Patents

Literature

72results about How to "Reduce buried depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

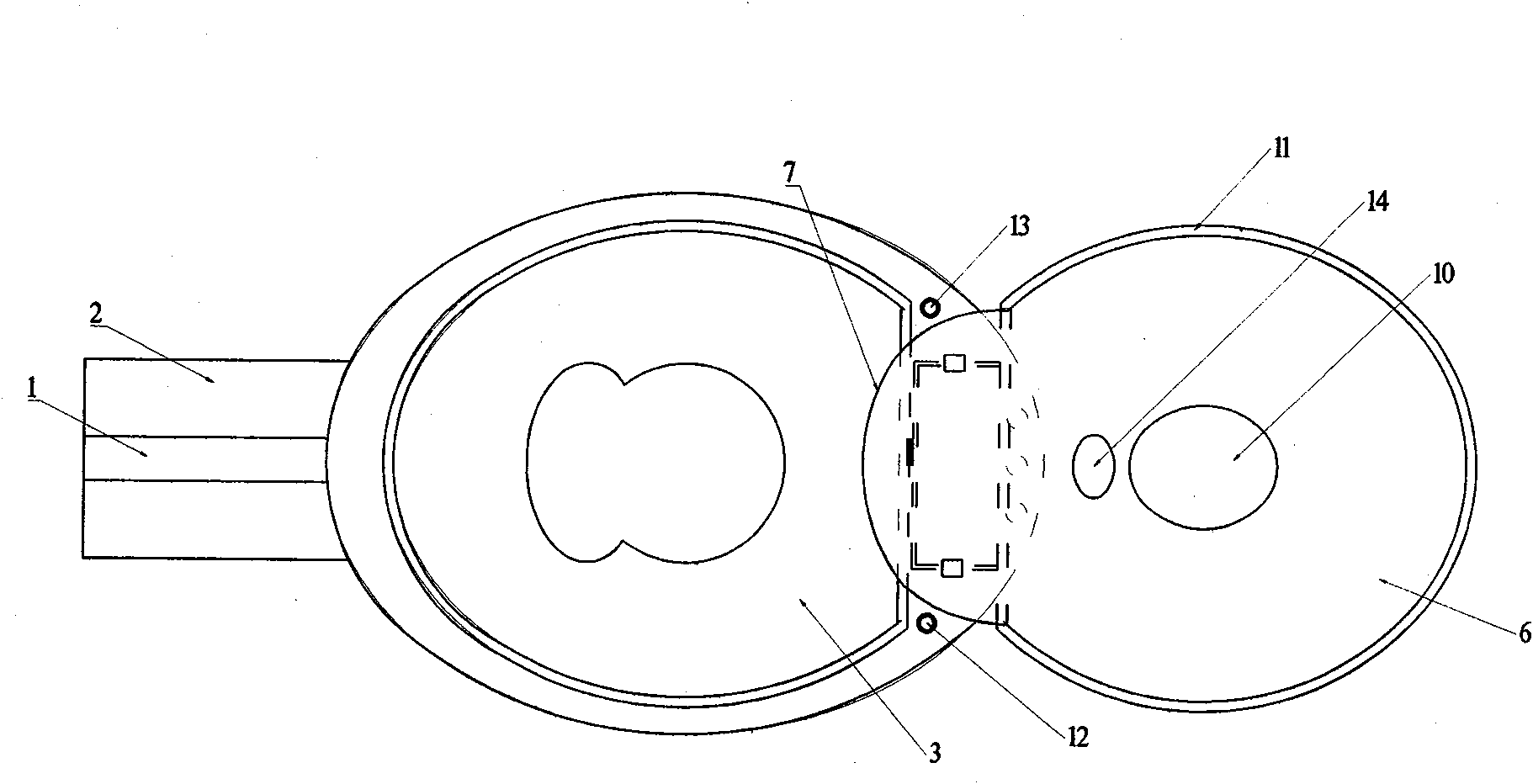

Initial stage rain water flow discharging device

InactiveCN101660319AAvoid separationEfficient separationSewerage structuresGeneral water supply conservationWater flowEnvironmental engineering

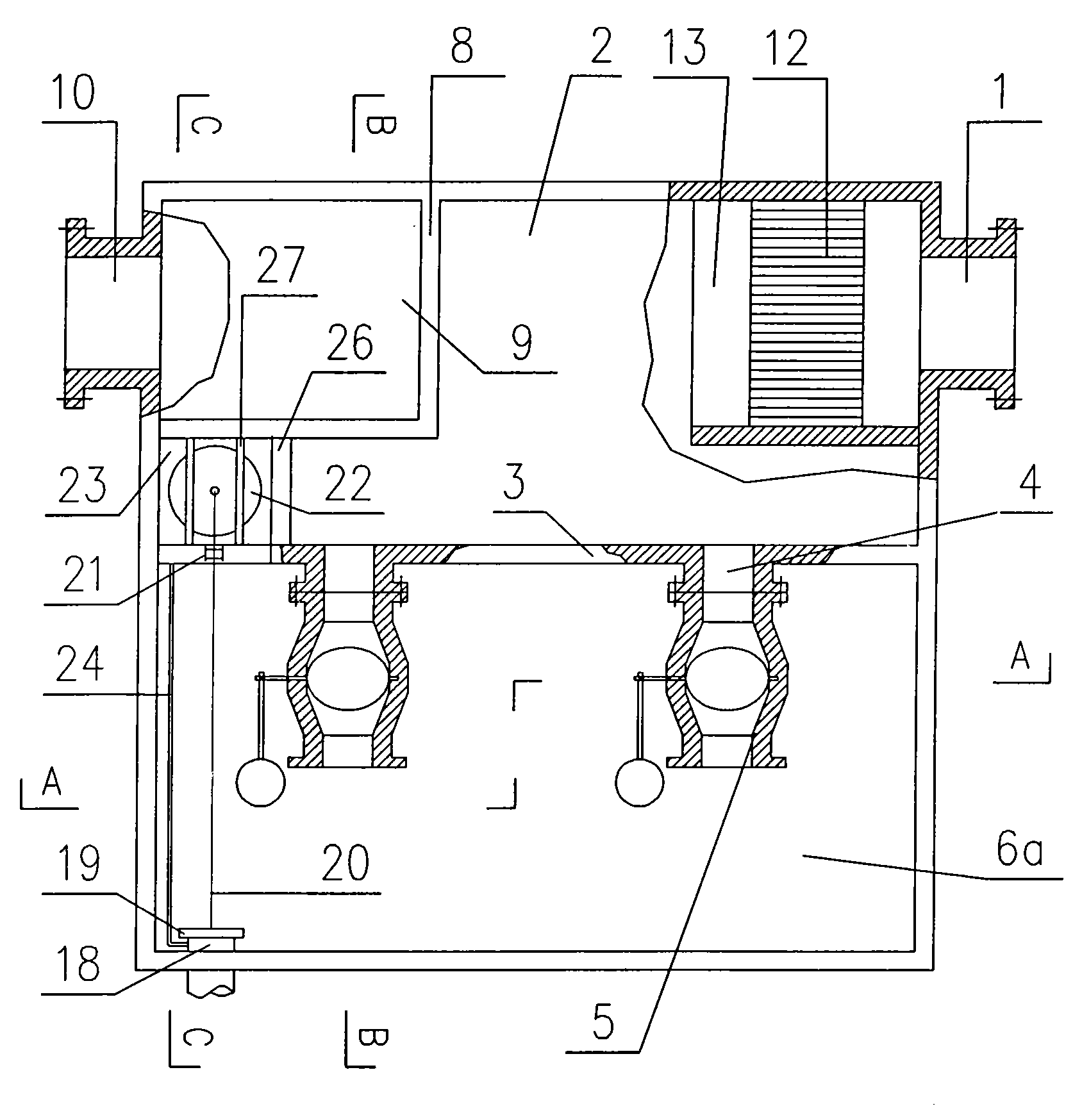

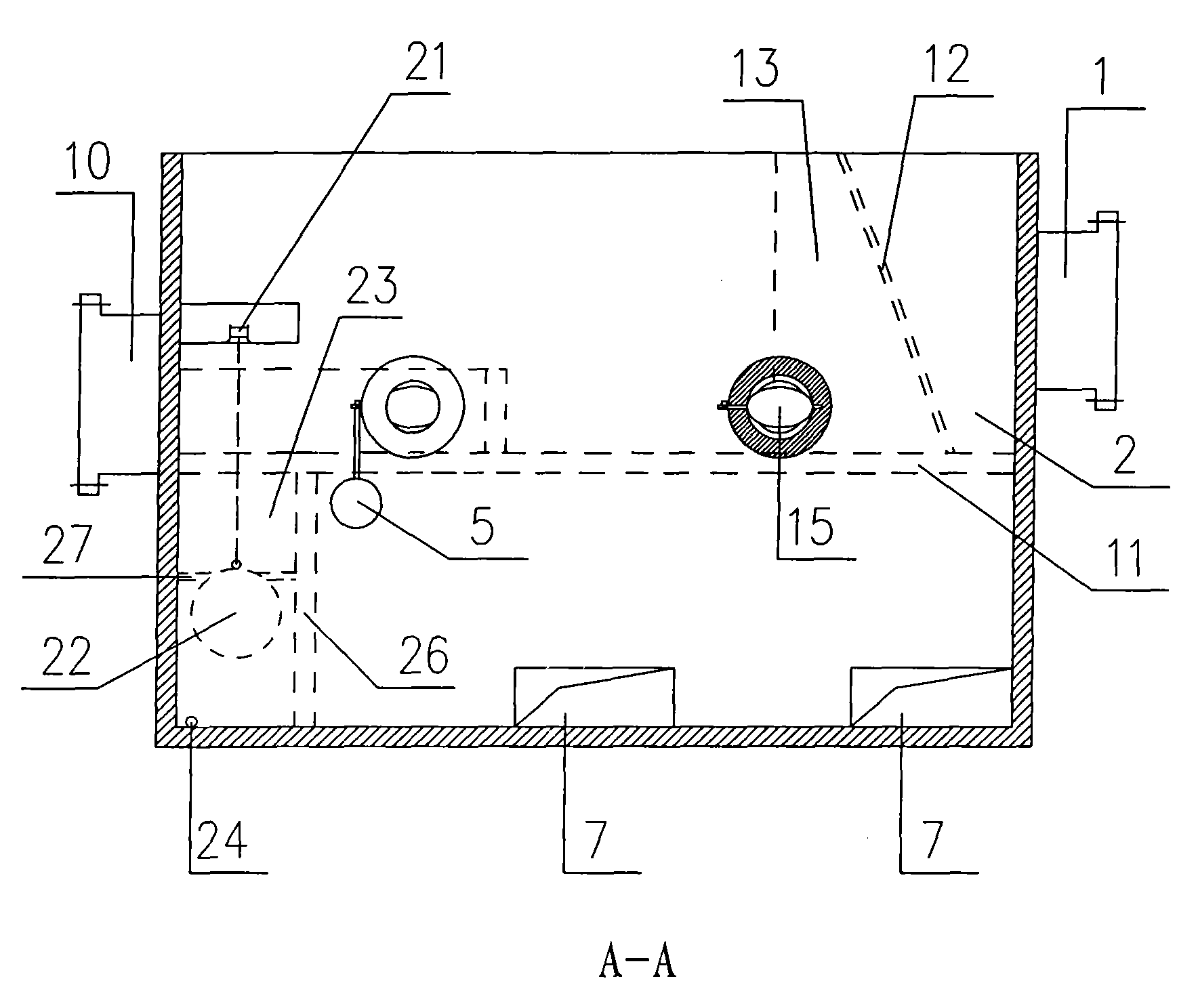

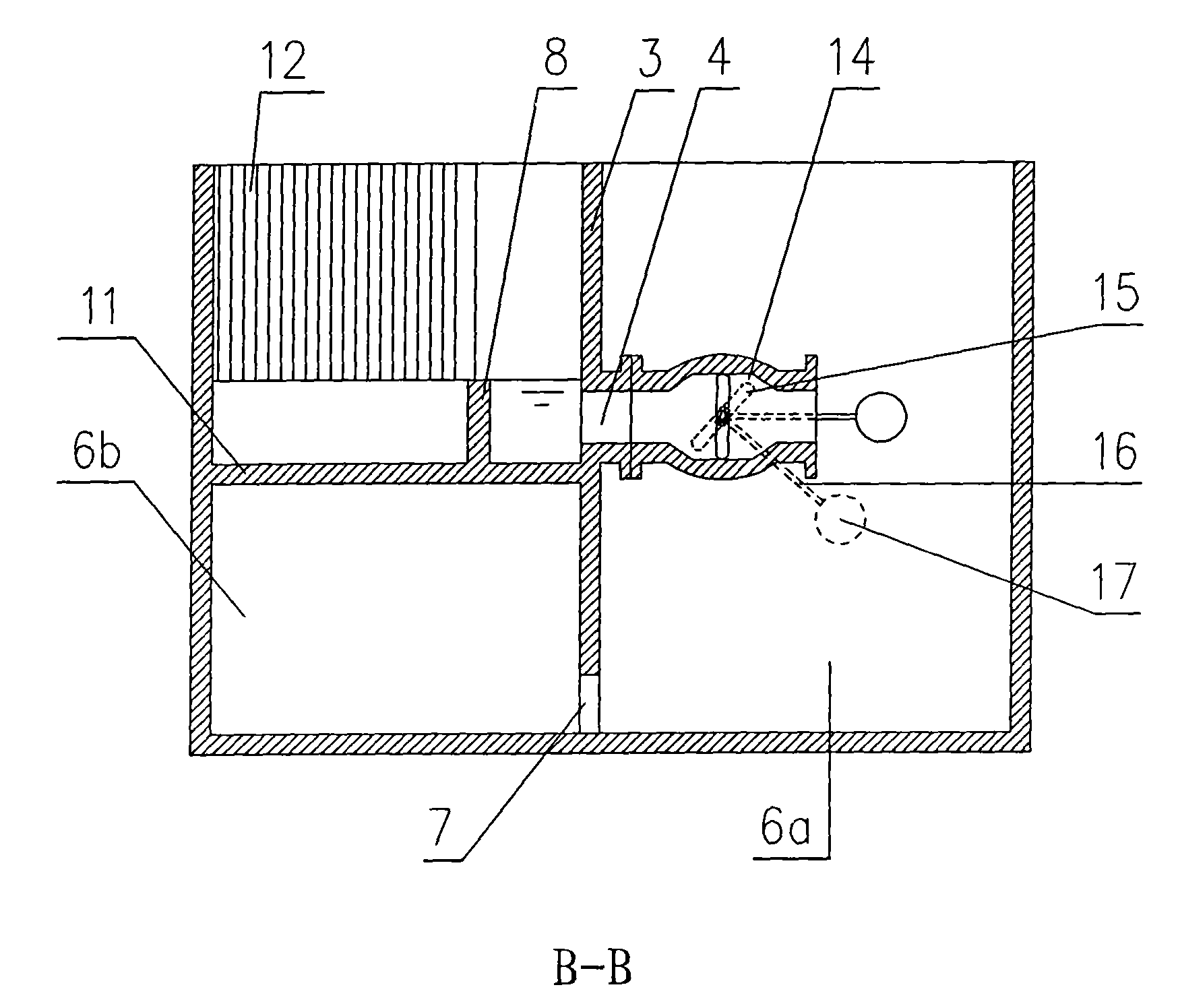

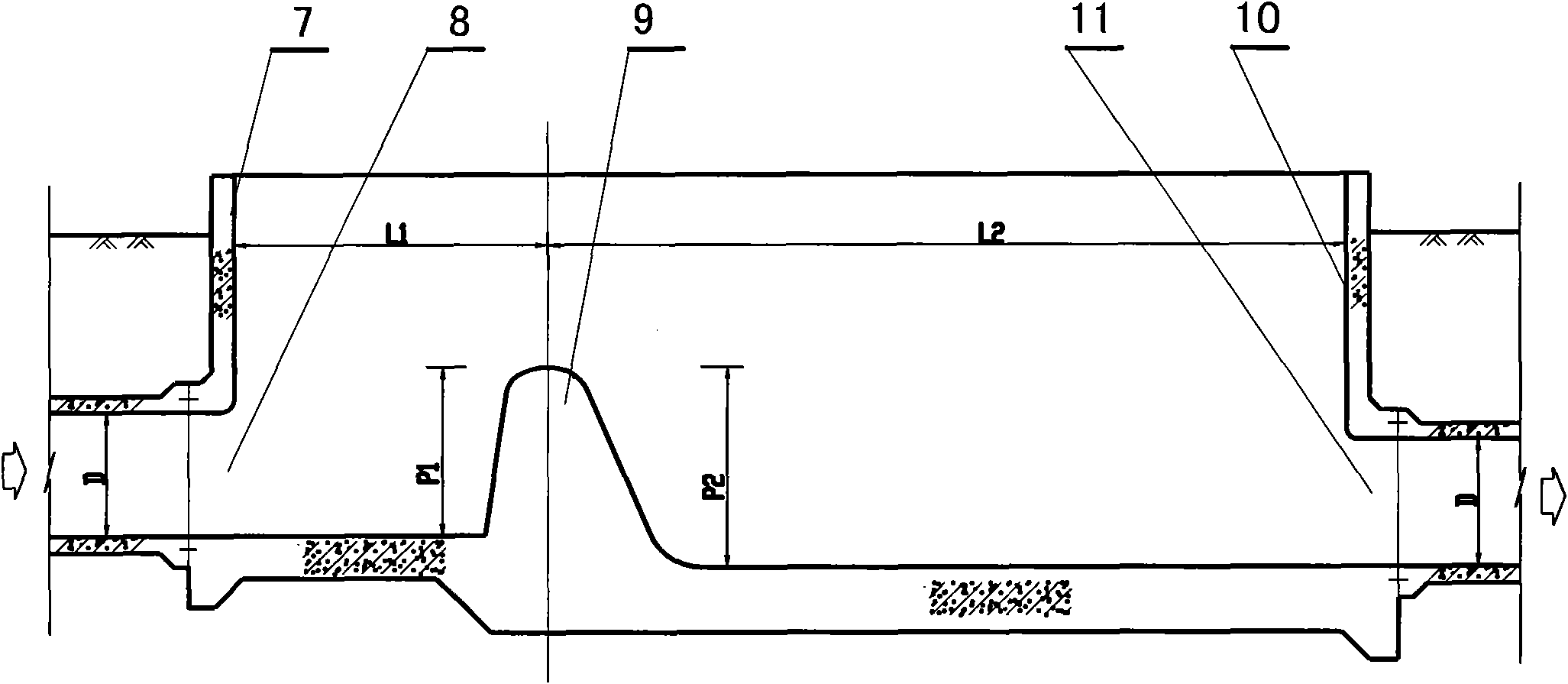

The invention discloses an initial stage rain water flow discharging device which is mainly composed of an impoundment chamber, a flow discharging partition, a flow discharging water communicating pipe, a water flow control mechanism, a flow discharging front chamber, a flow discharging rear chamber, a shunting downflow weir, a shunting flow conduction chamber, a delayed automatic draining mechanism and the like. Compared with the prior art, the device of the invention can effectively separate severely polluted initial stage rain water from later stage clean rain water, has the advantages of optimized structure, compact structure, high space utilization ration, space occupation saving, no energy consumption, no need of staff operation, high automation degree, convenient management and thelike.

Owner:CHONGQING UNIV

Arid region heavily-salted original soil afforesting method

ActiveCN104082031ABuried depthReduce buried depthClimate change adaptationAfforestationAridHalophyte

The invention discloses an arid region heavily-salted original soil afforesting method. The arid region heavily-salted original soil afforesting method includes the steps that sand doping is firstly carried out to improve the physical structure of soil in a planting area, annual growth halophyte is planted in the first year to achieve afforesting and soil partial desalting, ridging is carried out in the second year to construct furrow terrains, tamarix chinensis, amorpha fruticosa and sweet clover which are resistant to salt are planted on ridges in a trickle irrigation mode to achieve biological salt moving and soil fertilizing, and suaeda salsa is planted in furrows in a trickle irrigation mode to increase the earth surface cover degree, improve physical-chemical properties of soil and desalt the soil. By means of the arid region heavily-salted original soil afforesting method, the physical improvement and the biological improvement of the salted soil are integrated, the technical measures of furrow cultivation and water saving trickle irrigation are combined, the arid region heavily-salted original soil afforesting method is easy and convenient to operate and low in cost, and the stability and the sustainability of the heavily-salted original soil afforesting are achieved.

Owner:新疆中农宏远农业科技有限公司

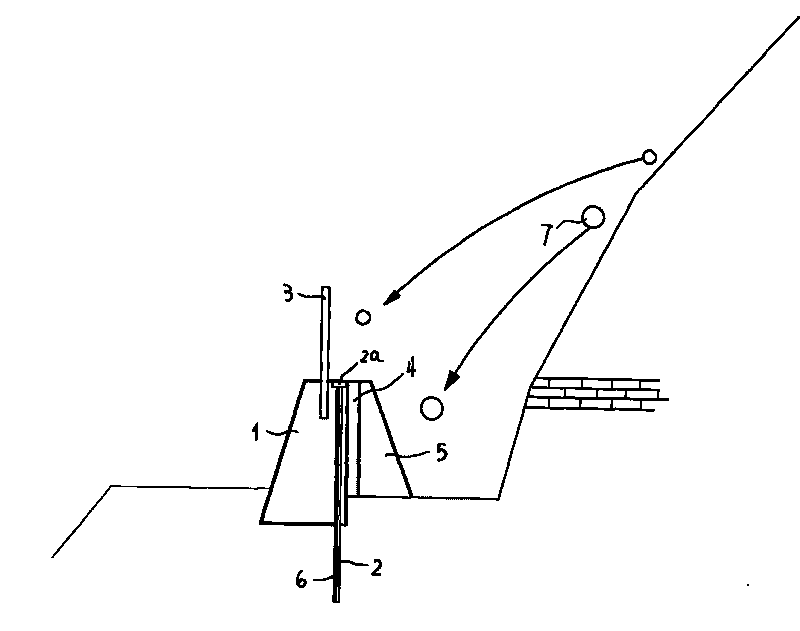

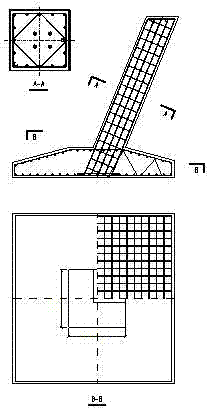

Novel energy consumption damping stone blocking structure

InactiveCN101736707AReduce the amount of masonryIncreased resistance to overturning momentProtective constructionStone wallEngineering

The invention relates to a novel energy consumption damping stone blocking structure which belongs to structures for preventing and controlling stone rolling disasters. The structure comprises a stone blocking wall which is a flag concrete stone blocking wall; the top of the stone blocking wall is preembedded with a steel rail fence; a prestress anchor cable is arranged in the stone blocking wall, and the front slope surface of the stone blocking wall is sequentially provided with a foam plastic layer and a gravel filling layer which are arranged for playing the buffering function. The invention has the characteristics of light weight, economy, safety and simple construction.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

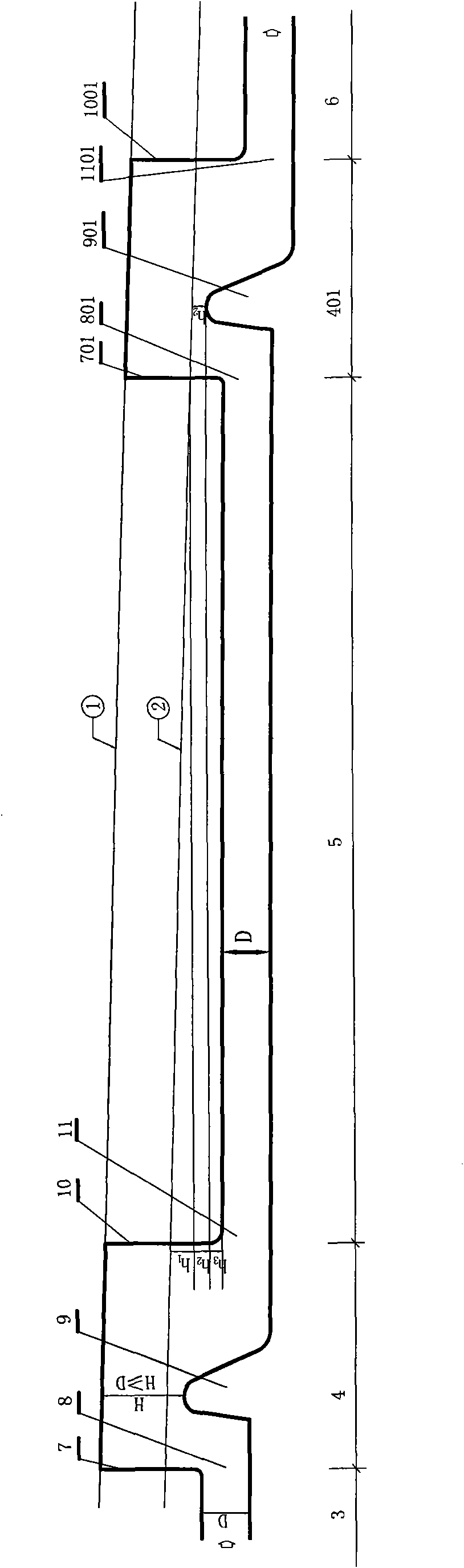

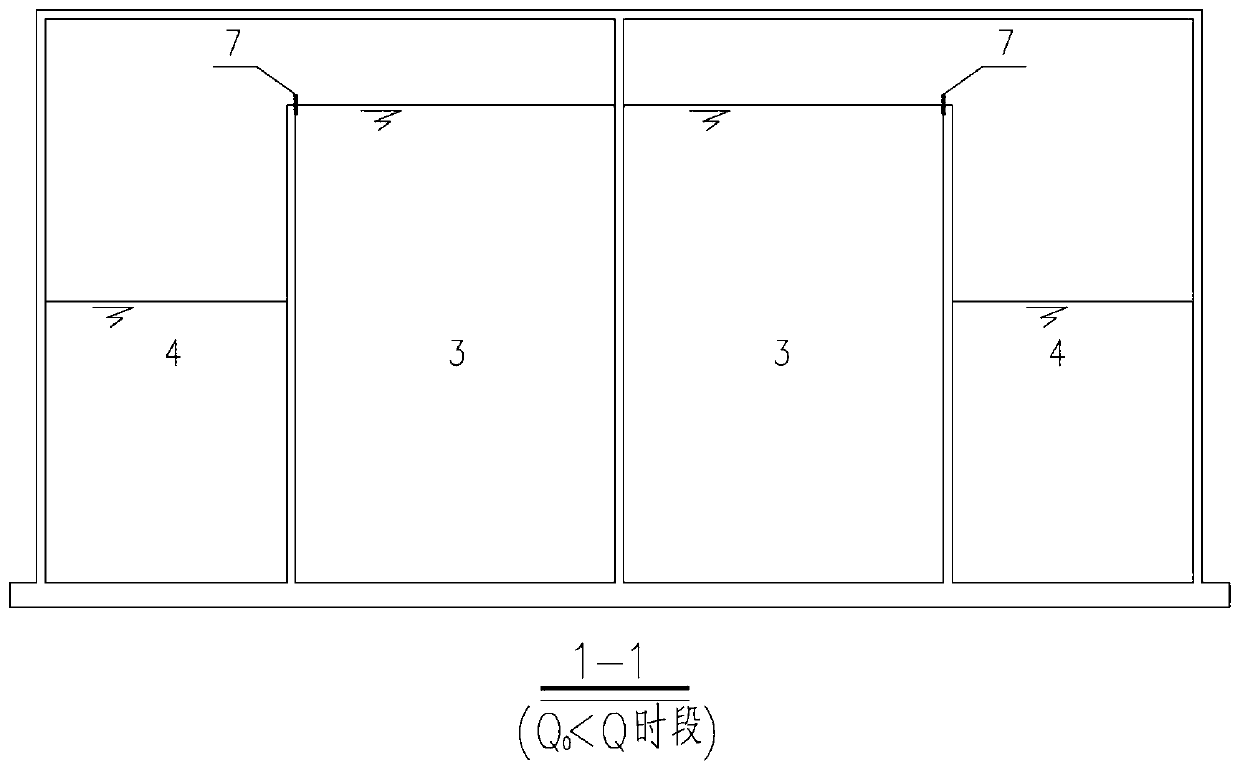

Gravity pressure water delivery system with automatic-adjusting weir well

ActiveCN101672024AReduce water pressureMaintain minimum pressure requirementsHydraulic engineering apparatusWater supply installationControl systemEngineering

The invention relates to a gravity pressure water delivery system with an automatic-adjusting weir well, in particular to a hydraulic adjustment and control system used for water delivery engineering.The system comprises: an adjusting weir well which is arranged between a water inlet and a water outlet and connected through a pipeline. The weir well comprises: a weir well water inlet connected with an upstream pipe at the bottom part of the inlet breast wall of the adjusting weir well, wherein two sides of the inlet breast wall are respectively connected with the side wall of the weir well; the outlet breast wall of the adjusting weir well is connected with the side wall of the weir well and the bottom part of the outlet breast wall is a weir well water outlet connected with a downstreamwater delivery pipe; an overflow weir is arranged at the bottom part of a shaft between the inlet and the outlet breast wall and lies across between two side walls; for longer gravity pressure water delivery engineering, different water delivery flow rates need different water heads; the adjusting weir well can automatically adjust the water heads; when the water delivery flow rate is less than design flow rate, surplus water heads are consumed in sections and the internal water pressure of a pressure pipe culvert is reduced; and at the minimum operating flow rate, the minimum pressure requirement indispensible to the pipe culvert is kept. The water delivery system not only has simple hydraulic control, but also ensures the safe and reliable water delivery of the engineering.

