Construction system and method for cast-in-place box girder support of soft foundation area urban railway

A technology for bases and cities, applied in infrastructure engineering, bridges, bridge materials, etc., can solve the problems of large foundation damage and easy settlement, and achieve the effects of high rigidity of the bearing platform, small settlement deformation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

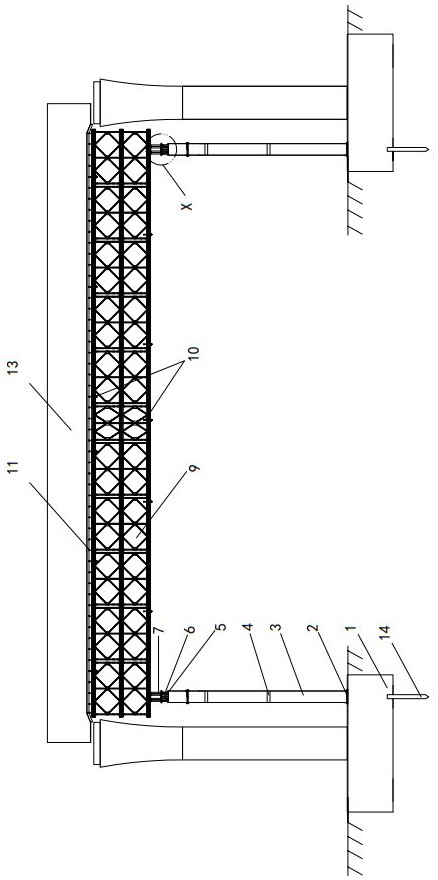

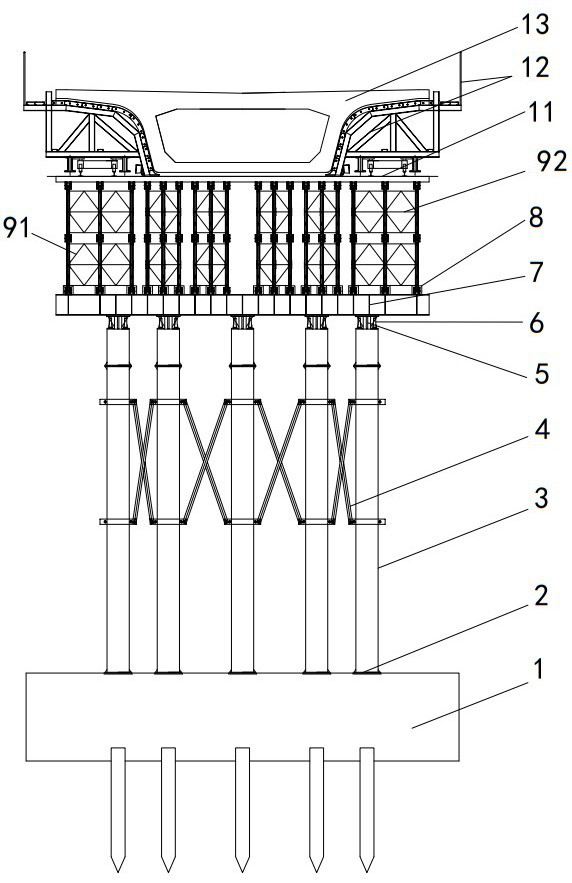

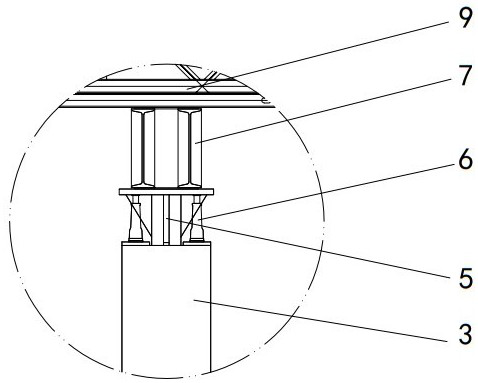

[0022] Depend on figure 1 combine Figure 2-3 As shown, a construction system for cast-in-place box girder brackets for urban railways in soft ground areas includes a cap 1, and a plurality of uprights 3 are arranged on the cap 1, and two adjacent uprights 3 are braced by scissors. 4 are connected, and each column 3 is provided with an active joint 5 and a lifting mechanism 6, and the lifting mechanism 6 is connected with the active joint 5 and is used to adjust the horizontal height of the active joint 5, and the described active joint 5 is provided with Bailey beam 9, said Bailey beam 9 is provided with the steel form 12 that is convenient to cast-in-place box girder. The beneficial effect of the present invention is that the load-bearing capacity of the bearing platform is fully utilized, the original foundation reinforcement and replacement treatment a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com