Preparation method and production equipment of skin-core composite fiber with high melt index and fiber rod thereof

A high melt index, composite fiber technology, applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of uneven capillary structure, poor capillary water absorption effect, low production efficiency, etc., to ensure the capillary water absorption effect , high melt index, and the effect of ensuring water absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

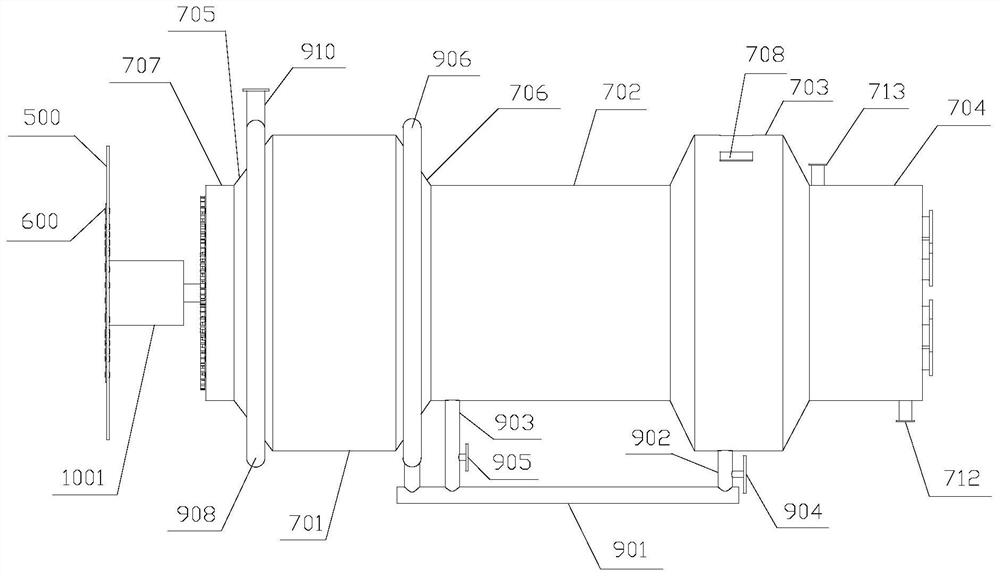

[0040] The invention provides a sheath-core composite fiber with a high melt index, including a skin layer and a core layer arranged from outside to inside, the skin layer is made of PE material and PP cooling masterbatch, and the PP cooling masterbatch accounts for 10% of the skin layer, the core layer is made of PP material, and the melting point of the skin layer is lower than the melting point of the core layer.

[0041] Among them, PP cooling masterbatches with different peroxide contents are mixed with PE materials in different proportions to obtain a mixture, and its melt index is measured. As shown in Table 1, with the increase of the content of PP cooling masterbatch, the melting index of the mixture shows obvious When the cooling masterbatch content is less, 2.5% and 2% have little difference in improving the fluidity of PE materials, but when the cooling masterbatch content exceeds 10%, 2.5% has made the PE material melt index Therefore, preferably, the peroxide con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com