Owner:天津市水务规划勘测设计有限公司

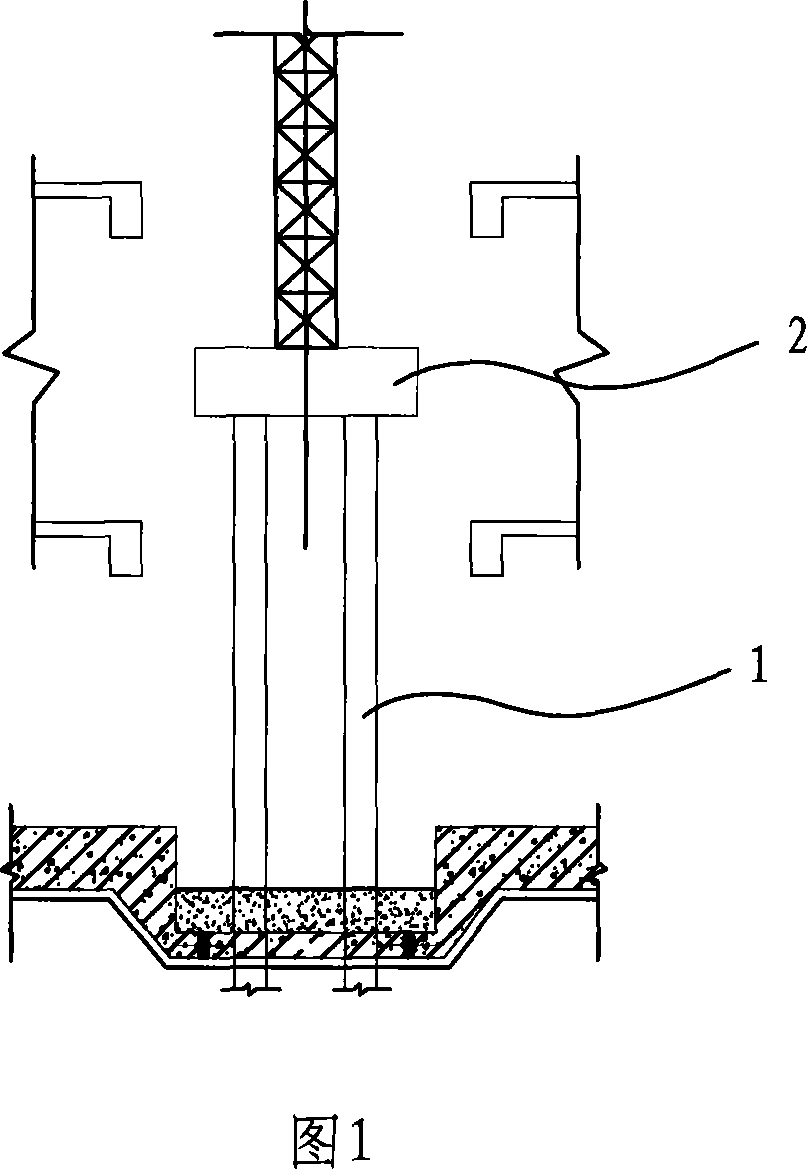

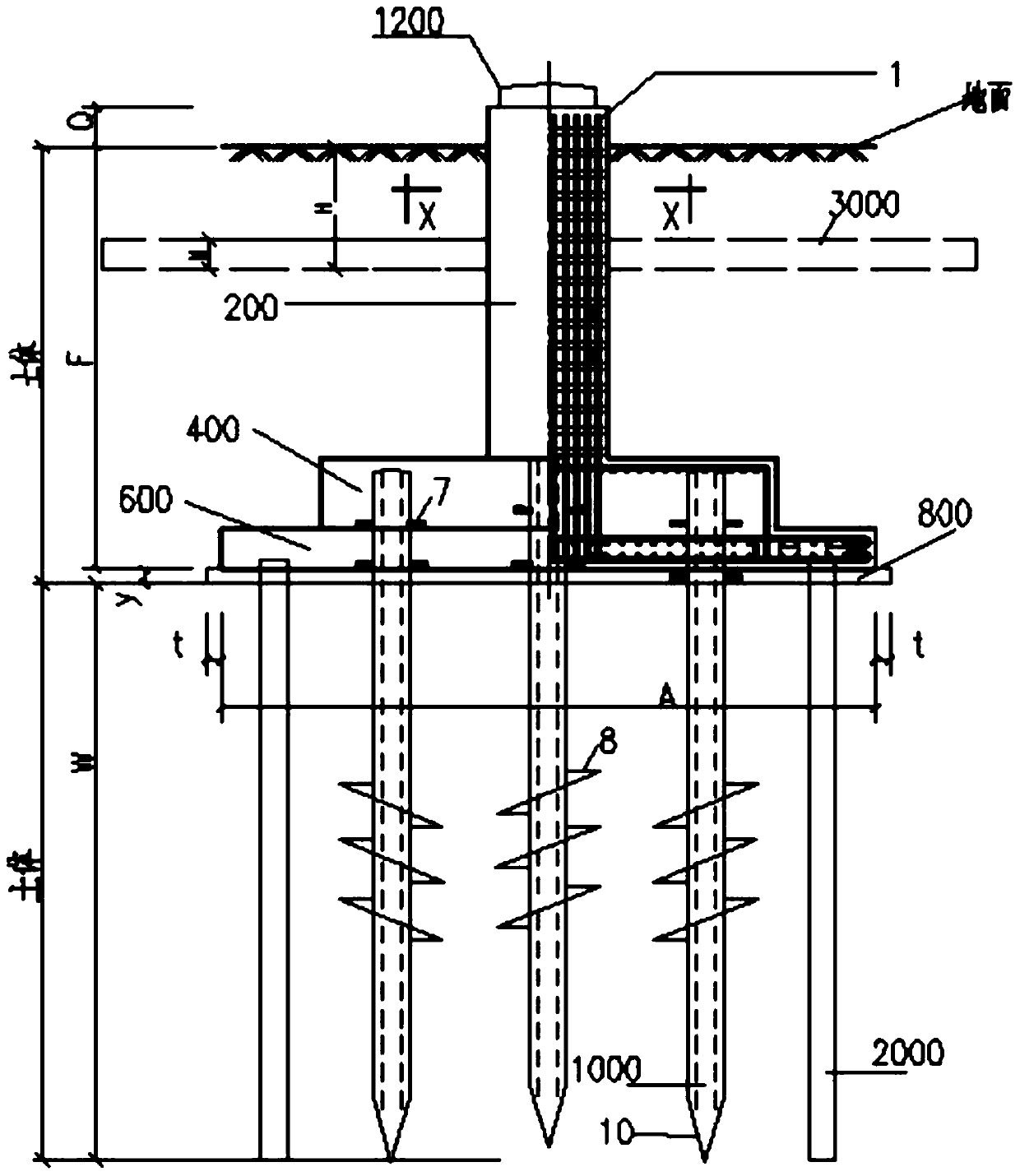

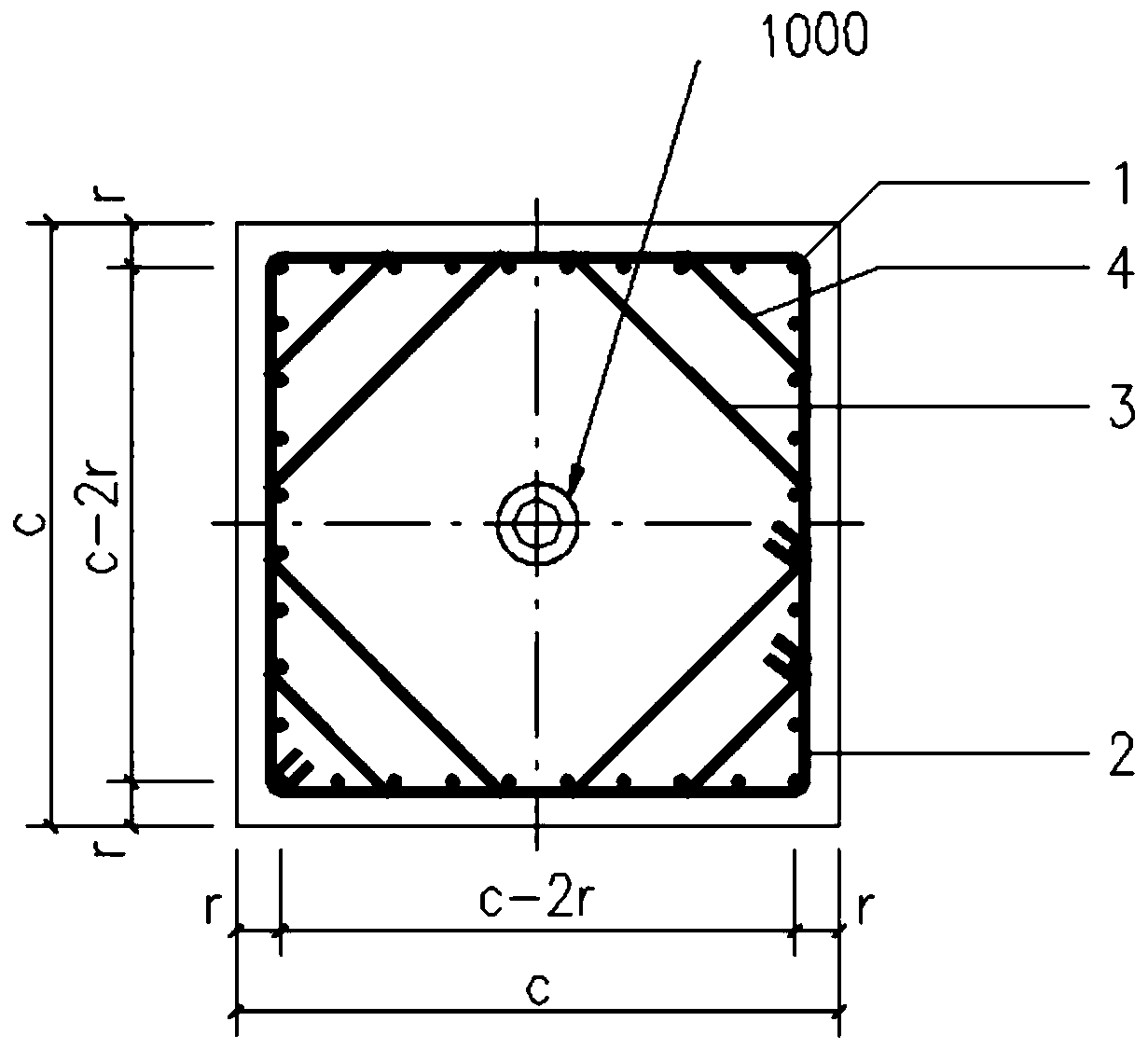

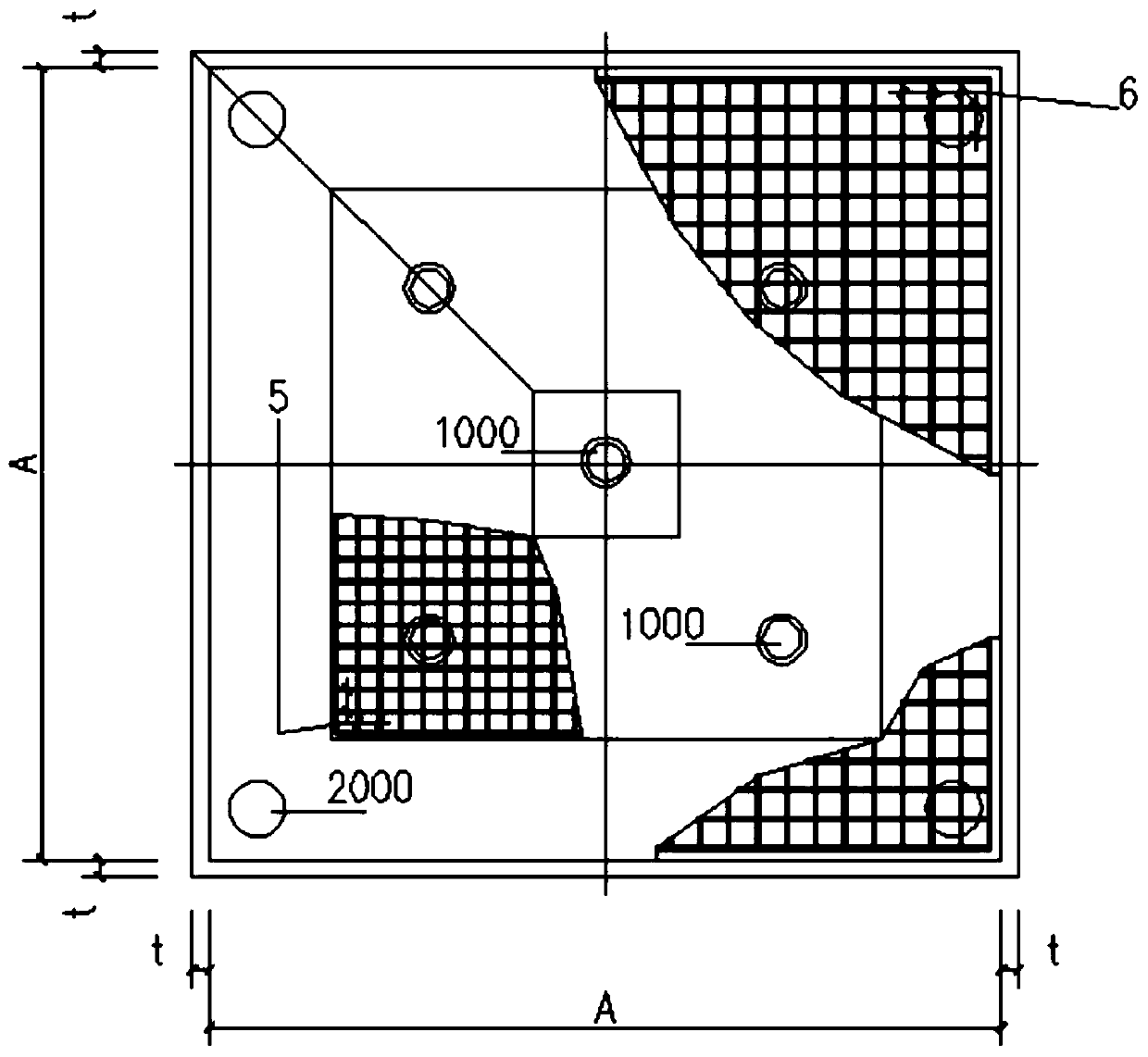

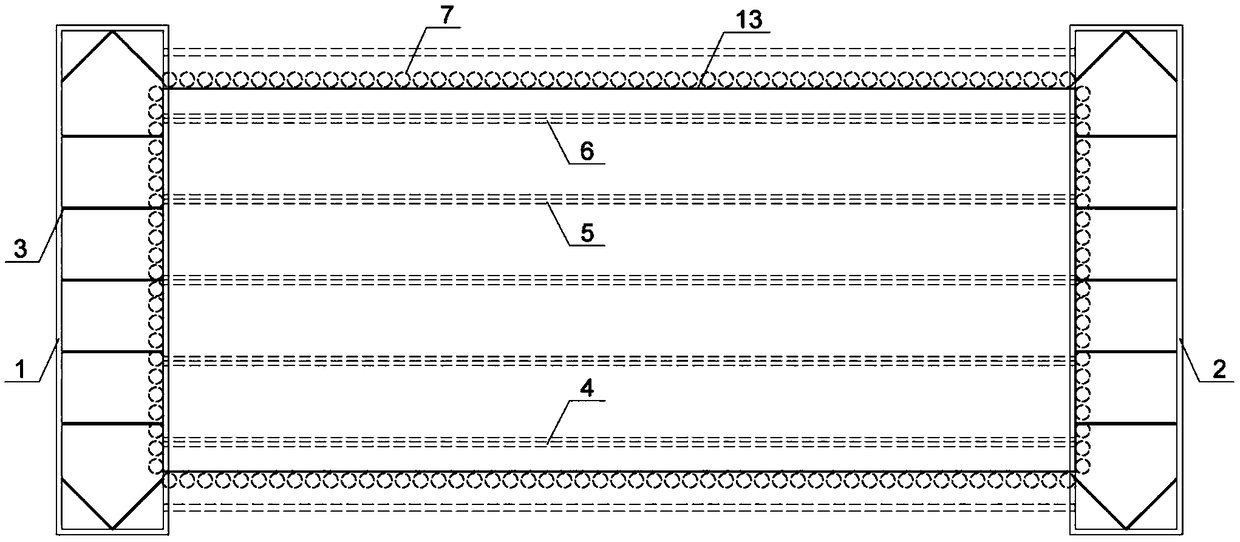

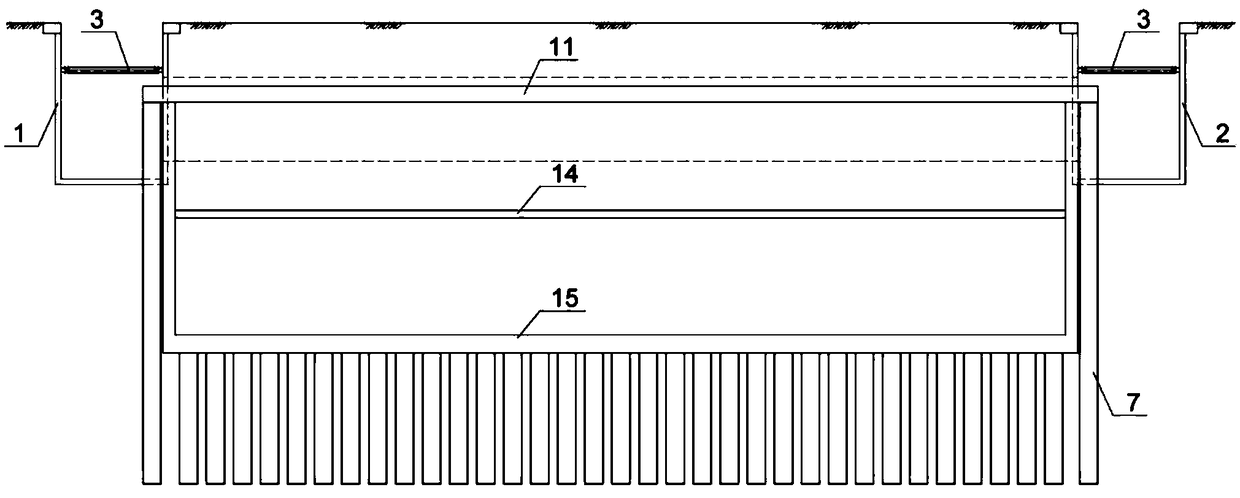

Tower crane foundation for construction and manufacturing method thereof

The invention discloses a tower crane foundation for building, comprising foundation platform of tower crane, at least four grouting piles under the foundation platform of tower crane. It is characterized in that foundation bottom can be revealed from the top of said grouting pile and water stopping structure is set between grouting piles and building bottom plate. The invention discloses the manufacturing method for said tower crane at the same time. Aiming at high-rise building with ultra-large area and multi-floor basement, the invention adopts tower crane foundation of high-pile platform. Not only the problem that because high-rise floor retracts in podium tower crane can not be attached with it is solved but also the assignment of tower crane becomes flexible, covering area is bigger and it can be used in advance. Mechanical utilization achieves to the maximum and it has a very good effect for decreasing manual consumption and construction period.

Owner:ZHONGYIFENG CONSTR GRP

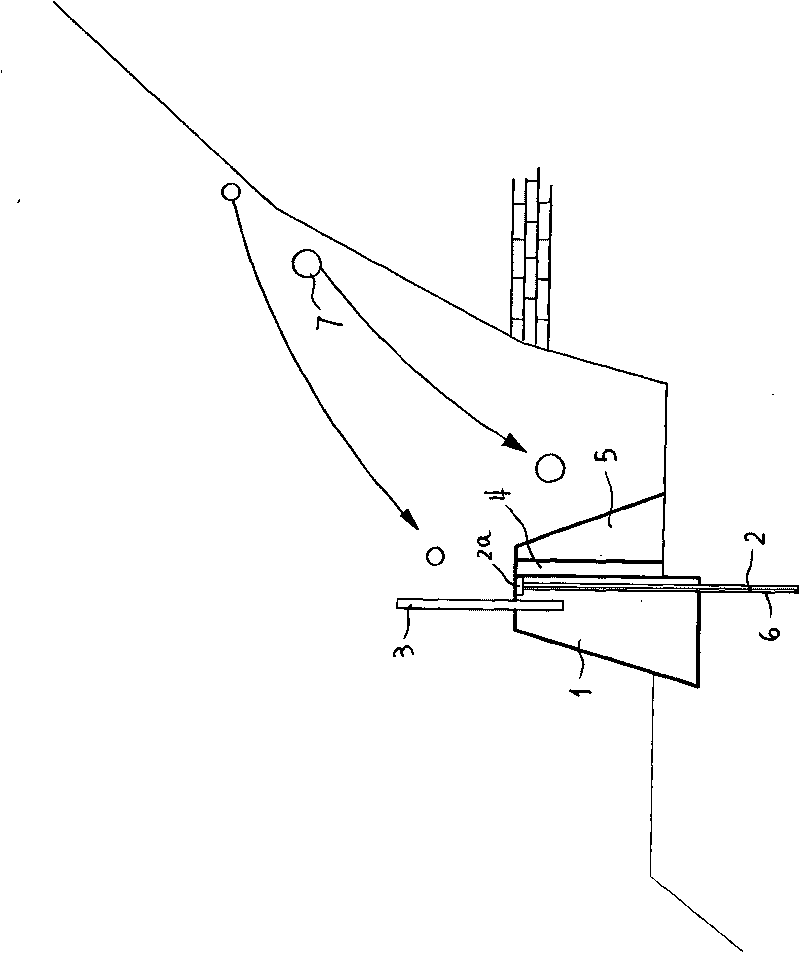

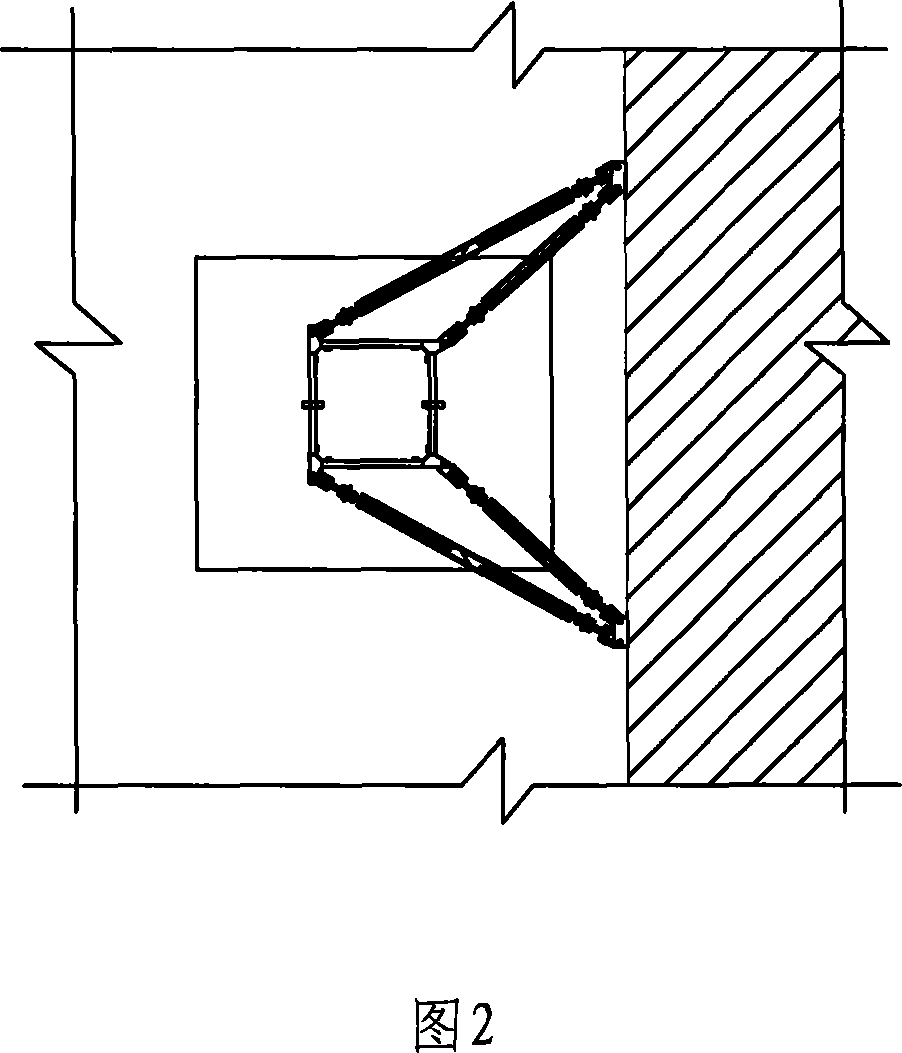

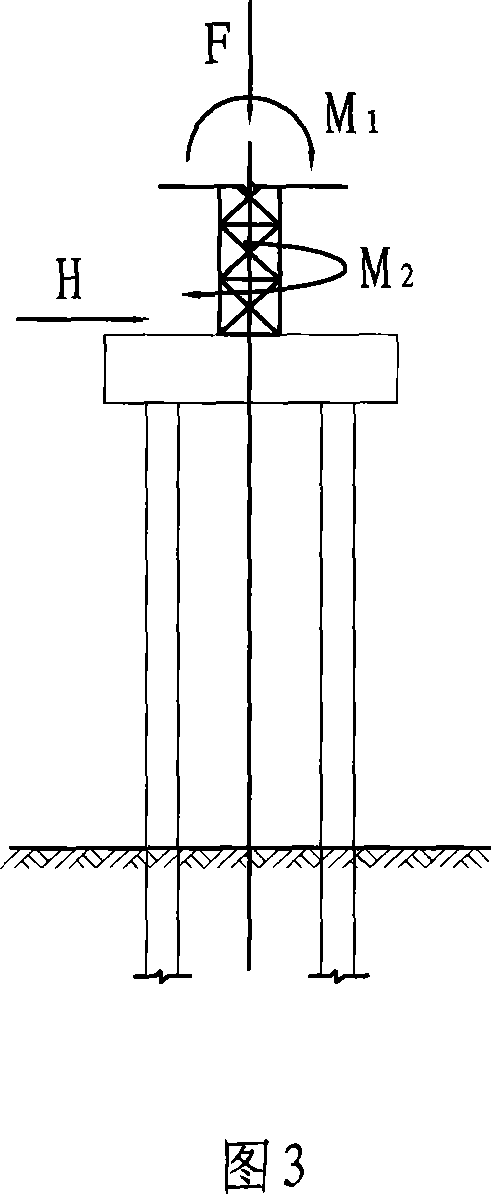

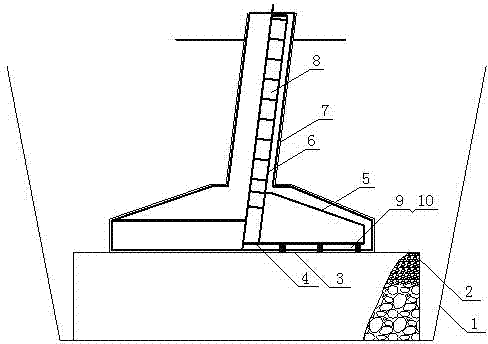

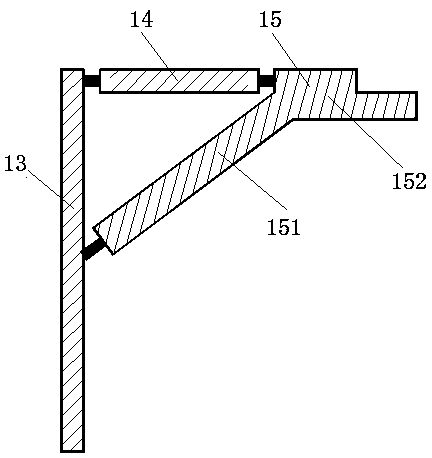

Construction method of inclined column type corrosion resistant foundation for power line in salt lake area

