Patents

Literature

67results about How to "Small settlement deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Three-connected-arch tunnel double-side cavity construction method for soft geological

InactiveCN101196116AReasonable division of single excavation areaSuitable for manual excavationUnderground chambersTunnel liningEnvironment effectWall rock

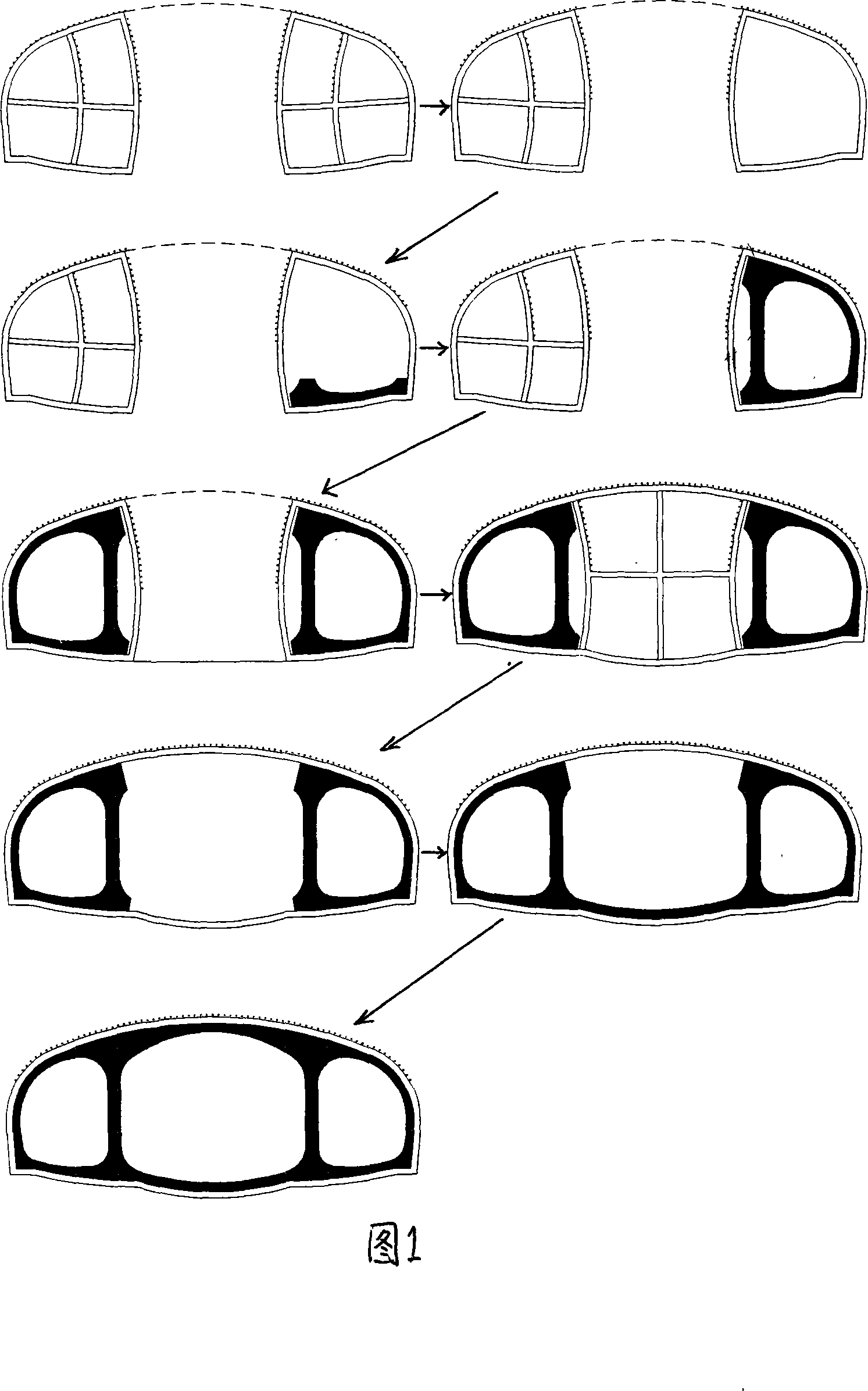

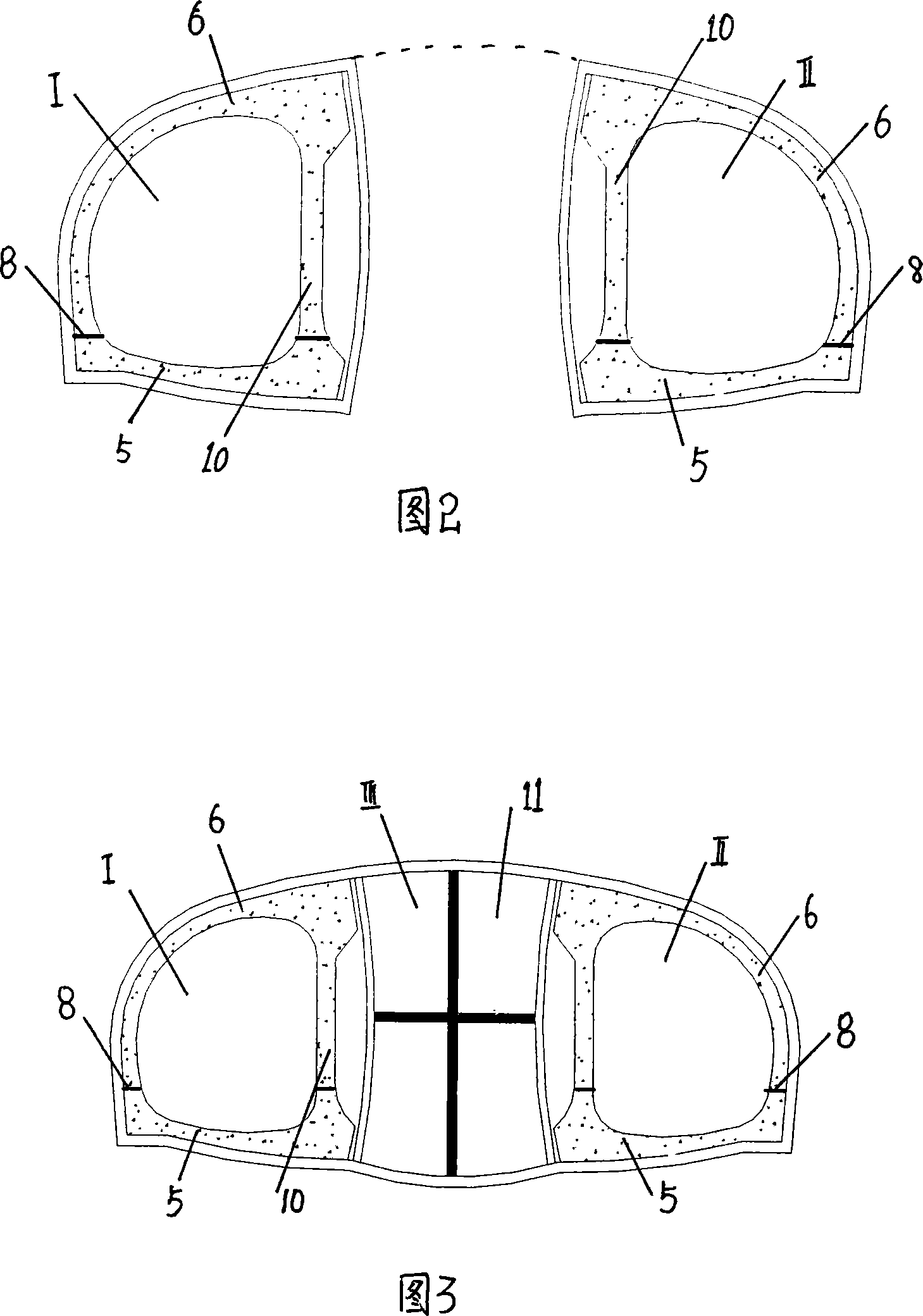

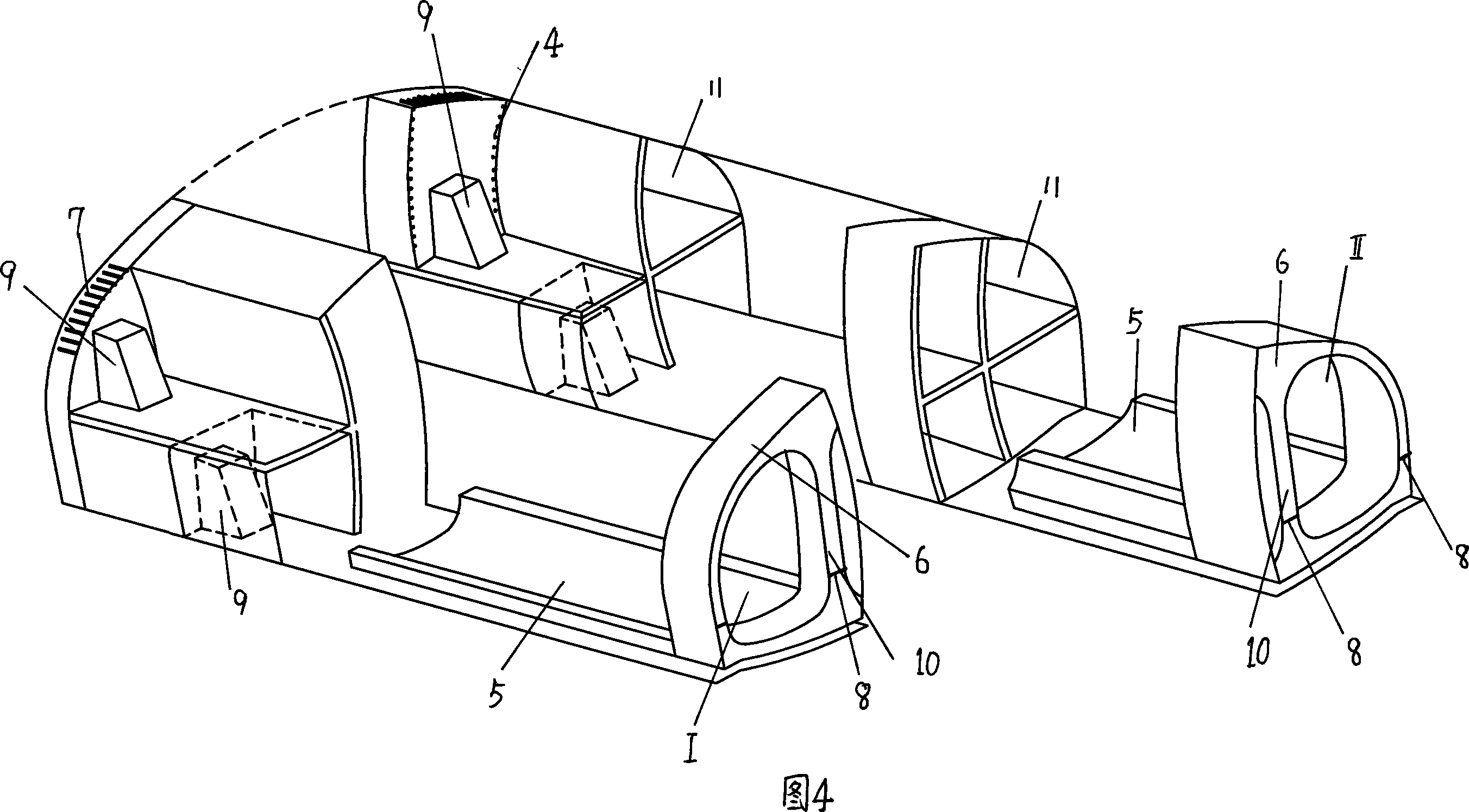

The invention relates to the technical field for the engineering of large-section tunnel, in particular to an engineering method for the double lateral tunnel of a three-arc tunnel on soft and weak geological condition, which resolves the problem of longer duration for the exposure of wall rock, easy deformation of tunnel and poor waterproof effect in existing tunnel engineering method. The invention comprises: (1) excavation of lateral tunnel; (2) lining of later tunnel: first of all, dismantle the primary support of the whole section, then pour the arc invert secondary lining and arc section secondary lining with the construction joint being configured at the lower section of the middle wall for the lateral tunnel; (3) after the circular lining a left lateral tunnel I and a right lateral tunnel II on a same section, excavate and line a middle tunnel III. This method realizes simple equipment and convenient engineering; with the construction sequence of building the lateral tunnel and then the middle tunnel, the invention gives full play to the supporting function of the secondary lining of the middle wall, so as to reduce the load borne by the primary support of the arc section of middle tunnel and elevate the safety coefficient; the invention reduces the settlement and impact on peripheral environment, so as to ensure the stability and safety of the excavation working face; small number of construction joint and high working efficiency.

Owner:CHINA RAILWAY 12TH BUREAU GRP

Construction method for wind-blown sand tunnel

ActiveCN102134998ASolve the collapseEasy constructionUnderground chambersTunnel liningBearing capacityEnvironmental geology

The invention discloses a construction method for a wind-blown sand tunnel, belonging to the construction field of tunnels. The construction method for the wind-blown sand tunnel is realized by the following steps: 101: construction of upper steps; 102: construction of lower steps; 103: construction of inverted arch combining parts; 104: construction of secondary lining; and 105: ring closing of inverted arch. Aiming at the loose, soft and unstable geometrical conditions of sand layers, wind-blown sand layers and the like, the construction method for the wind-blown sand tunnel solves the problems of collapse due to frequent sand leakage, and deformation of supporting in the normal construction method; the inverted arch combining parts are constructed firstly, therefore, the bearing capability of the wall corner foundation of a primary supporting is enhanced, the side pressure transferred by soil bodies at two sides is inhibited effectively, simultaneously conditions are created for achieving the aim that the deformation of the primary supporting finally tends to be stable by quickly starting the construction of the secondary lining; the excavation is carried out according to the characteristics of the tunnel, such as long distance, ultra-shallow buried layer, large profile and granular bulk rocks, the technical difficult problems in the field are overcome, therefore, the construction method provides important guide significance for the construction of the tunnels of similar geometrical conditions.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

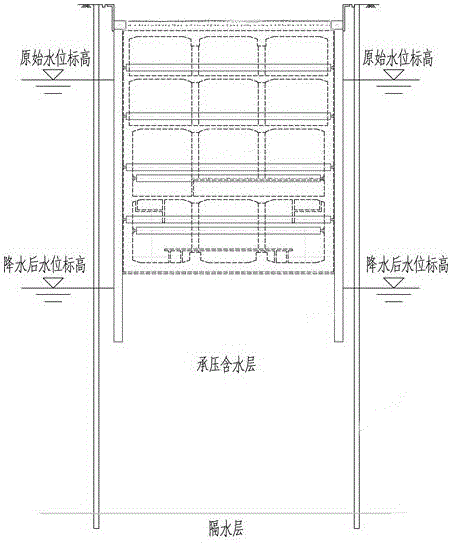

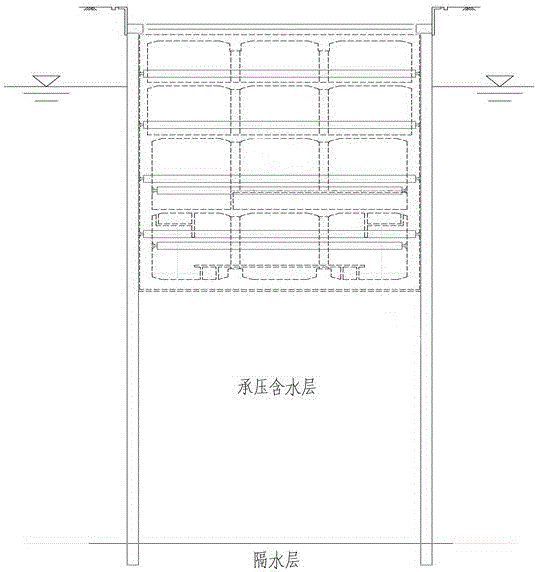

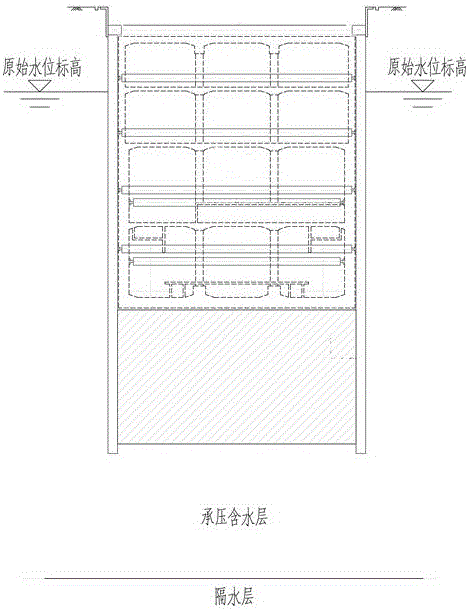

Strongly-permeable stratum deep foundation pit bottom sealing water stopping structure and construction method thereof

ActiveCN105002913AImprove reliabilityImprove waterproof performanceProtective foundationExcavationsSlurry wallReinforced concrete

The invention discloses a strongly-permeable stratum deep foundation pit bottom sealing water stopping structure, which comprises diaphragm walls, underwater plain concrete boards, reinforced concrete partition walls, uplift piles and inner supports, wherein the diaphragm walls are arranged around the foundation pit througgh casting; the inner supports support the diaphragm walls; the reinforced concrete partition walls are formed on the foundation pit below the diaphragm walls through casting; the reinforced concrete partition walls and the diaphragm walls of each two faces form a casting block in a surrounding mode on the foundation base; the uplift piles are casted on the foundation base inside the block; each underwater plain concrete board is formed through casting at each block opening formed by the reinforced concrete partition walls and the diaphragm walls in a surrounding mode; and the uplift piles are firmly embedded in the underwater plain concrete boards. The underwater plain concrete boards enhance overall strength and ridigity of the foundation pit bottom, dual effects of reinforced pit bottom and permeation prevention are provided, influences on stability of the pit bottom by high pressure water and raised pit bottom caused by excavation of the foundation pit can be effectively solved, and lateral displacement of the pit wall and settlement deformation of the surrounding enviornment can be well reduced.

Owner:RANKEN RAILWAY CONSTR GROUP +1

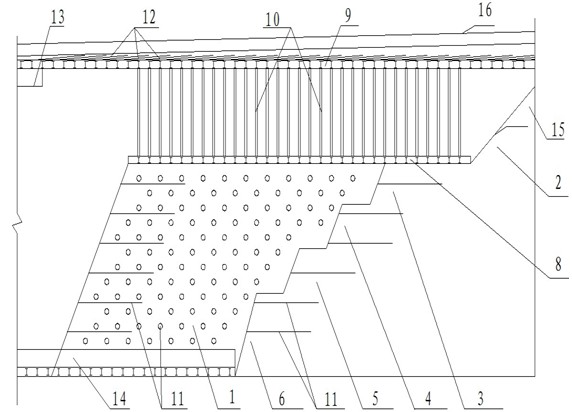

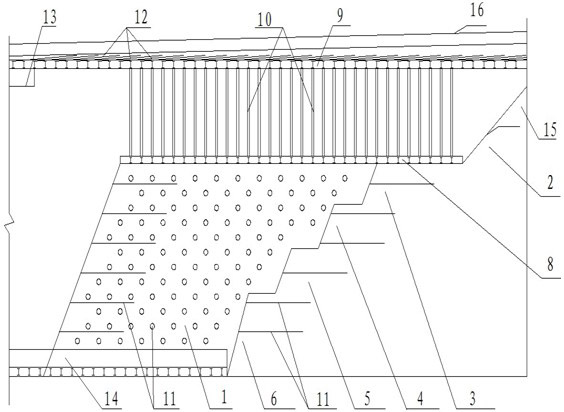

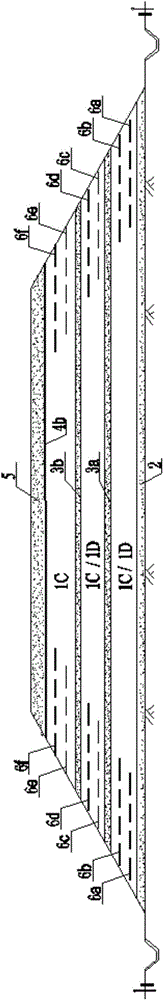

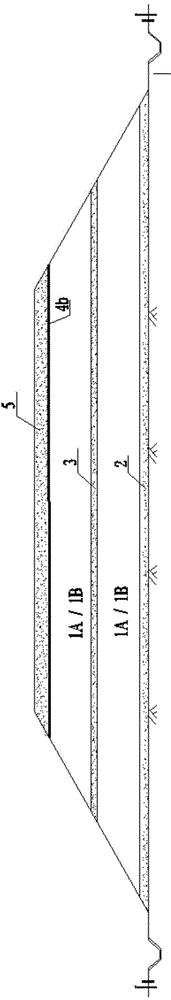

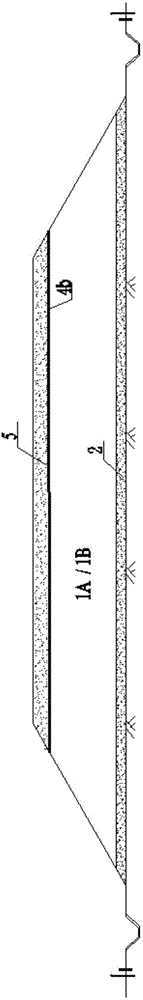

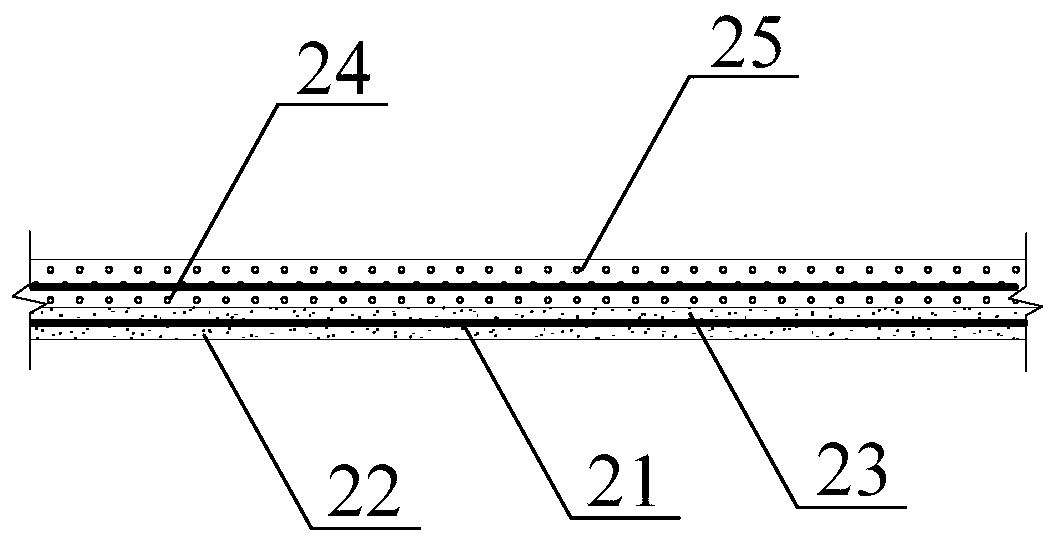

Design method and structure for preventing settlement-deformation damage of soft-rock subgrade of road

