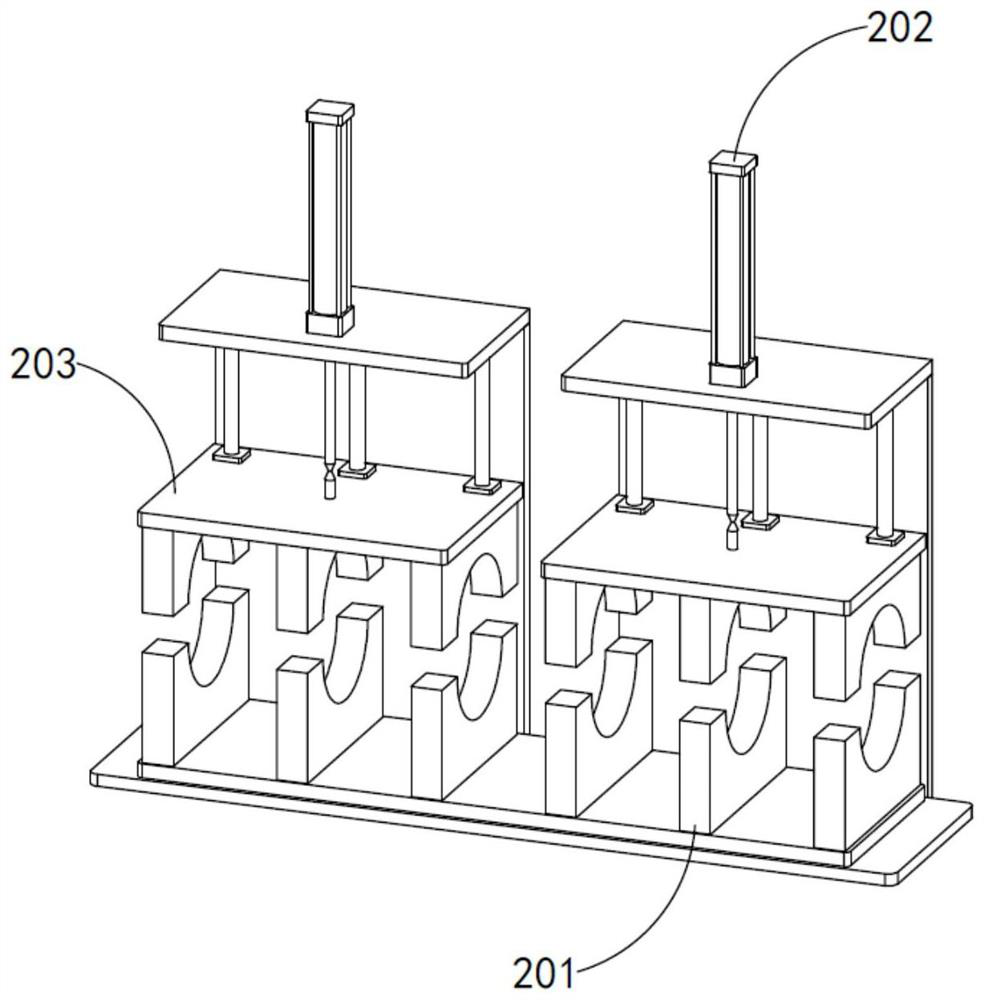

[0046] like figure 2 As shown, the parts that are the same as or corresponding to those in Embodiment 1 adopt the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences between Embodiment 1 and Embodiment 1 are described below; the differences between Embodiment 2 and Embodiment 1 The advantage is that: the No. 1 clamping block 201 and the No. 2 clamping block 203 in the clamping mechanism 2 are equipped with aluminum bushings at the same time, so as to fasten and clamp outer tubes with different outer diameters.

[0047] The working process is as follows:

[0048] The operator places the ultrafiltration membrane column on the No. 1 clamping block 201 of the clamping mechanism 2, controls the No. 1 lifting cylinder 202 to move the No. 2 clamping block 203 down to clamp and fix the ultrafiltration membrane column, and then moves the limiting The positioning mechanism 3 is reset and retracted, and the operator places the end caps on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com