ActiveCN102926398AEnhanced lateral rollover resistanceImprove stabilityProtective foundationGlass fiberSalt lake

The invention relates to the technical field of power transmission, and particularly relates to a construction method of an inclined column type corrosion resistant foundation for a power line iron tower in a salt lake area. The construction method comprises the following steps of: 1) a foundation treating step; 2) a glass fiber reinforced plastic corrosion-resistant layer mounting step; 3) a steel foundation binding step; 4) a glass fiber reinforced plastic template supporting step; 5) a concreting step; 6) a glass fiber reinforced plastic sealing step; 7) a concrete maintaining and support structure removing step; and 8) a foundation pit backfilling step. The method provided by the invention is characterized in that compared with the conventional rigid straight column foundation, the center slope of the flexible-board inclined column type foundation is the same as the slope of major materials of tower legs of an upper power transmission line structure; as a result, the horizontal acting force on the top surface of the foundation and the bending moment acting on a foundation base plate are reduced, the integrated force condition of a main column and the base plate of the foundation is greatly improved, the lateral antidumping and anti-sliding stability of the foundation is enhanced, the designed dimension of the foundation is reduced and 5%-15% of concrete material quantity for a main foundation body is saved; and therefore, the economical efficiency is quite obvious; and the glass fiber reinforced plastic covered concrete foundation improves the corrosion resistance of the salt lake region. The schematic diagram of the construction method is shown in the following figure.

Owner:QINGHAI ELECTRIC POWER DESIGN INST +3

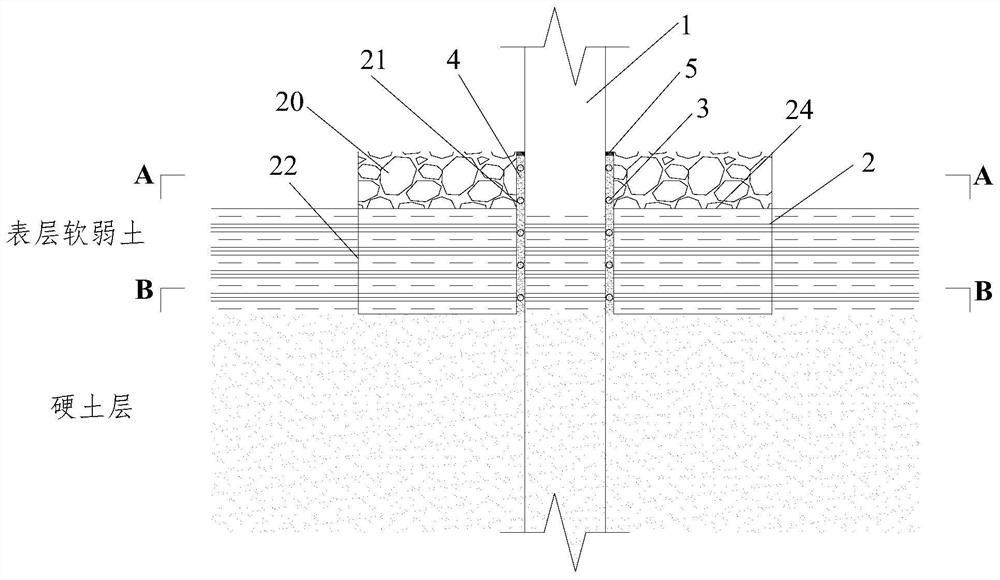

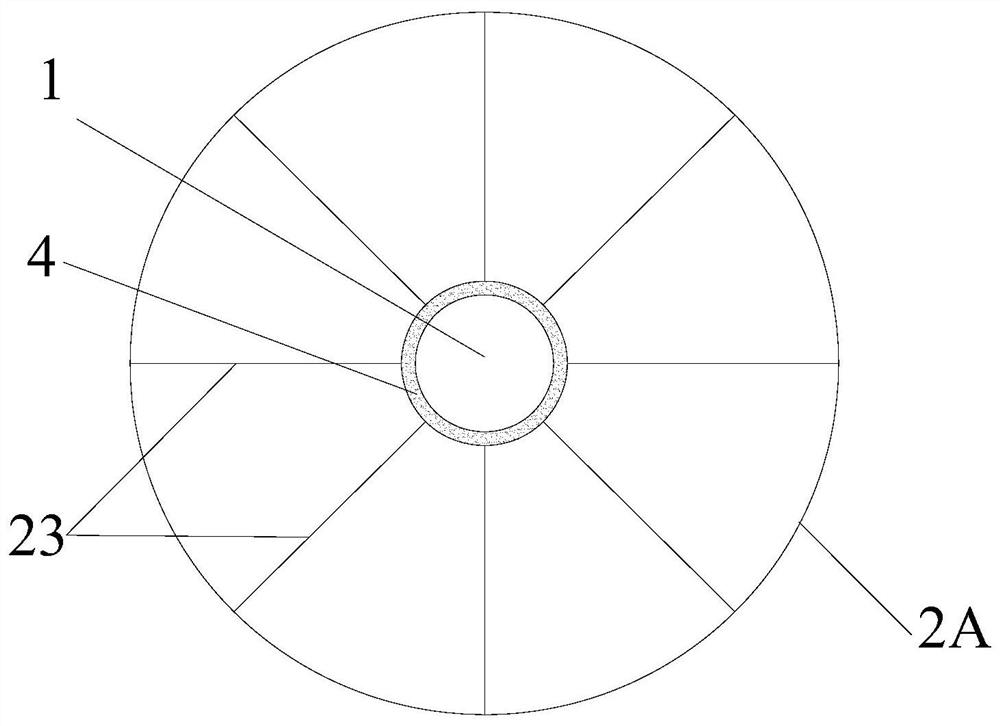

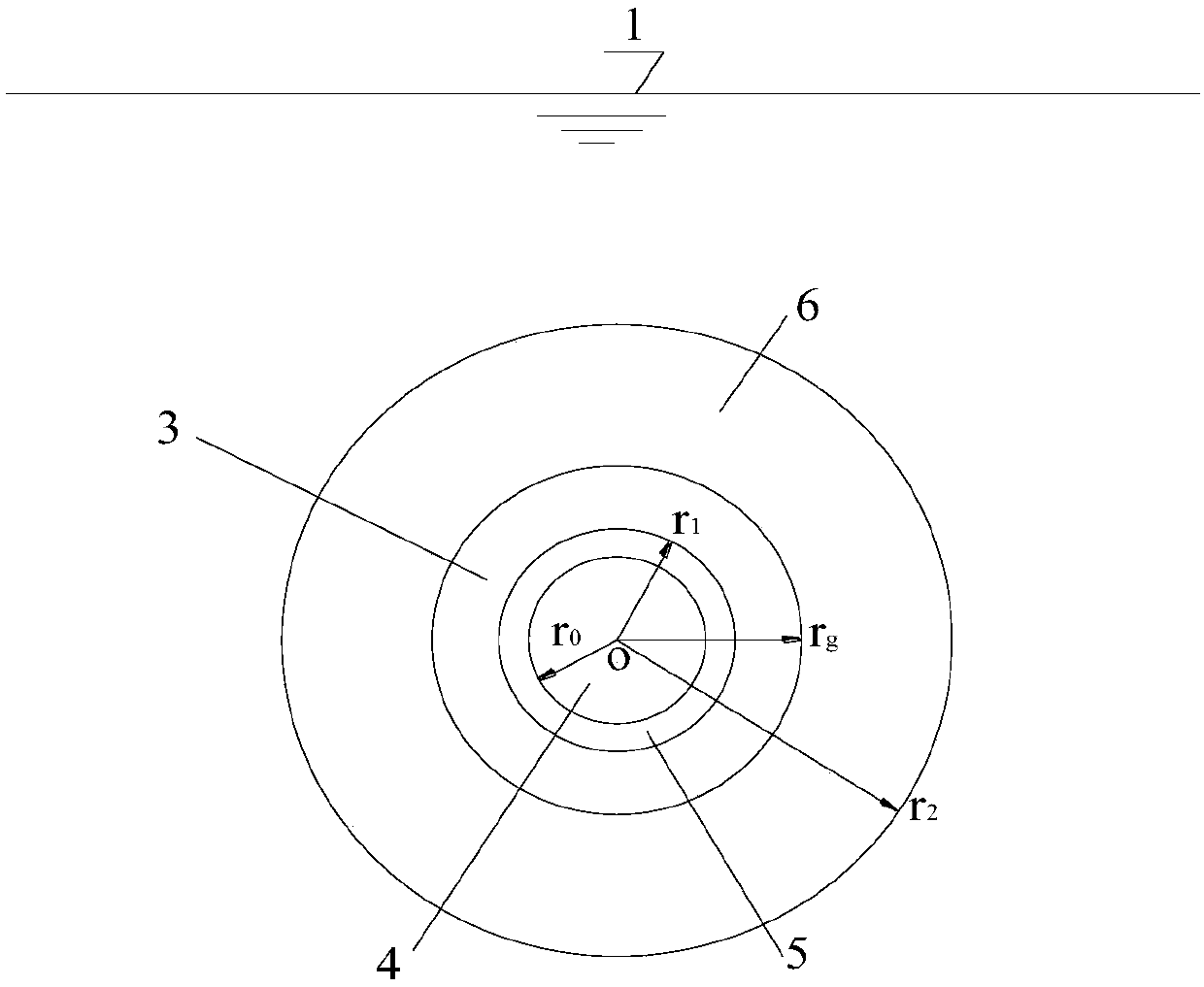

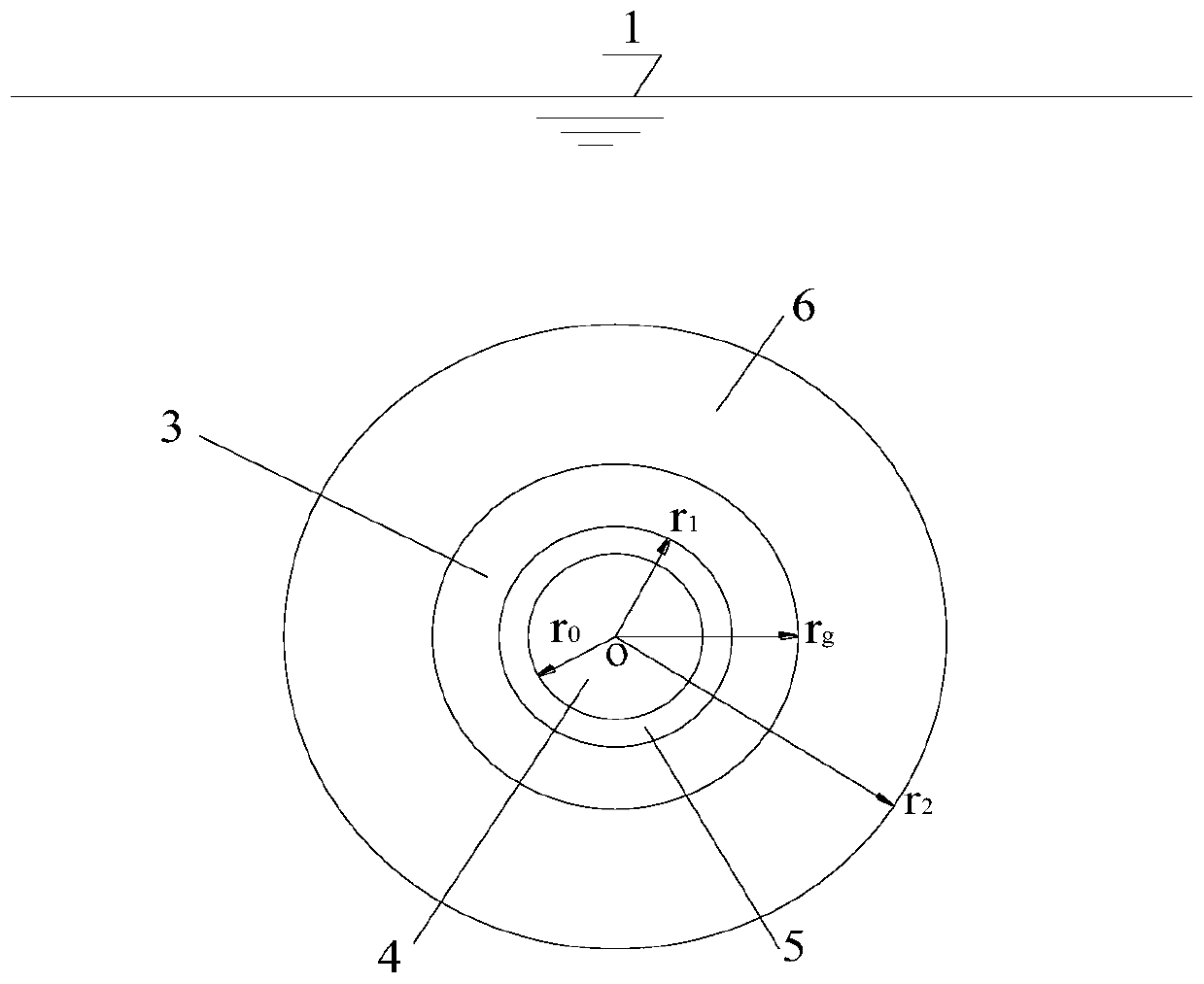

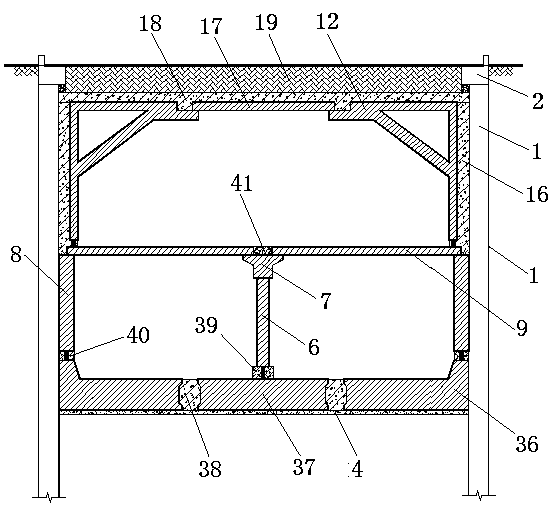

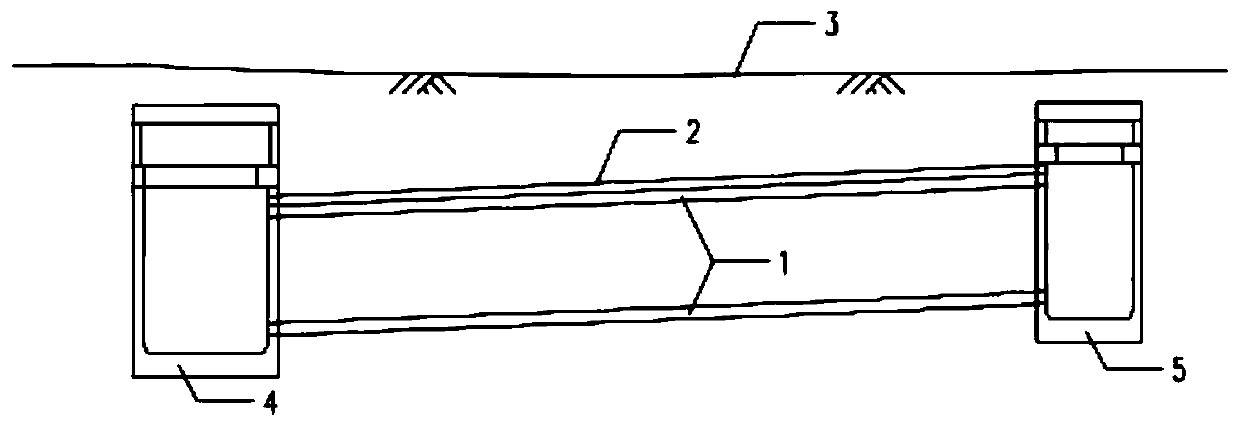

Pile box barrel composite foundation for offshore wind power and construction method thereof

The invention discloses a pile box barrel composite foundation for offshore wind power. The pile box barrel composite foundation comprises a single pile and a barrel body, wherein the barrel body comprises an inner barrel body, an outer barrel body, a negative pressure barrel top plate and a plurality of negative pressure barrel partition plates; the inner barrel body is coaxially arranged in an inner cavity of the outer barrel body and arranged on the single pile in a sleeving mode; the inner barrel body and the single pile are connected into a whole through grouting; the negative pressure barrel top plate is arranged between the upper portion of the inner barrel body and the upper portion of the outer barrel body in a sealing and covering mode, so that a negative pressure barrel is formed on the lower portion of the negative pressure barrel top plate, an open box barrel is reserved on the upper portion of the negative pressure barrel top plate, and the interior of the open box barrelis divided into a plurality of weight areas through a plurality of rib plates; the plurality of negative pressure barrel partition plates are evenly connected into the negative pressure barrel in theradial direction to divide the negative pressure barrel into a plurality of negative pressure cabins; and after the barrel body penetrates into seabed soil and the negative pressure barrel top platereaches the designed elevation, the weight areas of the open box barrel are filled with riprap weights, and the box-shaped foundation is formed. The invention further discloses a construction method of the pile box barrel composite foundation for offshore wind power. By means of the pile box barrel composite foundation for offshore wind power and the construction method thereof, the anti-overturning bearing capacity can be improved, and the buried depth of the single pile is reduced.

Owner:CCCC THIRD HARBOR ENG

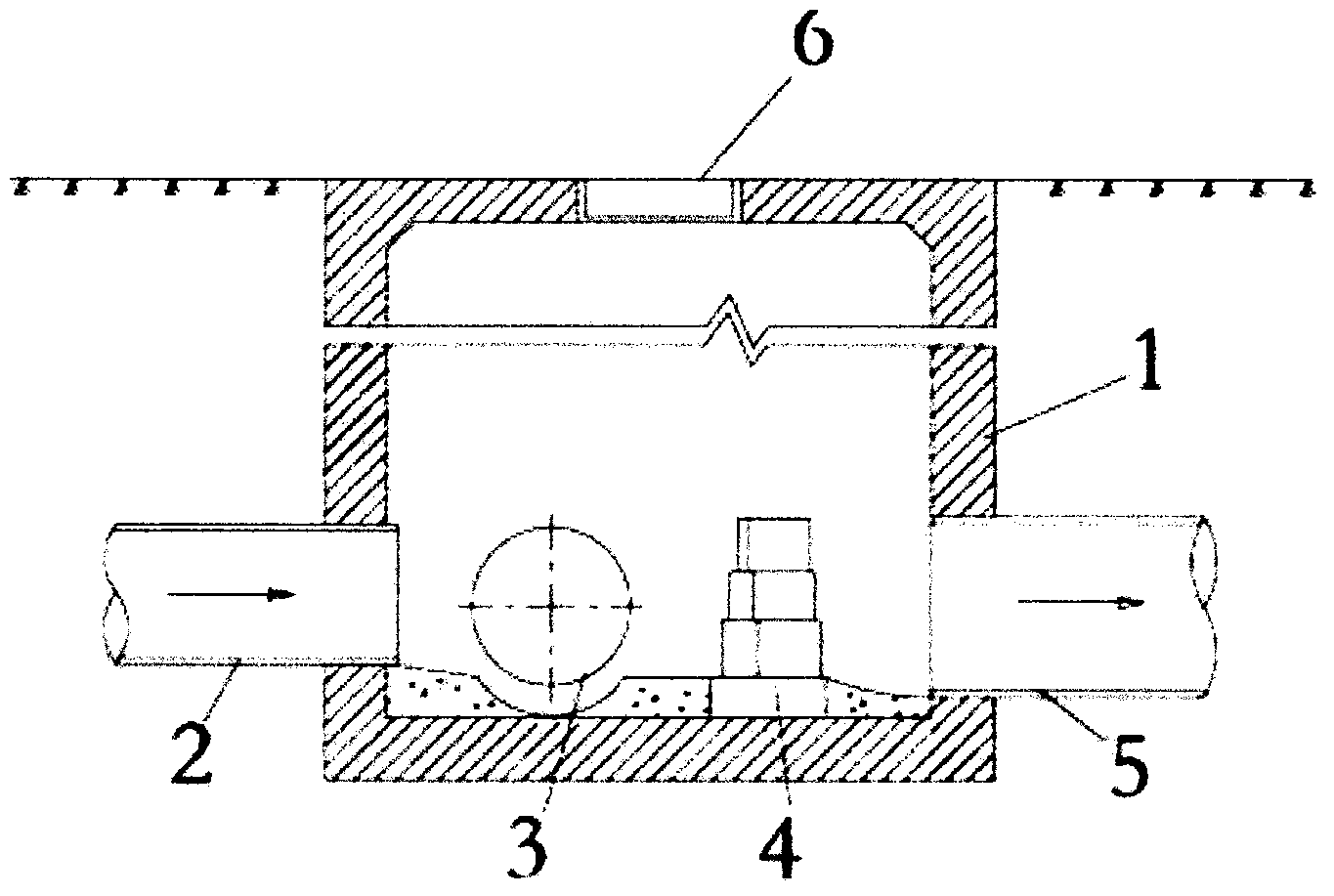

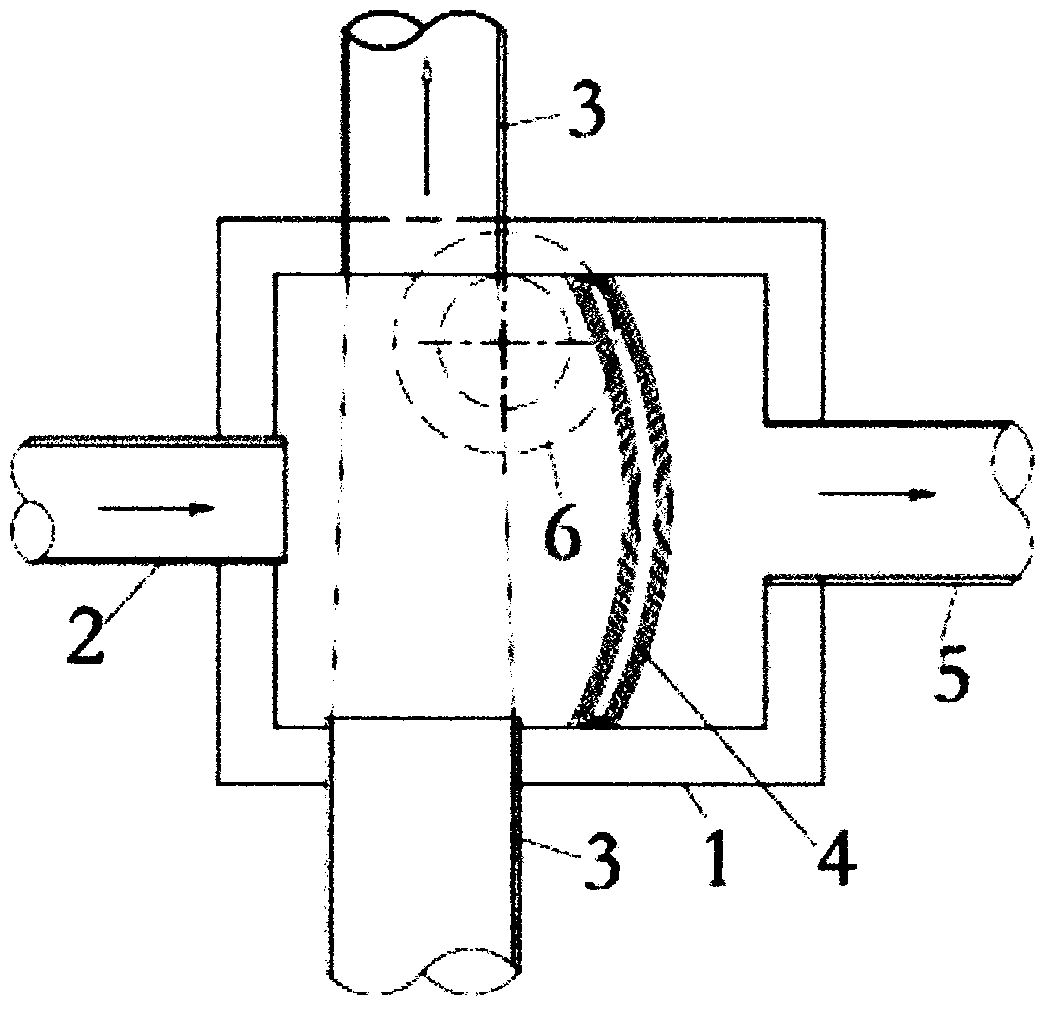

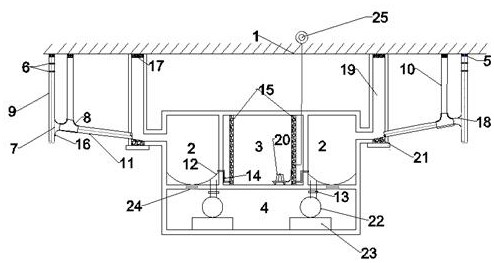

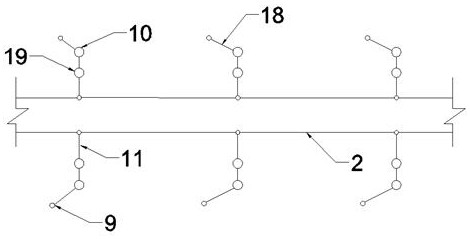

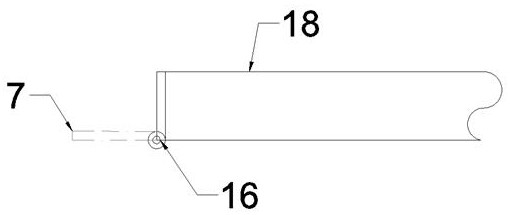

Electrically-controlled automatic adjustable overflow weir intercepting well

InactiveCN103572829ASmoothly into the riverPrevent overflowSewerage structuresShortest distanceSludge

The invention discloses an electrically-controlled automatic adjustable overflow weir intercepting well comprising a hollow well body. An adjustable arc overflow weir is disposed inside the well body. A telescopic bar is disposed inside the overflow weir. A combiner pipe, an intercepting trunk and an overflow pipe with an orifice tangent with the inner wall of the well body are connected to the well body. A top opening of the well body is covered with an intercepting well cover. The overflow weir is adjustable, the water level in the intercepting well can be controlled, and overflow can be controlled timely; in addition, the intercepting trunk buried is shallower than the traditional trunk, so that construction cost is reduced and construction is easier. The overflow weir is in an arc shape; therefore, on one hand, water passage length of the overflow weir is increased and water flow is increased under the same conditions; on the other hand, wastewater in the intercepting trunk flows by the intercepting well, the water passage section changes in short distance, water speed changes soon, disturbances occur, sinking of particles in the wastewater is disturbed, and sedimentation of sludge in the intercepting well is prevented.