The invention discloses a design method and a structure for preventing settlement-deformation damage of a soft-rock subgrade of a road. The design method comprises the steps of (A) testing the uniaxial saturated ultimate compressive strength; (B) judging and sorting by selecting soft rocks; (C) filling the bottom part of an embankment with a layer of sand gravels; (D) filling the subgrade part with the soft-rock fillers in a layering manner, and finally paving a layer of composite geomembrane with two fabrics and one membrane; (E) after filling the soft rocks every time, filling a layer of sand gravels; and (F) reducing the distance of sandwich fillers for the soft rocks easy to humidify and disintegrate and paving a geogrid to carry out reinforcement on embankment slopes. The structure is characterized in that the bottom part of the embankment is filled with one layer of sand gravels, one layer of composite geomembrane with the two fabrics and one membrane is paved on the sand gravel, the subgrade part is filled with the soft rocks in sequence in a layering manner, finally one layer of composite geomembrane with two fabrics and one membrane is paved, the geogrid is adopted at the embankment slopes, and qualified fillers of a roadbed are paved on the top-layer composite geomembrane with two fabrics and one membrane. The design method disclosed by the invention has the advantages that the implementation is easy, the stability is improved, the effect of preventing the settlement-deformation damage of the soft-rock subgrade of the road is obvious and the cost is low.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

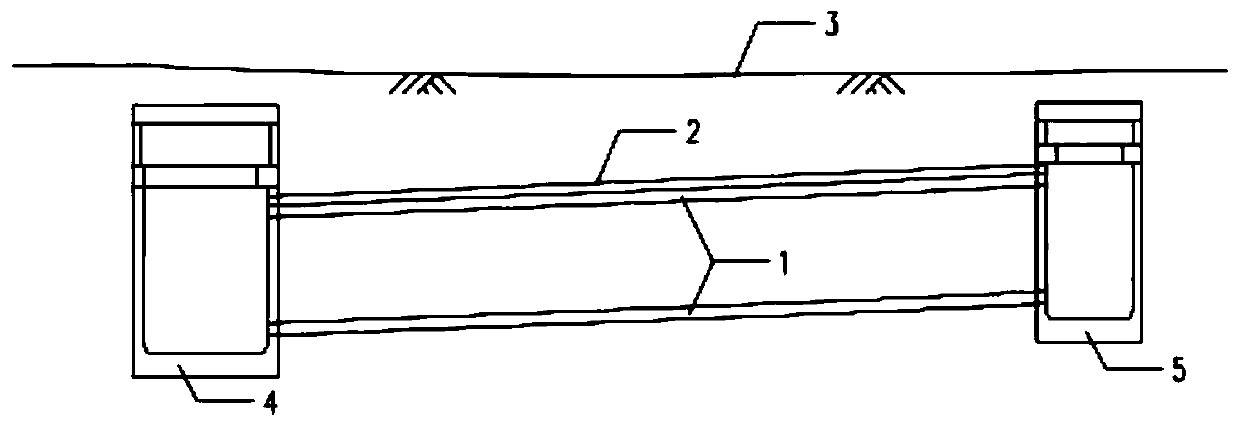

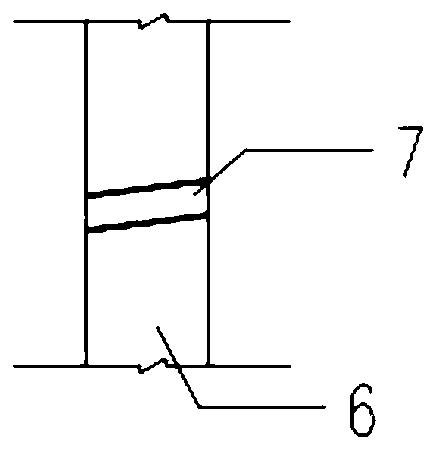

Cylindrical base sea embankment structure for tretching over and protecting suhmarine pipeline and its mounting method

InactiveCN1776120AImprove protectionFast construction of structuresBreakwatersQuaysBarrel ShapedEngineering

This invention discloses a lie across submarine line protective barrel shape foundation coastal dike structure and installation method. It consists of seabed inserted barrel shape foundation and wave or soil stop wall on it, wherein the barrel shape foundation consisting of four integrated barrel units, each side of submarine line has two barrel unit connected by connection board and top cover board, four barrel units are connected by arc shape board. Said structure is fabricated on land, then conveyed to site for positioning by air floating, lying across submarine line, pumping out air and water in barrel units, inserting it to sea bed, putting upper structure on foundation and making joint. Said invention is easy installation, small settlement deformation, fine protection to submarine line, strong wave and soil stop effect and low cost.

Owner:TIANJIN UNIV +1

Construction organization method of complete set of tunnel mechanical equipment

ActiveCN108915696AImprove management abilityImprove the construction work environmentUnderground chambersTunnel liningArchitectural engineeringMechanical equipment

The invention discloses a complete set of tunnel mechanical equipment, which specifically refers to an excavation trolley (or an excavation gantry), a drainage and steel bar binding trolley, a liningtrolley, a spray maintenance trolley, a ditch cable trough trolley, an inverted arch self-propelled hydraulic trestle and a wet spray manipulator, referred to as five trolleys, one trestle and one wetspray machine. A construction organization method matched with the complete set of mechanical equipment comprises the following construction organization steps: S1, hole excavation; S2, initial support; S3, inverted arch lining; S4, arched wall lining; S5, ditch cable troughs and the complete set of mechanical equipment. The construction organization method is reasonable, effectively improves tunnel management effect, improves construction operation environment, ensures construction safety and quality, improves construction progress and is worthy of promotion.

Owner:CHINA RAILWAY SEVENTH GRP CO LTD +1

Strong-water-permeability stratum building foundation pit horizontal grouting sealing bottom construction method

InactiveCN110528523ALow costImprove protectionFoundation engineeringStructural engineeringEngineering

The invention discloses a strong-water-permeability stratum building foundation pit horizontal grouting sealing bottom construction method. The strong-water-permeability stratum building foundation pit horizontal grouting sealing bottom construction method includes the following steps that horizontal grouting sealing bottom construction is conducted, wherein precise positioning and horizontal grouting hole drilling are conducted through a horizontal directional drilling machine, and after hole drilling is completed, retreating type grouting is conducted when drill stems are dragged back, and ahorizontal sealing bottom is formed at the bottom of a foundation pit; and vertical curtain construction is conducted, wherein after sealing bottom horizontal grouting is completed, closed vertical curtains are formed on the four sides or the three sides of the foundation pit, complete lap joint connection is conducted on the vertical curtains and the horizontal sealing bottom, and in other words, a strong-water-permeability stratum foundation pit water insulation structure is formed. According to the strong-water-permeability stratum building foundation pit horizontal grouting sealing bottomconstruction method, vertical curtain construction is conducted after horizontal sealing bottom construction is conducted; firstly, the horizontal sealing bottom can be rapidly formed for the foundation pit to control underground water; then, the vertical curtains and the horizontal sealing bottom structure are connected together, and therefore a three-dimensional anti-seepage structure can be formed for the foundation pit project, and the effects of supporting, water insulation and foundation pit project reinforcing are achieved; and while the surrounding environment is well protected, the project cost is saved, and the project risk is lowered.

Owner:湖南宏禹工程集团有限公司

Transition structure for preventing and treating bump at bridge-head and construction method thereof

PendingCN109853381AShorten the construction periodGuaranteed accuracySingle unit pavingsBridge structural detailsRoad surface roughnessAbutment

The invention provides a transition structure for preventing and treating bump at bridge-head and a construction method thereof. The structure of the transition structure for preventing and treating the bump at the bridge-head comprises a beam body; bridge abutments are fixedly mounted at the two ends of the beam body; one ends of towing plates are fixedly mounted at the middle parts of the bridgeabutments; the other ends of towing plates are buried in a subgrade; the parts behind the bridge abutments and the upper parts of the towing plates are filled with backfilled earth; combined approachslab members are laid on the upper surface of the backfilled earth; and one ends of the combined approach slab members are fixedly mounted on the external sides of the upper ends of the bridge abutments. The construction method comprises the steps of erecting the bridge abutments molded with brackets, constructing the towing plates on the brackets to form two layers of backfill structures, and arranging the combined approach slab members to improve a bearing structure; and therefore, road surface roughness and breakage at the bridge head connecting part caused by uneven settlement of the backfilled earth in the using process are reduced to realize an effect of preventing and treating the bump at the bridge-head; and meanwhile, through the structure combination, energy saving and environmentally friendly properties are realized, the construction period is shortened, template members are saved, and accuracy and quality are very well guaranteed.

Owner:SHENYANG JIANZHU UNIVERSITY

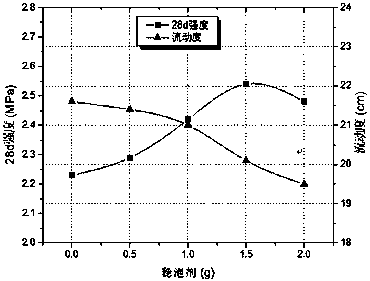

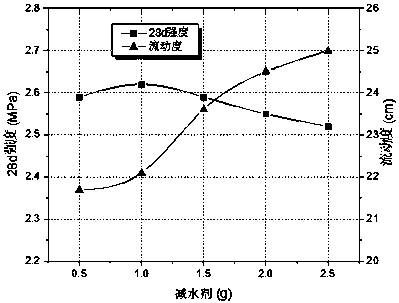

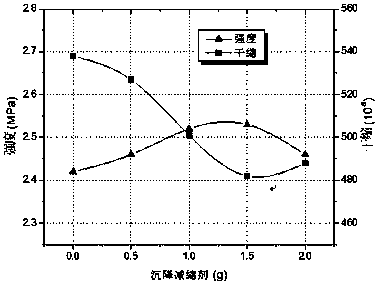

Large-flow state light foamed mixed soil

The invention provides large-flow state light foamed mixed soil which comprises the following components by mass: 1.5-3.5kg of cement, 1.0-2.5kg of an admixture, 0-2.5kg of clay, 0.5-2.5kg of sand, 1.5-3.5kg of water, 150-300g of a foam group, 0.5-2.0g of a water reduction agent, 0-2.0g of a sedimentation shrinkage reduction agent and 0-1.5g of a foam stabilizer, wherein the foam group is made byfoaming a high-performance animal protein modification foaming agent. The light foamed mixed soil has the characteristics of being high in flowability, high in strength, high in stability, low in shrinkage deformation, high in durability, low in cost, convenient to construct, and the like, the flowability of the light foamed mixed soil can be increased by 30-50% when being compared with that of common foamed light soil, the stability is improved by 50-100%, and the light foamed mixed soil is particularly applicable to fields such as backfill of complex parts such as brokebacks of bridge platforms, pipe galleries / pipelines, tunnels and coal mines, and heat preservation and water resistance of lining layers and roofs in municipal administration and road engineering, and belongs to novel, light, large-flow state foamed light mixed soil with excellent properties.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

