Grouting bottom-sealing structure and construction technology of deep foundation pit in high-pressure water-thick sandy pebble stratum

A grouting back cover and high pressure bearing technology, applied in infrastructure engineering, construction, etc., can solve the problems of foundation leakage, long construction period, large grouting volume, etc., and achieve the effect of slow construction period and huge cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

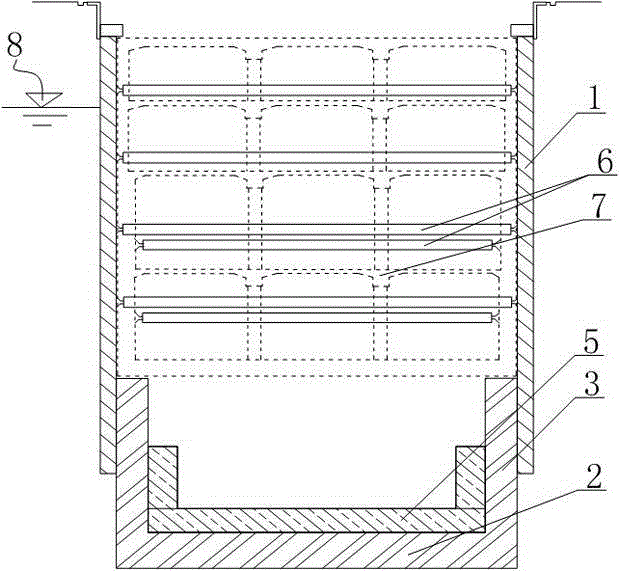

[0038] This embodiment is a station of the Beijing subway, its length is 139.2m, the depth of the foundation pit of the standard section is 31.6m, and the width is 24.9m. The floor of the station is mainly located on the pebble layer with strong water permeability, and the confined water level outside the pit is 13m away from the bottom of the pit.

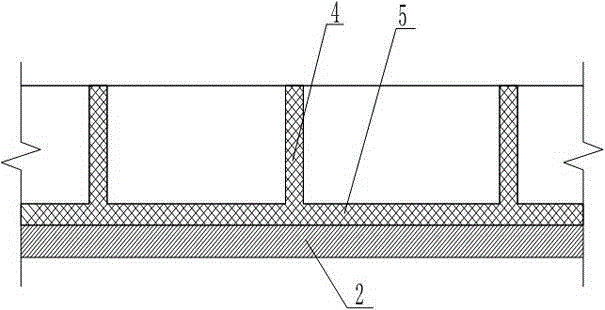

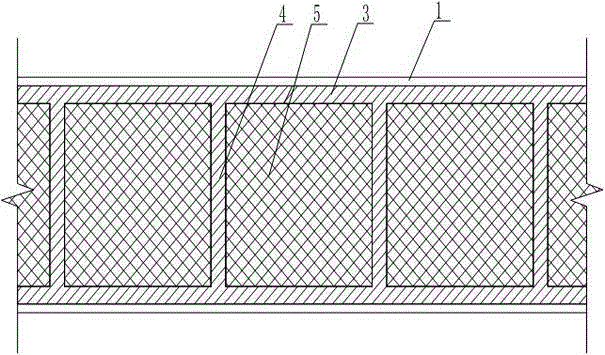

[0039] According to the existing technology in the basement full-scale grouting and back-sealing scheme: the enclosure structure adopts a 1.0m thick underground diaphragm wall, the embedded depth is 15m, and the sleeve valve pipe is used for full-scale grouting within the 15m range of the basement. Inject double liquid slurry in the range of 3m, such as Figure 4 shown. It is estimated that the construction cost of the enclosure structure is about 62.29 million, the grouting cost is 112.8 million, and the grouting construction period is 3 months.

[0040] In the actual construction process, the construction structure is as follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com