Owner:SUZHOU UNIV OF SCI & TECH

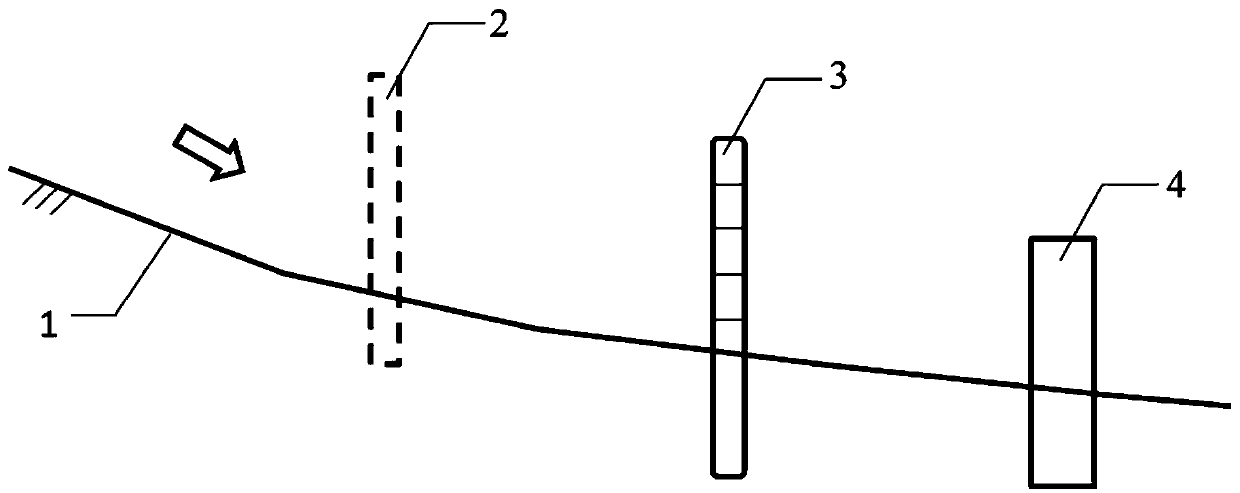

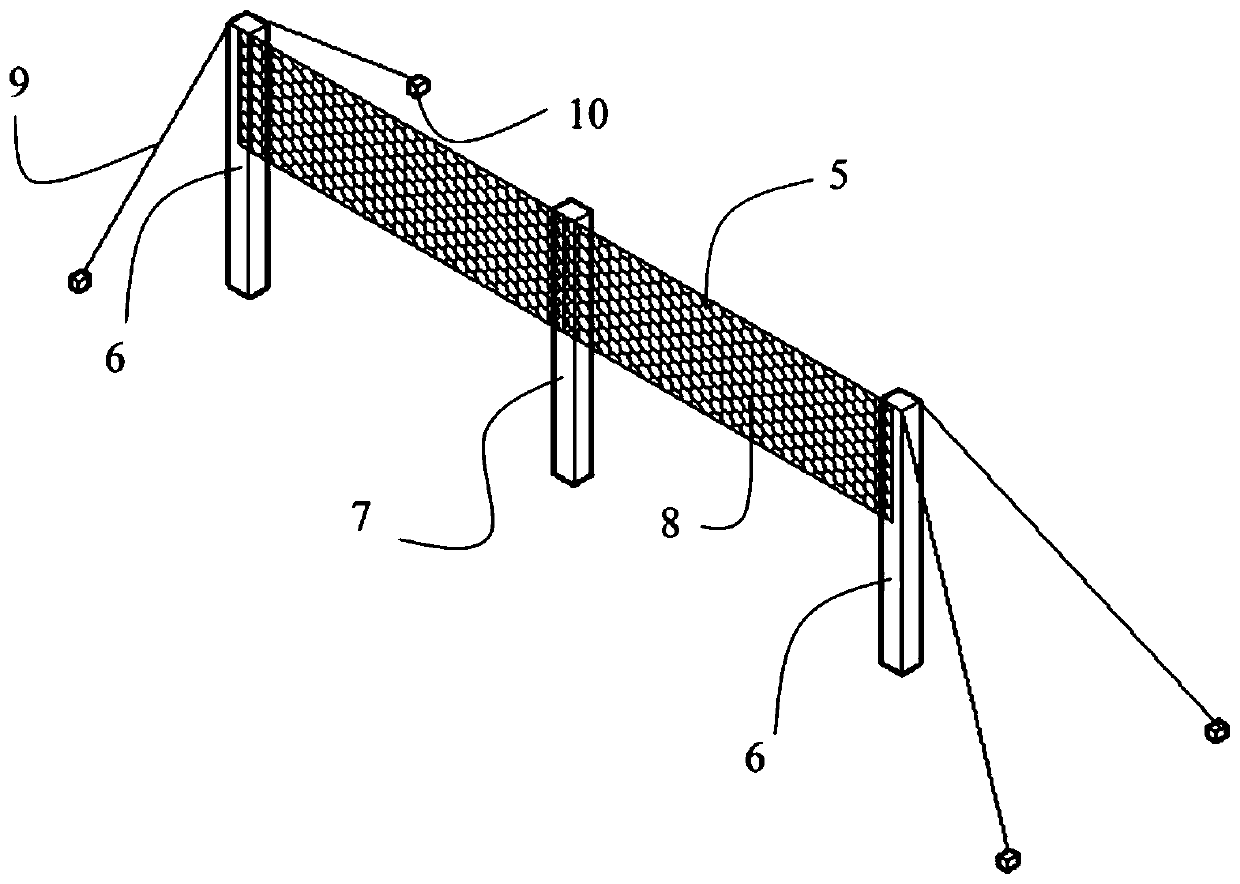

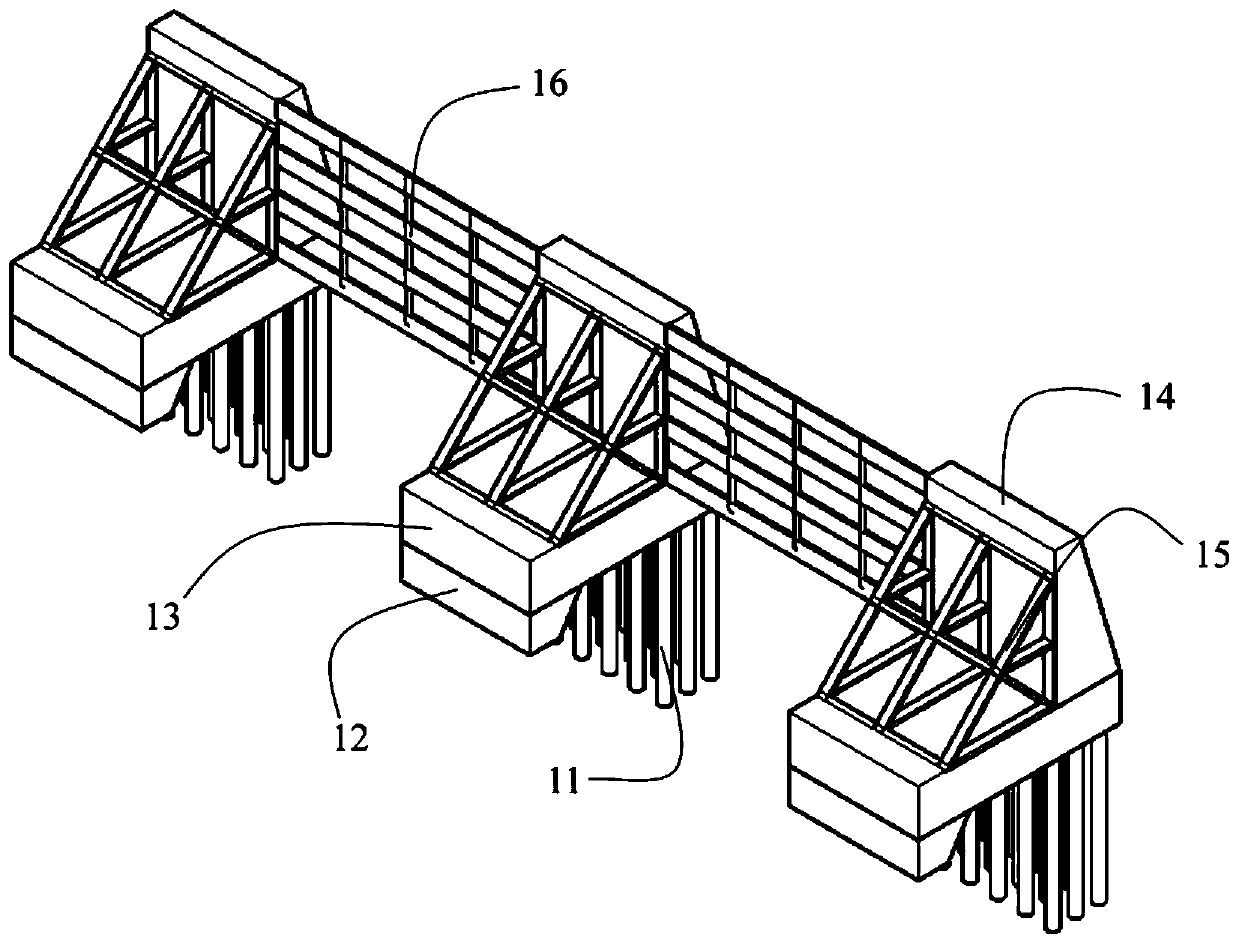

Debris flow multi-stage dissipative blocking structure

PendingCN110004882AConsume impact energyReduce shockProtective constructionFoundation engineeringButtressEngineering

The invention relates to the technique of prevention of geological hazards, in particular to a debris flow prevention technique. The invention discloses a debris flow multi-stage dissipative blockingstructure, thus damage action of a debris flow can be lowered, and the disaster loss is relieved. According to the debris flow multi-stage dissipative blocking structure, from flowing area of the debris flow to the accumulation area, the debris flow multi-stage dissipative blocking structure is arranged in a step-by-step mode along debris flow channels from the upstream to downstream, and at leastincludes a flexible blocking net, a pile-carrying-type grid wall and a permeable buttress-type gravity dam. According to the debris flow multi-stage dissipative blocking structure, according to different geological conditions, types of the debris flows and the like, the matching structure of the flexible blocking net 2, the pile-carrying-type grid wall 3 and the permeable buttress-type gravity bam is reasonably selected, benefits of the investment in engineering construction can be given full play to the maximum extent, and cost benefit optimization is achieved. The debris flow multi-stage dissipative blocking system is very suitable for prevention of the debris flow disasters.

Owner:SOUTHWEST JIAOTONG UNIV

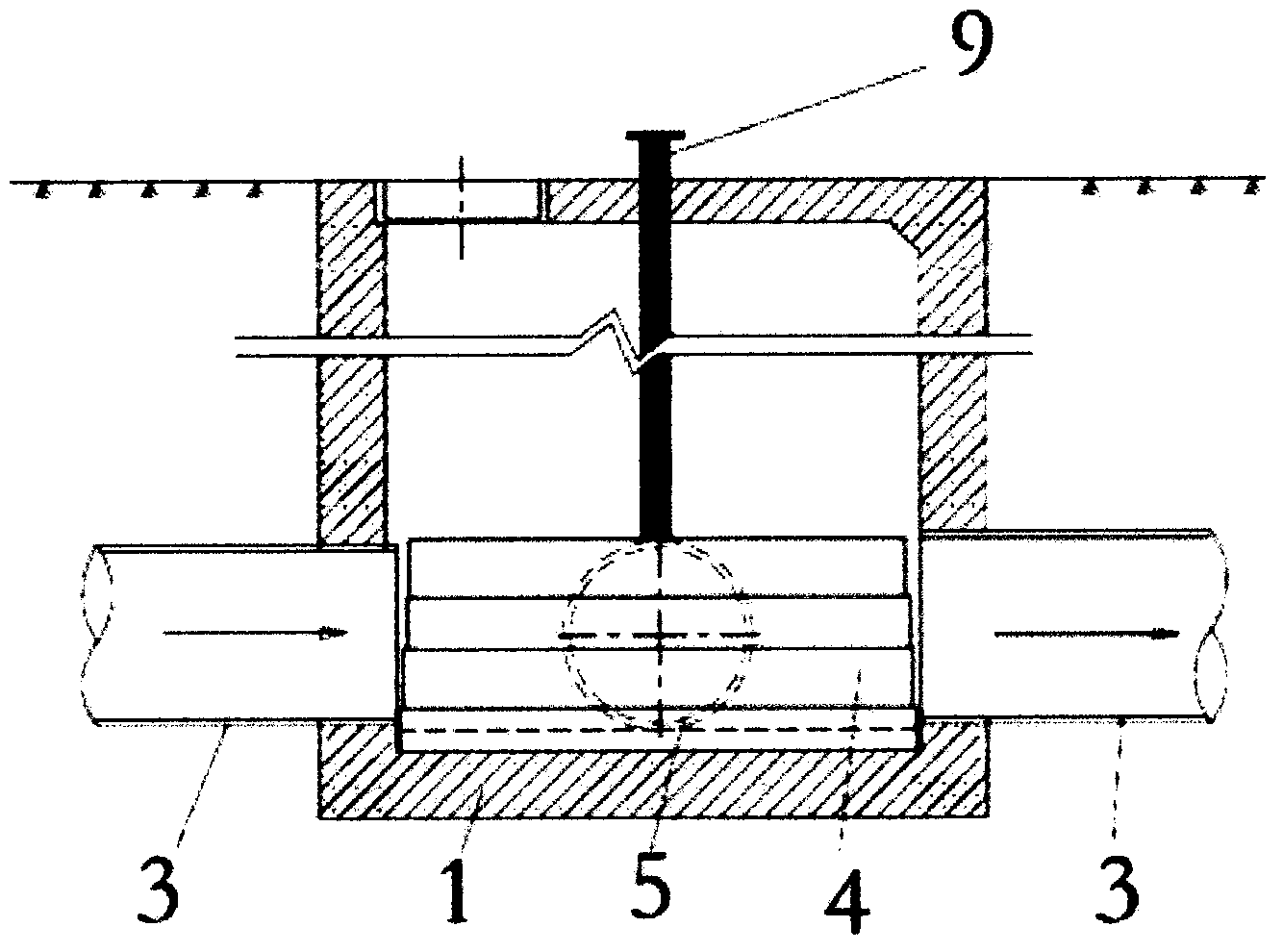

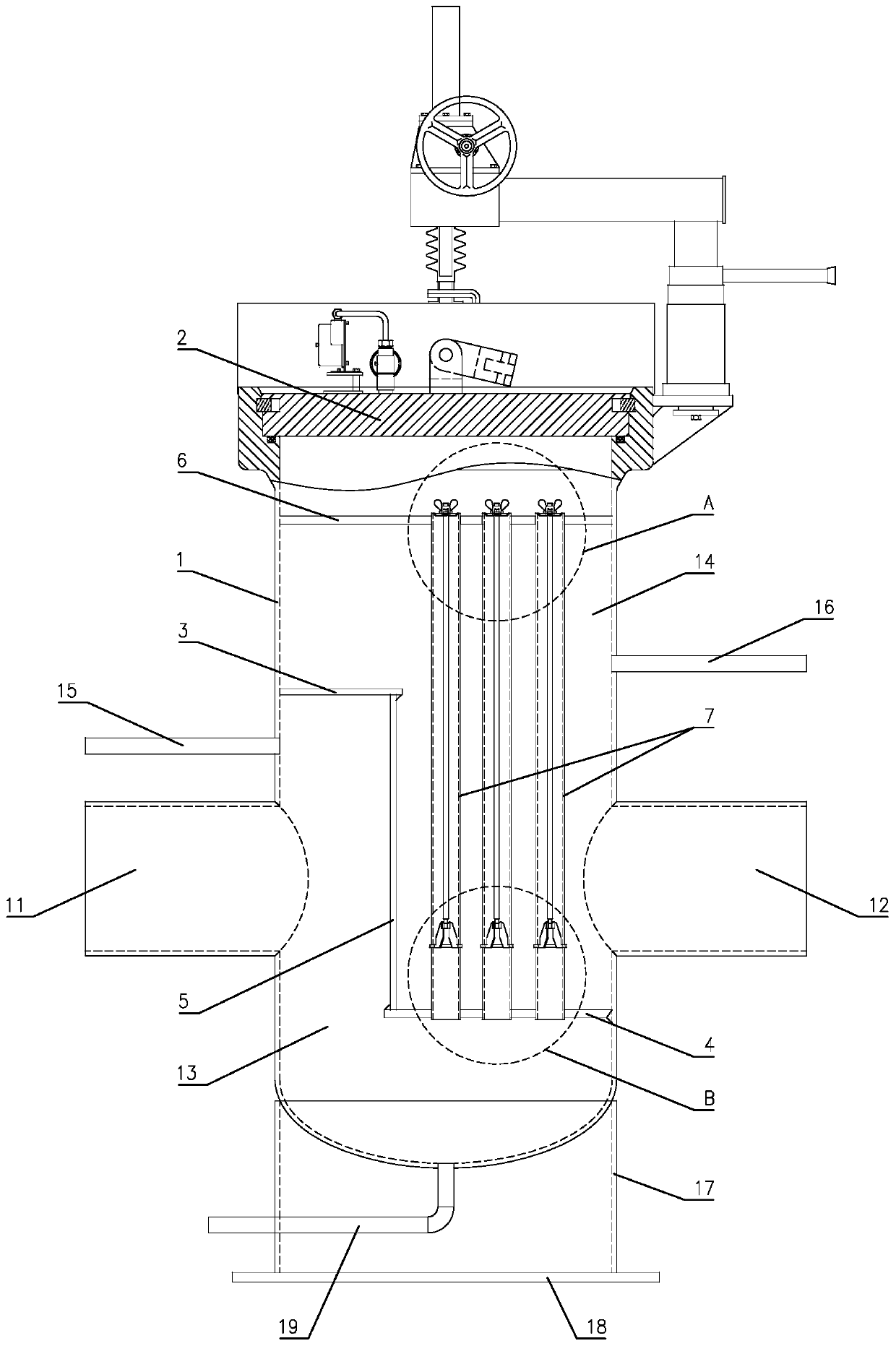

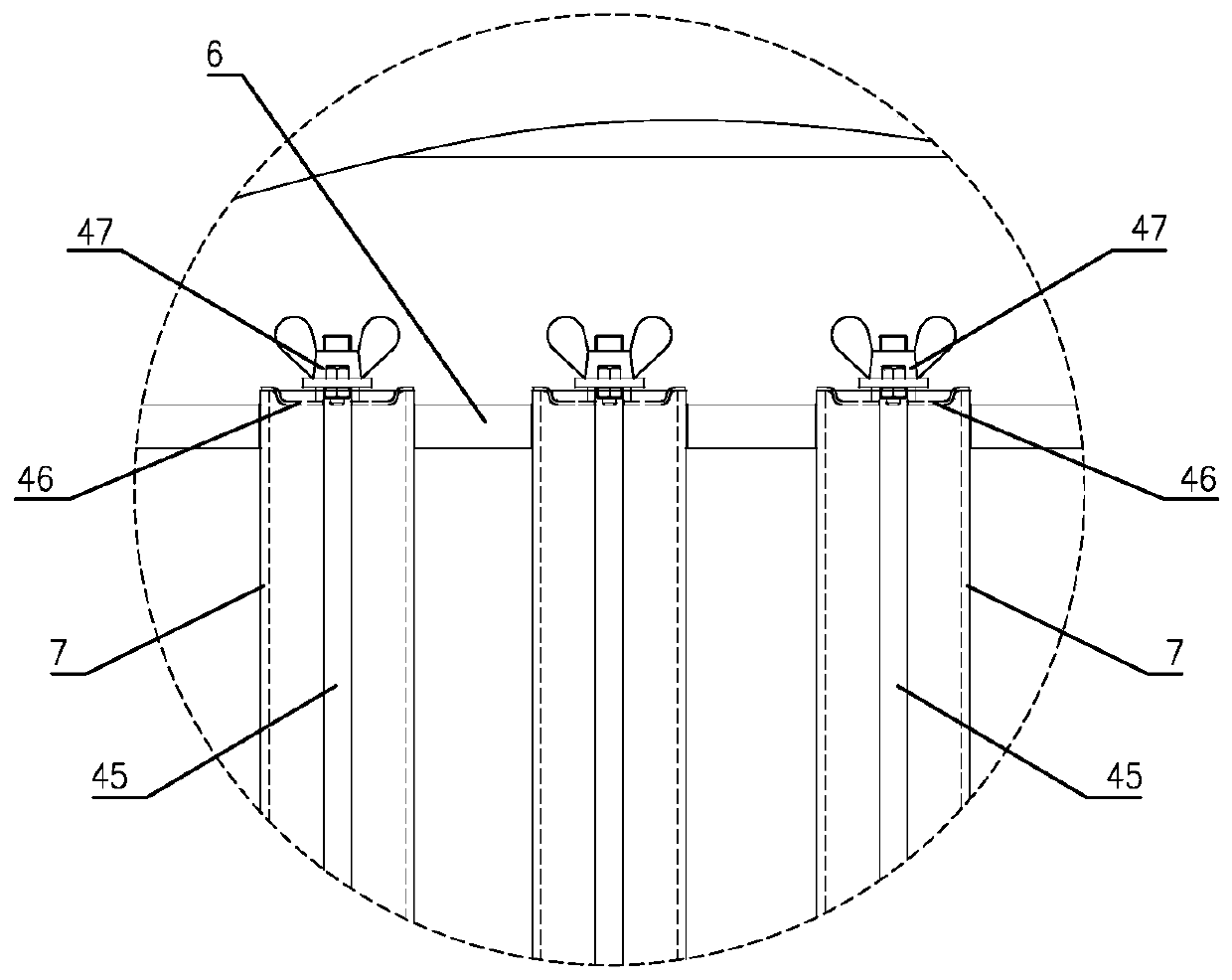

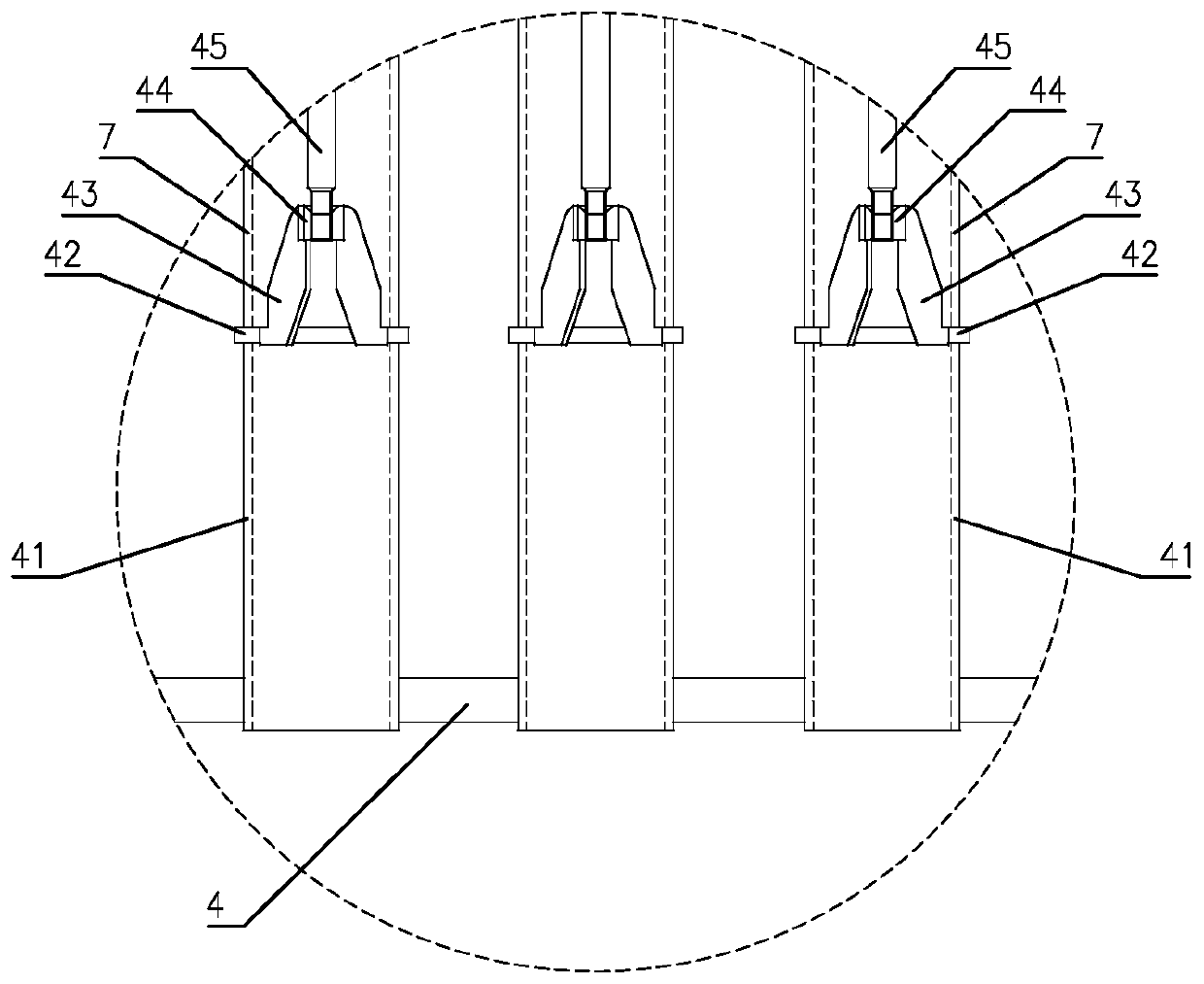

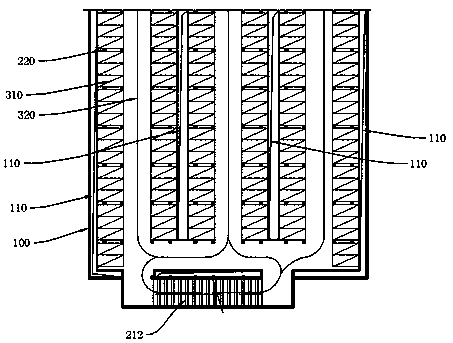

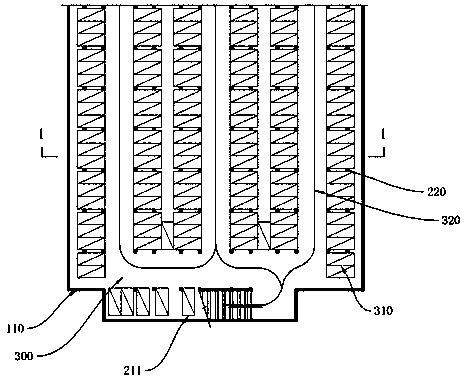

Direct-buried gas filter

ActiveCN111389128ACompact structureAdaptableDispersed particle filtrationTransportation and packagingMechanical engineeringMechanics