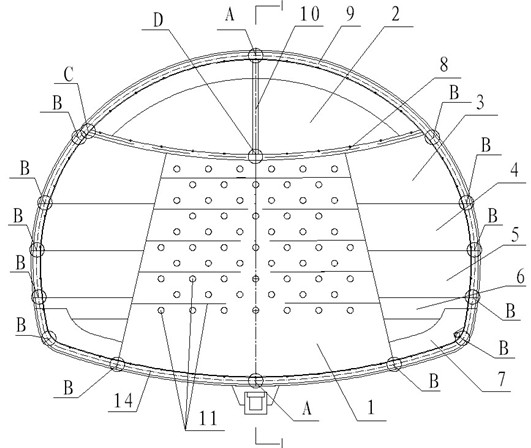

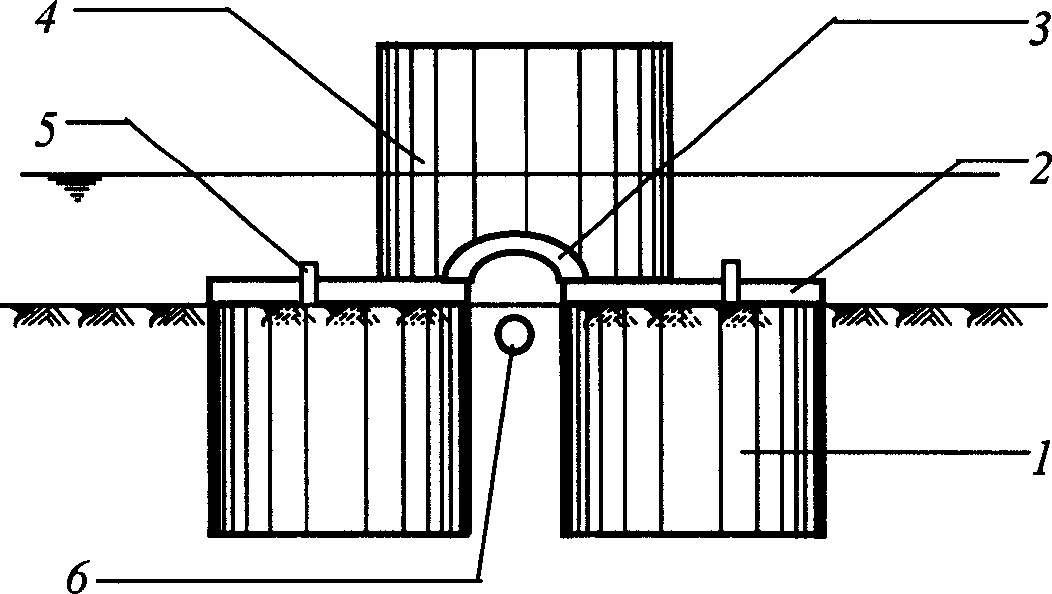

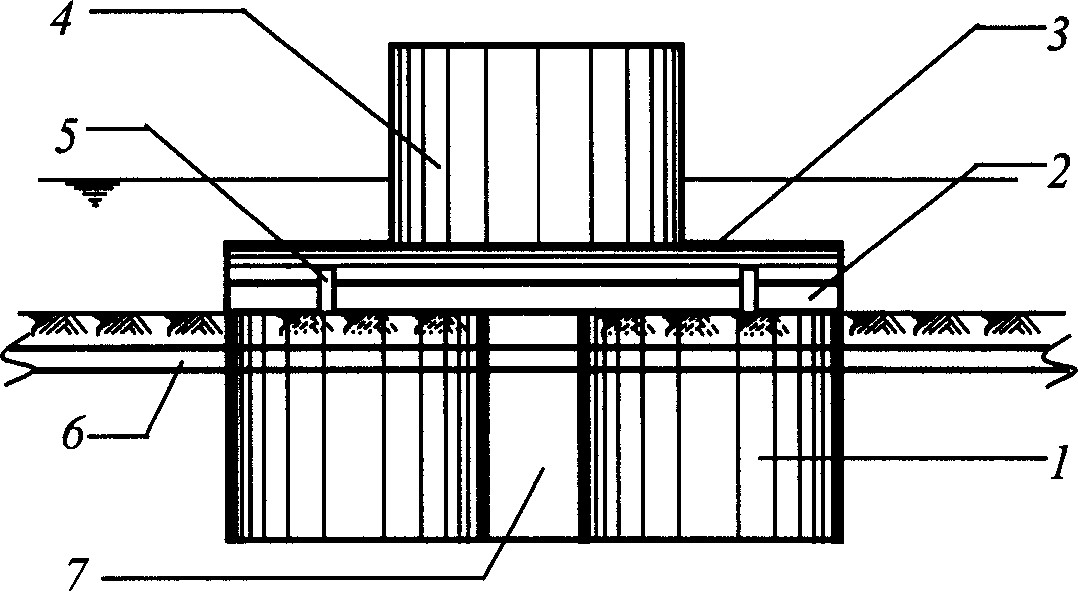

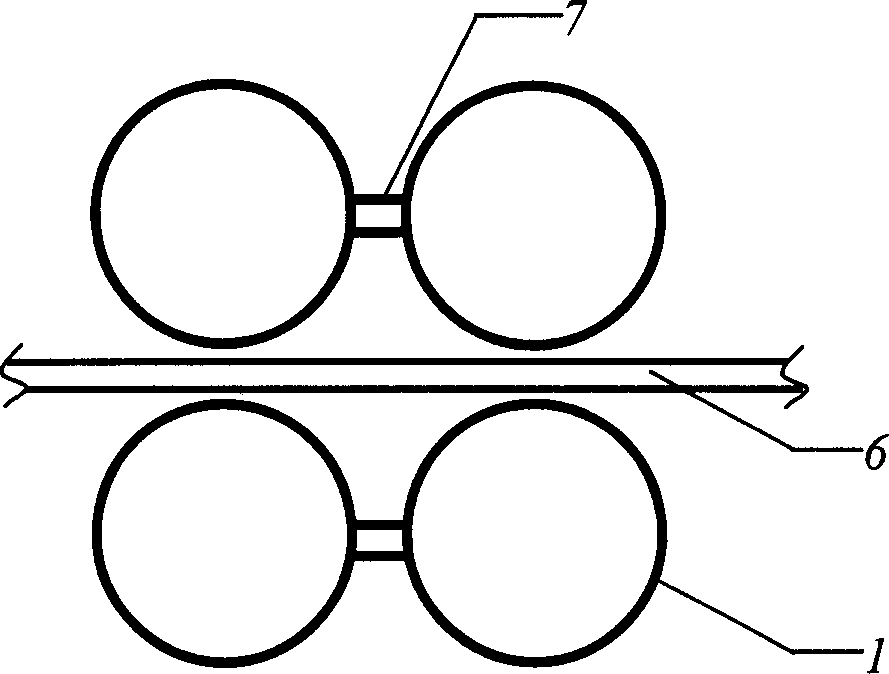

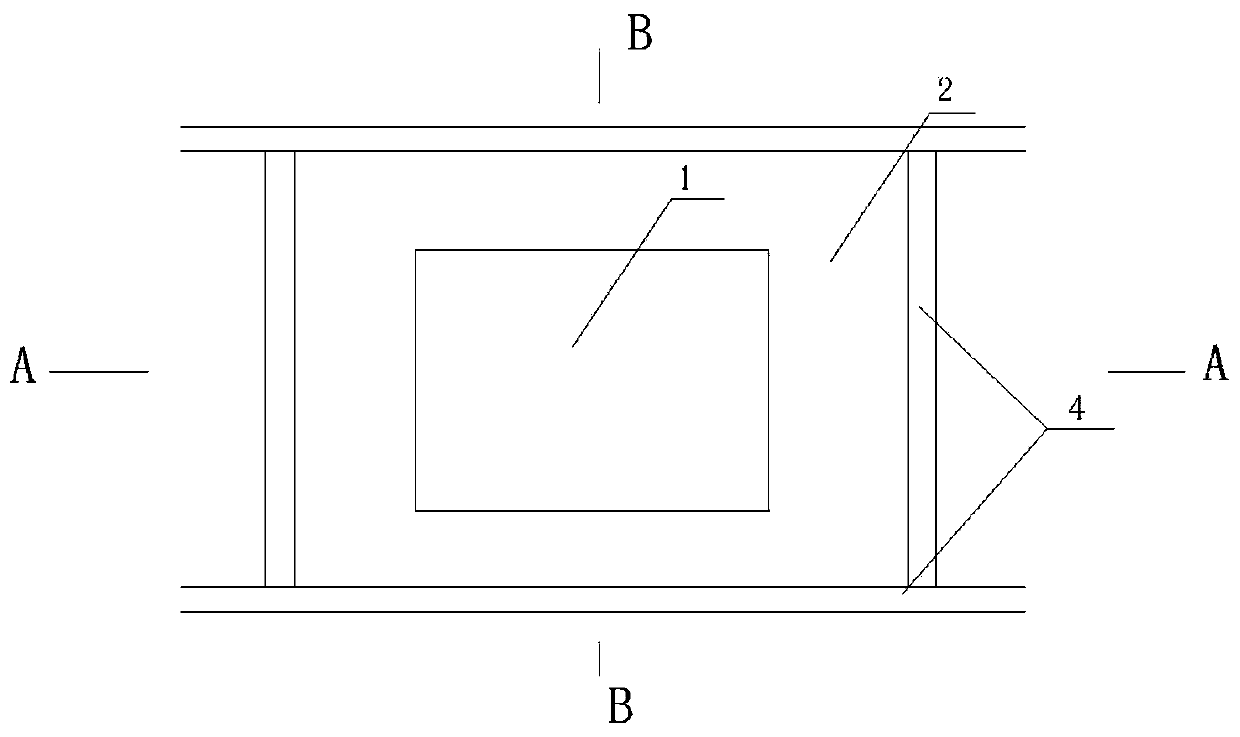

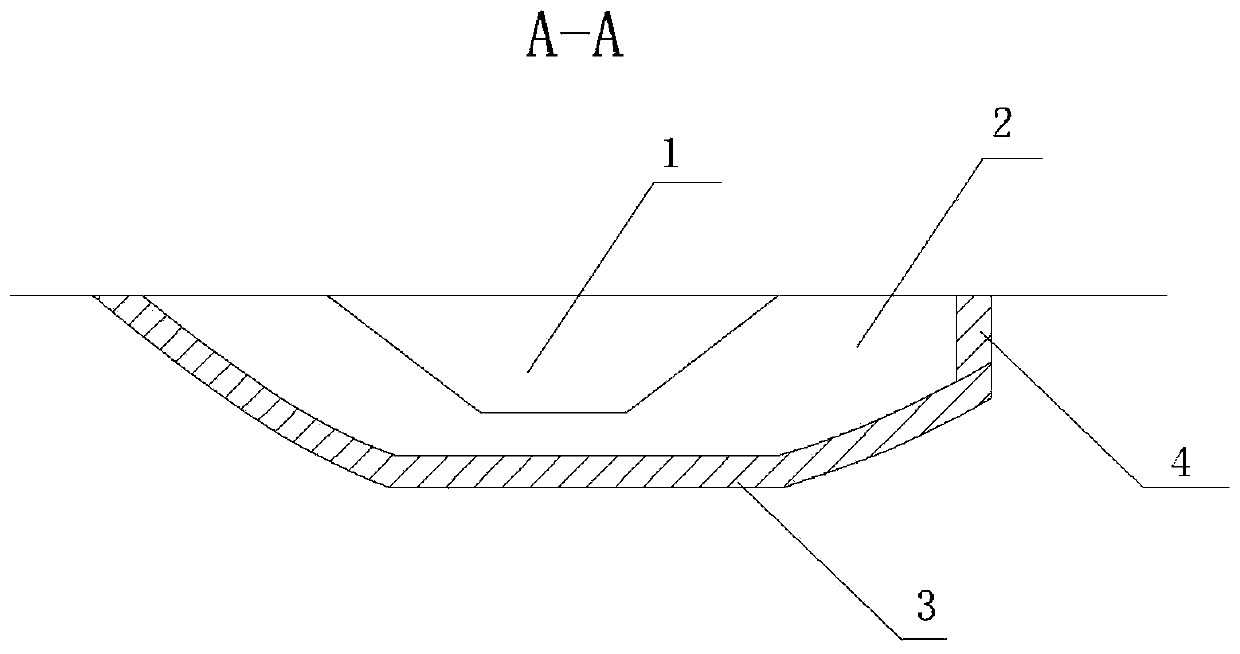

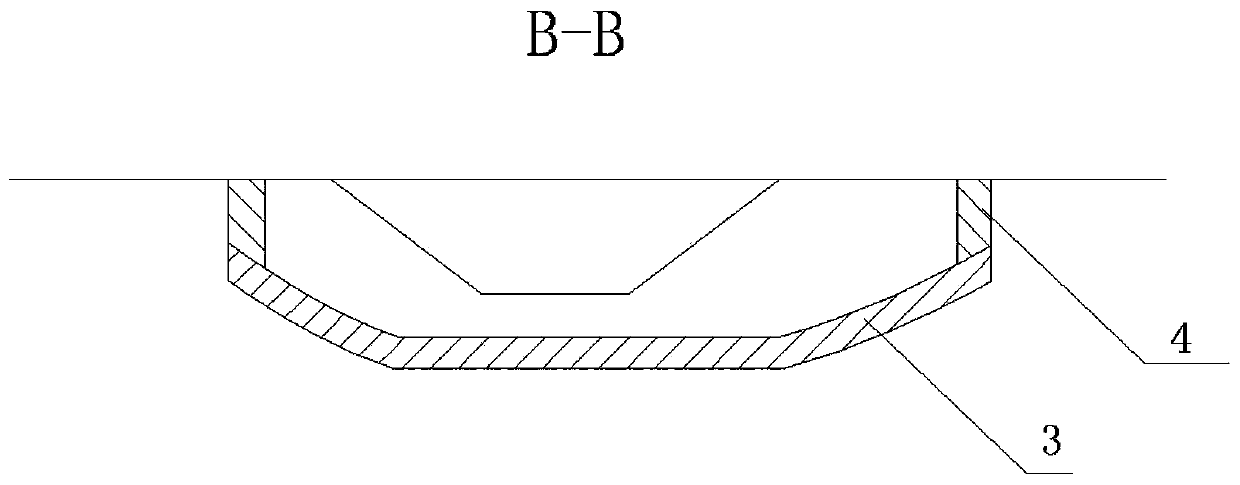

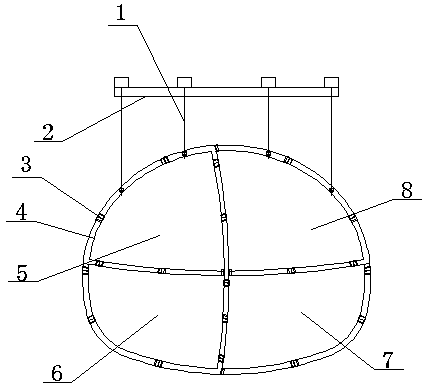

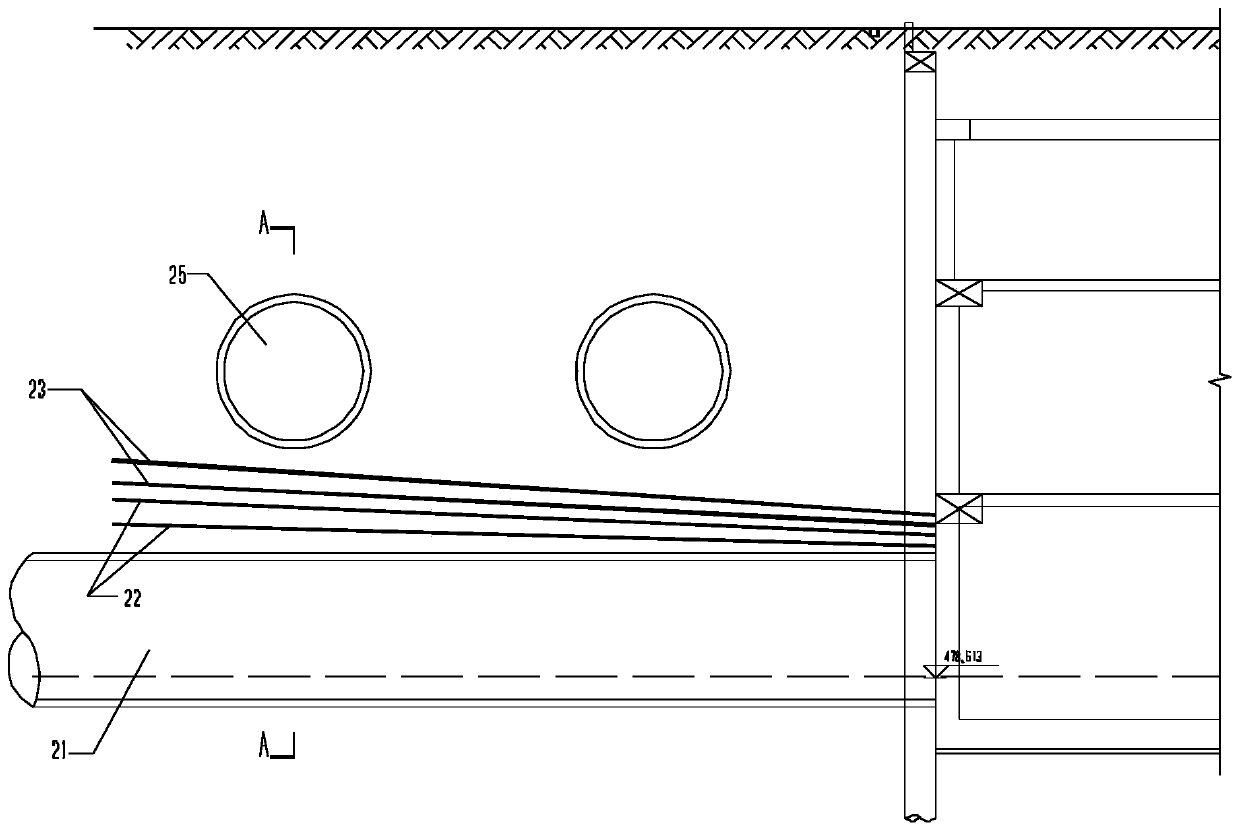

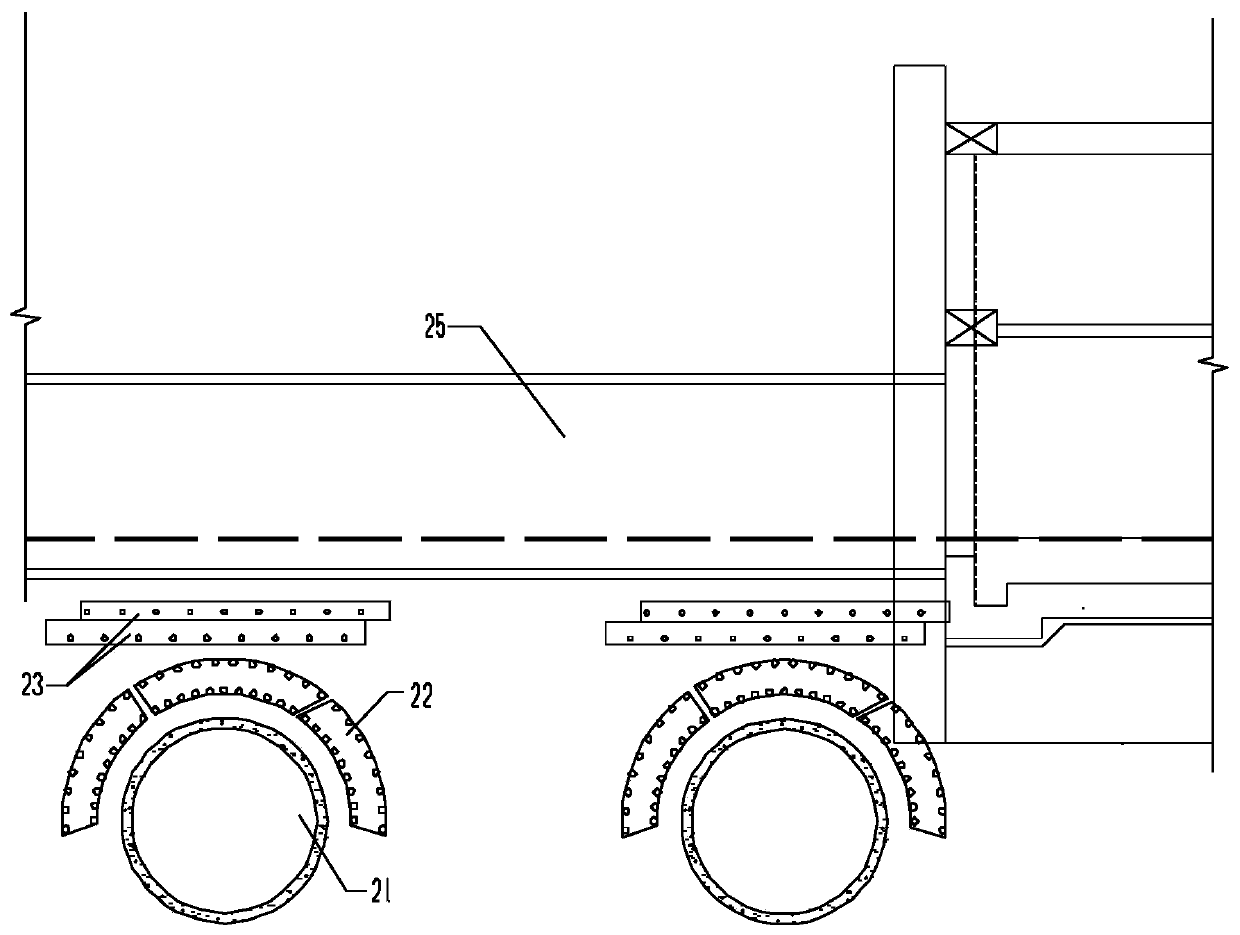

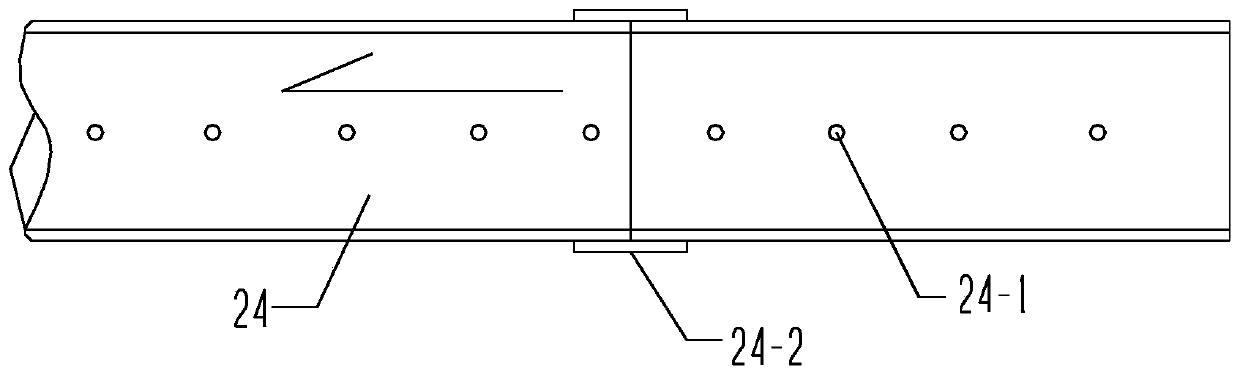

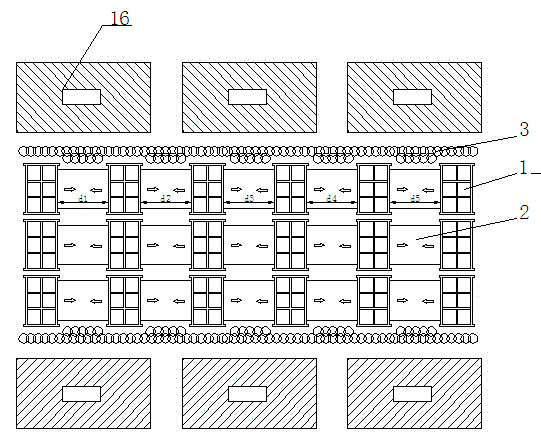

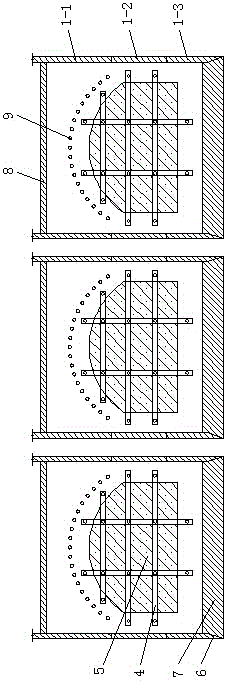

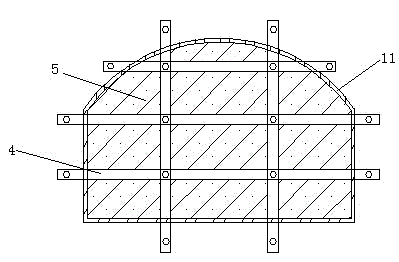

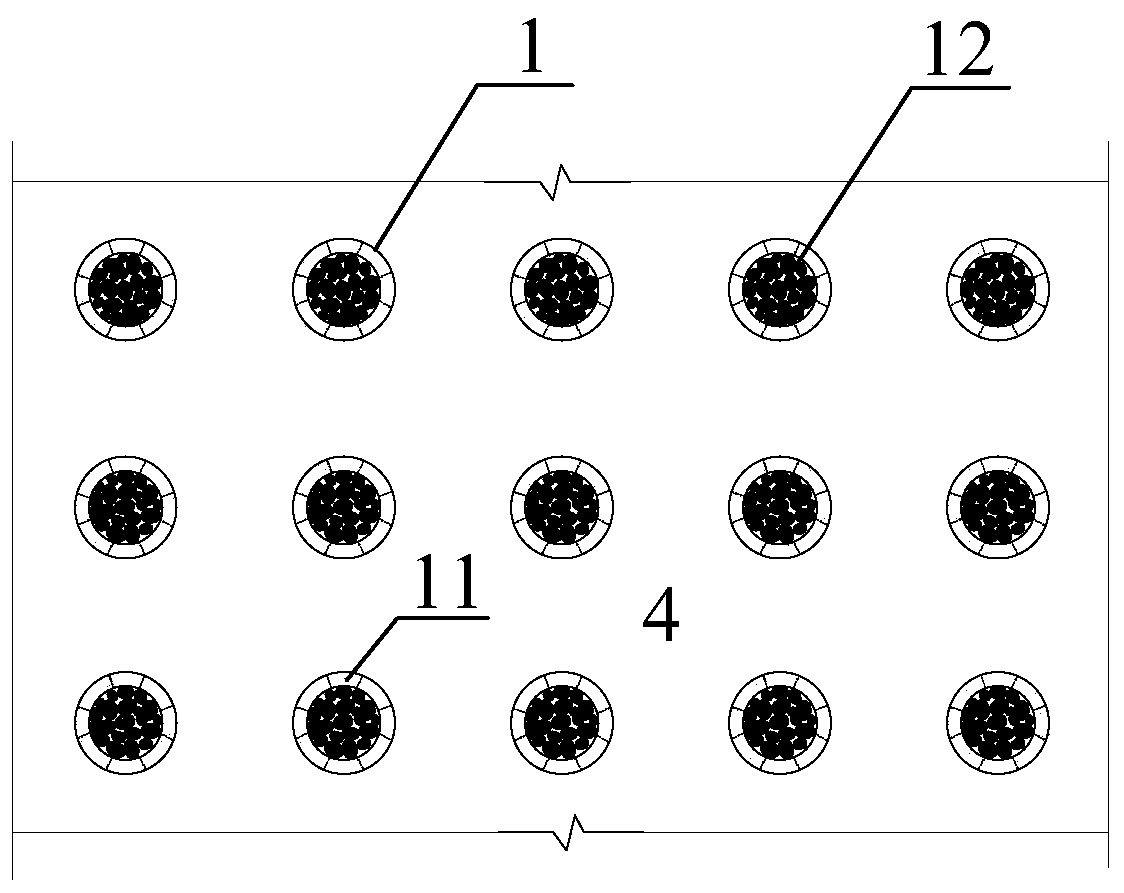

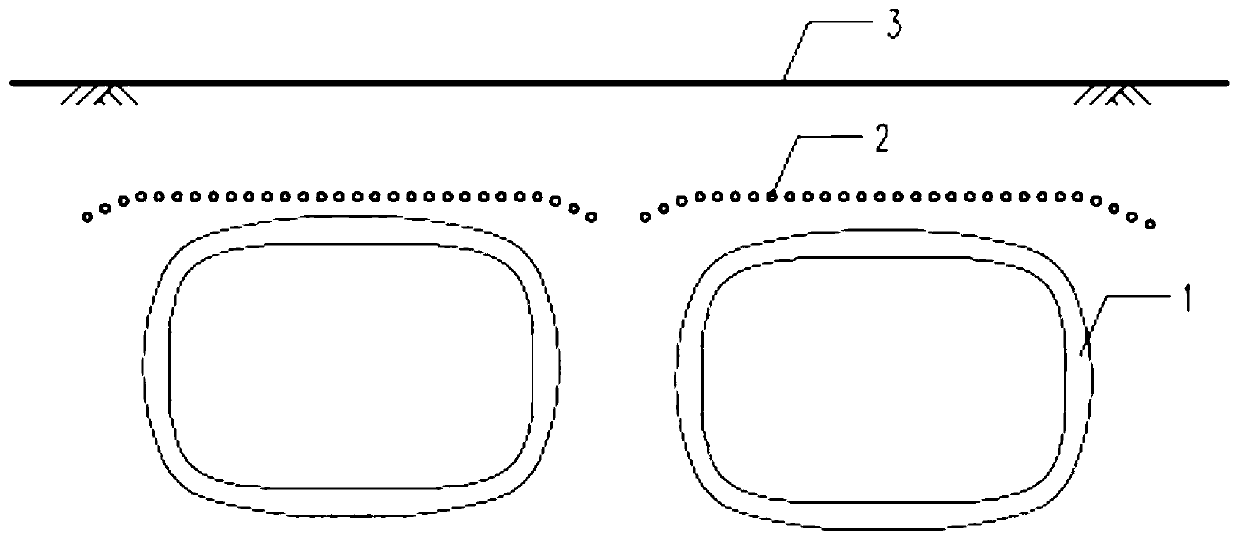

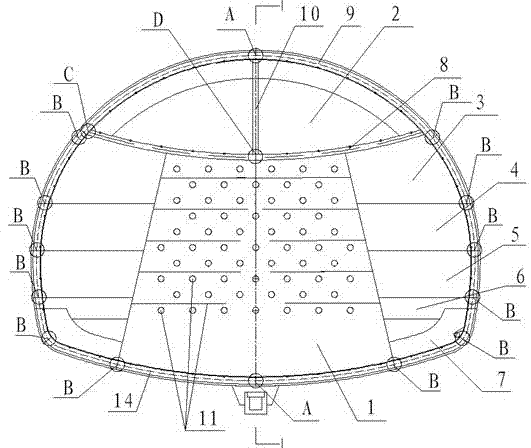

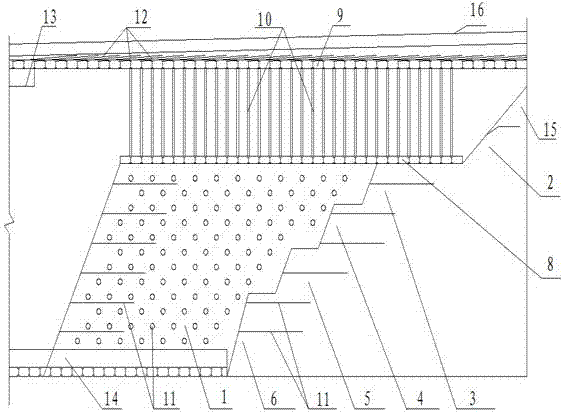

Construction structure and construction method for controlling settlement of shallow-buried and underground-excavated large-section tunnel

PendingCN111472790ASmall settlement deformationAvoid settlement deformationUnderground chambersTunnel liningArchitectural engineeringMesh reinforcement

The invention discloses a construction structure and a construction method for controlling settlement of a shallow-buried and underground-excavated large-section tunnel. A full-section method has thedefects that the stability of surrounding rock is reduced due to a large excavation surface, and a double-side-wall heading method is safe in construction, but low in speed and high in cost. The construction structure comprises an oval structure defined by four fan-shaped chambers and ground steel beams (2) laid on the ground, wherein a supporting structure is arranged outside each fan-shaped chamber in a surrounding mode, each supporting structure is composed of two layers of reinforcing meshes (4) arranged outside the corresponding fan-shaped chamber and a plurality of reinforcing grids (3)laid between the two layers of reinforcing meshes, and a plurality of locking anchor rods (1) are arranged on the ground steel beams, pass through holes in the ground and then are welded in the reinforcing grids. The construction structure and the construction method are used for controlling the settlement of the shallow-buried and underground-excavated large-section tunnel.

