Connecting structure of roof battens and counter battens and construction method thereof

A technology for connecting structures and construction methods, which is applied to roofs, building structures, and building maintenance using tiles/slate tiles. The effect of simple construction process and simple construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] refer to Figure 1 to Figure 9 , the technical scheme of the connection structure of a tile-hanging strip and a water-slip strip in this embodiment is as follows:

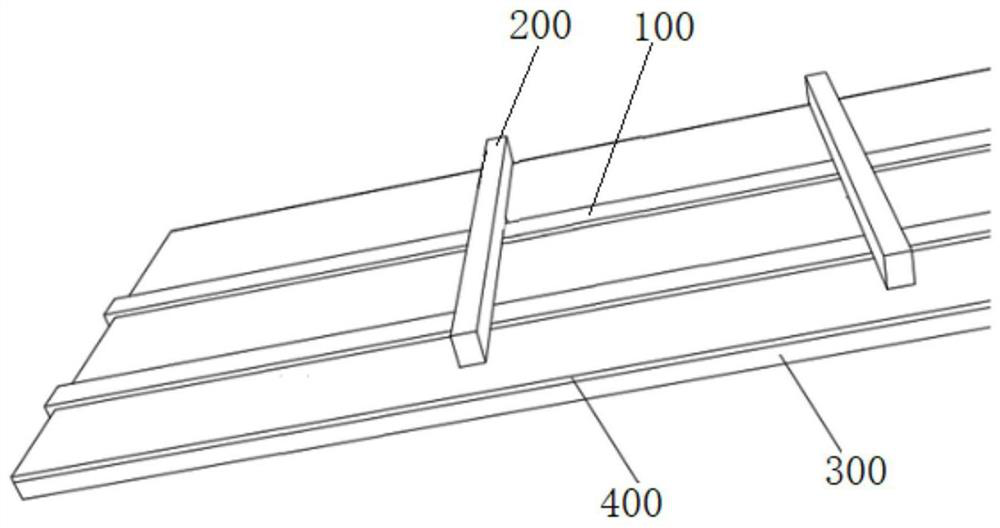

[0030] A connection structure between tile hanging strips and running strips, comprising a number of running strips 110 uniformly arranged longitudinally on a roof panel 300 to be repaired, and a number of hanging strips 110 evenly arranged horizontally on the running strips 100 for hanging tiles. Both ends of the tile strip 200 and the water-slip strip 100 are respectively hung on the two ends of the roof panel 300 , and a waterproof layer 400 is provided between the water-slip strip 100 and the roof panel 300 .