The invention discloses a direct-buried fuel gas filter. The gas filter comprises a shell and a quick-opening blind plate mounted at an opening in the upper end of the shell, an air inlet and an air outlet are correspondingly formed in the left and right sides of the shell; an inner cavity of the shell is divided into an air inlet cavity and an air outlet cavity through a baffle assembly, the baffle assembly comprises a left baffle, a right baffle plate and a vertical baffle plate, the left baffle plate is horizontally arranged and located on the upper side of the air inlet, the right baffle plate is horizontally arranged and located on the lower side of the air outlet, and the upper end and the lower end of the vertical baffle plate are correspondingly connected with the left baffle plateand the right baffle plate. A support plate which is located on the upper side of the air outlet and is in a horizontal state is further arranged in the inner cavity of the shell, a plurality of vertical coalescence filter elements are arranged between the support plate and the right baffle plate, the lower ends of inner holes of a coalescence filter elements are communicated with the air inlet cavity, and the upper ends of inner holes of the coalescence filter elements are closed. The gas filter has the advantages of being compact in structure, high in adaptability and good in filtering effect, the burial depth and the installation difficulty can be effectively reduced, moisture in gas can be filtered out, and the safety and reliability of gas pipe network operation and the gas quality of the tail end are enhanced.

Owner:江苏盛伟燃气科技有限公司

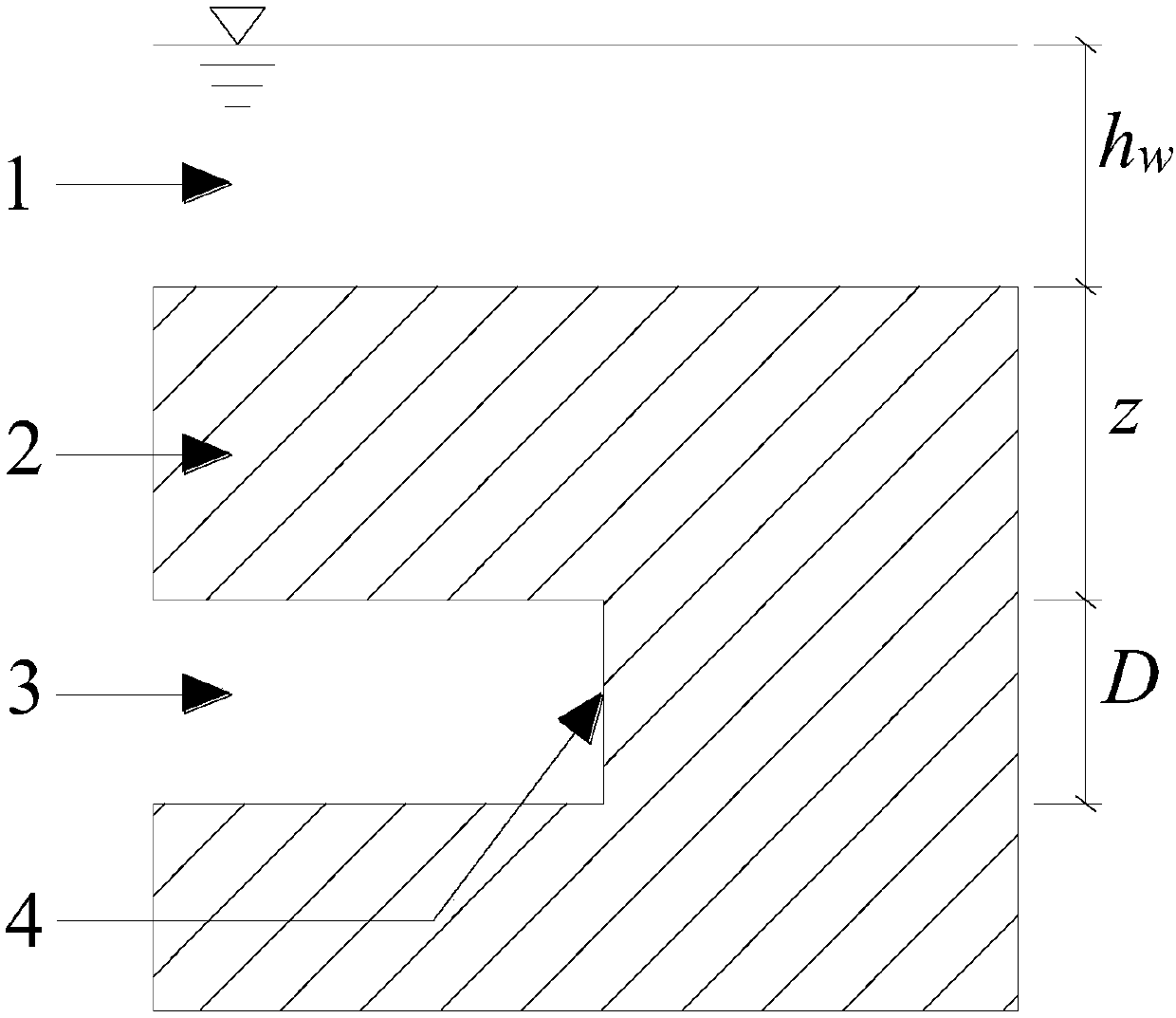

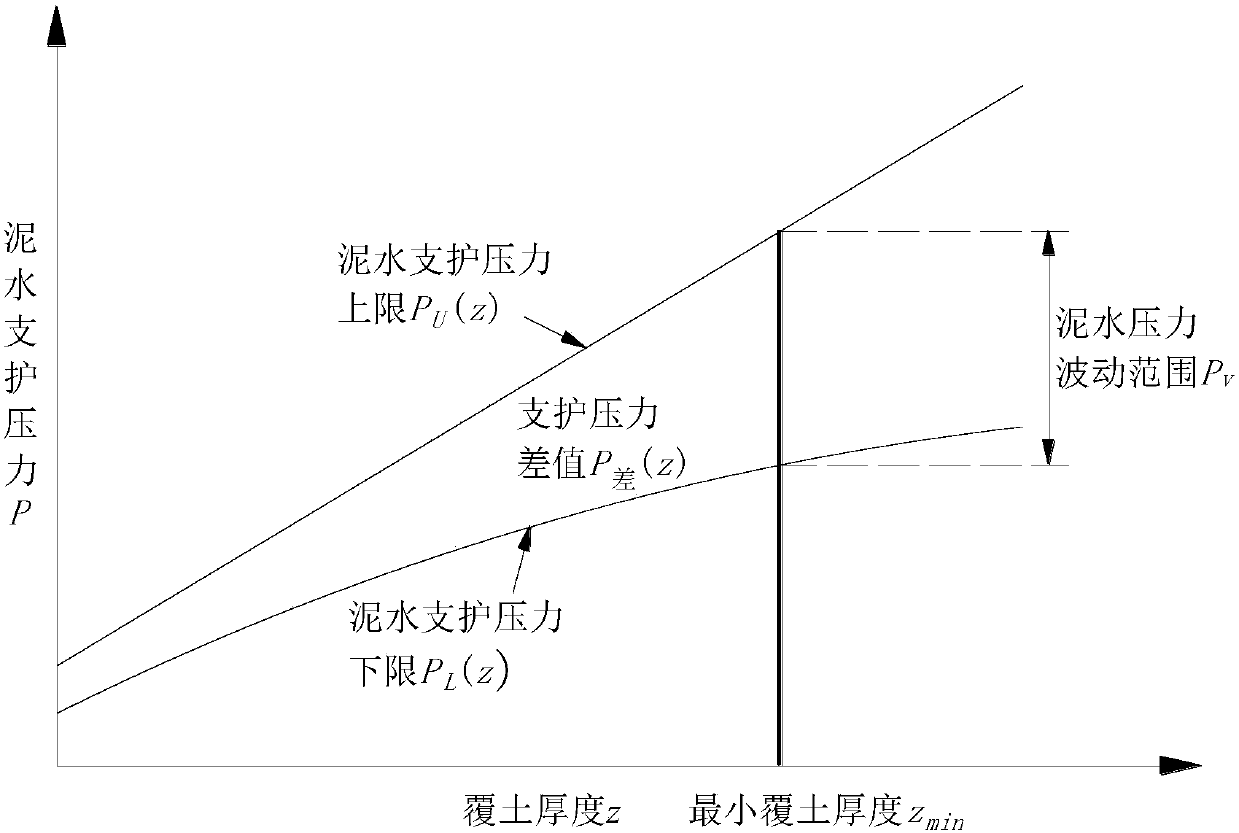

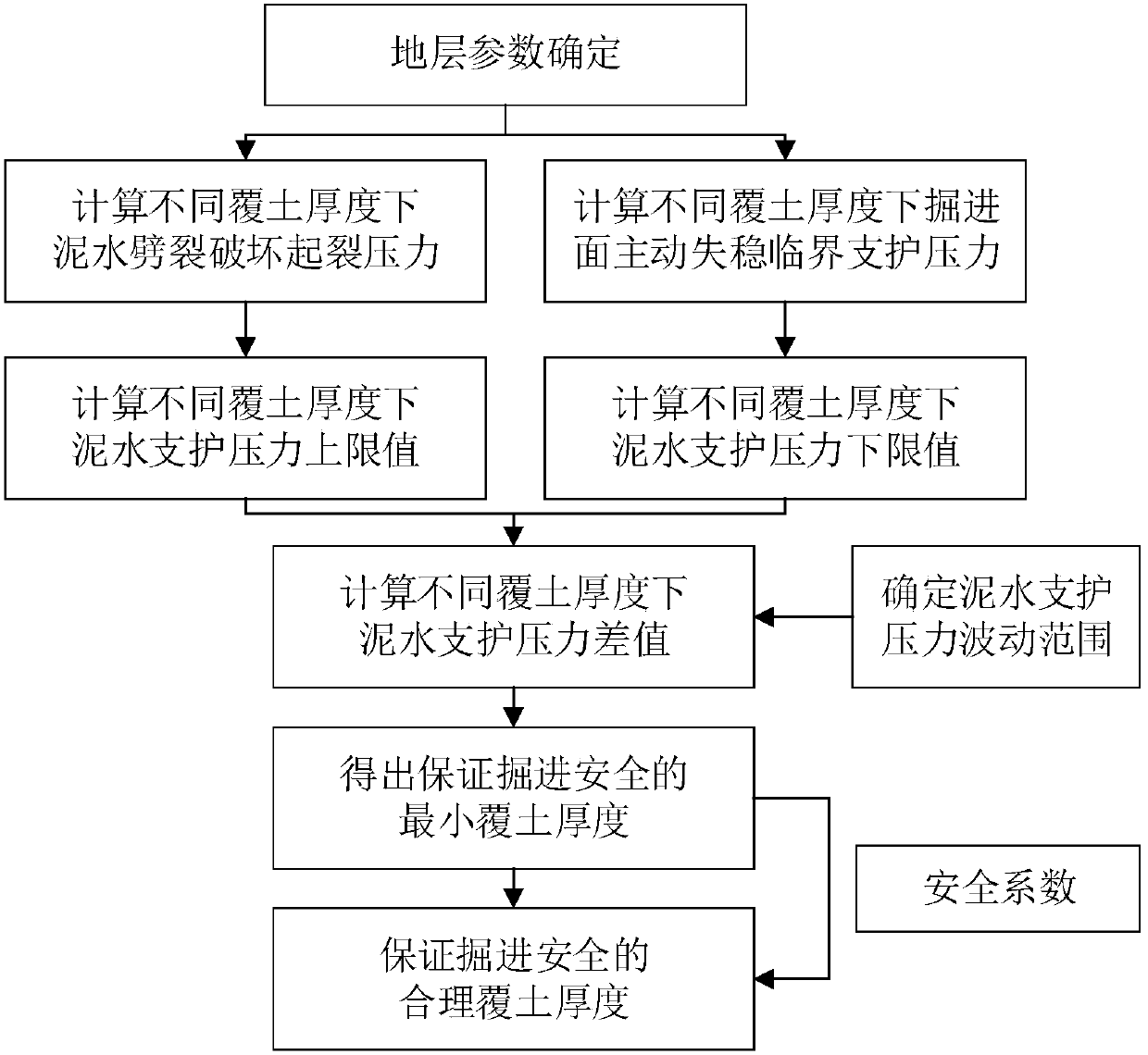

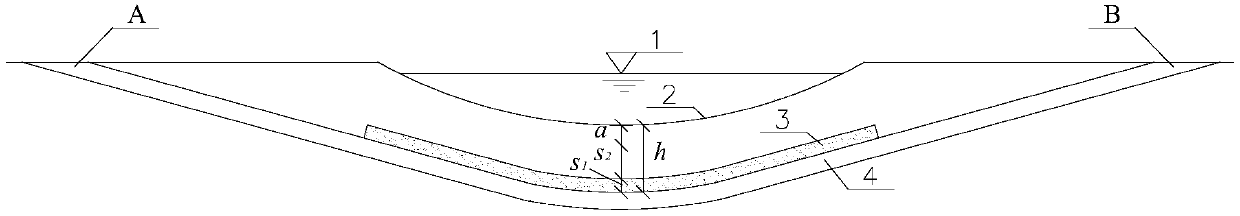

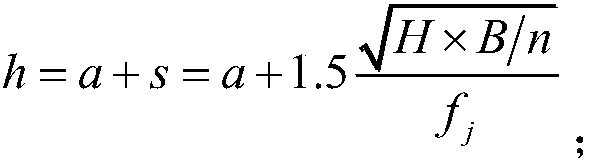

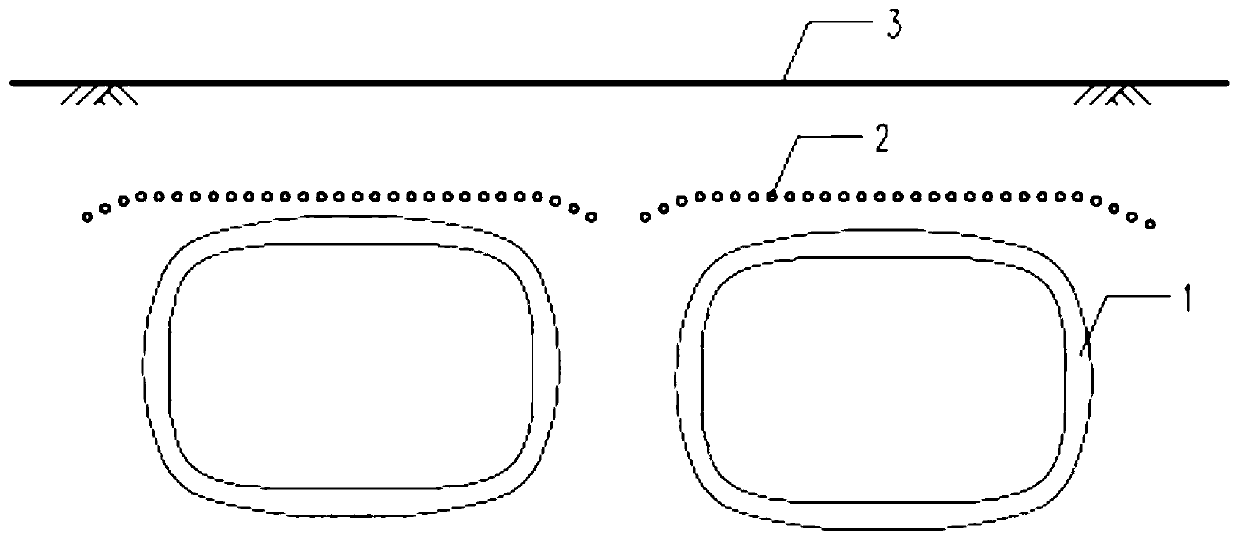

Method for reasonably earthing and setting cross river-sea shield tunnel

ActiveCN108573095AGuarantee normal constructionFlexible wiringGeometric CADTunnelsLower limitEngineering

The embodiment of the invention provides a method for reasonably earthing and setting a cross river-sea shield tunnel. The method comprises the following steps: acquiring tunnel design and a construction parameter and determining physical and mechanical parameters of an earthing layer and a water layer on the tunnel; calculating a muddy water support pressure upper limit value capable of guaranteeing shield tunneling safety under different earthing thicknesses; calculating a muddy water support pressure lower limit value capable of guaranteeing shield tunneling safety under different earthingthicknesses; calculating a shield muddy water support pressure allowable difference value capable of guaranteeing tunneling safety under different earthing thicknesses; determining the maximal fluctuation range of shield muddy water support pressure in the tunneling process; enabling the maximal fluctuation range of the shield muddy water support pressure to be equal to the shield muddy water support pressure allowable difference value under a certain earthing thickness to acquire the minimal earthing thickness and considering safety coefficient to acquire earthing thickness. According to themethod, the rationality of the earthing thickness of the cross river-sea shield tunnel is guaranteed, and cleavage and instable failure of the tunneling face of the cross river-sea shield tunnel are avoided.

Owner:BEIJING JIAOTONG UNIV

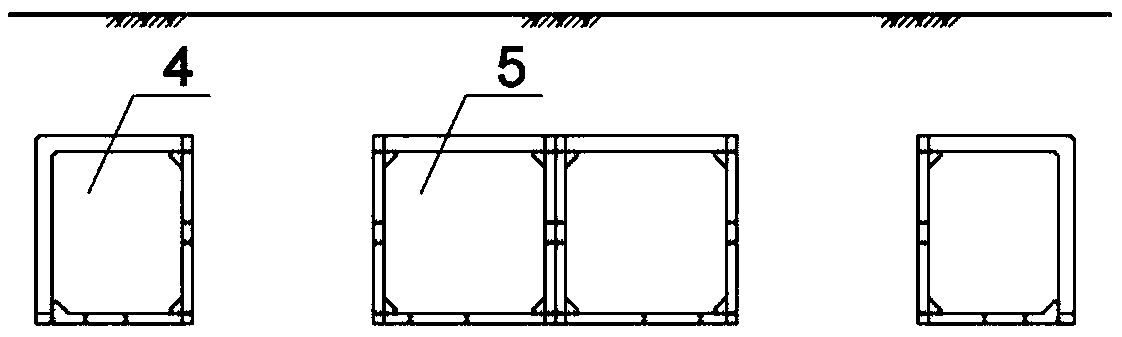

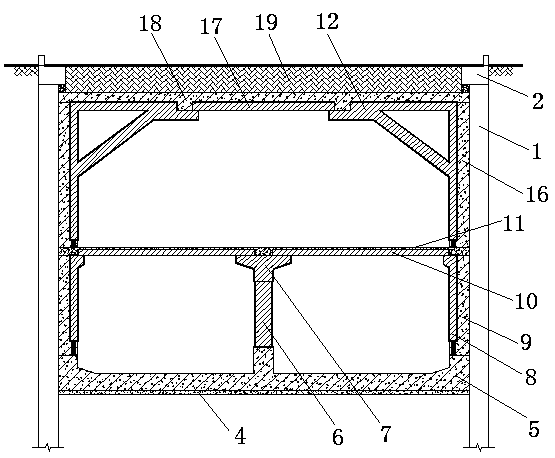

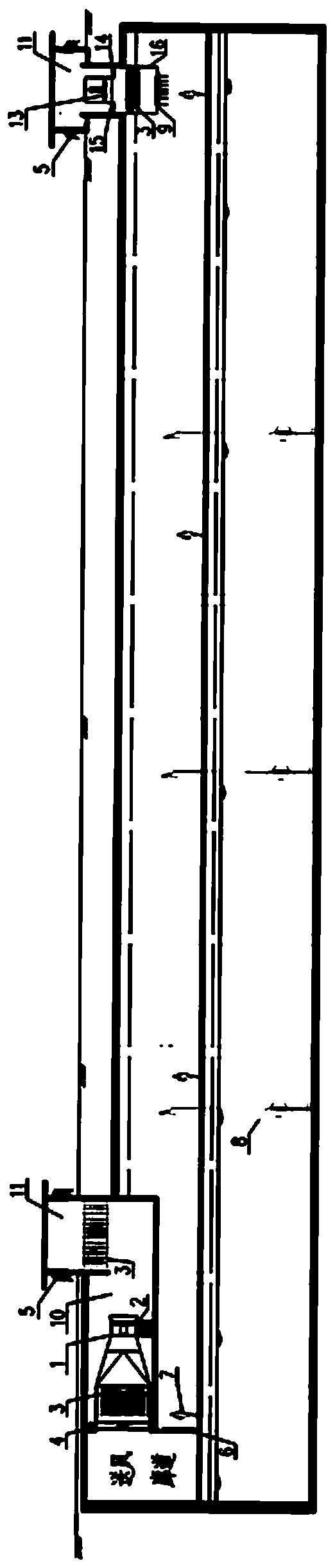

Double-layer comprehensive pipe gallery

ActiveCN107747320ASimple structureReduce construction costsArtificial islandsUnderwater structuresReclaimed waterProcess engineering

The invention relates to a double-layer comprehensive pipe gallery. A natural gas cabin, an electric cabin and a comprehensive cabin are arranged in the double-layer comprehensive pipe gallery, a natural gas pipeline can be contained in the natural gas cabin, an electric power pipeline and a communication pipeline can be contained in the electric cabin, a water supply pipeline, a reclaimed water pipeline, a heat power pipe and a communication pipeline are contained in the comprehensive cabin, and the natural gas cabin and the electric cabin are arranged above the comprehensive cabin to form adouble-layer distribution structure, and the natural gas cabin is independently arranged in a sealed manner; a function cabin is further arranged on the upper layer of the double-layer comprehensive pipe gallery, the function cabin can be communicated with the natural gas cabin, the electric cabin and the comprehensive cabin in the longitudinal direction of the double-layer comprehensive pipe gallery, and the top of the function cabin is provided with a function through opening which can be communicated with the exterior of the top of the double-layer comprehensive pipe gallery and can be sealed. The double-layer comprehensive pipe gallery is internally provided with the function cabin used for meeting the functions of hoisting, line leading and the like, the occupied space is effectivelyreduced, the structure is simple, the construction cost is low, and application and popularization are facilitated.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