Owner:中交哈尔滨地铁投资建设有限公司 +2

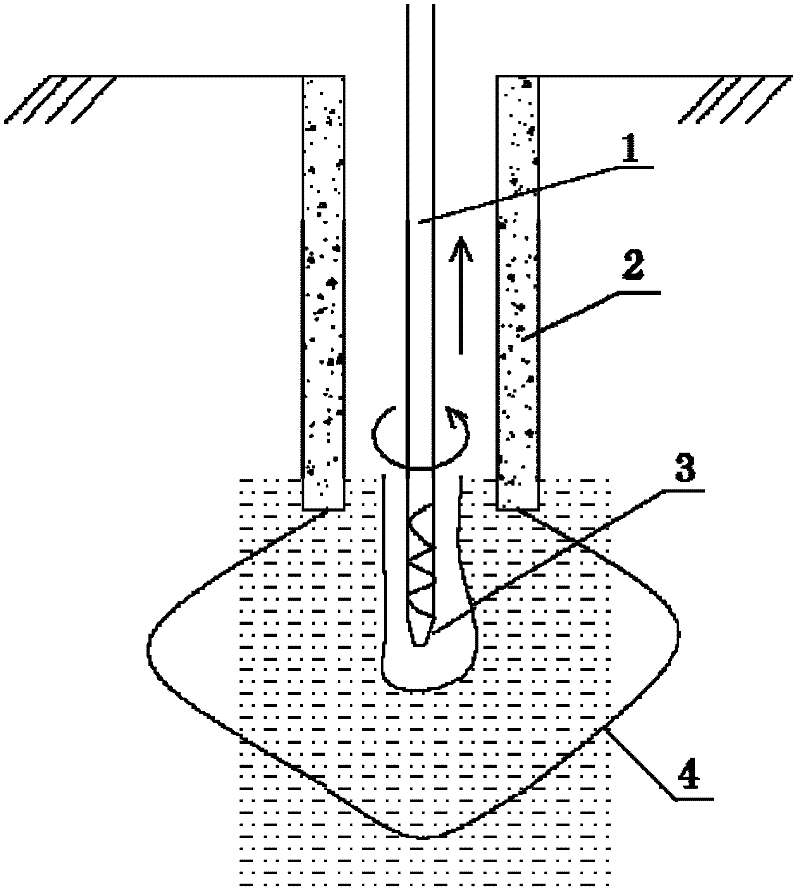

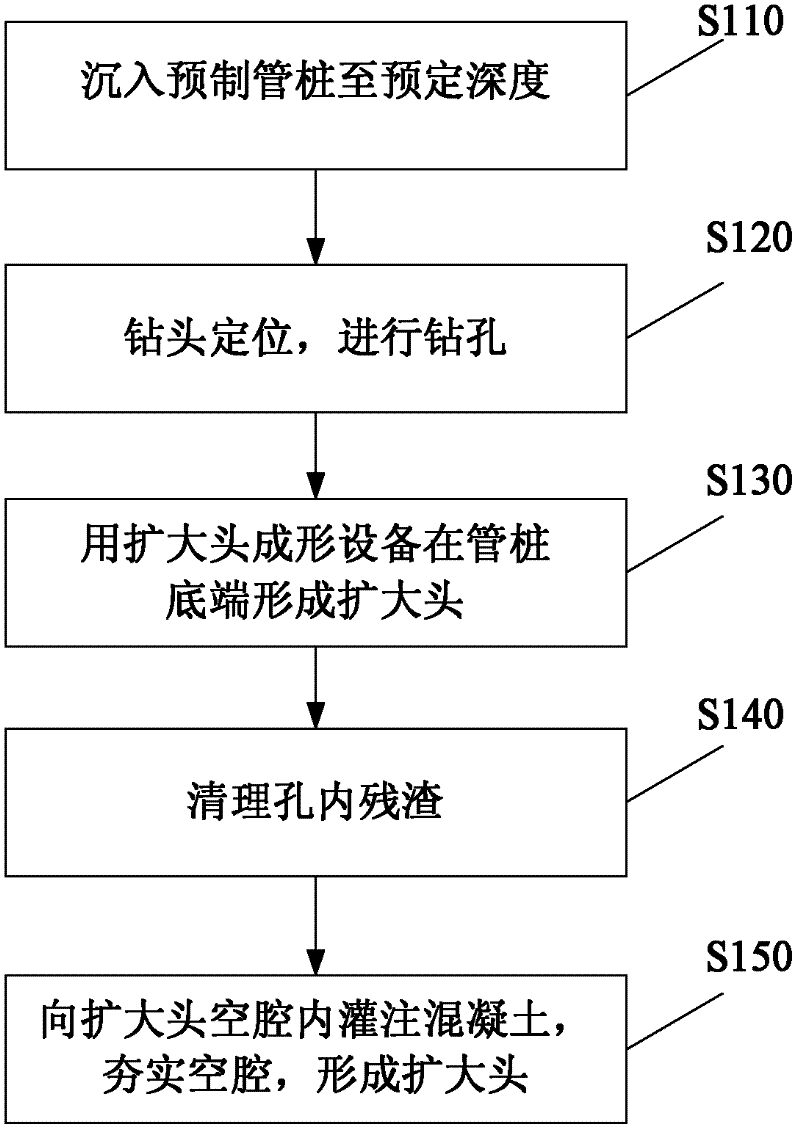

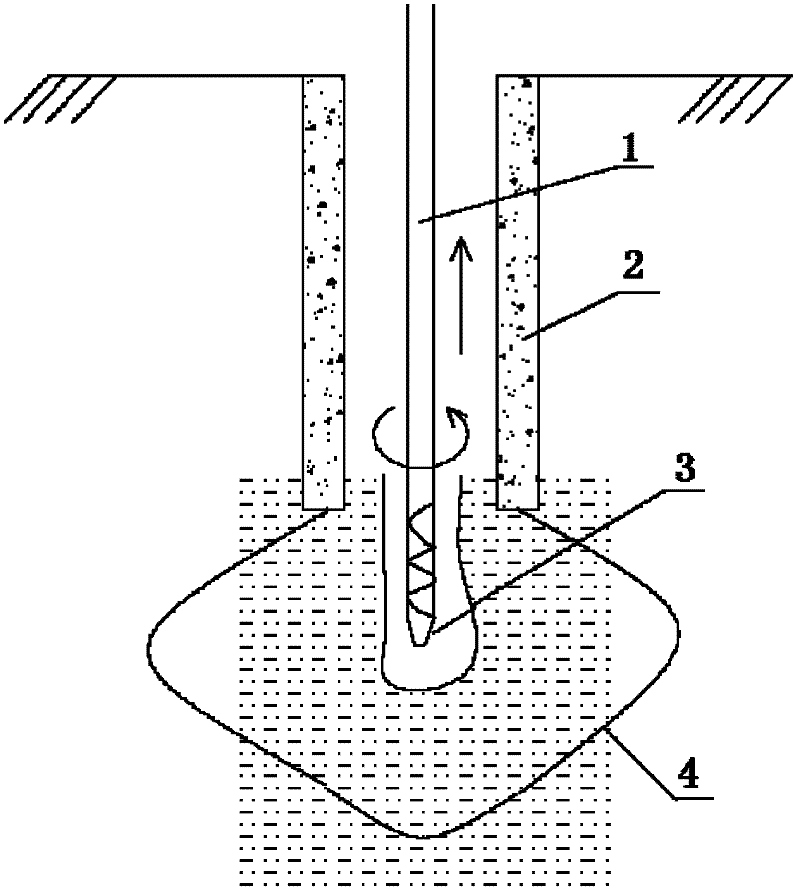

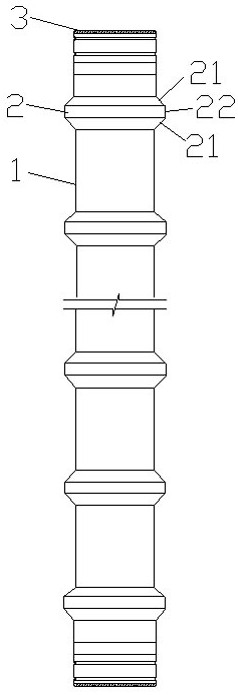

Prefabricating pipe pile construction method

Provided is a prefabricating pipe pile construction method. The prefabricating pipe pile construction method comprises the following steps: (1) cleaning construction site and using a piling machine or a high-frequency oscillation hammer to press a prefabricating pipe pile into a foundation soil layer to a preset depth; (2) enabling a drilling machine drill bit to be aligned with the center position of the prefabricating pipe pile, performing drill bit positioning, drilling a hole to exceed the bottom end of the prefabricating pipe pile, and then moving out the drill bit; (3) hoisting an expansion head forming device through a suspension device and placing the expansion head forming device in a pile hole of the prefabricating pipe pile, performing extrusion expansion rotation cut to the position of the bottom end of the prefabricating pipe pile to form a cavity, and enabling the expansion head forming device to be suspended out of the pile hole; (4) clearing residue in the pile hole and the cavity; and (5) utilizing a concrete output device to pour concrete into the cavity arranged at the bottom end of the pile hole, and performing tamping so as to form an expansion head. The prefabricating pipe pile construction method is simple and convenient to operate, high in construction efficiency and safe, has little damage to the prefabricating pipe pile, enables the expansion head to be formed stably, effectively improves bearing capacity of the prefabricating pipe pile, and enables sedimentation deformation to be greatly reduced.

Owner:MCC COMM CONSTR GRP CO LTD

Method for preventing surface collapse when shield tunneling machine starts and immediately underneath passes existing shield tunnel

PendingCN109707388APlay a protective effectPlay an isolation roleUnderground chambersTunnel liningShield tunnelingPre embedding

The invention provides a method for preventing surface collapse when a shield tunneling machine starts and immediately underneath passes an existing shield tunnel. The method for preventing surface collapse when the shield tunneling machine starts and immediately underneath passes the existing shield tunnel specifically comprises the steps that firstly, multiple layers of pipe sheds are arranged between a shield tunnel portal contour line and an existing tunnel, then an extension steel ring is added at a shield tunnel portal opening, the steel ring is reinforced by adopting a steel ring support structure, the extension steel ring is connected with a portal pre-embedded ring plate, at least two wire brushes are arranged in the middle of the extension steel ring, a cord fabric rubber plate is arranged on the end part of the extension steel ring, a plurality of cavities are formed, a ring of ball valves are mounted on the position, corresponding to every cavities, outside the extension steel ring, an anti-head-planting structure is arranged on the bottom of the extension steel ring, finally, a shield tunneling machine cutter disc is improved before a shield goes down a well, a strengthened net is arranged on the opening position of the cutter disc, and anti-twist blocks are arranged on a shield body. According to the method for preventing surface collapse when the shield tunnelingmachine starts and immediately underneath passes the existing shield tunnel, it is guaranteed that in the process of starting and immediate underneath passing an existing line, the existing line is not influenced, shield construction can be completed in planned time, and whole subway construction is not delayed.

Owner:URBAN MASS TRANSIT ENG CO LTD OF CHINA RAILWAY 11TH BUREAU GRP +1

Building dense region underground-space-building caisson construction method

The invention belongs to the technical field of underground architectural engineering, relates to a caisson construction method for developing an underground space at an old building dense region where an underground garage is not simultaneously built, and particularly relates to a building dense region underground-garage-building local caisson construction method. The method adopts interval caissons, an odd number of the caissons are disposed in the dense building group according to an adjacent building interval, a middle box body is sunk firstly, box bodies on two sides are symmetrically sunk then, and symmetrical forward tunneling is performed under protection of the caissons through the combination with a hidden digging method. The construction method can solve many problems of underground garage excavation construction in the building dense region well, and effectively eases a situation of a parking difficulty.

Owner:山东轨道交通勘察设计院有限公司 +1

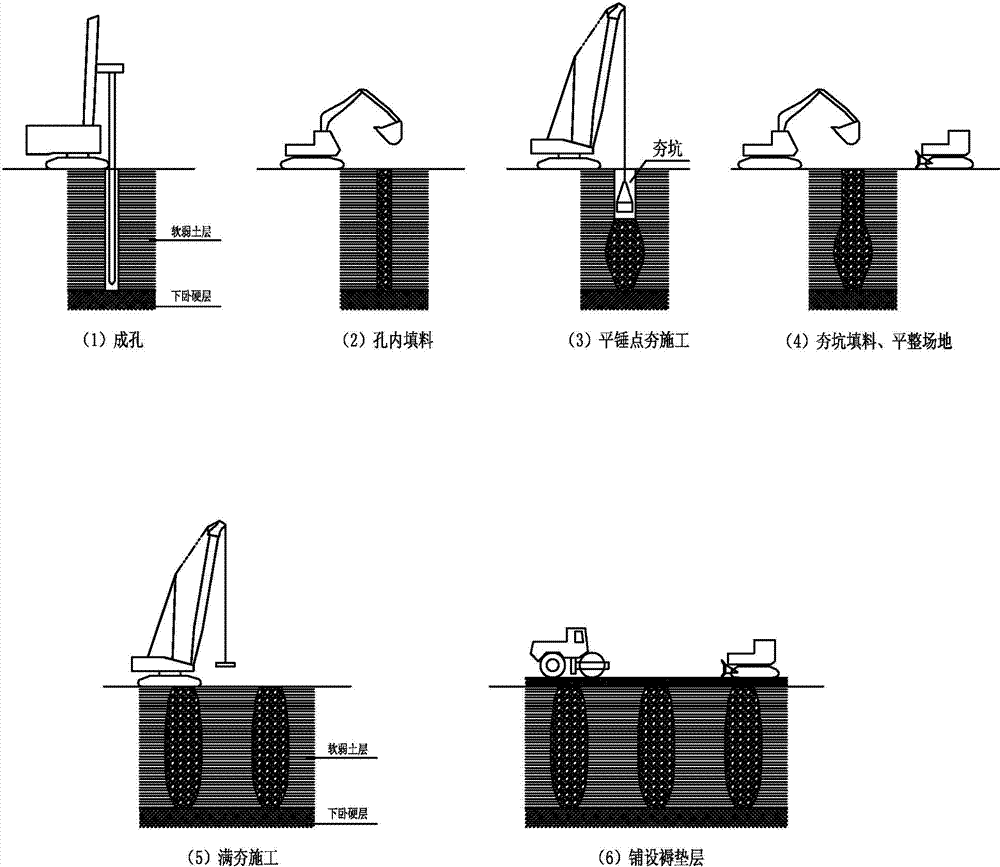

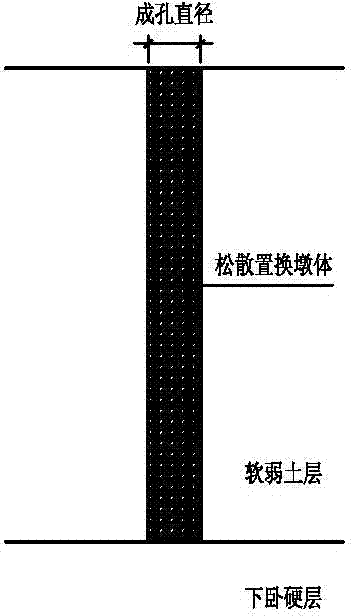

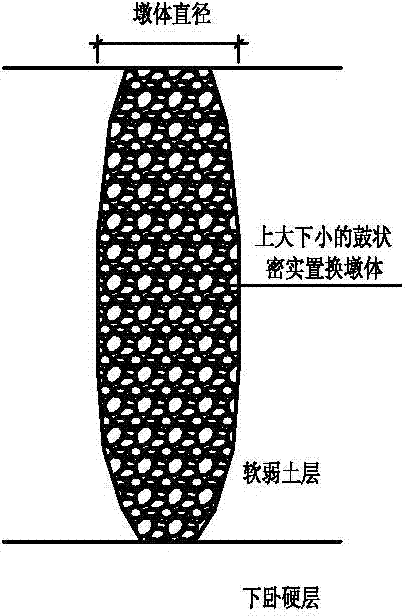

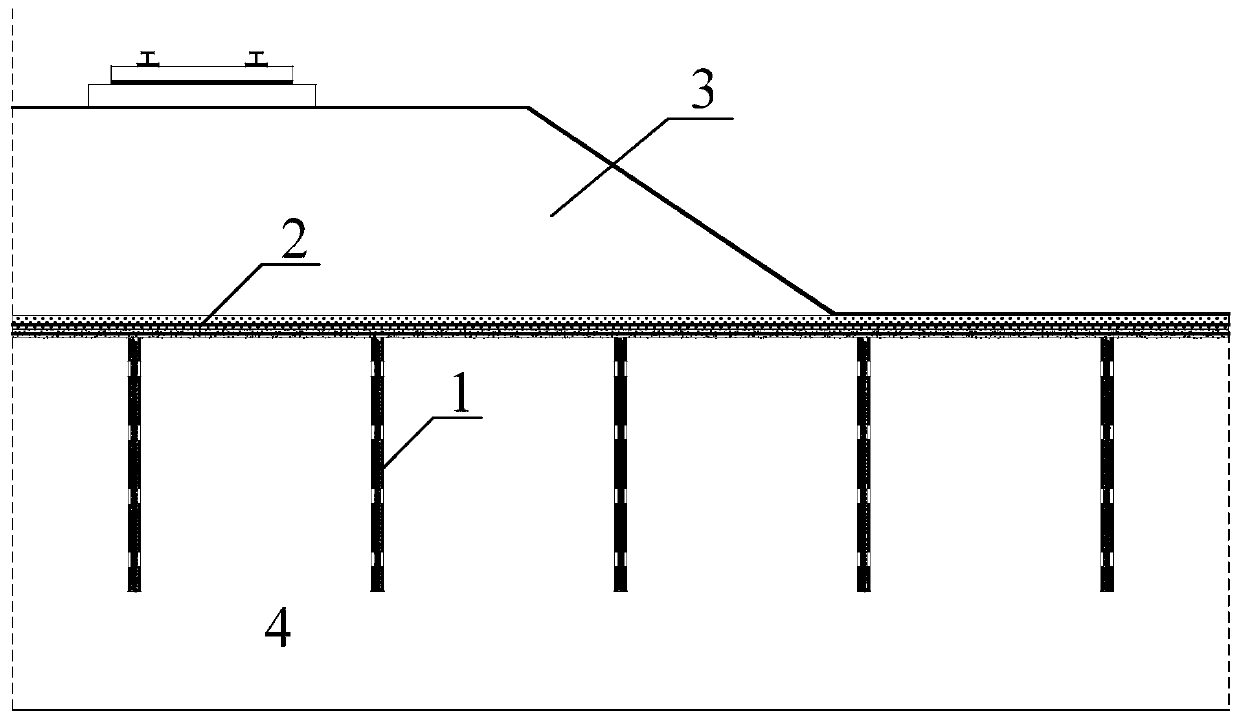

Pre-hole-forming padding substitution hammer flattener dynamic compaction method

ActiveCN104727295AGood drainageEasy constructionSoil preservationEnvironmental resistanceDynamic compaction

The invention provides a pre-hole-forming padding substitution hammer flattener dynamic compaction method, by means of the method, partial substitution to a soft soil foundation is achieved, and a substitute mound body is in good contact with an underlying hard layer. The method comprises the following steps: 1, pre-forming a hole in foundation soil; 2, filling the hole with materials till the ground surface is reached; 3, conducting hammer flattener local compaction construction to filler at the ground surface, wherein a drum-shaped compact mound body with upper end large is formed; 4, after conducting backfill and flattening the field, adopting full compaction for further consolidating inter-mound soil bodies and superficial soil bodies; 5, laying a cushion layer. The method has the advantages that the partial substitution treatment can be conducted to the deep foundation of a type such as saturated clayey soil, sludge, mucky soil or a weak intercalated layer, according to the depth, dynamic compaction which is different in energy level is applied to a substitute body, the compact mound body is formed, the cushion layer is laid, the composite foundation is formed, and meanwhile the method has the advantages of being convenient in construction, low in construction cost, short in construction duration, environment protective, high in foundation bearing capacity and small in sedimentation deformation.

Owner:CHINA ZHONGHUA GEOTECHN ENG

Expansive soil foundation structure containing ballastless track roadbed and construction method

ActiveCN110965398AReduce bump deformationSave engineering investmentRailway tracksBulkheads/pilesRebarHollow core

The invention provides an expansive soil foundation structure containing a ballastless track roadbed and a construction method. The structure comprises porous pipe piles, an expansive soil foundation,a geosynthetics reinforced cushion layer and a ballastless track roadbed, the porous pipe piles and the expansive soil foundation are arranged at the lowermost portion, and the geosynthetics reinforced cushion layer and the ballastless track roadbed are sequentially arranged above the porous pipe piles and the expansive soil foundation from bottom to top; a plurality of porous pipe piles are vertically arranged in the expansive soil foundation, each porous pipe pile comprises a hollow porous pile body and an elastomer material filling the hollow porous pile body, each hollow porous pile bodyis of a hollow reinforced concrete structure, and each porous pipe pile further comprises a radial through hole penetrating through the inner wall and the outer wall of the corresponding hollow porouspile body in the radial direction. According to the method, the expansion and shrinkage deformation of the expansive soil foundation during water immersion and loss is effectively reduced, so that the expansion and shrinkage deformation of the ballastless track roadbed is controlled within a reasonable range, the requirements of high-speed and safe operation of trains on the ballastless track roadbed are met, and the expenses for reinforcing and treating the expansive soil foundation are saved.