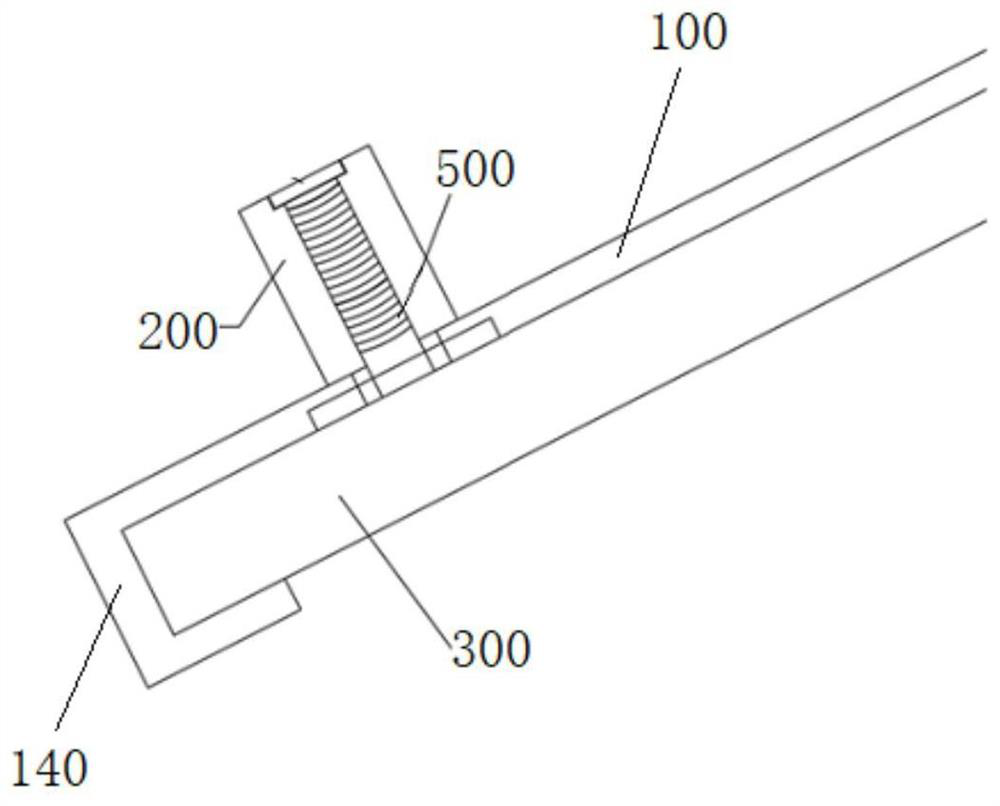

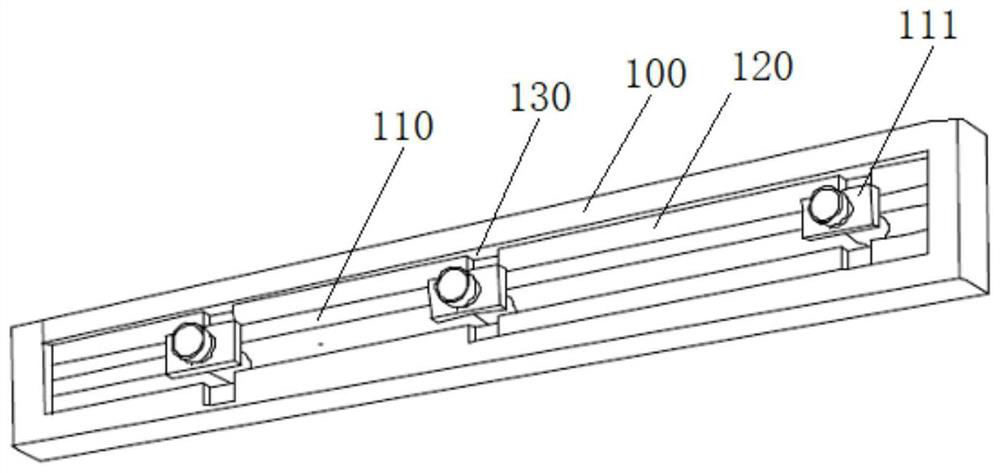

[0031] On the side of the water strip 100 away from the roof panel 300, a track 110 is extended along its length direction, and a bolt pad 111 that can slide along it and is one-to-one corresponding to a plurality of tiles 200 is arranged in the track 100. A side of the water strip 100 close to t...

Embodiment 2

[0037] This embodiment provides a construction method for the connection structure of the tile strip and the water strip described in Embodiment 1, the construction method includes

[0038] The first step: according to the actual situation of the specific project to be repaired on the roof, select the appropriate hanging tile strip 200 and smooth water strip 100;

[0039] Step 2: laying the water-slip strip 100, the two ends of the water-slide strip 100 are respectively hung on the two ends of the roof panel 300, and at this time, the bolt pads 111 arranged in the track 110 are slid to be parallel to the direction of the water-slide strip 100;

[0040] Step 3: Lay the tiles 200, pass the bolts 500 through the tiles 200 and connect with the nuts 111a on the bolt pads 111 slidingly arranged in the track (110), and then adjust the tiles according to the size of the tiles 200 position, when adjusting the position of the tile strip 200, you only need to slide the bolt spacer 111 al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com