Mixing device for electronic packaging high-thermal-conductivity material

An electronic packaging, high thermal conductivity technology, used in electric furnaces, mixers, heat treatment, etc., can solve problems such as unsatisfactory product quality and efficiency, inability to obtain glass products, uniformity adjustment defects, etc., to improve the adaptability adjustment performance. , Improve the efficiency of hot melt and reduce the effect of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

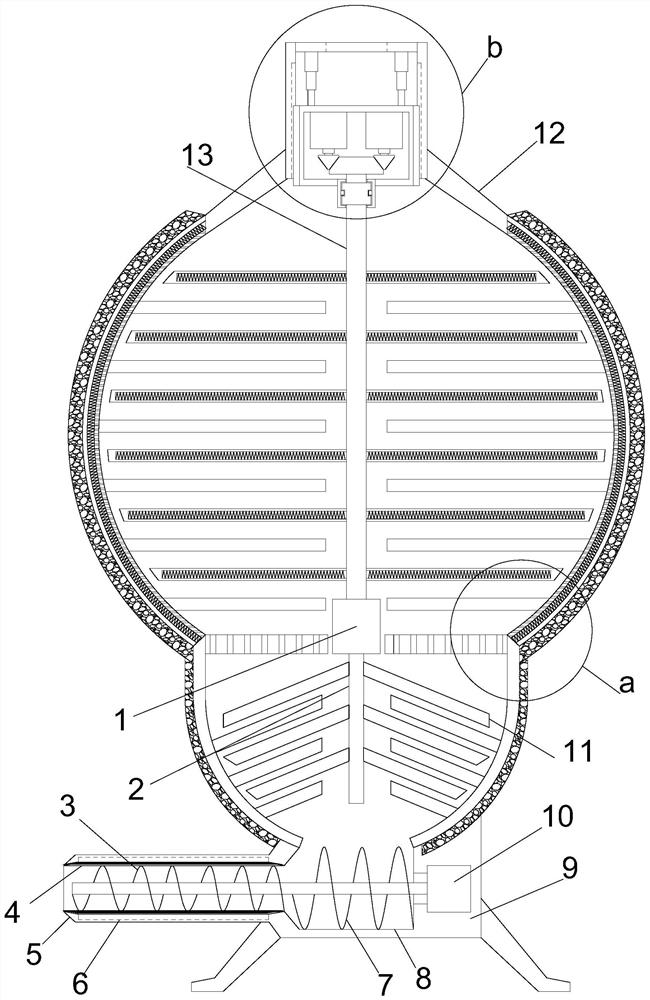

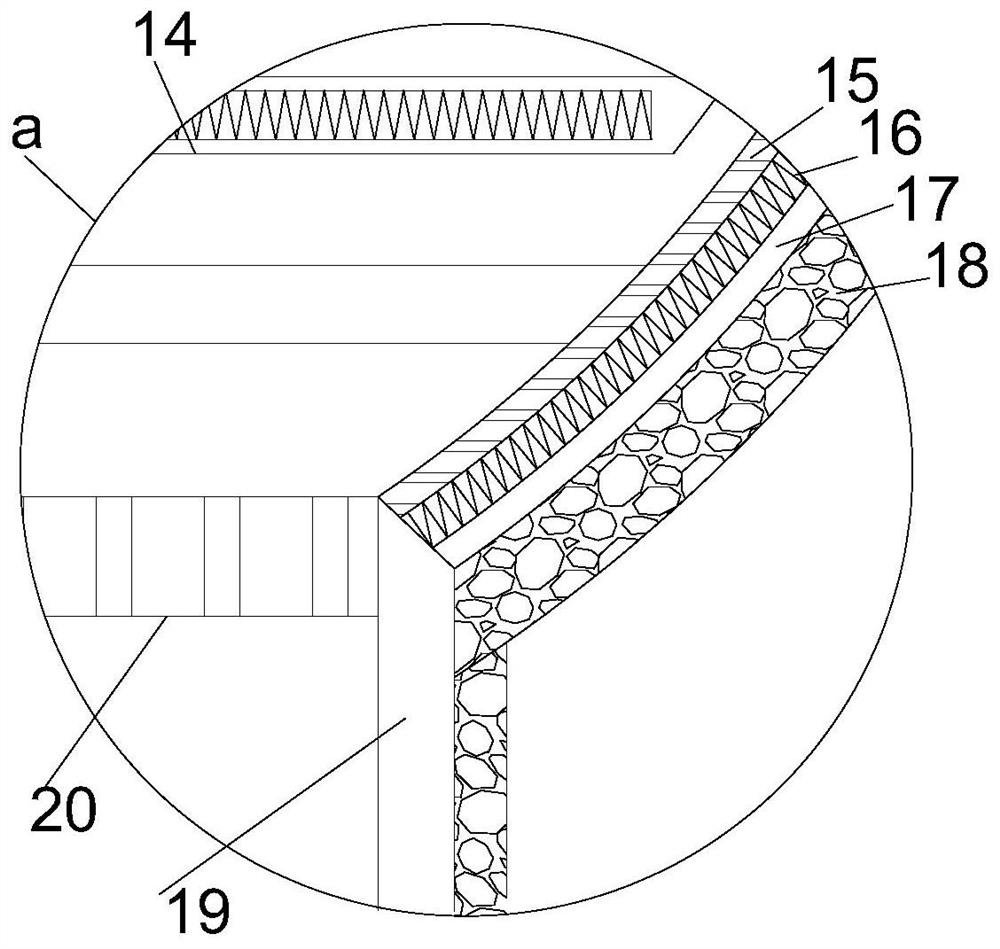

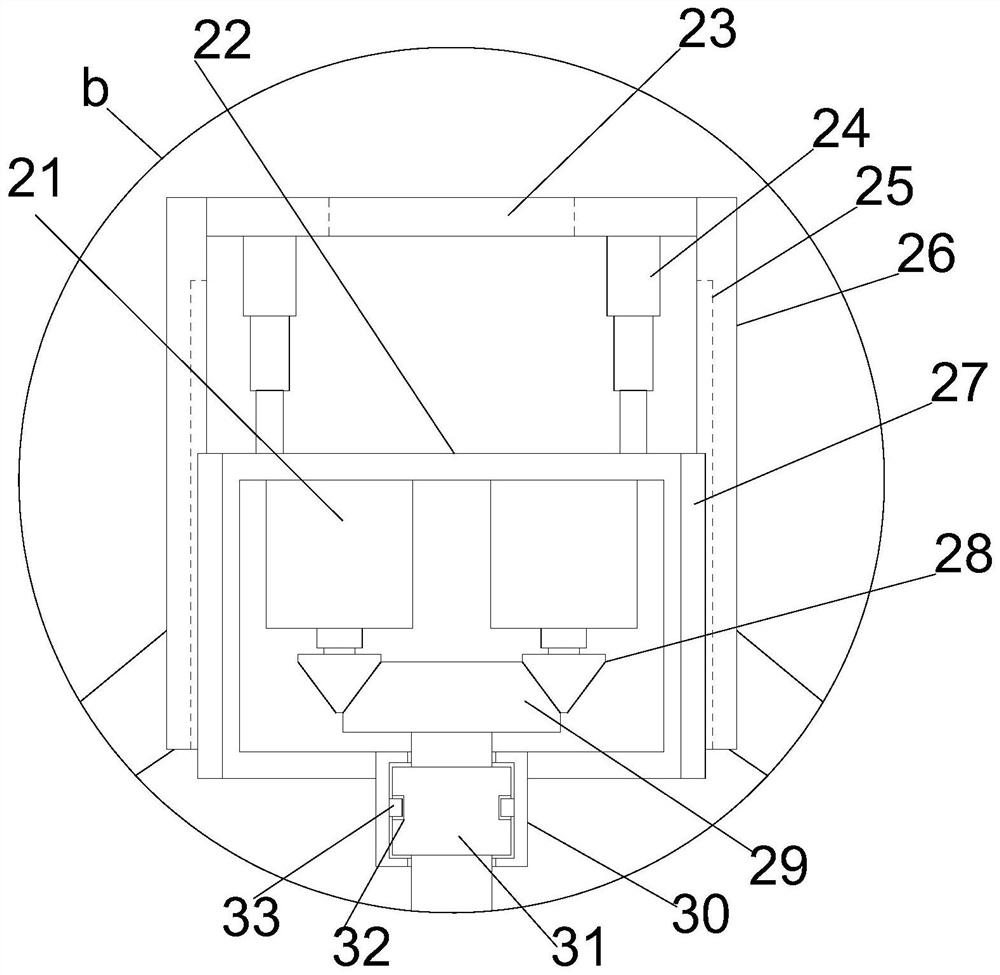

[0022] see Figure 1~4 , in an embodiment of the present invention, a mixing device for electronic packaging high thermal conductivity materials, including a vertically arranged arc surface installation cylinder 17, a spherical surface installation cylinder 19 is vertically arranged at the middle position of the lower end of the arc surface installation cylinder 17, and the spherical surface installation cylinder 19 is vertically arranged. The lower end of the cylinder 19 is horizontally provided with a support installation plate 9, and the four corners of the lower end of the support installation plate 9 are all provided with support installation columns, and the upper end of the support installation plate 9 cooperates with the spherical surface installation cylinder 19. A support installation cylinder 26 is vertically arranged on the top of the cylinder 17, and several guide material installation columns 12 are arranged at an equal angle on the lower edge of the support insta...

Embodiment 2

[0025] On the basis of Embodiment 1, the asbestos insulation layer 18 provided externally can make the heat inside the device not easy to dissipate, improve the efficiency of internal heat accumulation, and reduce the heat dissipation when the material is exported through the vacuum insulation layer 6, making it To ensure good circulation, ensure that the device can carry out continuous and stable mixing operations, and realize the lifting adjustment of the lifting transmission cylinder 22 through the electronically controlled lifting column 24, so that the mixing gap can be changed to adapt to the mixing operation of different raw materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com