Lead-free alloy new material alloy pipe preparation device for food mechanical part

A lead-free alloy, food machinery technology, used in metal processing equipment, equipment for feeding molten metal into molds, manufacturing tools, etc., can solve the problem of restricting the preparation efficiency of lead-free alloy new material alloy pipes and the time-consuming pipe molds. Cooling, slow melting of melting equipment and other problems, to achieve good economic benefits and practical significance, reasonable structure and layout, easy to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

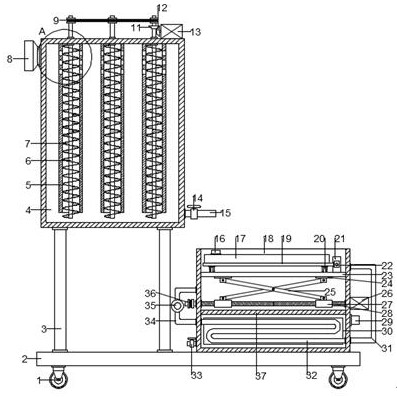

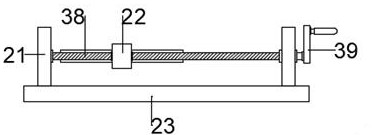

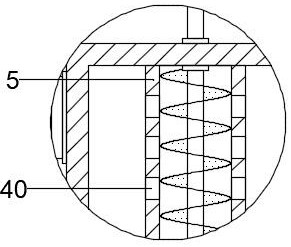

[0022] see Figure 1~4 , in an embodiment of the present invention, a device for preparing a lead-free alloy new material alloy tube for food machinery parts, including a base 2, a melting tank 4 and a box body 18, and the melting tank 4 is fixed on the base through a plurality of support rods 3 2, the upper part of the box body 18 is open and fixed on the base 2, and the upper part of the side wall of the melting box 4 is provided with a feeding port 8 for putting various metal raw materials into the interior for melting. There is a turning component for turning all kinds of metal raw materials inside it efficiently and evenly to promote its melting efficiency. The turning component includes a plurality of lifting cylinders 5, and the plurality of lifting cylinders 5 are installed in the inner cavity of the melting tank 4 at equidistant circumferential directions. There is a gap between the top and its lower part and the bottom of the inner cavity of the melting tank 4 so tha...

Embodiment 2

[0029] Further, in order to slow down the melting speed of the ice cubes and maintain the long-term cooling effect on the water flowing through the cooling pipe 32, the inner wall of the cooling chamber is attached with a thermal insulation layer 30 for reducing the entry of external heat.

[0030] The working principle of the present invention is: when in use, first put all kinds of metal raw materials into the melting tank 4 in proportion and start the driving motor 13 to melt them quickly and efficiently, then start the lifting motor 26 to drive the lifting plate 23 to rise to make the pipe mold The pouring port 16 of 17 is just a short distance below the discharge port 15, and then the pouring valve 14 is opened to pour the pipe mold 17. After pouring a pipe mold 17, close the pouring valve 14 and shake the handle 39 to drive the next pipe mold The pouring port 16 of 17 is located below the discharge port 15, and then the pouring valve 14 is opened for pouring. With this cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com