Owner:CENT SOUTH UNIV

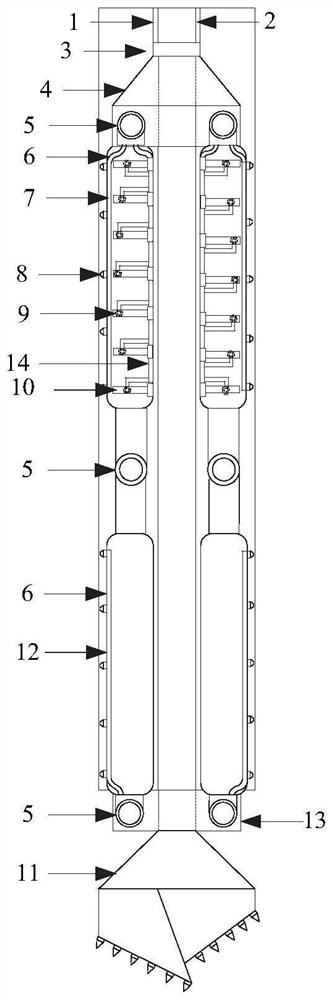

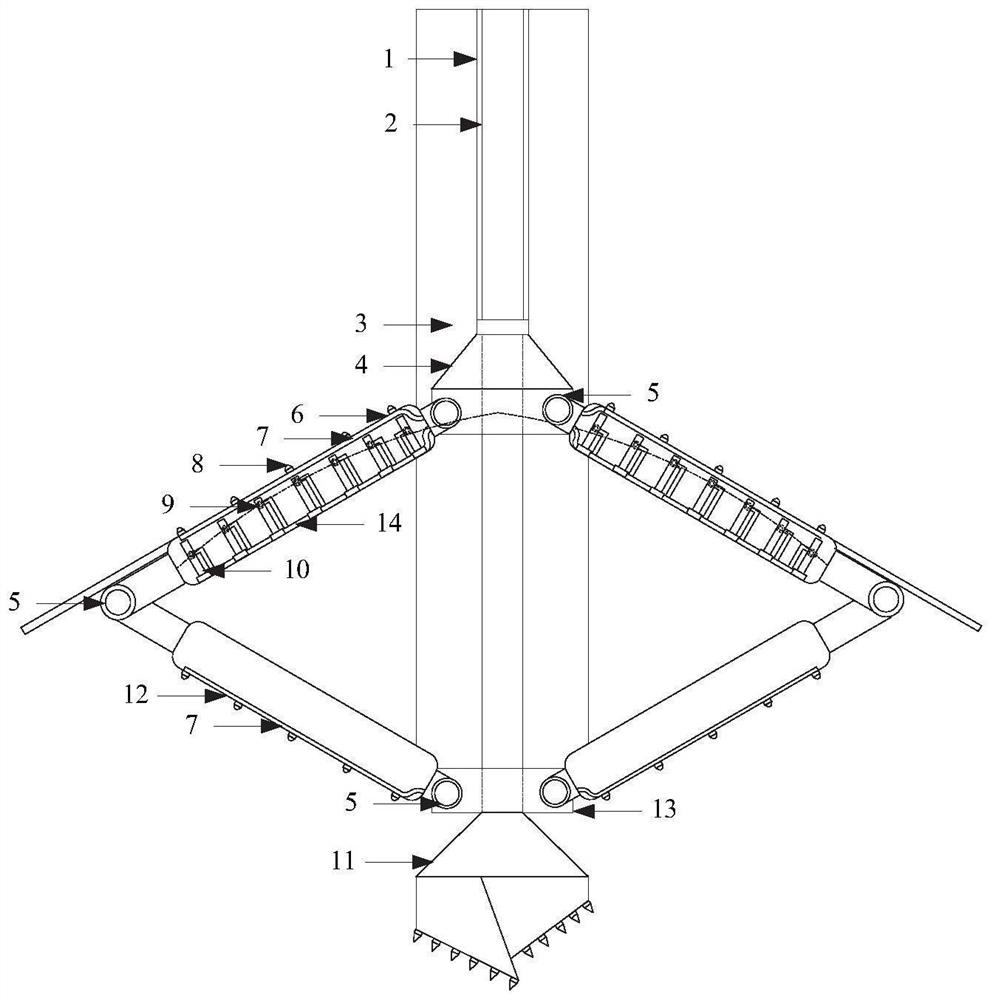

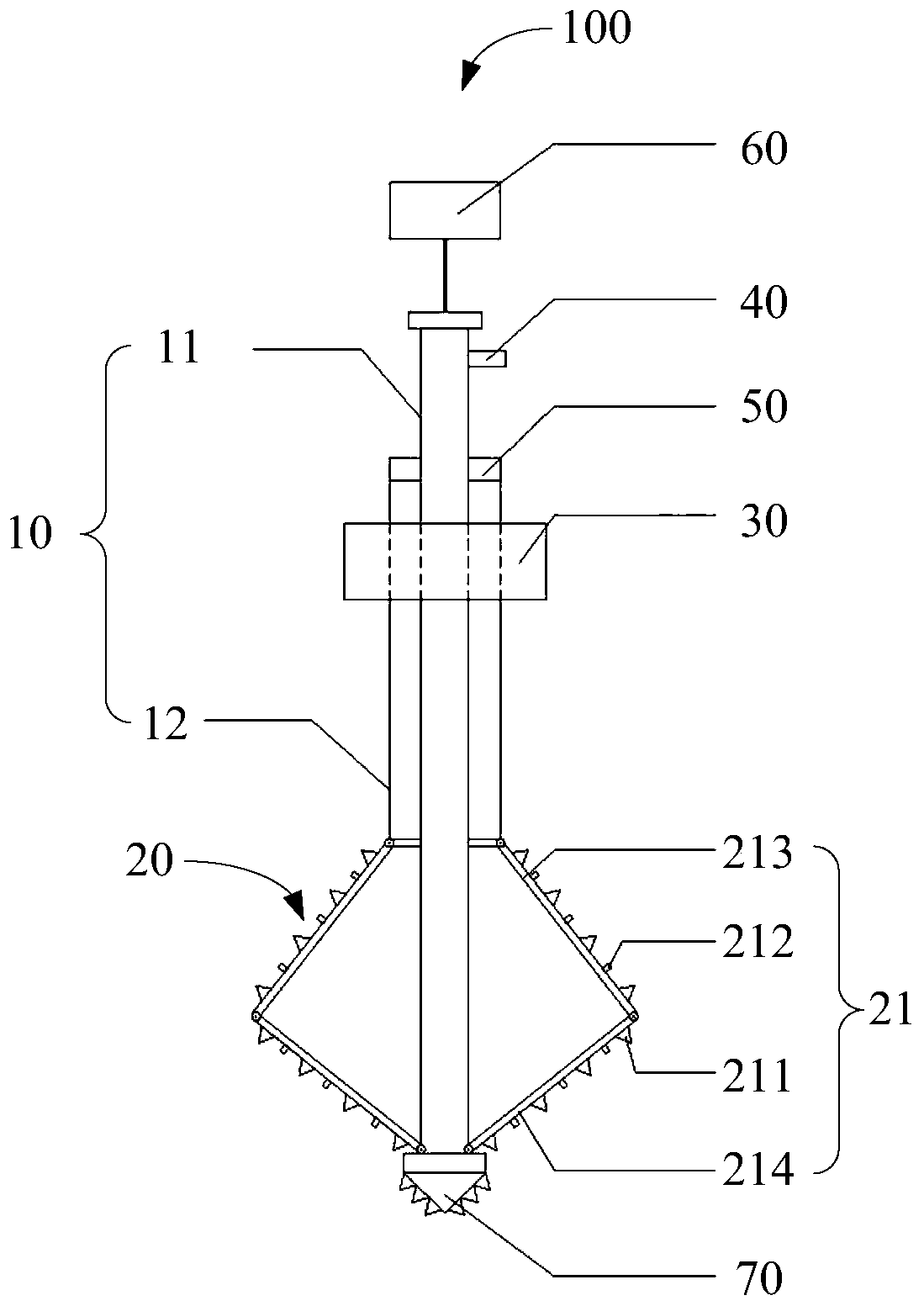

Digging, spraying, pressing and grouting pile and construction method and special drilling machine thereof

PendingCN113152440AThere is no problem of small expansion sizeSmall settlement deformationDrilling rodsDrilling casingsCement pasteMechanical engineering

The invention discloses a digging, spraying, pressing and grouting pile and a construction method and a special drilling machine thereof. The special drilling machine can scrape a soil layer around a pile body at the positions of a diameter expanding body and a wing plate on the surface of a pile hole into a cavity of the diameter expanding body with the depth of 10-20 cm and a groove of the wing plate with the depth of 10-20 cm and the width of 5-10 cm by using a scraper; cement paste which is sprayed in a rotating and fixed mode rises to the soil layer at the position of the diameter expanding body and the wing plate or rises to be filled in the cavity of the diameter expanding body or the soil layer in the groove of the wing plate which is scraped, loosened, dug and expanded by the soil scraper, and water in the cement paste permeates into the soil layer which is not loosened to soften a soil body; then high-pressure cement paste impacts and cuts in the softened soil layer in a jet mode to slump a hole wall of the cavity of the diameter expanding body or the groove of the wing plate groove scraped by the scraper, the area of the cavity of the diameter expanding body or the groove of the wing plate is thickened and deepened, concrete can be pressed into the cavity of the diameter expanding body or the groove of the wing plate to be connected with the pile body, the pile body is connected with the wing plate and the double-frustum diameter expanding body through the concrete, and the concrete is bonded with surrounding cemented soil and a compacted soil layer, so that the settlement deformation of a single pile is small, and the bearing capacity of the single pile is doubled or above.

Owner:李金良 +1

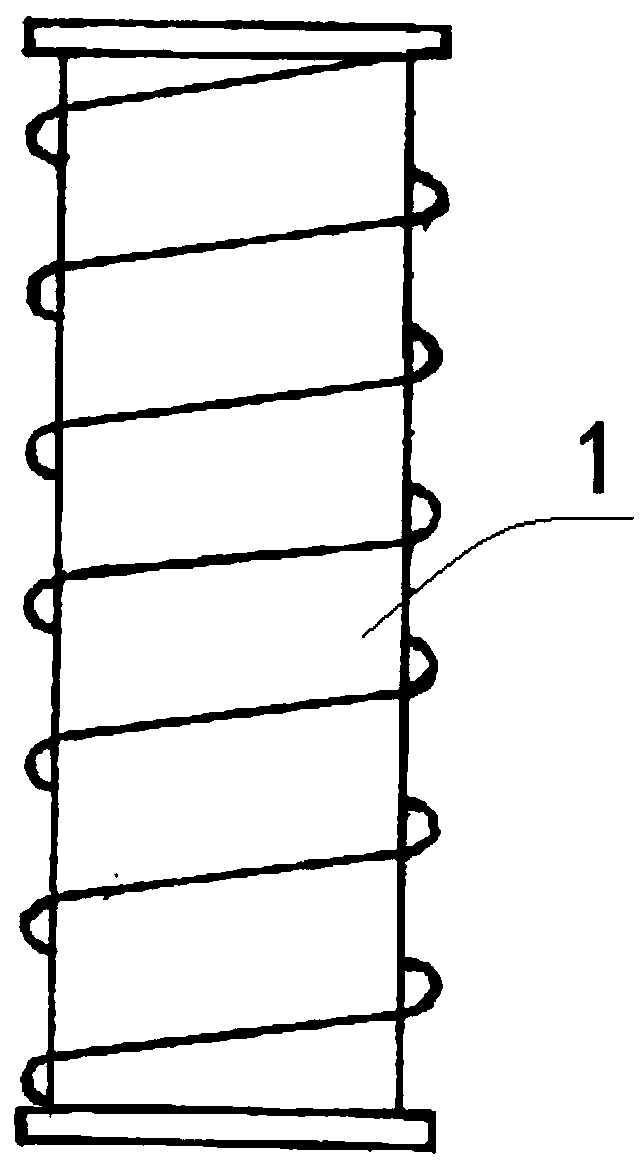

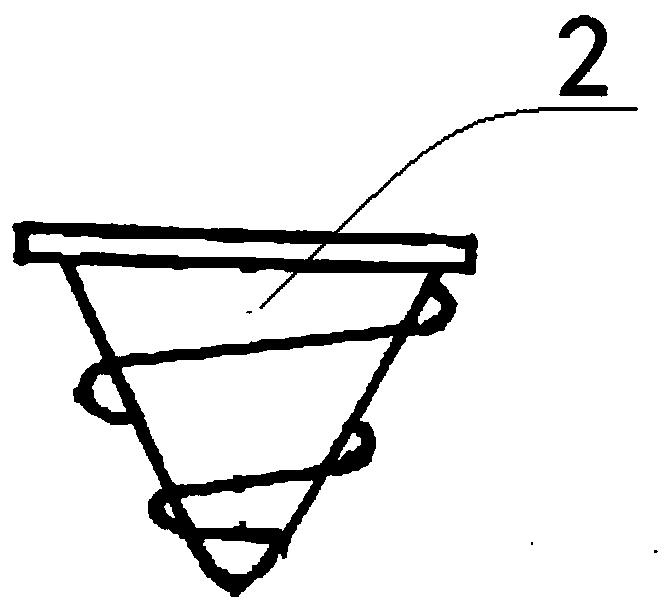

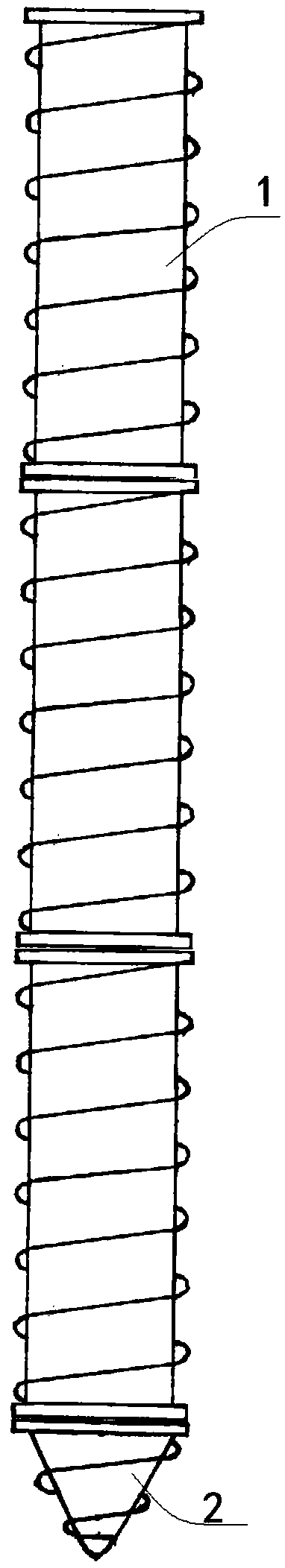

Drilling tool and construction method for long spiral compacted hole-forming bored concrete pile

PendingCN109441357ANo vibrationIncrease the limit end resistanceDrill bitsDrilling rodsDrill bitEngineering

The embodiment of the invention discloses a drilling tool and a construction method for a long spiral compacted hole-forming bored concrete pile. The drilling tool for the long spiral compacted hole-forming bored concrete pile includes a plurality of drill rods and a cone-shaped drill bit, wherein connecting flanges are correspondingly arranged at the two ends of each drill rod and the upper end of the cone-shaped drill bit, and cavities which can communicate with one another are formed in the drill rods and the cone-shaped drill bit; and a movable door for enabling the cavities to communicatewith the outside in time are arranged at the lower end of the cone-shaped drill bit, spiral plates are arranged on the circumferential surfaces of each of the drill rod and the cone-shaped drill bit,and the drill rods can be connected with each other to form a cylindrical body through the connecting flanges. According to the drilling tool and the construction method for the long spiral compactedhole-forming bored concrete pile, low construction noise and no pollution are achieved, and virtual soil at the bottom of a hole does not need to be cleaned after drilling, protruding of a pile material from the cone-shaped drill bit determines the long spiral drilling bored concrete pile without pile bottom sediment, and the effect of the ultimate end resistance of the pile bottom soil is improved.

Owner:谢金良

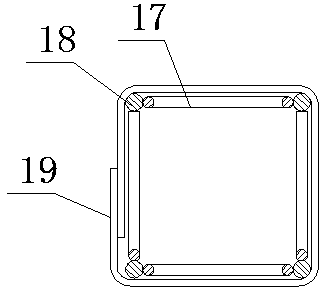

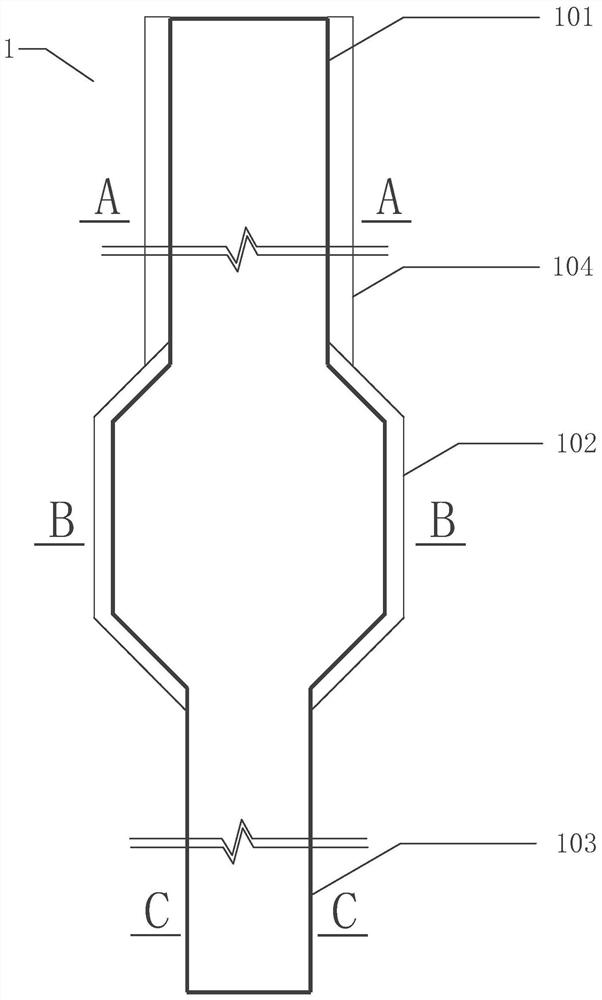

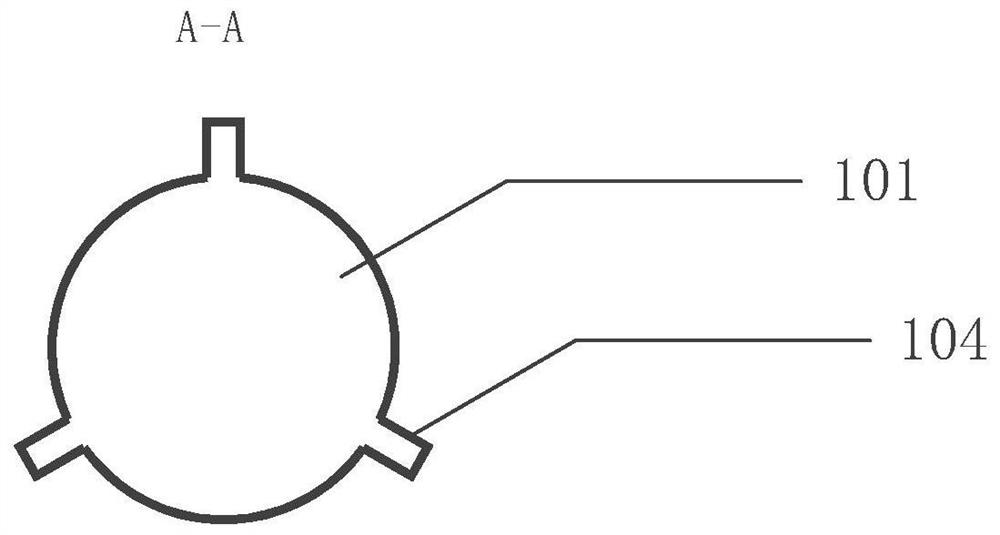

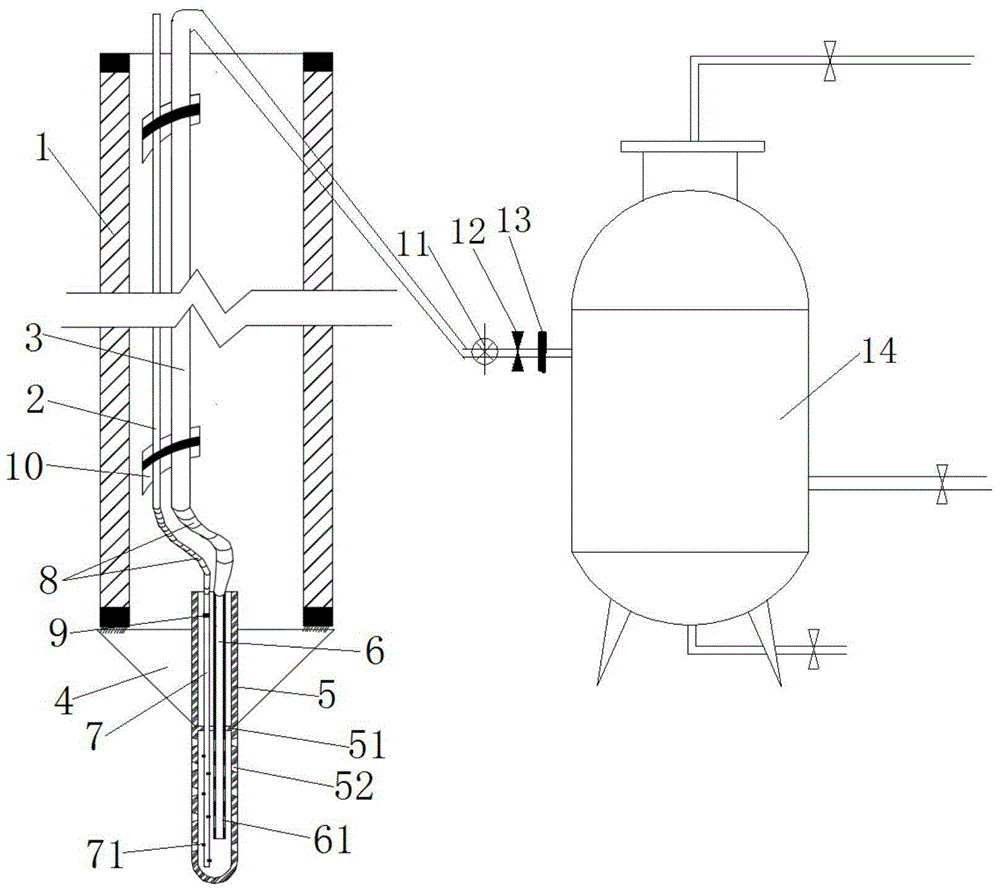

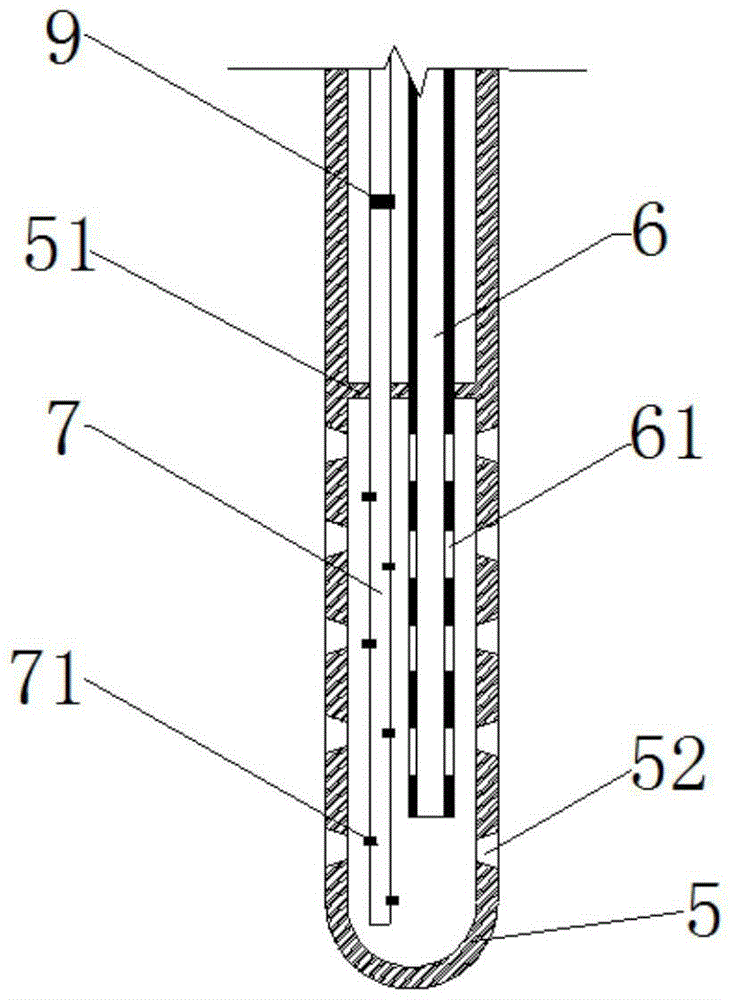

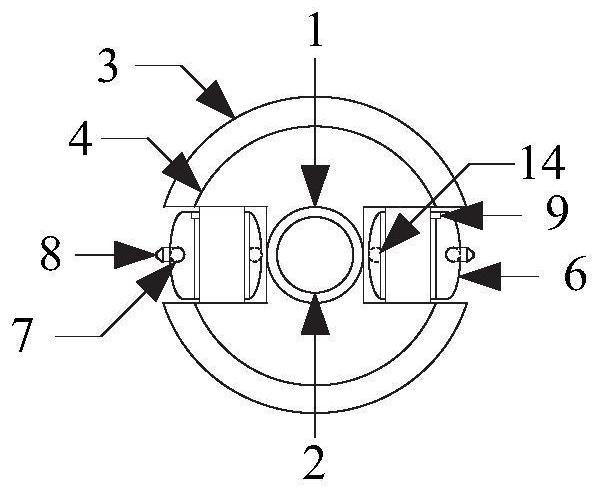

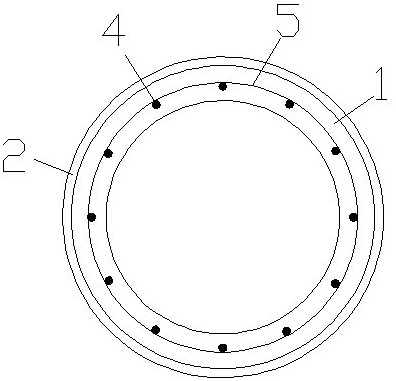

Controllable air exhausting device for constructing precast pile in gas-containing soil layer and construction method of device

ActiveCN105672252ASmall settlement deformationImprove carrying capacityProtective foundationBulkheads/pilesCarrying capacitySoil horizon

The invention discloses a controllable air exhausting device for constructing a precast pile in a gas-containing soil layer and a construction method of the device. The device comprises the precast hollow pile, and a closed-opening pile tip is arranged at the bottom of the precast hollow pile; the air exhausting device is arranged at the front end of the closed-opening pile tip and can prevent engineering disasters caused by gas eruption in the gas-containing soil layer, and therefore personal and property losses are reduced; and pile end and pile side soil bearing carrying capacity within the gas-containing soil layer range can be improved, and settlement deformation of a pile foundation obtained after construction is reduced. The construction method of the device is easy and convenient to operate.

