Drilling tool and construction method for long spiral compacted hole-forming bored concrete pile

A construction method and technology of cast-in-situ piles, which are applied in the direction of drilling equipment and methods, drilling without stripping topsoil, drill bits, etc., to achieve the effects of low cost, good integrity, and high bearing capacity of single piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

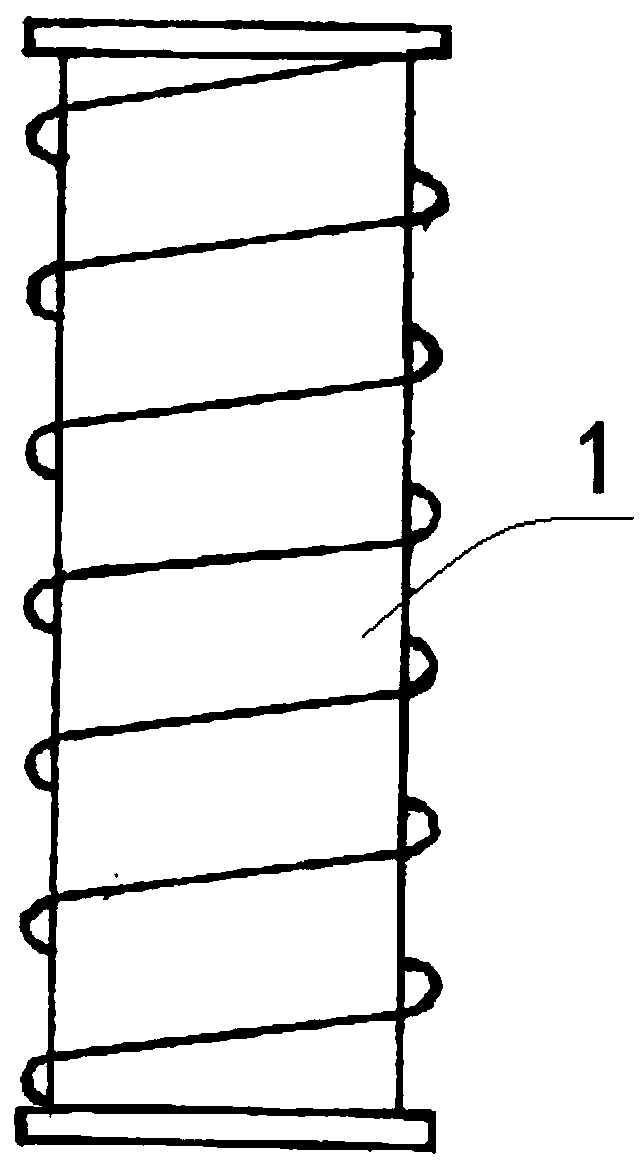

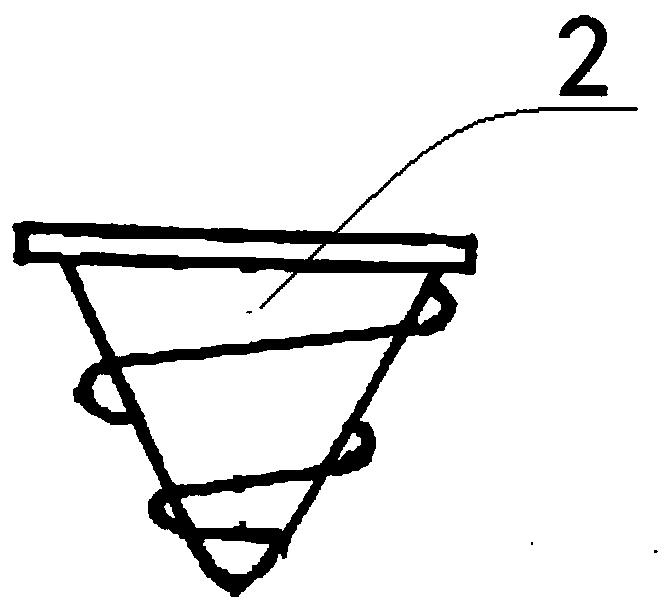

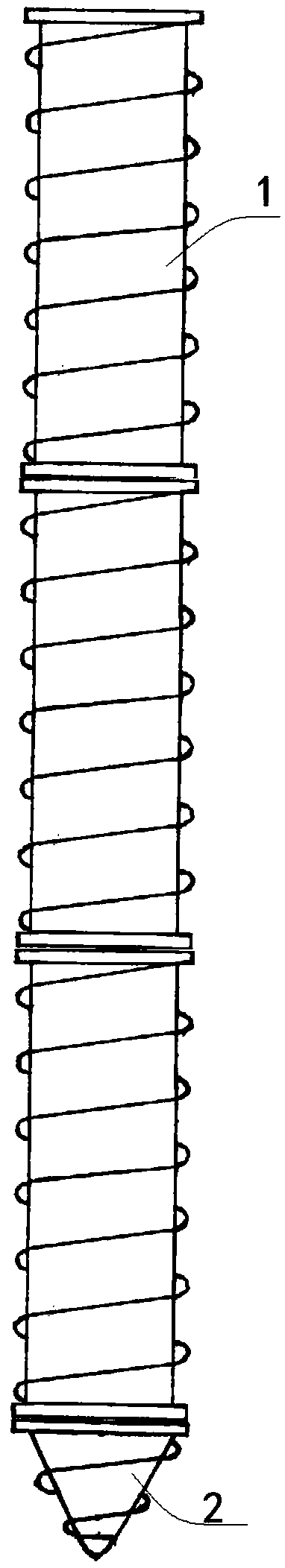

[0039] Such as Figure 1 to Figure 3 As shown, it is a drilling tool for long helical compacted cast-in-place piles provided in this embodiment, and the drill tool for long helical compacted perforated piles includes a multi-section drill pipe 1 and a cone-shaped drill bit 2. The two ends of each drill pipe 1 and the upper end of the cone-shaped drill 2 are respectively provided with connecting flanges. The multi-section drill pipe 1 and the cone-shaped drill 2 are provided with cavities that can communicate with each other. The lower end of the cone-shaped drill 2 There is a dodge door (not shown in the figure) that is used to make the cavity communicate with the outside in good time. The switch of the dodge door adopts the existing general and mature technology. The helical plate and the multi-section drill pipe 1 can be connected to each other to form a cylindrical body through the connecting flange, and the cone-shaped drill bit 2 is connected with the drill pipe 1 at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com