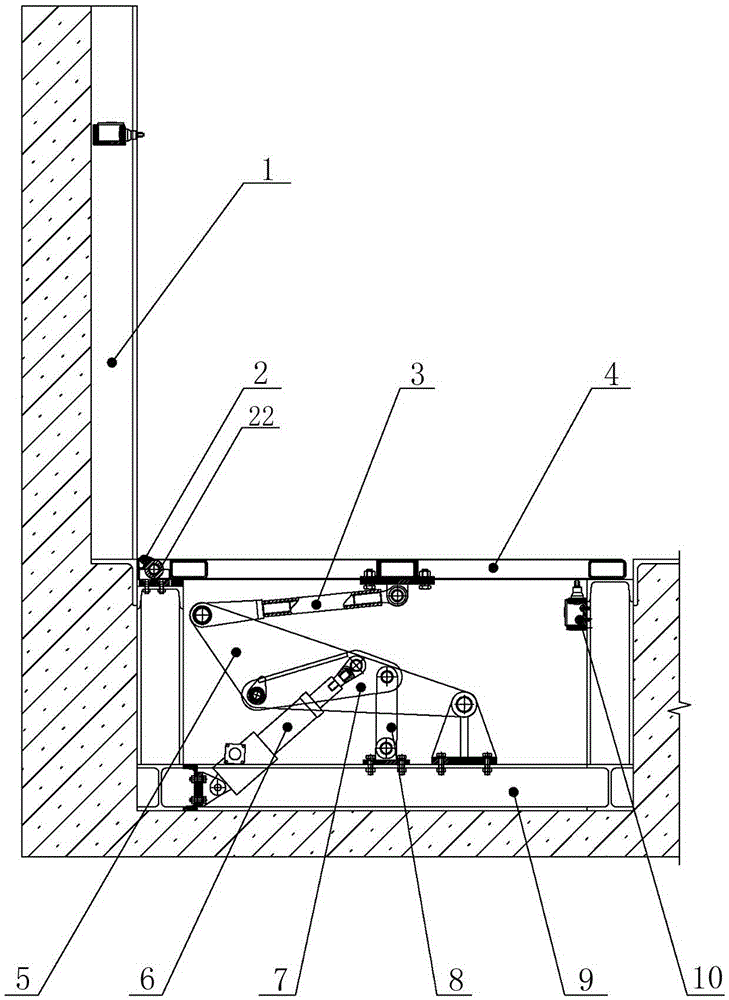

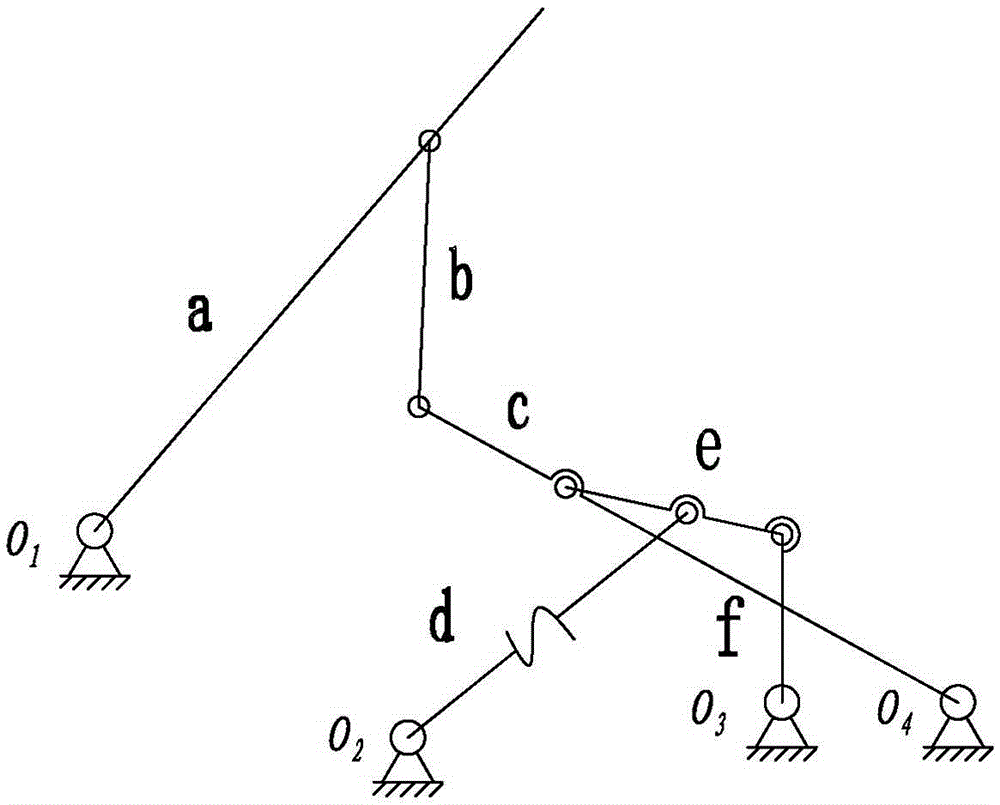

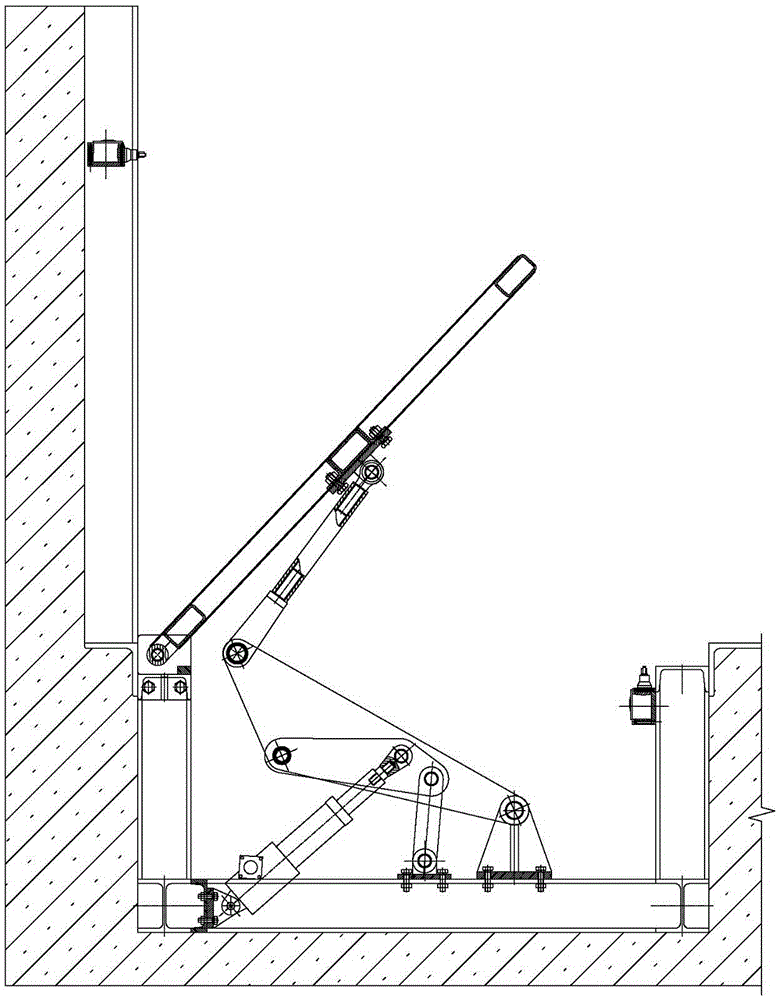

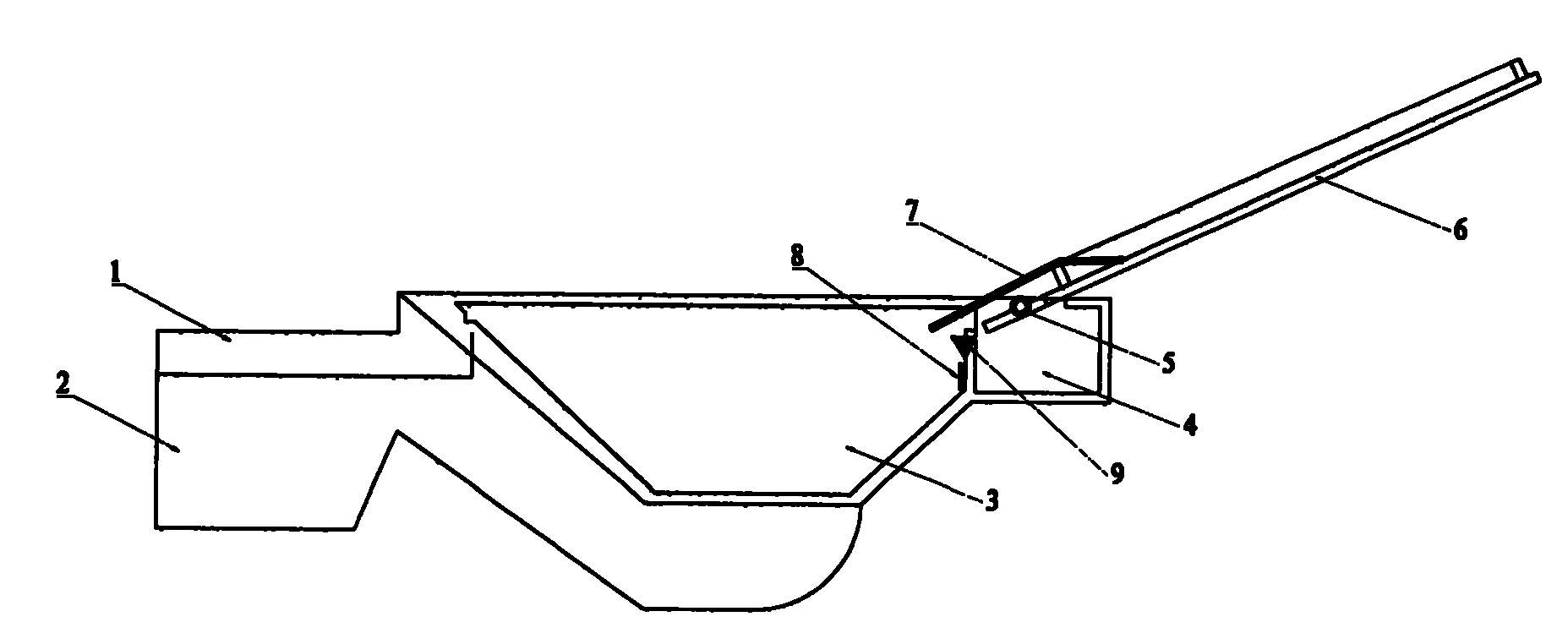

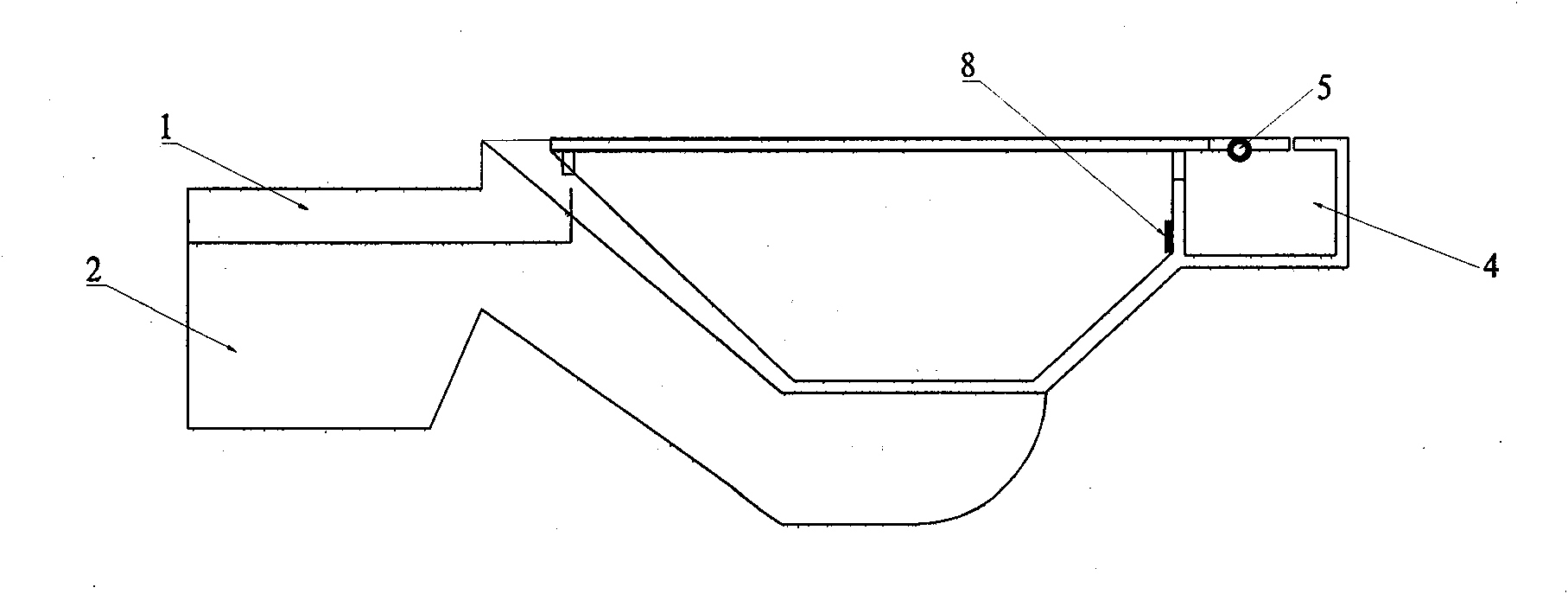

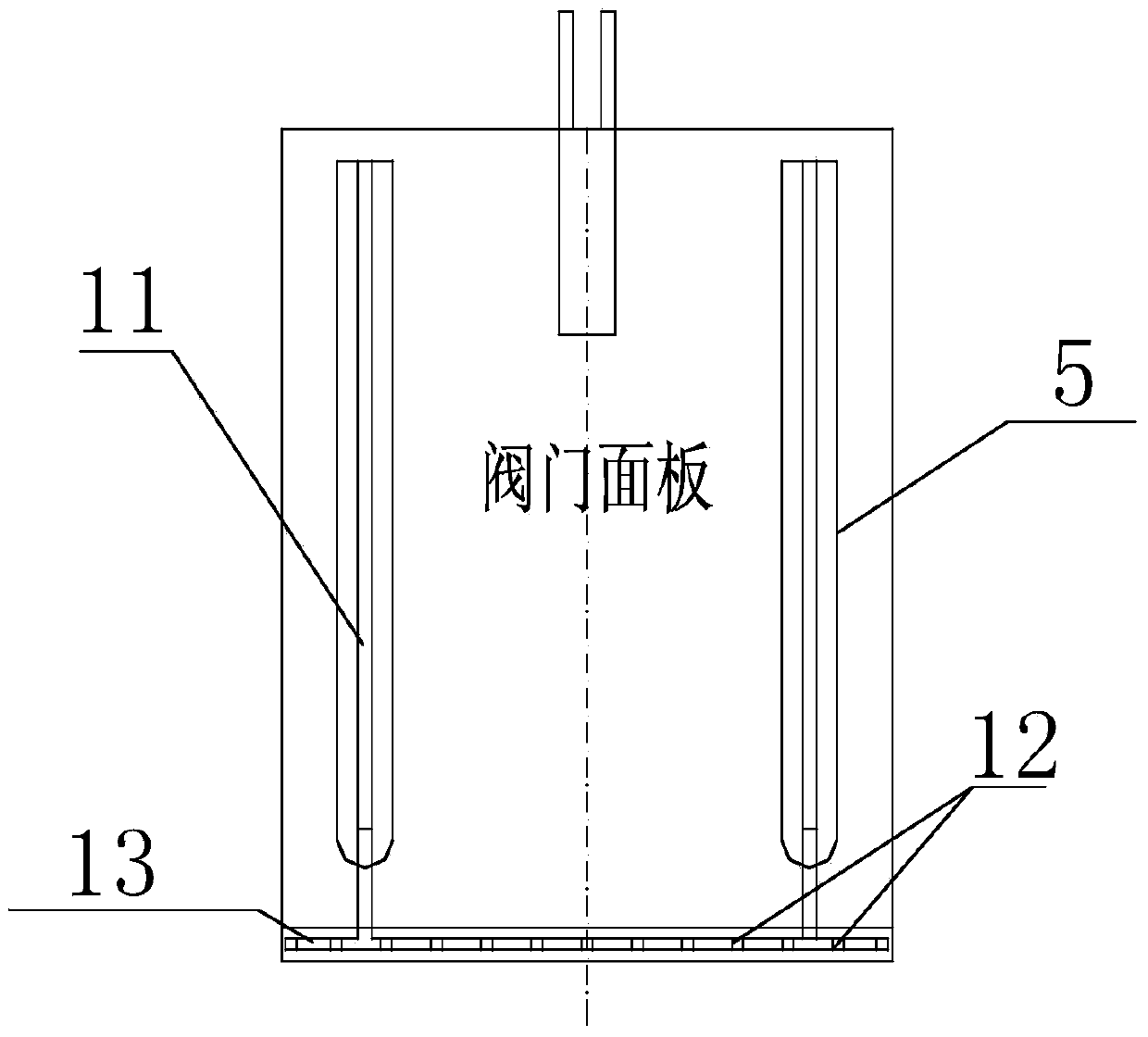

Buried turning plate type water stop gate

The invention provides a buried turning plate type water stop gate. The buried turning plate type water stop gate comprises a gate frame, a water stop gate plate, a power executing mechanism connected with the water stop gate plate, a power control system for controlling the power executing mechanism, and a sealing system and further comprises a bottom rack connected to the interior of buried space. The upper end of one side of the bottom rack is connected with a water stop gate plate door shaft. The height position of the water stop gate plate door shaft is matched with that of the upper edge of the buried space. The water stop gate plate is hinged to a door shaft seat fixed to the bottom rack through the water stop gate plate door shaft. The water stop gate plate is flush with the ground after being closed. The power executing mechanism comprises at least one set of folding type connecting rod structures connected between the water stop gate plate and the bottom rack and hidden in the buried space in a folded mode. The buried turning plate type water stop gate is good in water stop sealing performance, high in anti-hydraulic-pressure strength, reliable in structural performance, high in mechanical automation degree, high in adaptability, complete in function, convenient to maintain and small in buried depth size; the whole device is buried and hidden, so that space is saved, and labor cost is reduced.

Owner:CHINA INST OF BUILDING STANDARD DESIGN & RES

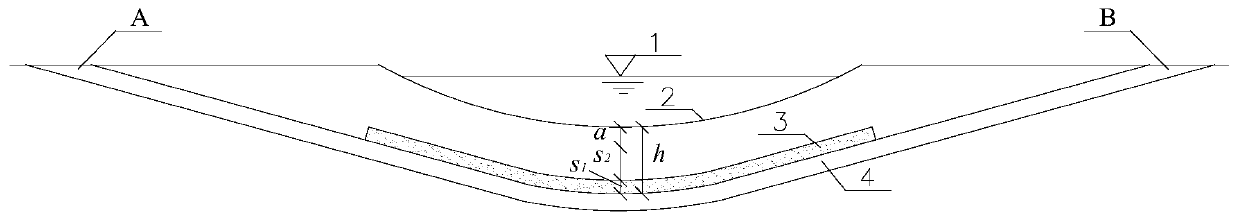

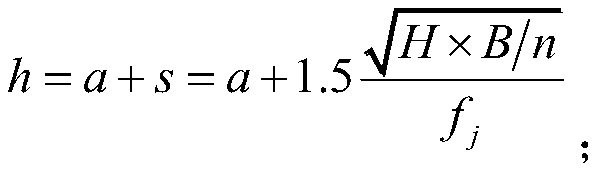

Method for determining minimum buried depth of underwater tunnel

ActiveCN107806350AShorten the lengthGive full play to the function of traffic reliefMining devicesWater seepageTunnel construction

The invention discloses a method for determining the minimum buried depth of an underwater tunnel. The method comprises the steps that the influences of a reinforcing scheme in the designing process of the underwater tunnel and a construction segment partition scheme in the construction process on the tunnel buried depth are considered; firstly, the vertical section of the tunnel is preliminarilydetermined according to the wiring conditions at the two ends of an underwater tunnel project and the route slope, then a crucial section of the tunnel is selected, the crucial section under the condition that reinforcement is conducted is calculated, and therefore the minimum buried depth of tunnel construction safety is ensured; and meanwhile the water seepage amount in the operational period after the tunnel is reinforced is calculated, and when the water seepage amount obtained through calculation is smaller than a water seepage amount control standard in the tunnel operational period, thedetermined buried depth is the minimum buried depth of the tunnel. When the minimum buried depth of the tunnel is determined, all crucial sections of the whole tunnel all need to meet the requirements of the minimum buried depth, and the method can further appropriately reduce the project construction cost under the premise that the tunnel construction safety is ensured.

Owner:CENT SOUTH UNIV

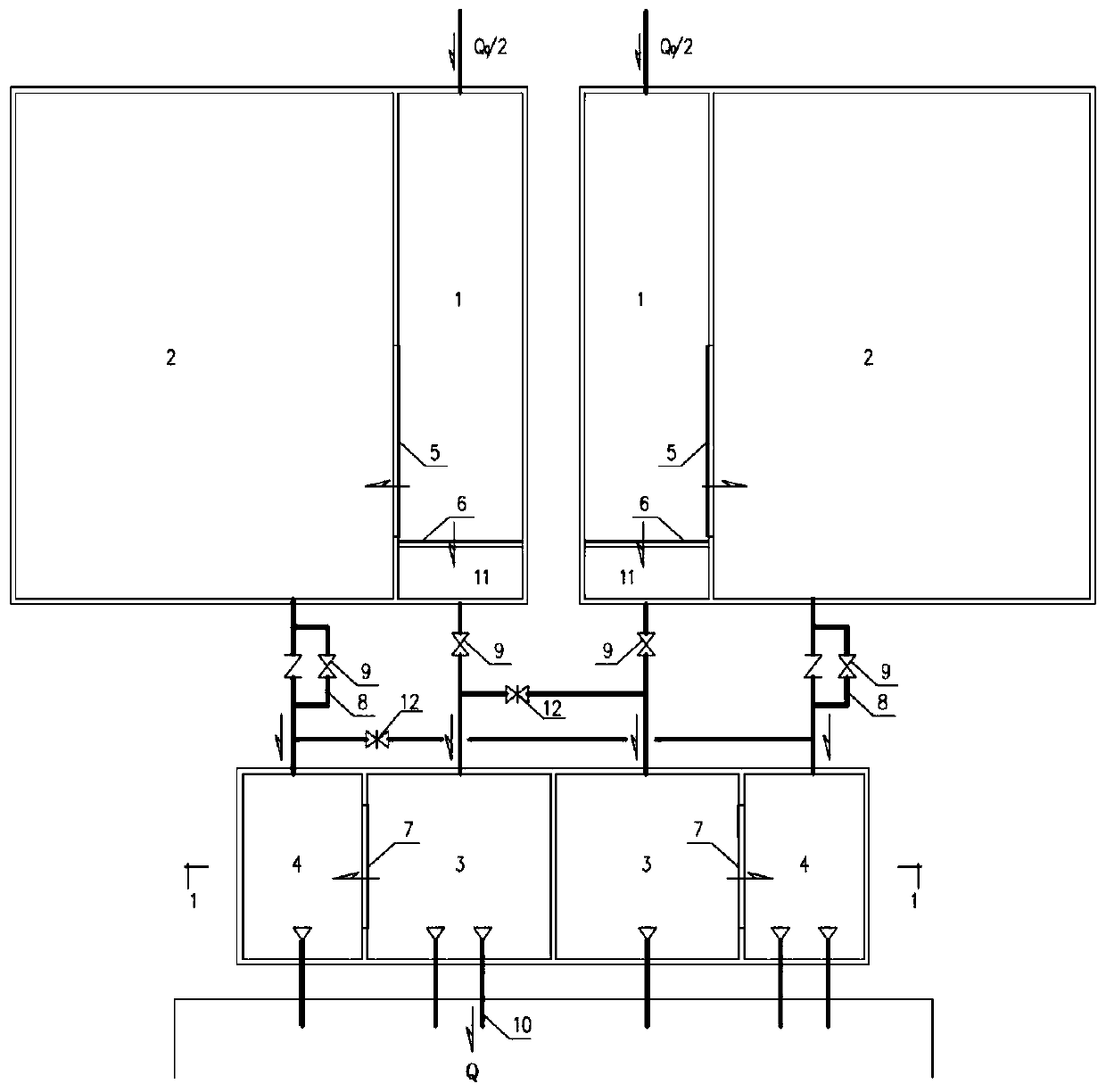

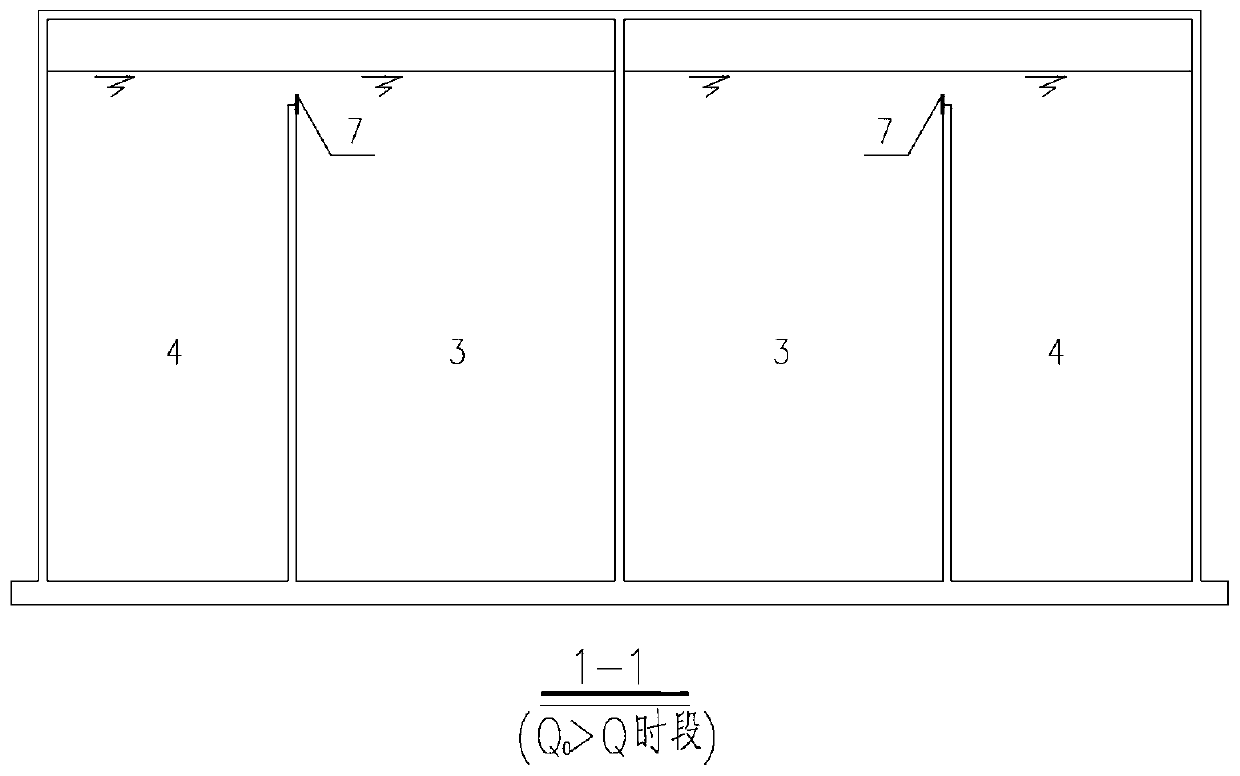

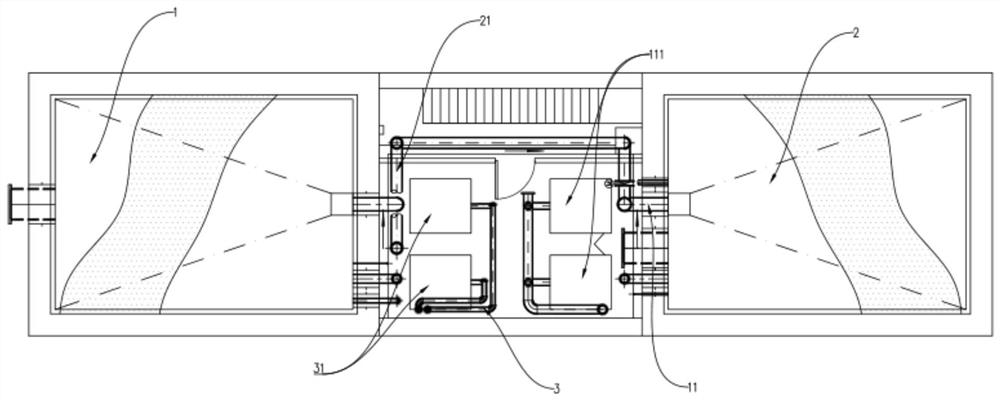

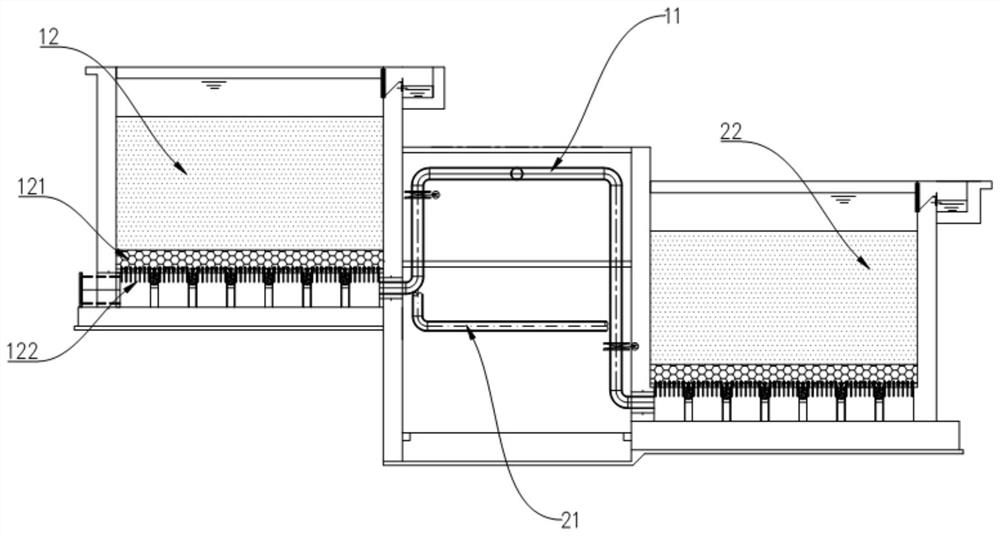

Clean water tank suction well system and use method thereof

PendingCN109944301AReduce the amount of waterAvoid or reduce energy wasteWater supply tanksPumping plantsBackflow prevention deviceEngineering