Owner:常州东吉路国际贸易有限公司

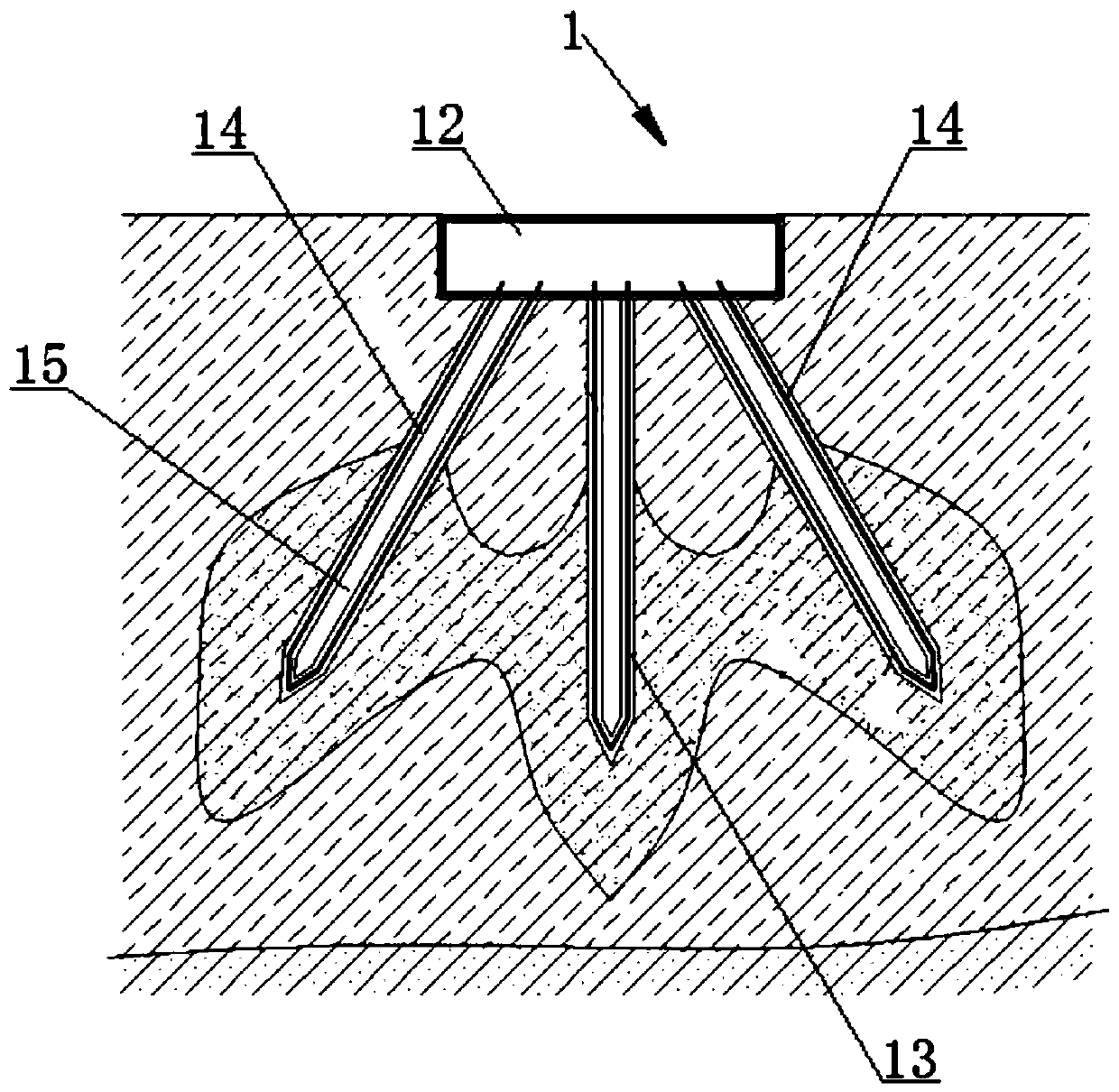

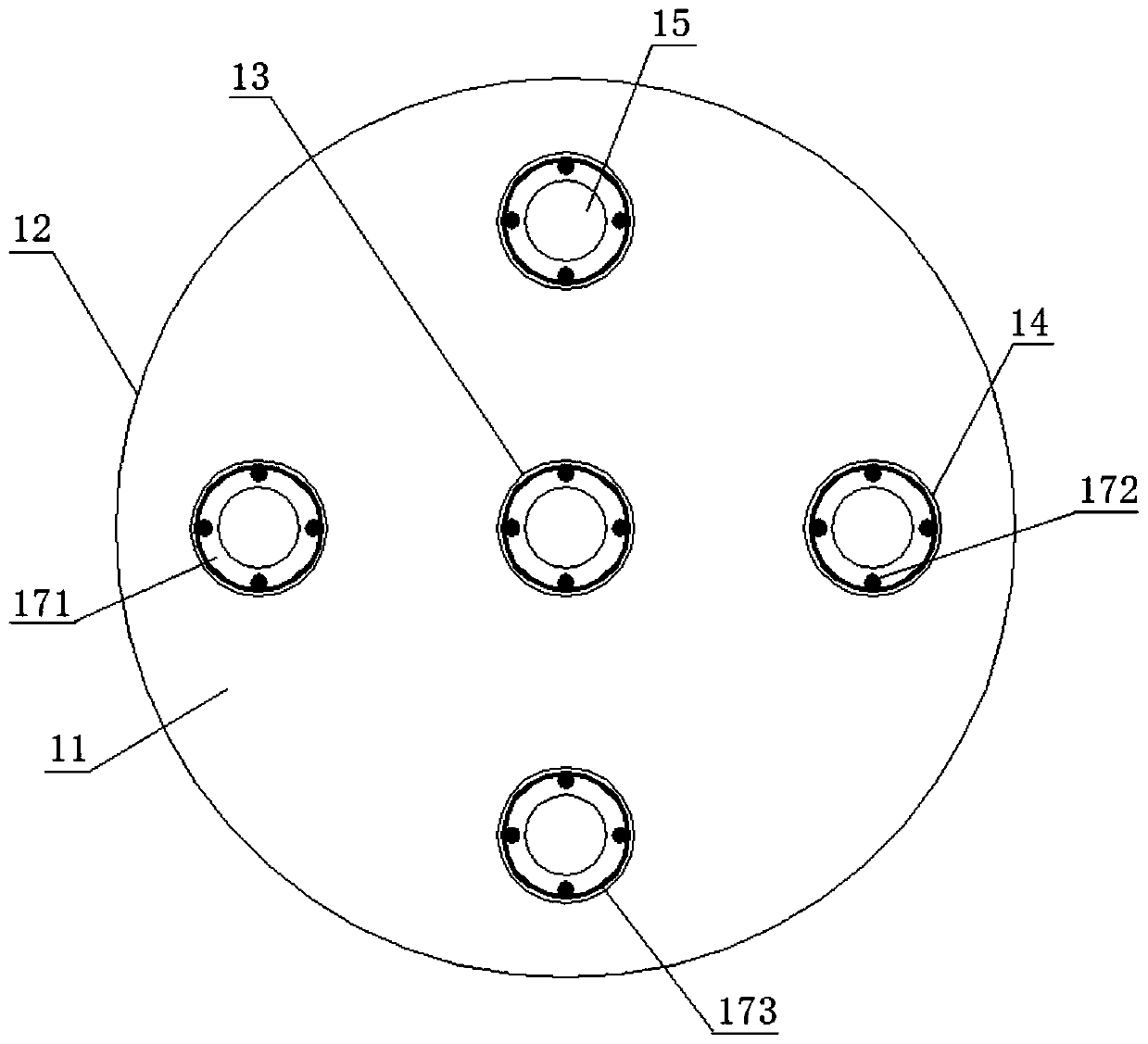

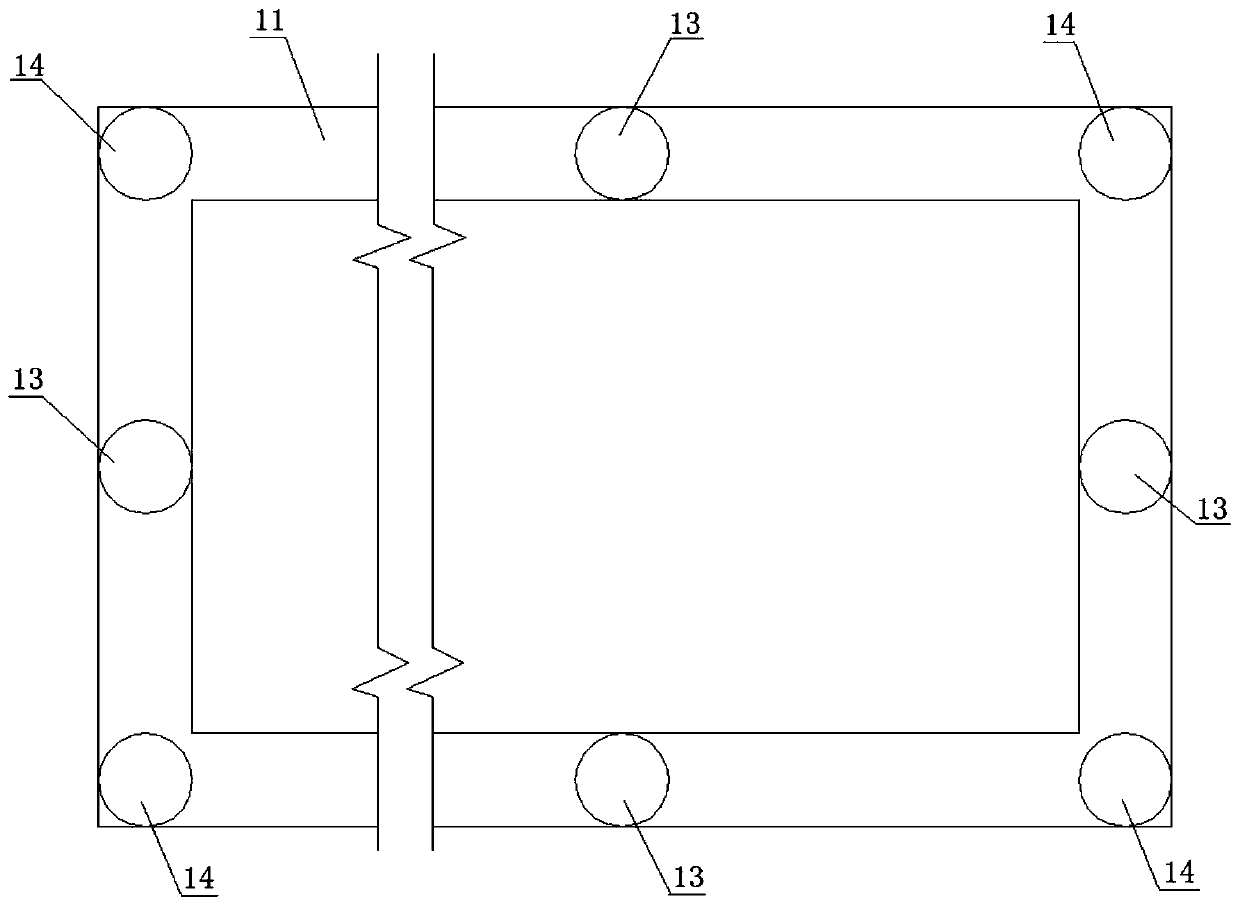

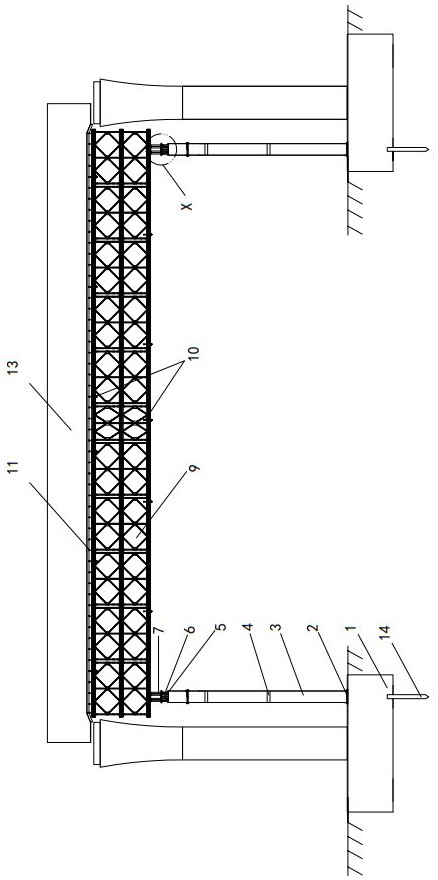

Foundation structure and construction method

PendingCN111188354AImprove bearing capacityImprove anti-overturn performanceFoundation engineeringGroutPile

The invention is applicable to the technical field of geotechnical engineering and provides a foundation structure and a construction method. The foundation structure comprises a foundation body, a bearing platform, a first supporting pile and a plurality of second supporting piles, wherein the foundation body is arranged in a construction site; the bearing platform is arranged in the constructionsite and is connected to the bottom of the foundation body; one end of the first supporting pile is inserted into the soil body in a manner of being perpendicular to the surface of the construction site; the other opposite end is connected with the bearing platform; all second supporting piles are arranged in a spaced manner; one end of each second supporting pile is obliquely inserted into the soil body in a manner of forming an included angle with the surface of the construction site; and the opposite other end of each second supporting pile is connected with the bearing platform, wherein the first supporting pile and the second supporting piles are each internally provided with a cavity and are also each provided with a grout spraying hole communicating with the corresponding cavity. In the foundation structure provided by the invention, the first supporting pile and the second supporting piles form a tree root-like structure to improve the bearing capacity and the toppling resistance of the foundation structure; the soil body is filled with a grout material via the grout spraying holes; the physical and mechanical properties of the soil body are improved; and safety guaranteeis provided for a built structure.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +1

