Support device and method used for soil heaping and backfilling of engineering construction

A supporting device and building technology, applied in the field of backfill soil support, can solve the problems of easy formation of landslides, disasters, serious land subsidence of the site, etc., and achieve the effects of improving stability and resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

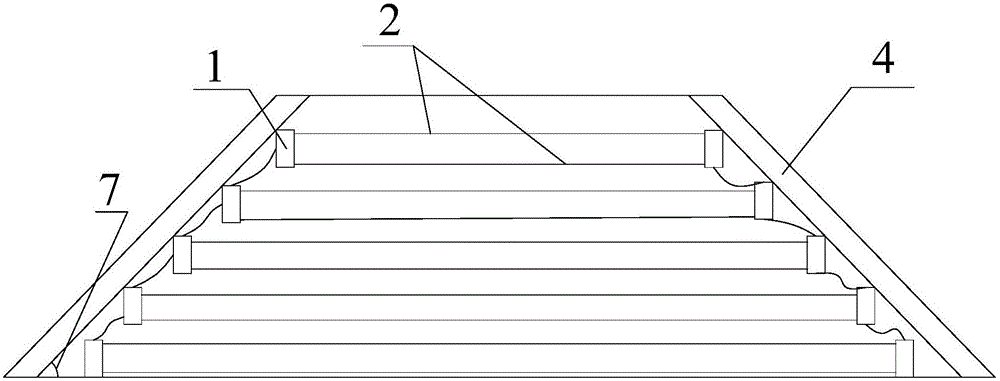

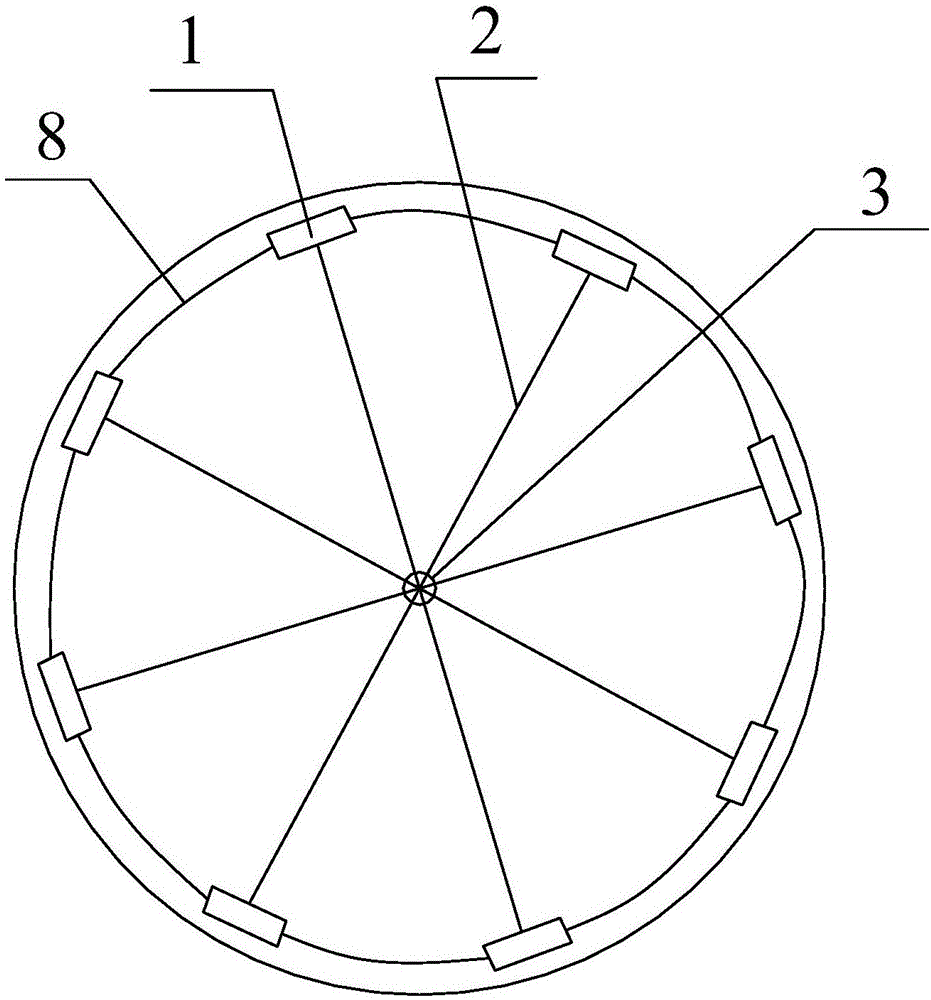

[0040] The maximum covering depth of the backfill is H=24m, the height of the concrete retaining beam is h=1.2m, the length of the concrete retaining beam is 3m, and the thickness is 0.5m, and reinforcement is set on the concrete retaining beam. The physical and mechanical property indexes of the known soil slope backfill are as follows: internal friction angle φ = 25°, cohesion c = 12kPa, weight γ = 19kN / m 3 .

[0041] Since no prestress is applied to the anchor cables in the design, the concrete retaining beam bears active earth pressure.

[0042] Then the active earth pressure coefficient Ka is: Ka=tan 2 (45°-φ / 2)=tan 2 (45°-25° / 2) = 0.41

[0043] Then the active soil pressure at the top of the concrete retaining beam is:

[0044] The active soil pressure at the bottom end of the concrete retaining beam is:

[0045] Therefore, the active earth pressure acting on the concrete retaining beam: the active earth pressure acting on the concrete retaining beam is: Ea=...

Embodiment 2

[0053] The maximum covering depth of the backfill is H=16m, and the height of the concrete retaining beam is h=1.2m. The physical and mechanical property indexes of the known soil slope backfill are as follows: internal friction angle φ = 25°, cohesion c = 12kPa, weight γ = 19kN / m 3 .

[0054] Since no prestress is applied to the anchor cables in the design, the concrete retaining beam bears active earth pressure.

[0055] Then the active earth pressure coefficient Ka is: Ka=tan 2 (45°-φ / 2)=tan 2 (45°-25° / 2) = 0.41

[0056] Then the active soil pressure at the top of the concrete retaining beam is:

[0057] The active soil pressure at the bottom end of the concrete retaining beam is:

[0058] Therefore, the active earth pressure acting on the concrete retaining beam: the active earth pressure acting on the concrete retaining beam is: Ea=1 / 2(σ aa +σ ab )×h=1 / 2(105.05+114.40)×1.2=131.67kN / m, and its action point is at the geometric centroid of the backfill.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com