The invention discloses a clean water tank water suction well system and a using method thereof. The clean water tank water suction well system comprises a chlorine adding contact tank, a clean watertank, a main water suction well, an auxiliary water suction well, an anti-backflow device, a flow regulating valve and a water pump water suction pipe, wherein the chlorine adding contact tank is communicated with the clean water tank through a high weir; the chlorine adding contact tank is communicated with the main water suction well through a low weir I; the outlet well is communicated with themain suction well through a pipeline and the flow is regulated through a flow regulating valve, the main suction well is communicated with the auxiliary suction well through the low weir II, the highweir, the low weir I and the low weir II are sequentially arranged from high to low, the clean water tank is communicated with the auxiliary suction well through a backflow prevention device to supply water for the auxiliary suction well, and the main suction well and the auxiliary suction well are respectively externally connected with a plurality of water pump suction pipes to supply water forthe city. According to the clean water tank suction well system and the use method thereof, the energy consumption is saved, the chlorination disinfection effect is improved, the high-water-level self-irrigation starting is realized under the condition that a vacuum pump is not arranged, the operation management is convenient, the construction cost is reduced, the ventilation condition of a pump room is improved, and the personnel patrol is more convenient.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST

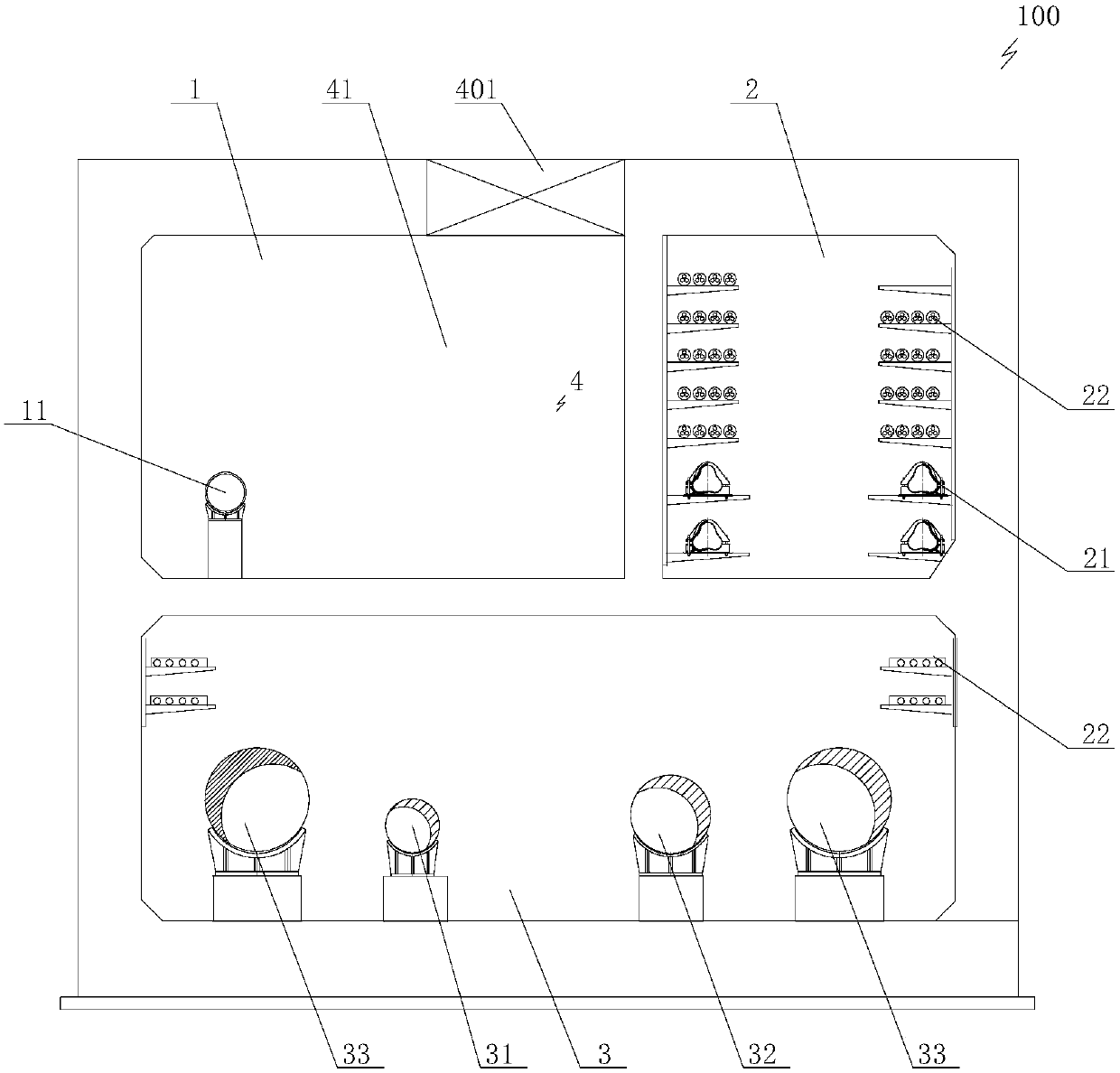

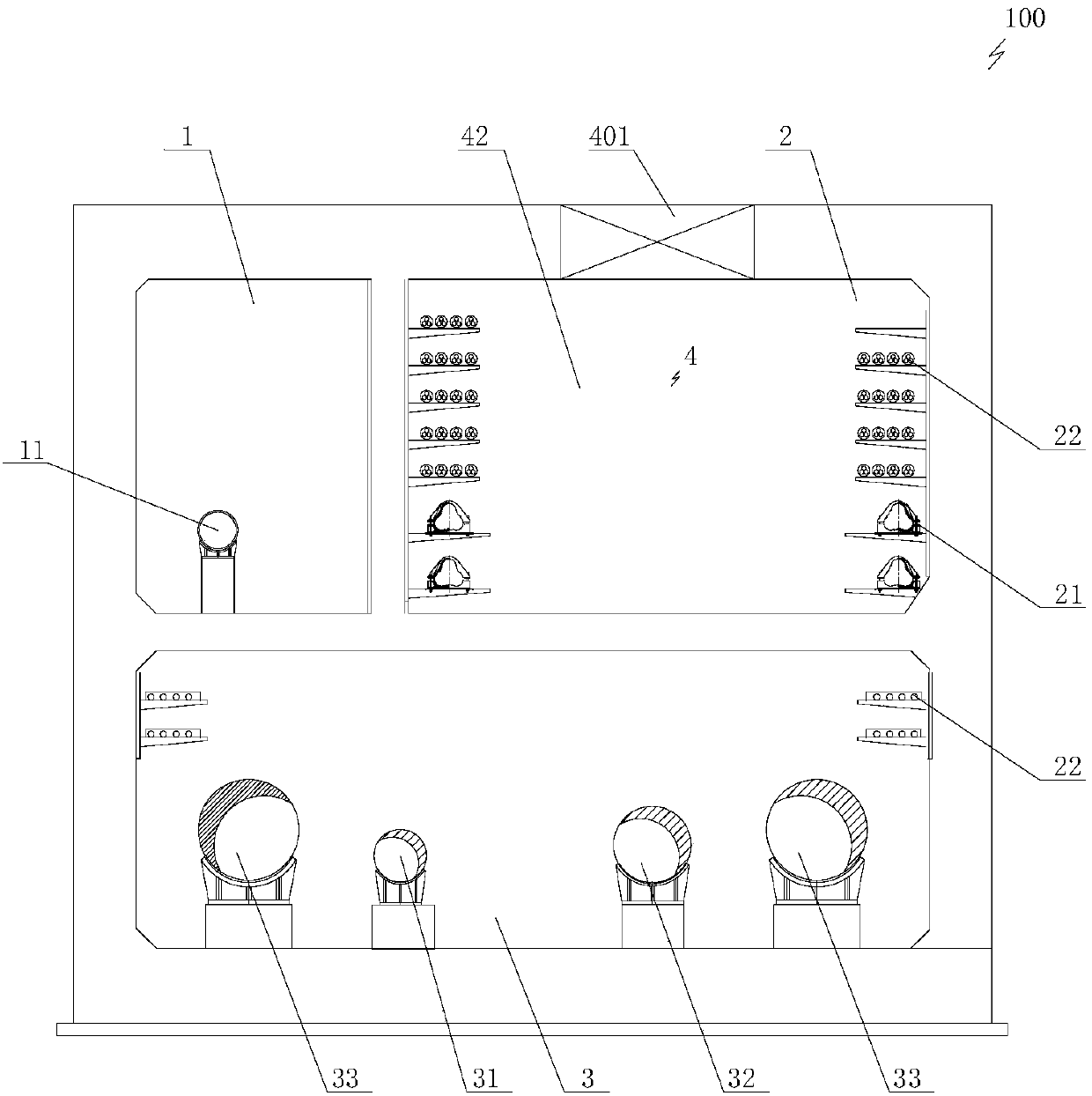

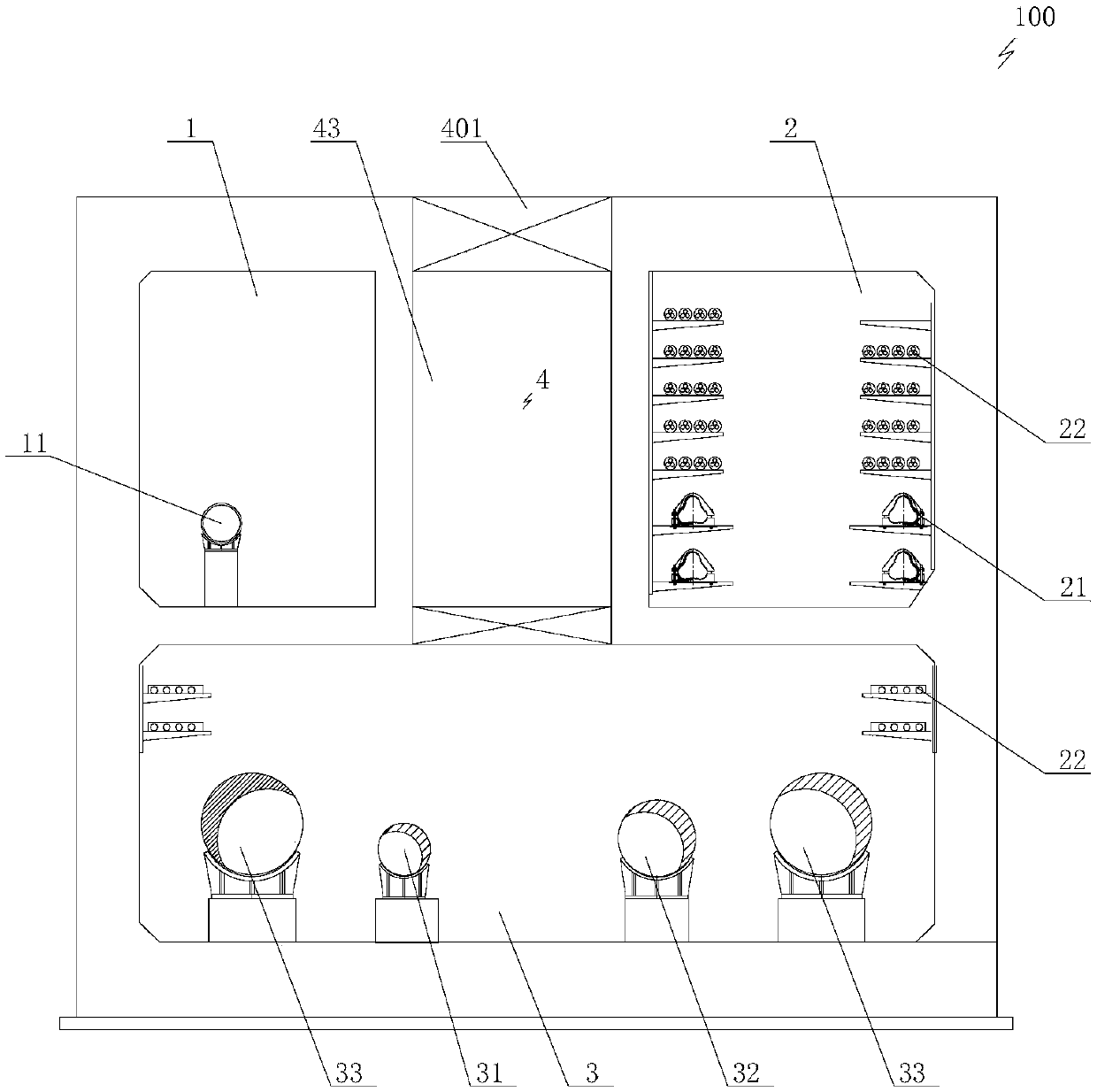

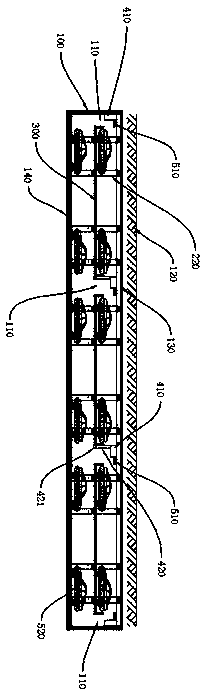

Multiple parking garage

ActiveCN111379451AReduce dosageLow construction costVertical ductsParkingsParking spaceStructural engineering

The invention discloses a multiple parking garage which includes a first laminating layer and at least one layer of a second laminating layer. The first laminating layer is located on the uppermost layer of a garage body, and the second laminating layer is located below the first laminating layer; a ramp between the first laminating layer and the second laminating layer is used for driving through; the entire parking garage body is enclosed by external walls, each adjacent upper and lower laminating layer are divided by laminated plates, the bottommost of the parking garage body is a bottom plate, the topmost of the parking garage body is a top plate, and the top plate, the laminated plates and the bottom plate are supported by vertical columns in turn; parking spaces and driving-through lanes are arranged on the laminated plates and the bottom plate correspondingly; and at least one void is formed in each laminated plate, vertical wind and smoke pipes are installed in the void, wind openings and smoke openings are formed in the positions, located at the lower edges of the laminated plates, of the vertical wind and smoke pipes correspondingly, and the ends, located on the first laminating layer, of the vertical wind and smoke pipes communicates with horizontal wind and smoke pipes. The floor height of the parking space is reduced, void space is additionally arranged, pipeline layout is facilitated, and vertical space is reduced or not occupied; and ventilation and smoke exhaust are realized through the void, the cost can be greatly saved.

Owner:上海博普建筑技术有限公司

Folding squatting pan

The invention relates to a folding squatting pan. The folding squatting pan mainly comprises a base and a cover, wherein the base is only provided with a defecating pool; the cover is a urinating pit; the squatting pan is perfect after the cover is opened; and the cover seems disappeared on the ground. Therefore, the folding squatting pan is safe, sanitary, odorless and occupies a small number of spaces. Compared with the conventional squatting pan, the squatting pan has the advantages of smaller upper surface area, low depth and easy assembly. A sealing rubber strip is arranged between the base and the cover, so that even more flush water cannot overflow, water is saved and blockage is prevented. The cover can be provided with a mirror, a lamp and a flushing nozzle, so that the folding squatting pan is more economized, sanitary and healthy.

Owner:戴鹏辉

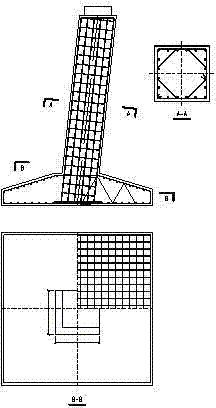

Composite foundation for collapsible loess region and construction method

PendingCN110820793AImprove construction efficiencyReduce the use of manpowerProtective foundationBulkheads/pilesGeotechnical engineeringStructural engineering

The invention discloses a composite foundation for a collapsible loess region and a construction method. The composite foundation for the collapsible loess region comprises a slab foundation and screwanchors buried underground, wherein the slab foundation comprises a main column, a step and a bottom plate arranged sequentially in the vertical direction; the screw anchors are vertically arranged and connected with the slab foundation; multiple concrete piles are connected onto the bottom surface of the bottom plate and are vertically arranged along a bottom surface edge of the bottom plate; one ends of the concrete piles are connected with the bottom plate; the other ends of the concrete piles downwards extend into a soil body; and the concrete piles are matched with the screw anchors through resistance so as to constrain the offset settlement of the slab foundation. Under the slab foundation, the concrete piles are arranged on four corners of the bottom plate, and the concrete pile foundations and non-collapsible soil under collapsible loess form frictional resistance so as to apply a constraining force to the circumference of the slab foundation, so that the effects on maintaining the overall foundation stability and preventing the foundation from being subjected to offset settlement after the soil body on the upper part touches water are achieved, and the composite foundation is ensured to be stably used at the collapsible loess region.

Owner:SHANDONG JIANZHU UNIV

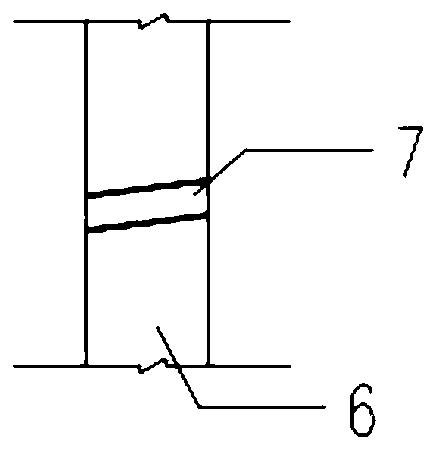

Construction method for achieving underground excavation and reverse operation by utilizing combined pipe jacking

ActiveCN109505611AReduce buried depthImprove space utilizationClimate change adaptationTunnelsSupporting systemLine tubing

The invention discloses a construction method for achieving underground excavation and reverse operation by utilizing combined pipe jacking. An open-cut method is adopted to excavate a pipe-jacking starting well and a pipe-jacking receiving well at the end of a station; the pipe-jacking starting well is utilized as a pipe-jacking construction operation space, a pipe-jacking machine and matched facilities are installed, and the rectangular pipe-jacking machine is adopted to execute successive jacking construction; the operation space provided by middle and side span pipe-jacking structures is utilized to sequentially remove side span pipe-jacking structure bottom steel pipe joints and middle span pipe-jacking structure bottom steel pipe joints, and vertical supporting systems such as a station surrounding structure and steel pipe posts are constructed; temporary supports are erected, part of a top plate structure of the station is constructed, and side span pipe-jacking structure side steel pipe joints and middle span pipe-jacking structure side steel pipe joints in adjacent pipe-jacking structures are sequentially removed; after the top plate structure reaches the designed strength, pipe-jacking structure bottom residual steel pipe joints are sequentially removed under the effect of a top plate shed, and an underground excavation and reverse operation method is adopted to excavate and construct structures such as side walls, middle plates and base plates of the station. The construction method can have the advantages that ultra-shallow earthing underground excavation construction can be achieved, the influence on ground traffic, ambient environment and underground pipelines is avoided, the top layer space utilization rate of the station is improved, the construction cost is reduced, the construction efficiency is high, and the construction risk is low.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD