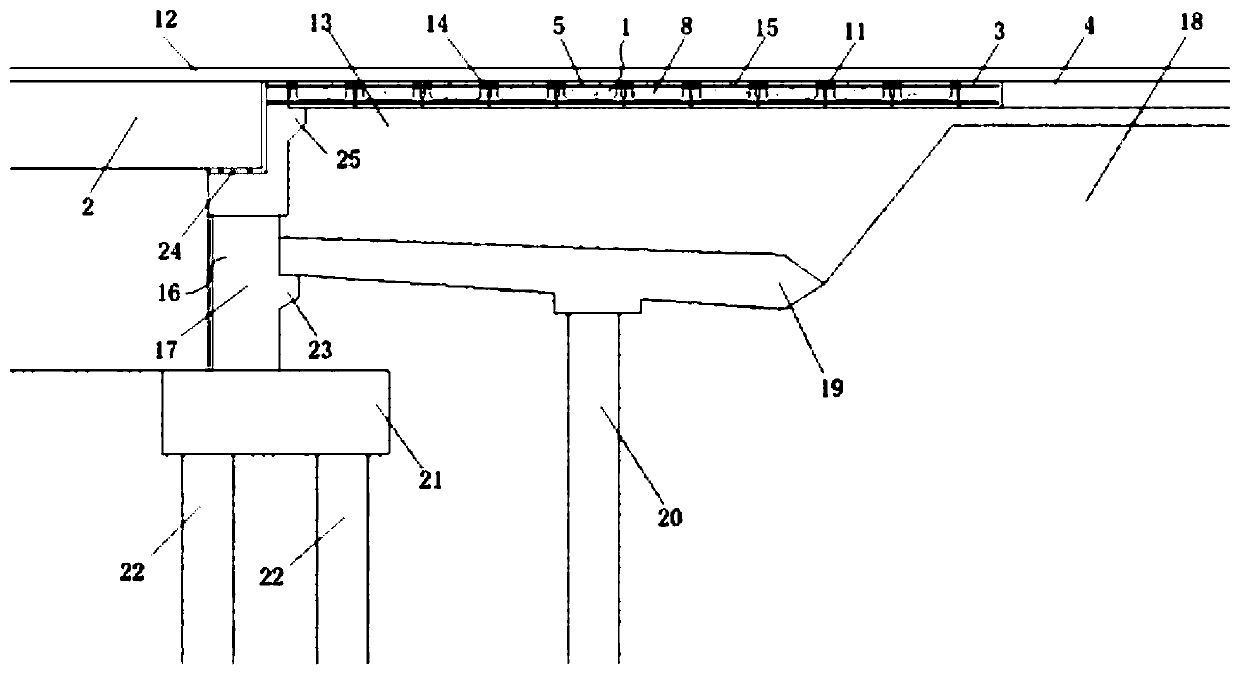

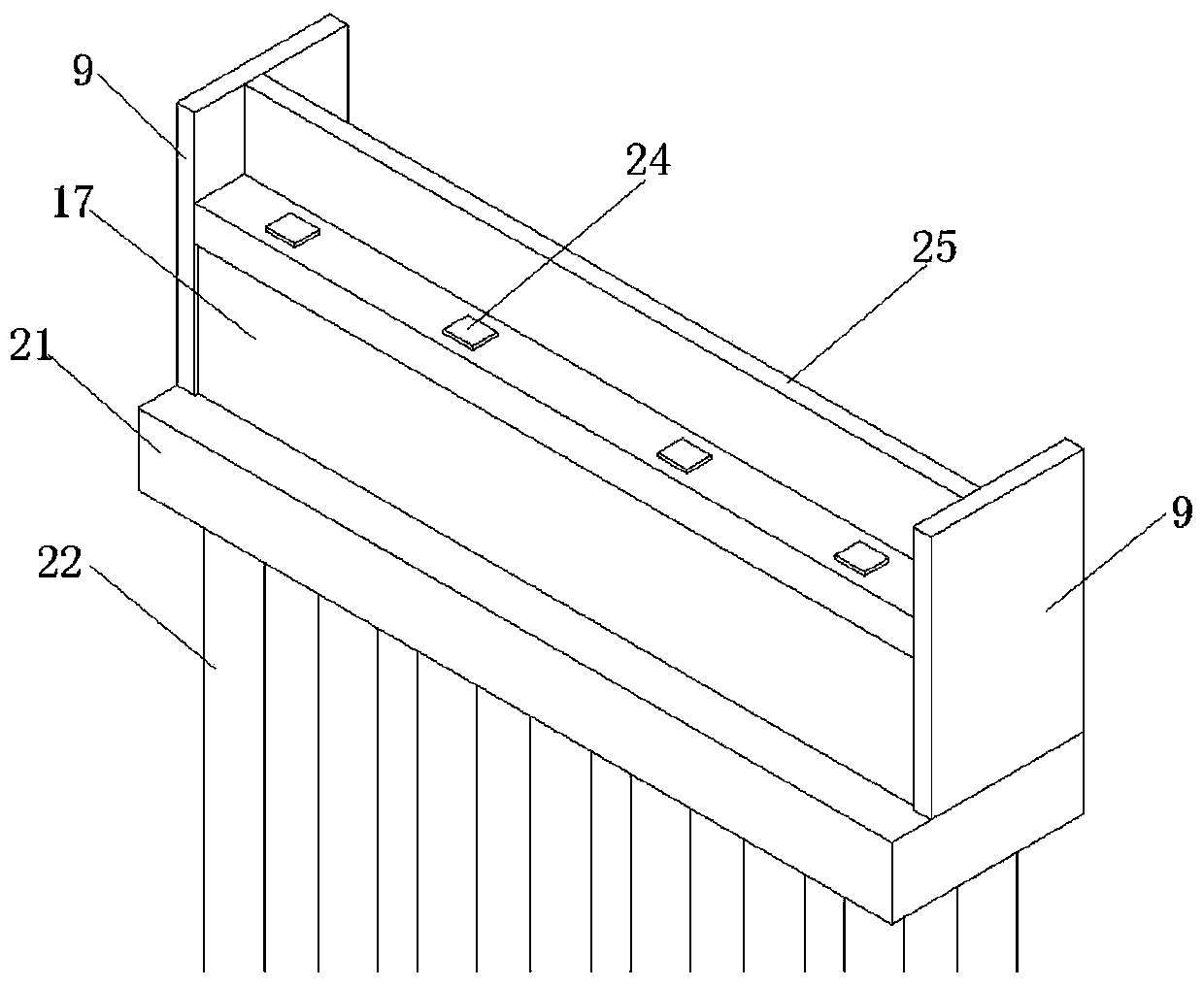

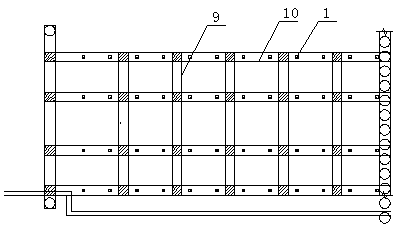

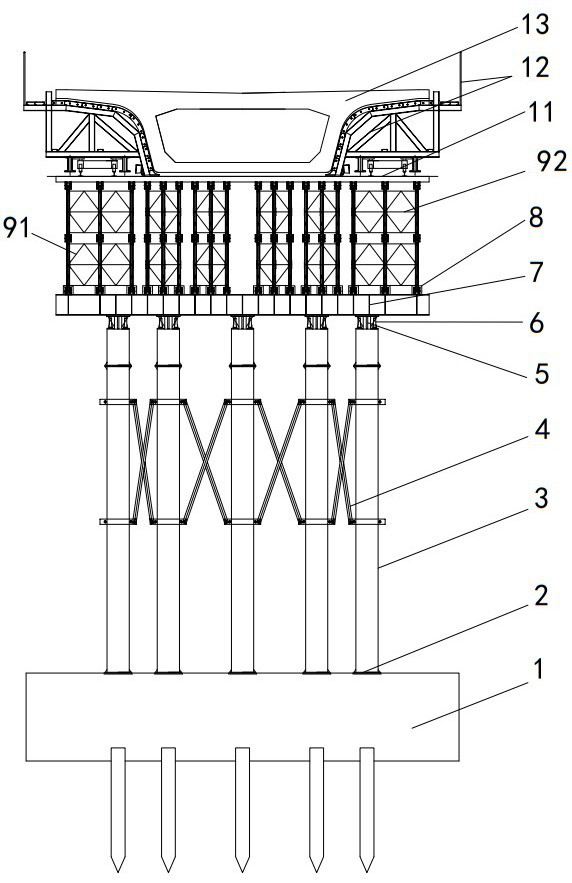

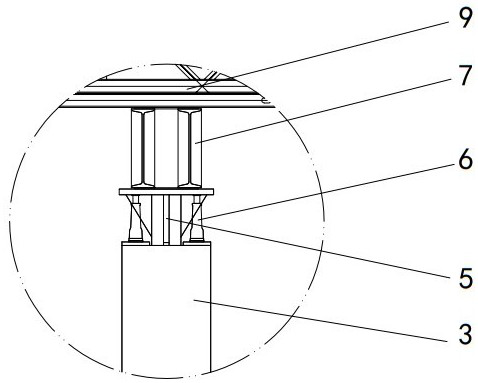

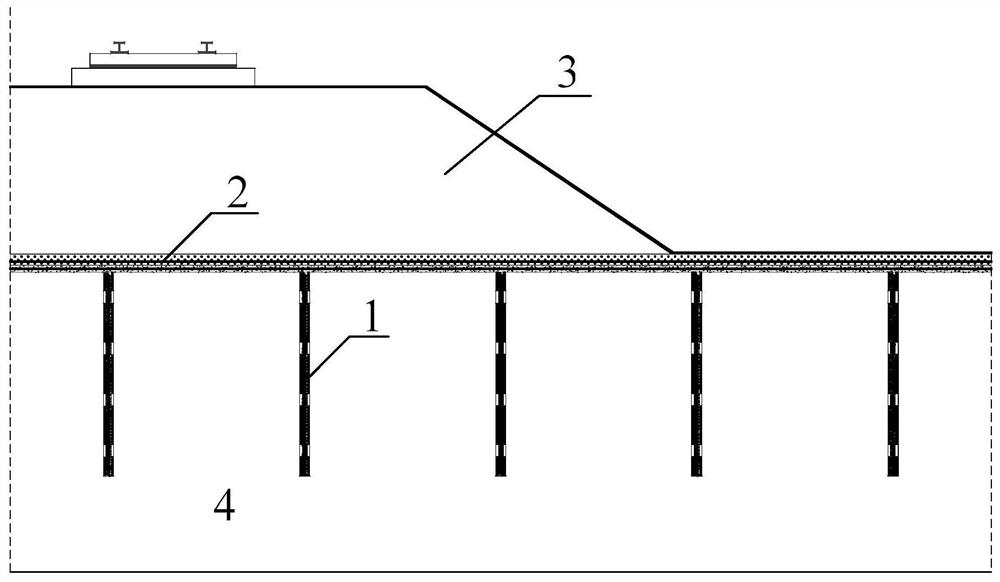

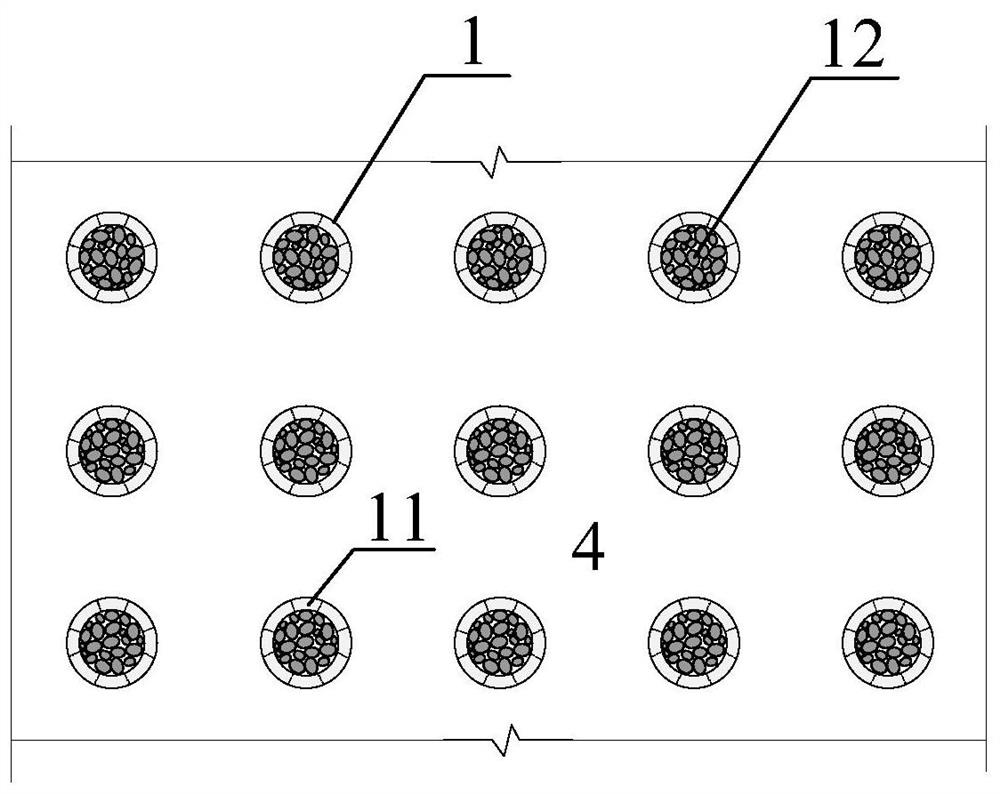

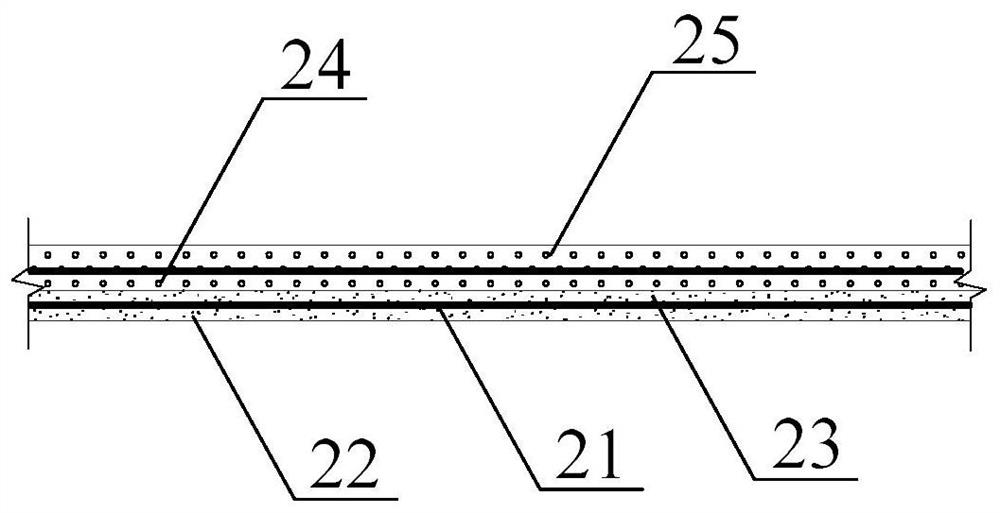

Construction system and method for cast-in-place box girder support of soft foundation area urban railway

PendingCN111719436ASolve the economySolve environmental problemsFoundation engineeringBridge erection/assemblyArchitectural engineeringStructural engineering

The invention discloses a construction system and method for a cast-in-place box girder support of a soft foundation area urban railway. The problems that in existing box girder construction, damage to a foundation is large, and sedimentation is prone to occurring are solved. The system comprises a bearing platform, a plurality of stand columns are arranged on the bearing platform, every two adjacent stand columns are connected through a diagonal bracing, each stand column is provided with a movable head and a lifting mechanism, the lifting mechanisms are connected with the movable heads and used for adjusting the horizontal height of the movable heads, the movable heads are provided with bailey beams, and the bailey beams are provided with steel molds facilitating cast-in-place of box girders. The construction method comprises the steps of constructing the cast-in-situ bored piles, constructing the bearing platform, arranging the bailey trusses and constructing the cast-in-situ box girder. The system also has the advantages of simple structure, convenience in assembly, long service life and the like.

Owner:温州市铁路与轨道交通投资集团有限公司

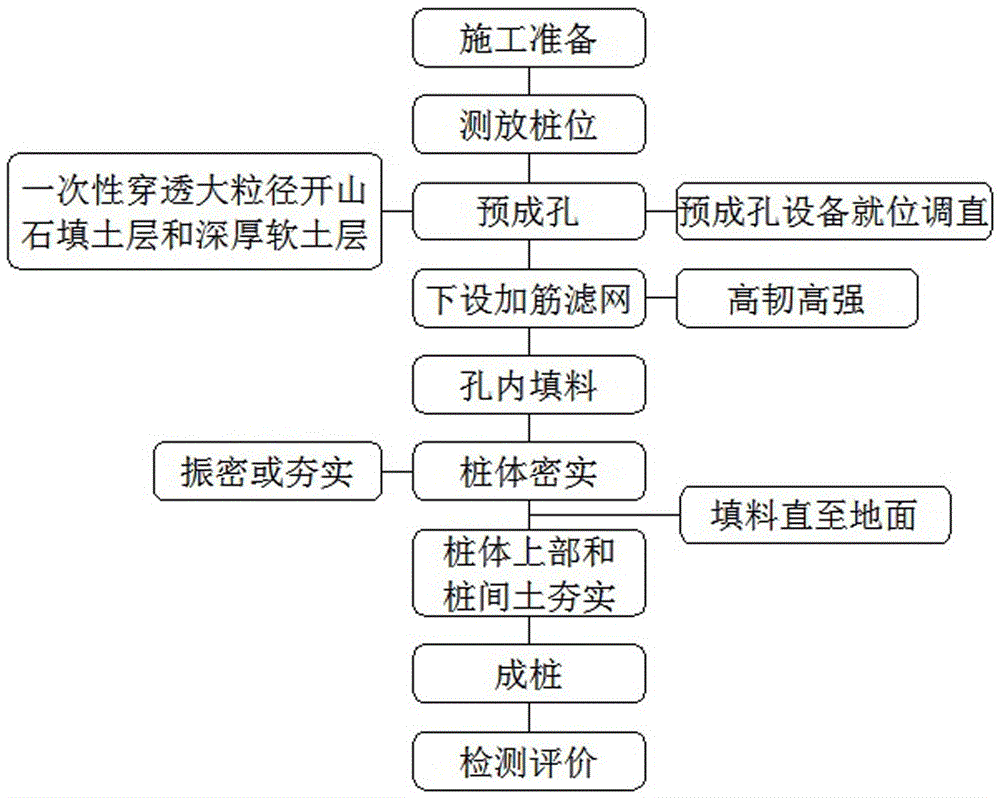

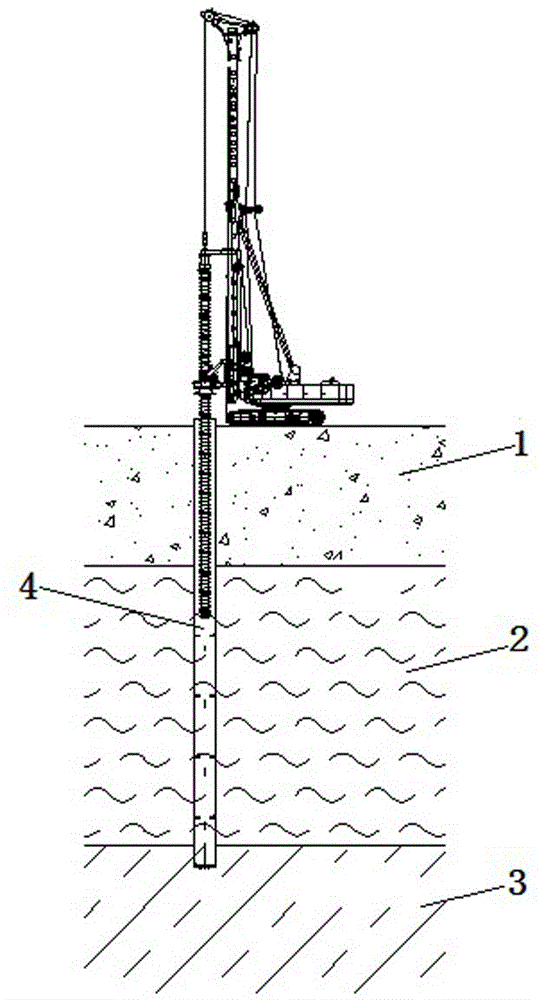

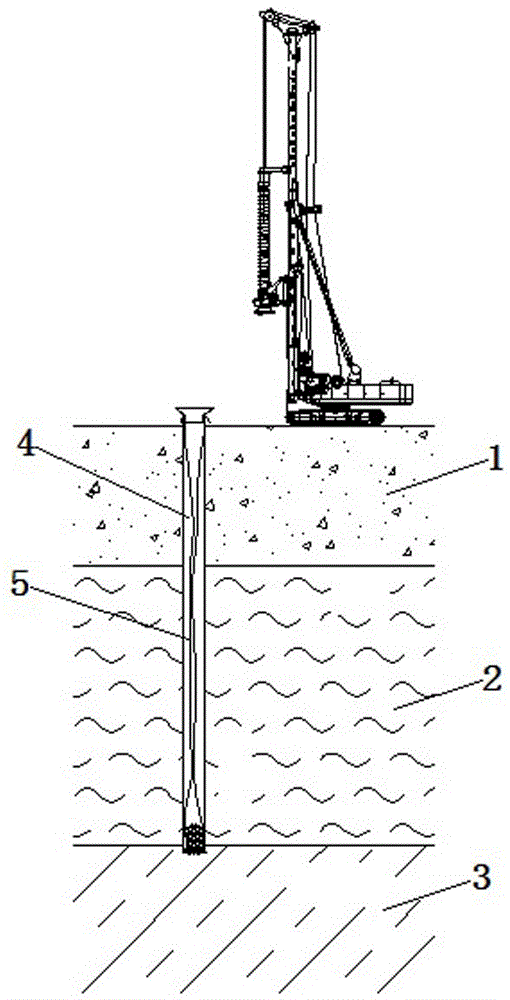

Pre-perforated lateral restraint pile and construction method thereof

InactiveCN105603961AImprove integrityImprove compactnessSoil preservationCrushed stoneShear capacity

The invention relates to the field of foundation treatment and deep foundation construction, in particular to a pre-perforated lateral restraint pile and a construction method thereof. The pre-perforated lateral restraint pile and the construction method thereof are characterized in that a coarse particle fill stratum and a deep soft soil layer can be penetrated in one time to realize bottoming of a pile body; under a load action, coarse particle materials are restrained laterally by a high-strength high-toughness reinforced filter screen, and bearing capacity and deformation resistance of the pile body can be given full play to; the pile body with coarse particle fillers and the reinforced filter screen is enhanced integrally, shear capacity is improved, and the problem of breakage of gravel piles is solved. The pre-perforated lateral restraint pile and the construction method thereof have the advantages that realization of one-time penetration of the coarse particle fill stratum and the deep soft soil layer, realization of underwater construction, realization of lateral restraint with the high-strength high-toughness reinforced filter screen, deformation control, controllability and adjustability of density and rigidity of the ultralarge-diameter coarse particle filled lateral restraint pile, formation of quick drainage passage, acceleration of soft soil solidification, low manufacturing cost, high efficiency, energy saving, environment friendliness and the like.

Owner:CHINA ZHONGHUA GEOTECHN ENG +2

Pipe group isolation pipe-jacking construction method

InactiveCN111206934AReduce deformation effectsReduce buried depthUnderground chambersTunnel liningSocial benefitsArchitectural engineering

The invention discloses a pipe group isolation pipe-jacking construction method, which is suitable for structures sensitive to deformation on the ground. The method comprises the following steps thatfirstly, a plurality of seamless steel tube guide pipes are pre-buried in a side wall of a pipe-jacking originating well; secondly, a plurality of seamless steel pipes are arranged above a corresponding jacking pipe through a miniature pipe jacking technology, and therefore a rib pipe group is formed; each seamless steel pipe extends out of an originating well along the corresponding seamless steel pipe guide pipe and penetrates into a receiving well of the jacking pipe; thirdly, after the seamless steel pipes are arranged, slurry is injected into each seamless steel pipe; after the slurry issolidified, the construction of the rib pipe group is completed; and finally, construction of the jacking pipe is conducted. The construction method gives consideration to economical efficiency and practicability, and disturbance to an upper soil body can be effectively isolated during pipe jacking construction under the condition that the upper soil body of a pipe jacking section is not excavatedor damaged, influence of construction on the surrounding environment is reduced, the tunnel burial depth is decreased, the underground space is saved, and therefore remarkable social benefits are achieved.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

Arched grouting device and method

ActiveCN113586140ASolving the disadvantages of grouting and arching technologyReduce shear stressMining devicesMaterial fill-upStructural engineeringDrill bit

The invention discloses an arched grouting device and method. The arched grouting device comprises a high-pressure jet grouting drill, a pile casing, an umbrella-shaped supporting device, a left-right high-pressure jet grouting system and a front-back grouting system; the high-pressure jet grouting drill comprises a drill rod and a jet-grouting drill bit; the jet-grouting drill bit is installed at the front end of the drill rod; the rear portion of the drill rod is sleeved with an up-down control rod, and a first connecting piece is fixed to the lower portion of the up-down control rod; the umbrella-shaped supporting device comprises at least two sets of supporting devices which are symmetrically arranged relative to the axis of the drill rod; each set of supporting devices comprises a first rigid support and a second rigid support; one end of the first rigid support is hinged to a first connecting piece, and the first connecting piece is matched with the inner wall of the pile casing arranged outside the up-down control rod in a sleeving mode; the other end of the first rigid support is hinged with one end of the corresponding second rigid support; the other end of the second rigid support is hinged to a second connecting piece, and the second connecting piece is fixed to the lower portion of the pile casing; the left-right high-pressure jet grouting system and the front-back grouting system are arranged on the first rigid support; and the front-back grouting system is arranged on the second rigid support.

Owner:SHANDONG UNIV +1

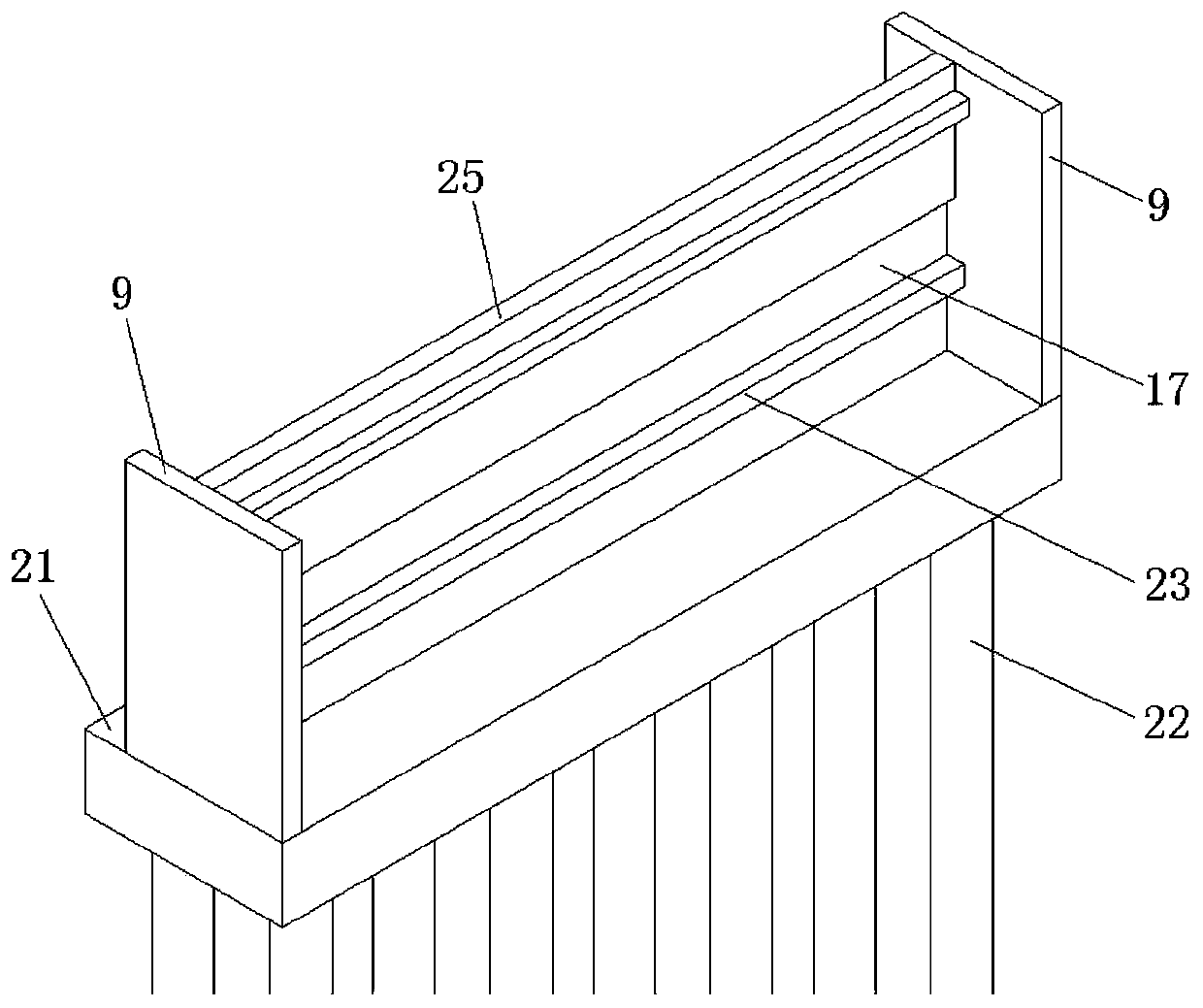

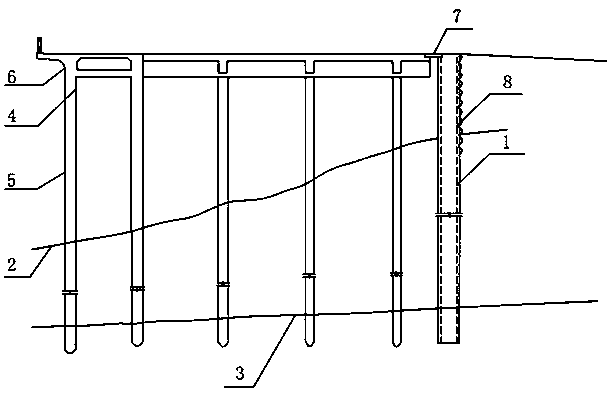

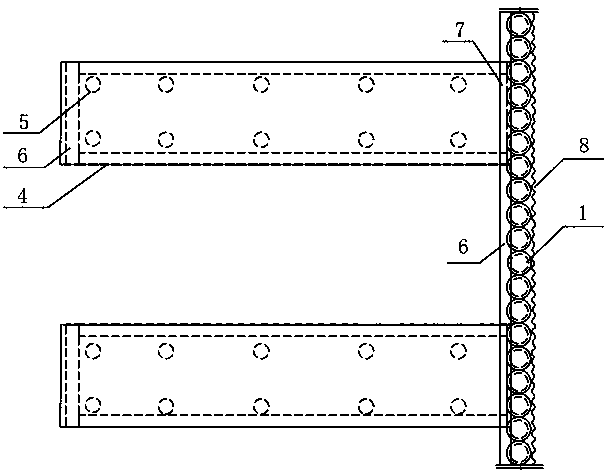

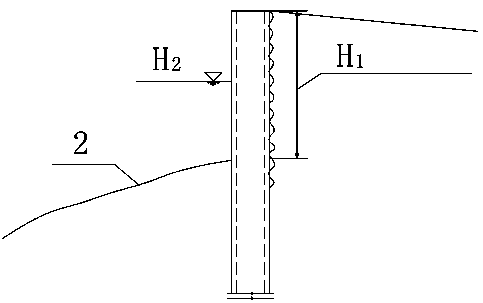

Row-frame-type hydrophilic platform cylinder vertical retaining wall seawall structure

InactiveCN109853505AReduce dosageReduce water pressureArtificial islandsBreakwatersEngineeringRevetment

The invention discloses a row-frame-type hydrophilic platform cylinder vertical retaining wall seawall structure which comprises a vertical retaining wall, wherein the lower part of the vertical retaining wall penetrates into a foundation bearing layer; the vertical retaining wall is of a '1' type thin-wall cylindrical structure which is continuously arranged; the '1' type thin-wall cylindrical structure is formed by closely adhering and arranging a plurality of thin-wall cylindrical structures; a row-frame-type hydrophilic platform is arranged on the water-facing side of the vertical retaining wall; prefabricated concrete piles are arranged below the row-frame-type hydrophilic platform; and the lower parts of the precast concrete piles penetrate into the foundation bearing layer, the vertical retaining wall and the row-frame-type hydrophilic platform are connected by adopting a flexible connecting structure, overhanging reverse arc wave suppression plates are arranged on the hydrophilic platform and the water-facing side of the vertical retaining wall, and a reversed filter is arranged on the back water side of the vertical retaining wall. The row-frame-type hydrophilic platform cylinder vertical retaining wall seawall structure has the characteristics of less project occupation, earth-rock conservation, good hydrophilicity, high construction efficiency and the like, and is suitable for seawall revetment engineering on soft soil foundation in coastal cities.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

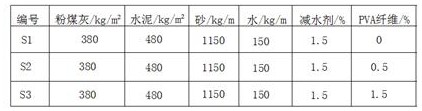

Preparation method of high-ductility cement-based composite material

The invention discloses a preparation method of a high-ductility cement-based composite material, the high-ductility cement-based composite material comprises fly ash, cement, sand, water, a water reducing agent and PVA fiber, the fly ash is 380kg / m < 2 >, the cement is 480kg / m < 2 >, the sand is 1150kg / m, the water is 150kg / m, the water reducing agent is 1.5% and the PVA fiber is 0.5-1.5%, after a cementing material is uniformly stirred, the water reducing agent is placed in the water to be uniformly stirred, then the water reducing agent and a cementing mixture are fully stirred to be in a plastic flow state, and the high-ductility cement-based composite material is prepared. The high-ductility cement-based composite material provided by the invention has good shock resistance and shock resistance, the fibers in the high-ductility cement-based composite material can hinder expansion of internal fine traces, and settlement deformation is greatly reduced due to the high-elasticity characteristic of the high-ductility cement-based composite material.

Owner:WUHAN UNIV OF SCI & TECH

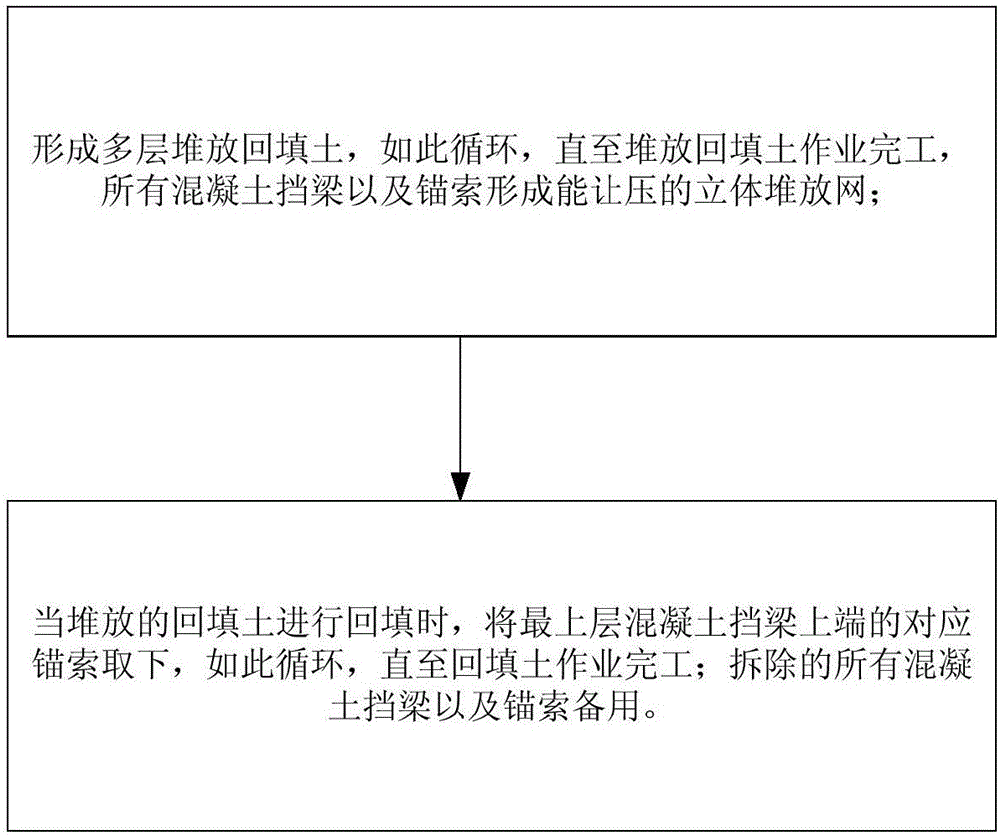

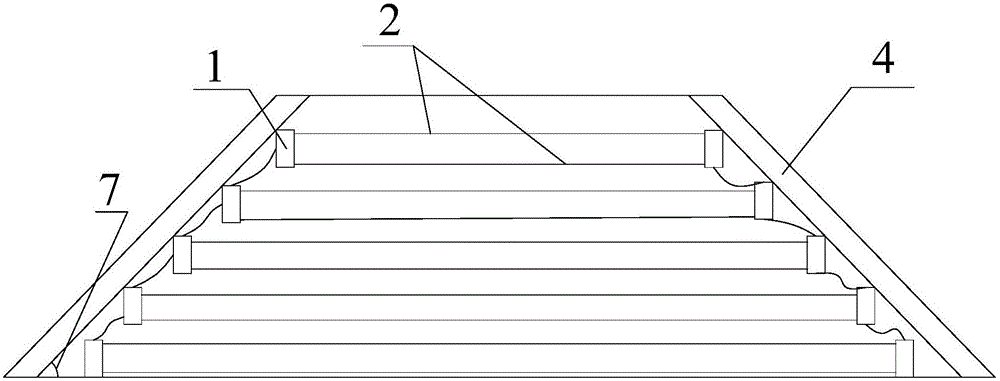

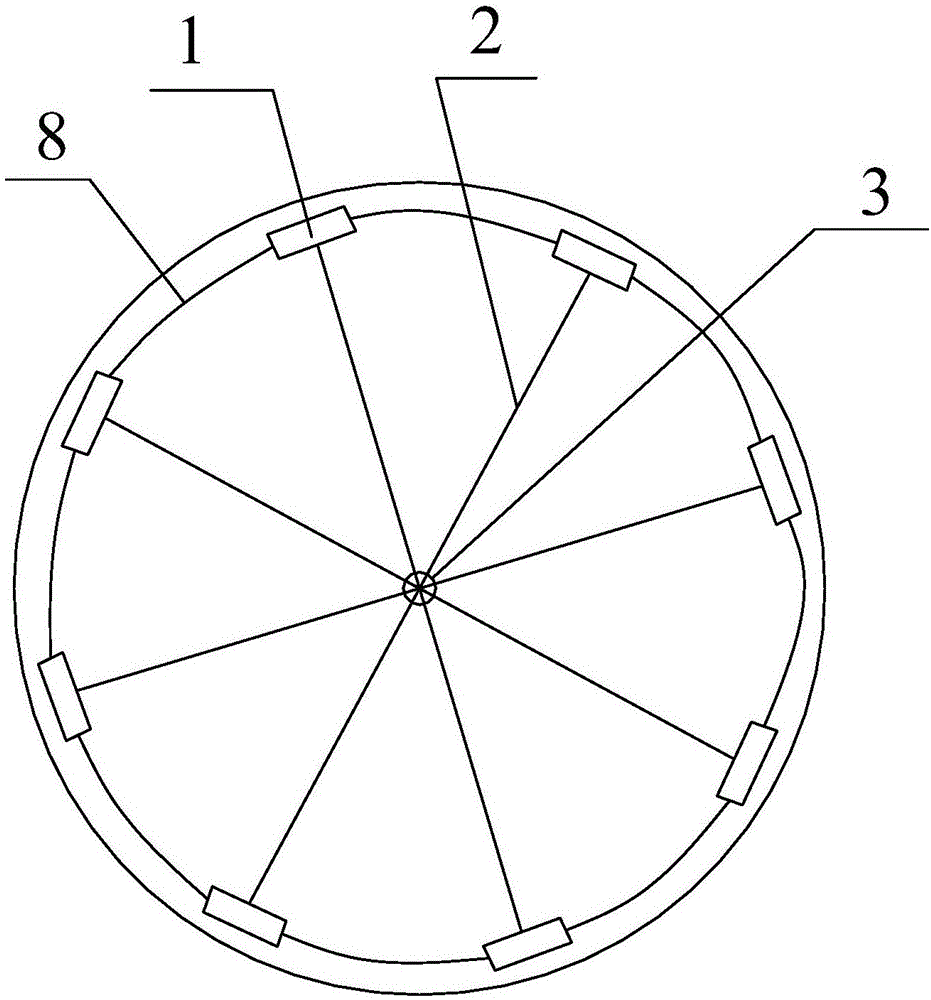

Support device and method used for soil heaping and backfilling of engineering construction

InactiveCN106368222AImprove stabilitySmall settlement deformationEmbankmentsExcavationsTerrainLandform

The invention discloses a support device and method used for soil heaping and backfilling of engineering construction. Backfilling soil can be heaped in multiple layers through the support device according to the terrain of a backfilling soil heaping position, the operation is repeated till backfilling soil is heaped completely, and a three-dimensional heaping network capable of yielding is formed by all concrete blocking beams and anchor cables; when the heaped backfilling soil is backfilled, the corresponding anchor cables at the upper ends of the uppermost concrete blocking beams are taken down, and the operation is repeated till backfilling soil operation is completed; and all the concrete blocking beams and the anchor cables are removed for standby application. The horizontal displacement of upper soil reinforced through the support device and method is much smaller than the displacement of soil which is directly backfilled without reinforcement, the maximum horizontal displacement occurs at top slope corners of backfilled soil, and settlement deformation is relatively small; and yielding springs are distributed at yielding positions and matched with connecting springs between the concrete blocking beams so that the three-dimensional heaping network can be formed, and adaptive coordination deformation according to the soil heaping heights and soil heaping terrains can be achieved.

Owner:SHANDONG UNIV OF SCI & TECH

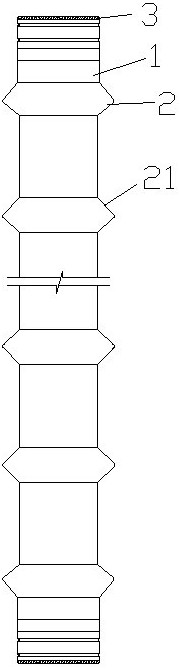

UHPC prefabricated special-shaped pile and preparation method thereof

PendingCN112343042APlay the role of end bearingImprove carrying capacityCeramic shaping apparatusBulkheads/pilesPre stressArchitectural engineering

The invention discloses a UHPC prefabricated special-shaped pile. The pile comprises a pile body of a hollow cylindrical structure, wherein the pile body is a non-prestressed reinforced concrete pileformed by prefabricating a steel reinforcement framework and UHPC, steel fibers are added into the UHPC, and a plurality of annular force bearing discs used for enhancing the settlement resistance ofthe pile body are further integrally formed on the pile body in the axial direction at intervals; each force bearing disc is an annular convex body which is formed by two loaded inclined planes and afriction surface and has a section of a trapezoidal structure on the pile body, or each force bearing disc is an annular convex body which is formed by two loaded inclined planes and has a section ofa triangular structure on the pile body; and an inclination angle alpha between the lower loaded inclined plane in the two loaded inclined planes and the horizontal plane is 45 degrees. A preparationmethod of the UHPC prefabricated special-shaped pile is simple in process, traditional tensioning and releasing process links are not needed, and the problem that in the releasing process of a traditional process, a steel mold cannot follow pile body compression deformation and steel mold manufacturing is solved.

Owner:宁波中淳高科股份有限公司

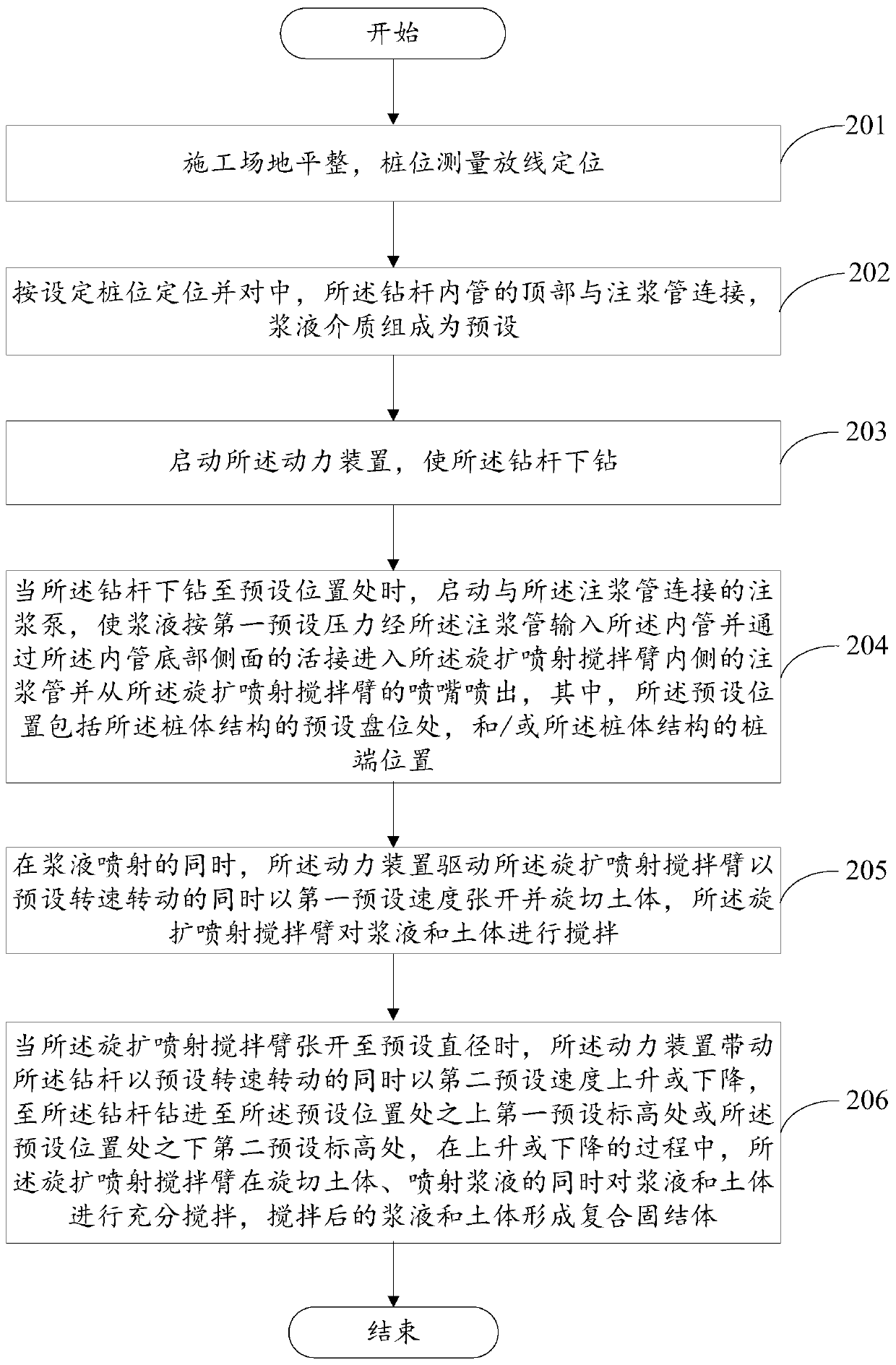

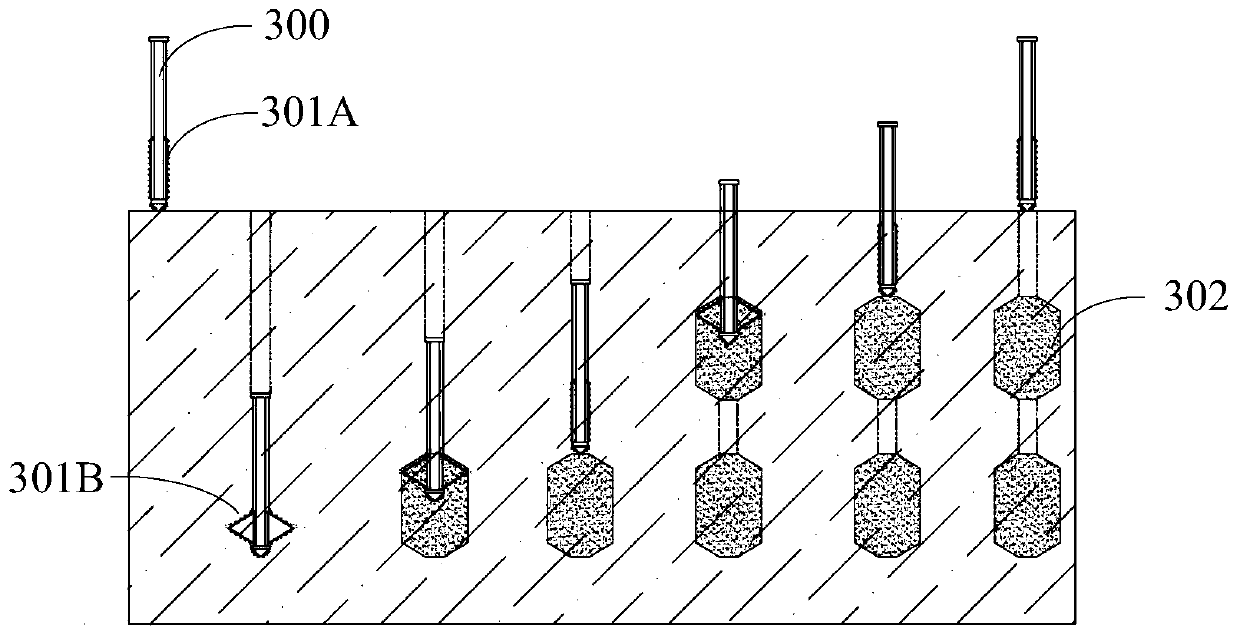

Composite consolidation body forming device and forming construction method thereof

InactiveCN110886293AStable qualityImprove pile foundation bearing capacityBulkheads/pilesGeotechnical engineeringEnvironmental geology

The invention discloses a composite consolidation body forming device. The composite consolidation body forming device comprises a drill rod, a rotary expansion jetting stirring arm and a power device, wherein the rotary expansion jetting stirring arm comprises at least one set of stirring arm assemblies, each stirring arm assembly is provided with a plurality of drill teeth and a plurality of nozzles communicating with a grouting pipe, and the plurality of drill teeth and the plurality of nozzles are arranged alternately; the power device is used for providing driving force for the drill rod,and when the power device is used for providing the driving force for moving the drill rod in the axial direction for the drill rod, the drill rod is driven to carry out axial displacement, and / or aninner pipe and an outer pipe are driven to carry out relative displacement; and when the power device is used for providing the driving force for rotating the drill rod around the axial direction forthe drill rod, the drill rod drives the rotary expansion jetting stirring arm to rotate. In this way, the composite consolidation body forming device is adopted, a soil body can be cut rotatably while a grouting liquid is jetted, and the grouting liquid and the soil body are fully and uniformly stirred, so that the quality of a formed composite consolidation body is more stable.

Owner:裴晓峰 +1

Construction method for wind-blown sand tunnel

ActiveCN102134998BSolve the collapseEasy constructionUnderground chambersTunnel liningWall rockTunnel construction

The invention discloses a construction method for a wind-blown sand tunnel, belonging to the construction field of tunnels. The construction method for the wind-blown sand tunnel is realized by the following steps: 101: construction of upper steps; 102: construction of lower steps; 103: construction of inverted arch combining parts; 104: construction of secondary lining; and 105: ring closing of inverted arch. Aiming at the loose, soft and unstable geometrical conditions of sand layers, wind-blown sand layers and the like, the construction method for the wind-blown sand tunnel solves the problems of collapse due to frequent sand leakage, and deformation of supporting in the normal construction method; the inverted arch combining parts are constructed firstly, therefore, the bearing capability of the wall corner foundation of a primary supporting is enhanced, the side pressure transferred by soil bodies at two sides is inhibited effectively, simultaneously conditions are created for achieving the aim that the deformation of the primary supporting finally tends to be stable by quickly starting the construction of the secondary lining; the excavation is carried out according to the characteristics of the tunnel, such as long distance, ultra-shallow buried layer, large profile and granular bulk rocks, the technical difficult problems in the field are overcome, therefore, the construction method provides important guide significance for the construction of the tunnels of similar geometrical conditions.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

Construction and construction method of expansive soil foundation with ballastless track subgrade

ActiveCN110965398BSmall shrinkage deformationSave engineering investmentRailway tracksBulkheads/pilesElastomerRebar

The invention provides an expansive soil foundation structure and construction method containing ballastless track subgrade, comprising porous pipe piles, expansive soil foundation, geosynthetic material reinforced cushion and ballastless track subgrade, the porous pipe pile and expansive soil The foundation is set at the bottom, and above it, a geosynthetic material reinforced cushion and a ballastless track subgrade are arranged in sequence from bottom to top; a plurality of porous pipe piles are vertically arranged in the expansive soil foundation, and the porous pipe piles include hollow porous The pile body and the elastomer material filled therein, the hollow porous pile body is a hollow reinforced concrete structure, and the porous pipe pile also includes a radial through hole passing through the inner and outer walls of the hollow porous pile body in the radial direction. The invention effectively reduces the expansion and contraction deformation of the expansive soil foundation when it loses water, so that the expansion and contraction deformation of the ballastless track subgrade is controlled within a reasonable range, which meets the high-speed and safe operation requirements of trains on the ballastless track subgrade, and saves expansive soil The cost of ground reinforcement treatment.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com