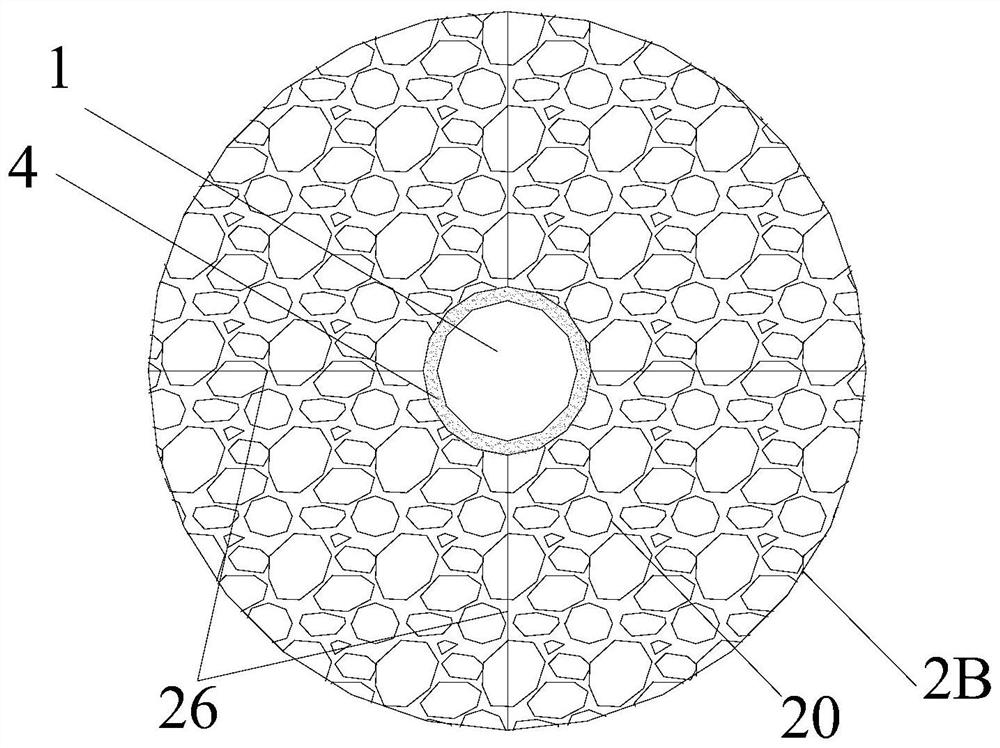

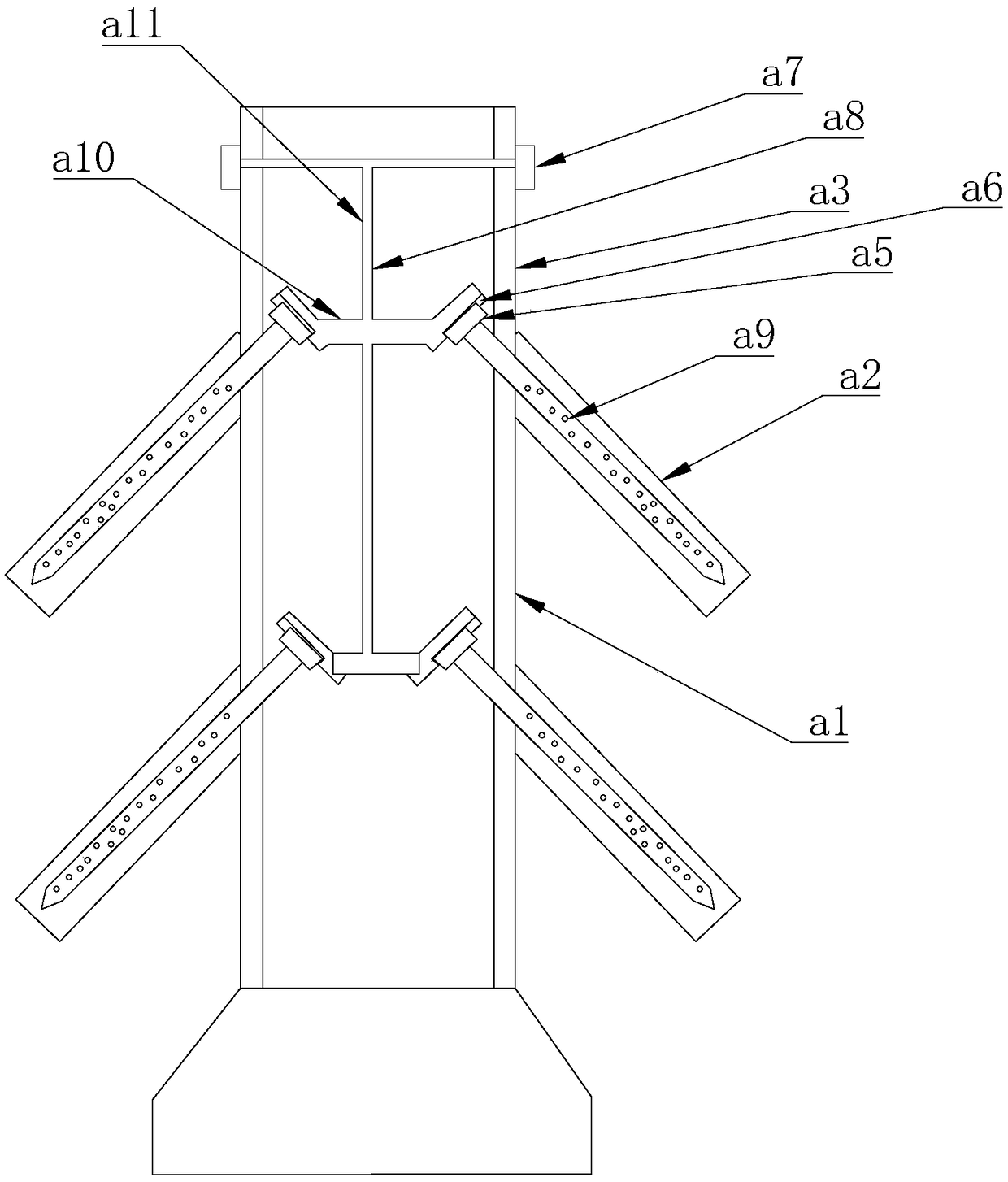

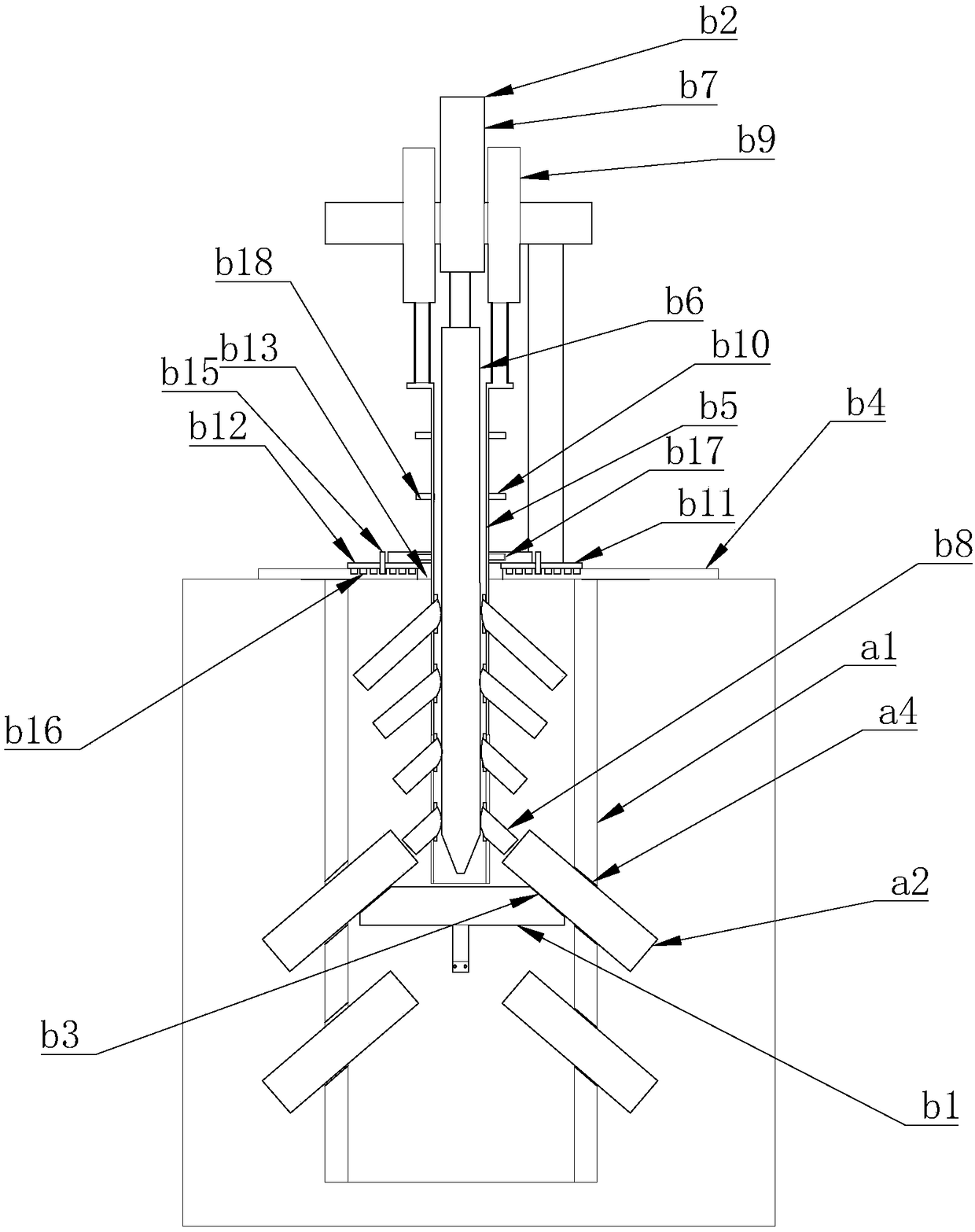

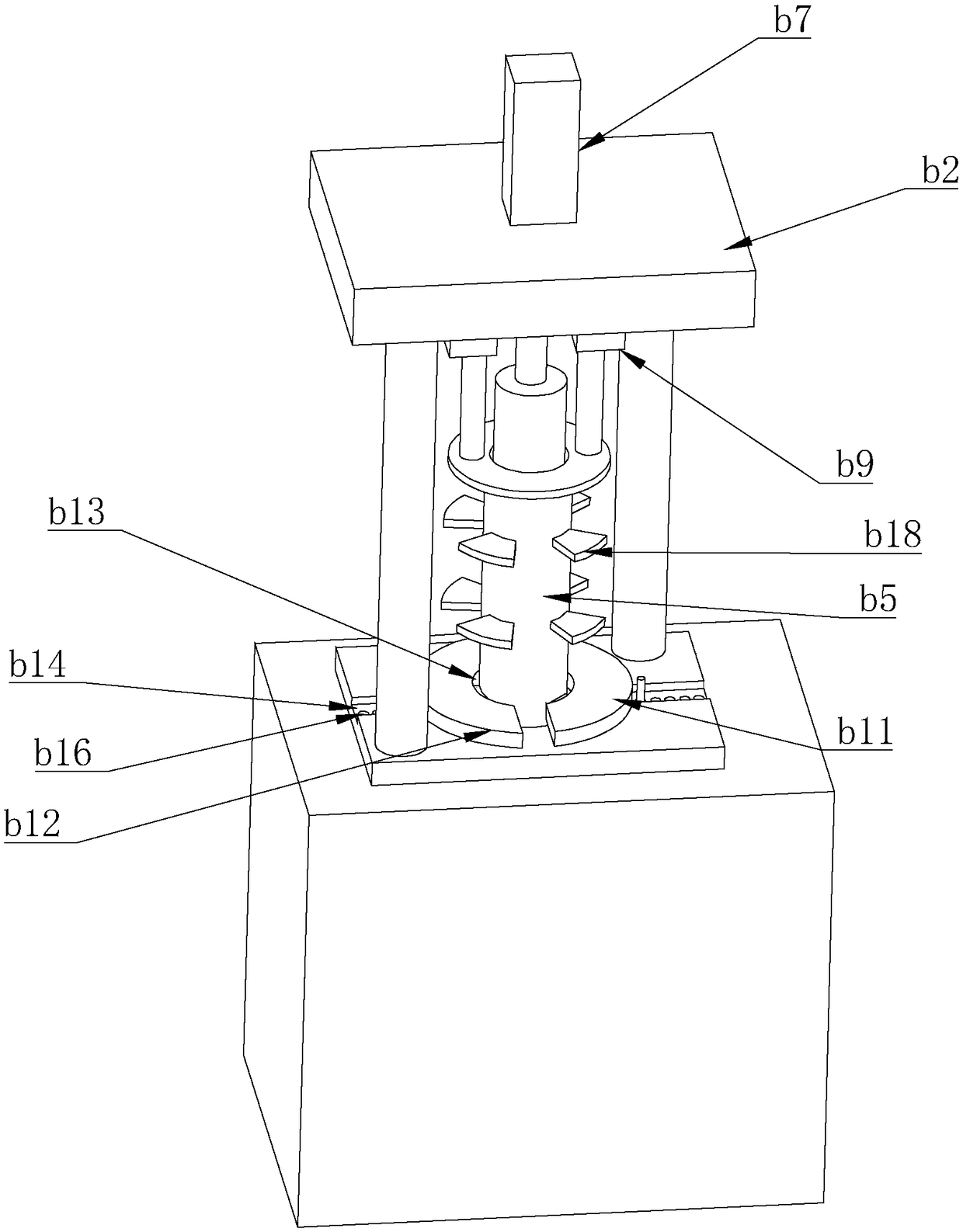

Lateral tree root hole digging pile and installation equipment thereof

PendingCN109487811AImprove the state of stressUniform and stable forceConnection contact member materialBulkheads/pilesElectrical resistance and conductanceTree root

The invention relates to a lateral tree root hole digging pile and installation equipment thereof. A plurality of tree root piles are driven into a ground pile foundation along a hole wall to form alateral tree root hole digging pile composite grounding foundation, and the tree root piles and the ground pile foundation are poured into an integral foundation. The lateral tree root piles can actively bear vertical and horizontal loads, the buried depth and pore size of an intermediate concrete foundation are effectively reduced, the stress state is improved, the engineering quantity is reduced,and meanwhile, the earthwork quantity of a foundation pit and the influence on the surrounding environment are reduced; economy and environmental protection are achieved, wiring terminals are arrangedat the ends, extending into a cement shell, of the tree root piles, and grounding terminals are arranged on the parts, exposing out of the ground, of the tree root foundation; the grounding terminalsare used for connecting grounding downleads, a grounding net which enables the grounding terminals to be connected with the tree root pile terminals is arranged on the tree root foundation, the treeroot piles serve as grounding electrodes, and effective grounding resistance of a whole tower is reduced to 5 omega by combining the multiple grounding electrodes in parallel to form a unified grounding module; and meanwhile, the concrete characteristics improve the corrosion resistance and structural strength of the grounding electrodes, and the maintenance cost of a grounding device is reduced.

Owner:WENZHOU ELECTRIC POWER DESIGN +1

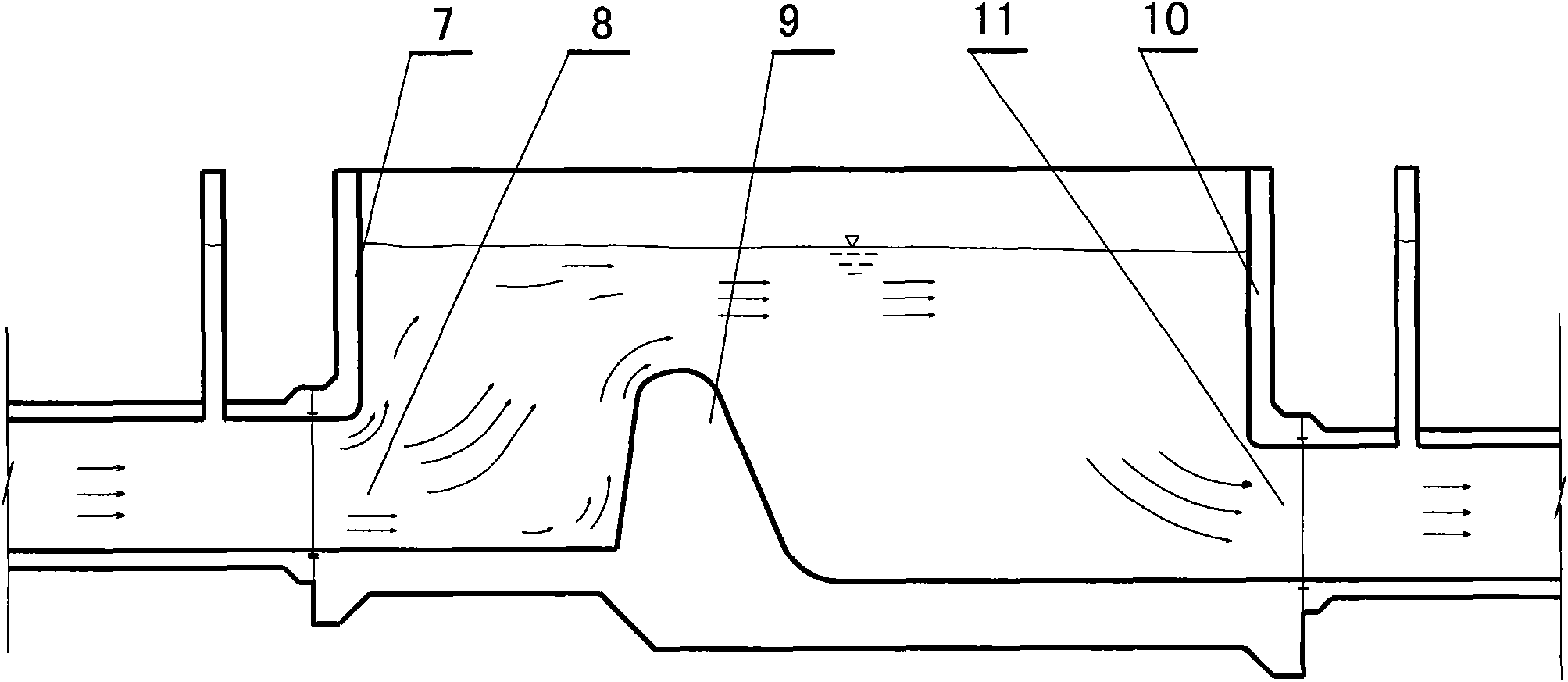

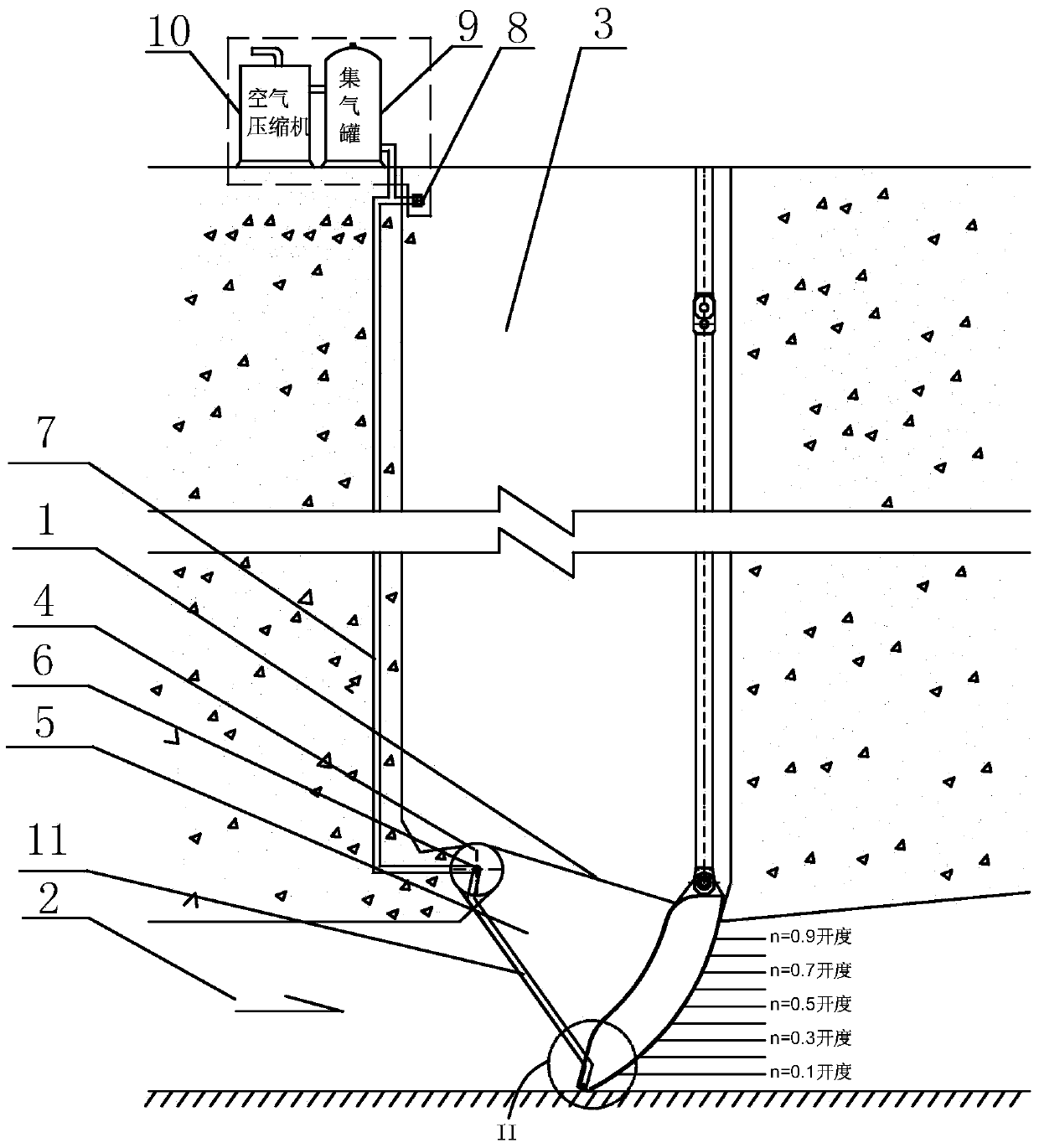

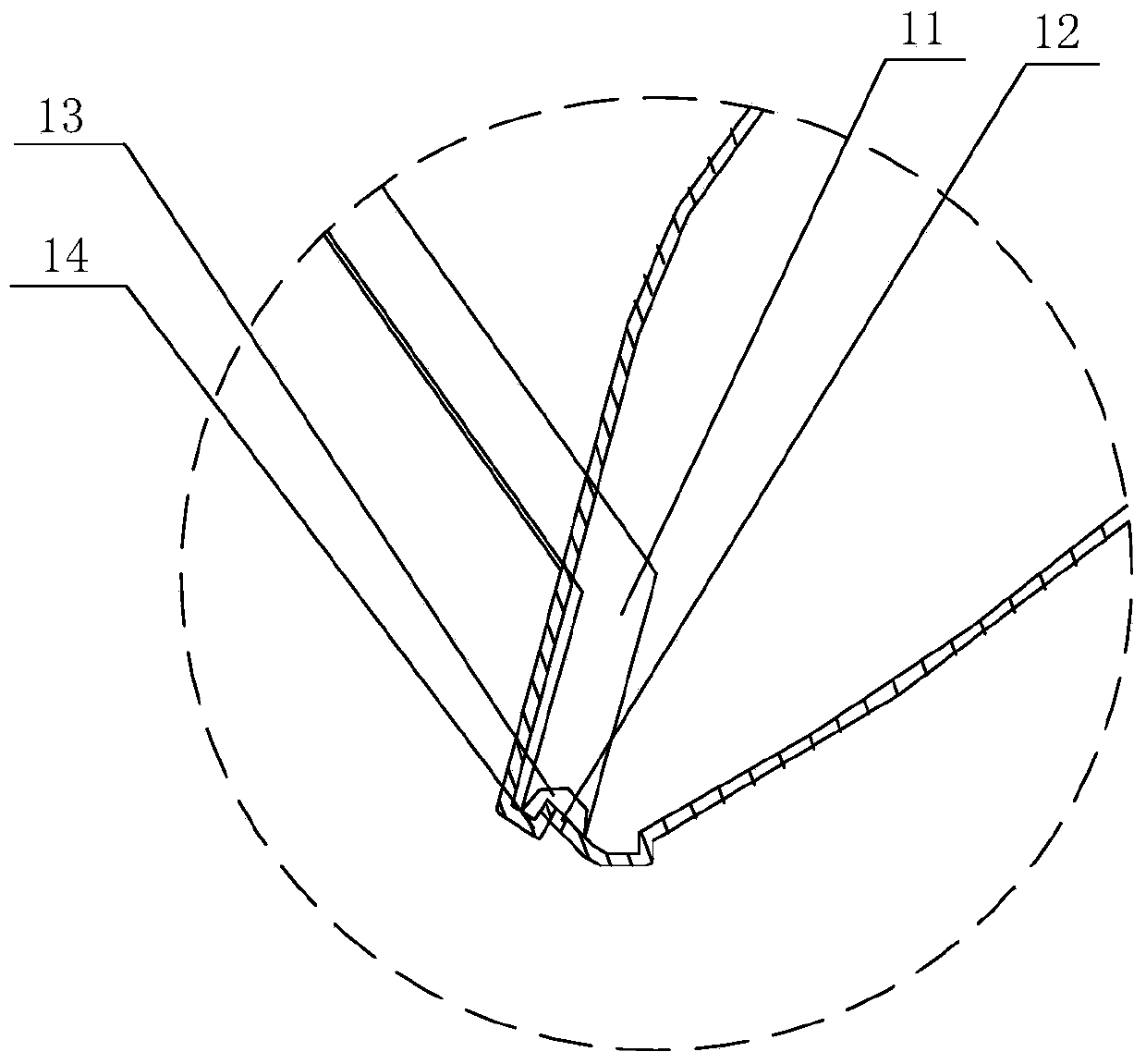

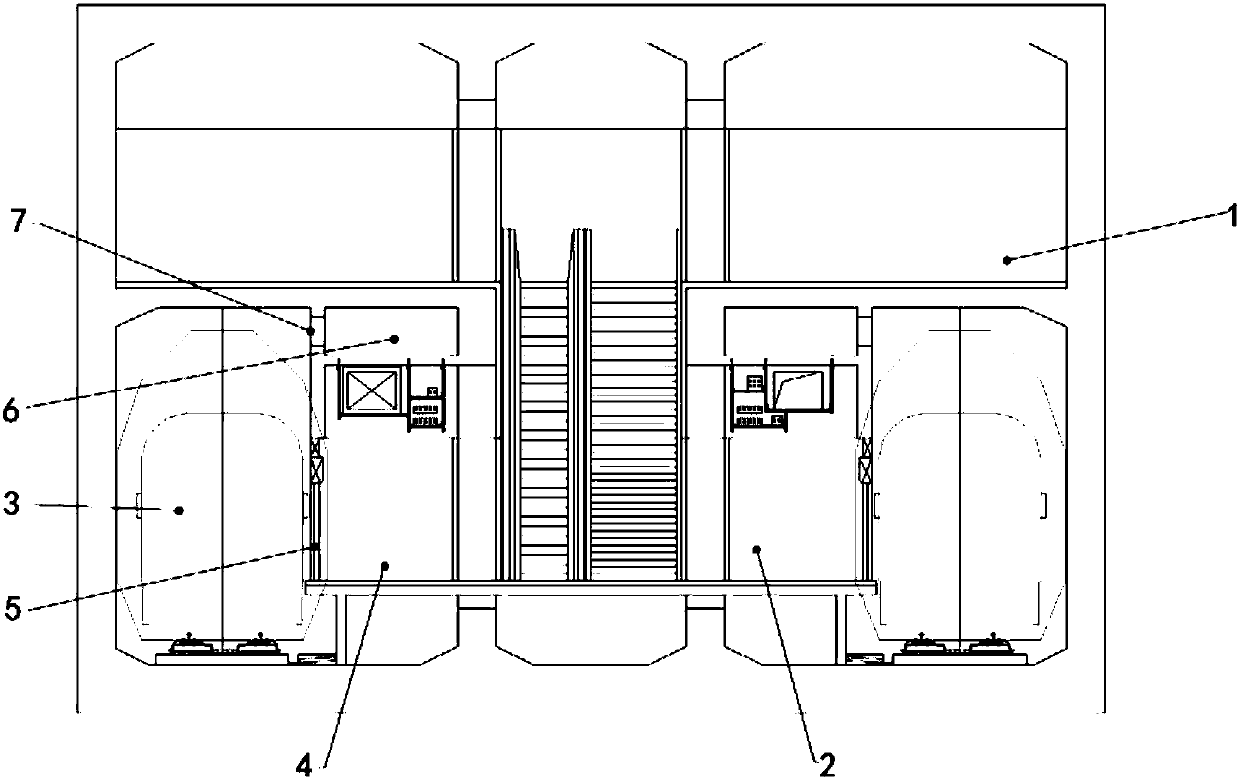

Bottom edge aerification system of water delivery valve of high lift lock

ActiveCN103758099AImprove water flow cavitation problemLow operating and management costsBarrages/weirsDry-docksWater flowHigh lift

The invention provides a bottom edge aerification system of a water delivery valve of a high lift lock. The bottom edge aerification system comprises a water delivery valve, a water gallery, a first vent pipe, a rotary joint and a second vent pipe. The water delivery valve adopts a slot-free anti-arc valve, and comprises a valve support hinge, a valve panel, and a valve support arm connecting the valve support hinge and the valve panel. The first vent pipe is buried in concrete when a valve chamber is poured, and an inlet end of the first vent pipe is positioned at the top of the valve chamber and connected with atmosphere. The second vent pipe communicated with the outside is led out of the bottom edge of the water delivery valve, and enters the valve support hinge along the valve support arm, and the rotary joint connecting the first vent pipe to the second vent pipe is arranged at the valve support hinge. The system can improve a water flow cavitation problem of a valve section of the lock, avoids cavitation erosion damage, can improve the operational safety of the lock, reduce the burial depth of the valve section and simplify a gallery body of the valve section, avoids a new cavitation source formed due to the excessively complicated body of the valve section, and can reduce the construction difficulty and construction cost of the gallery of the valve section.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Novel cross section pipeline integration and platform layer height design of intercity railway underground station

PendingCN107745714ASave installation spaceReduce buried depthRailway componentsRailway stationMechanical engineeringElectrical and Electronics engineering

The invention discloses a novel cross section pipeline integration and platform layer height design of an intercity railway underground station. The novel cross section pipeline integration and platform layer height design of the intercity railway underground station comprises a station hall layer. A platform layer is arranged below the station hall layer. Stairs are arranged between the platformlayer and the station hall layer. A rail top air duct is arranged above the platform floor. According to the novel cross section pipeline integration and platform layer height design of the intercityrailway underground station, the height of the platform floor of the station is decreased to 6.3m from 7.2m, thus the height of the station main structure is decreased by 900mm, the buried depths of the station fender and the main structure are reduced, the load of the large-scale system of the environmental control equipment is decreased by 25%, and the elevation height of the escalator of the inbound-outbound building is decreased by 900mm.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

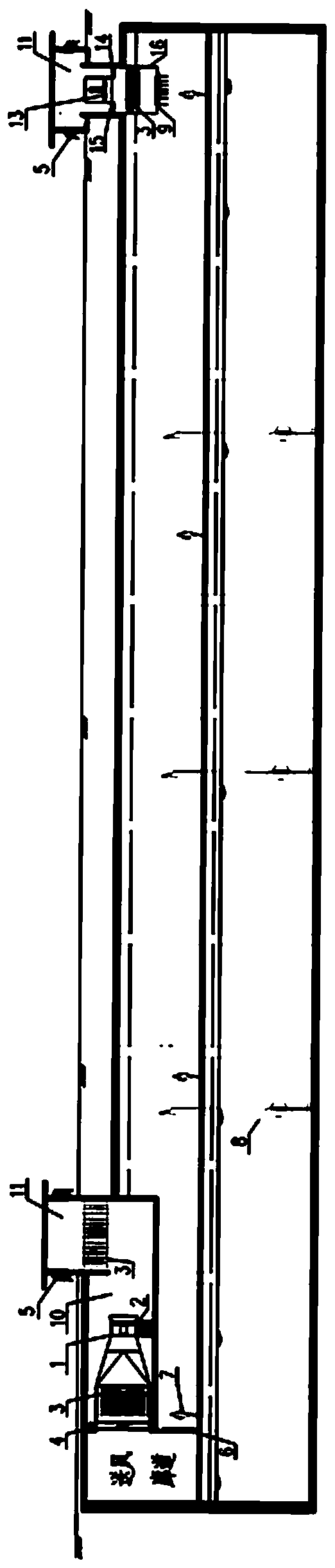

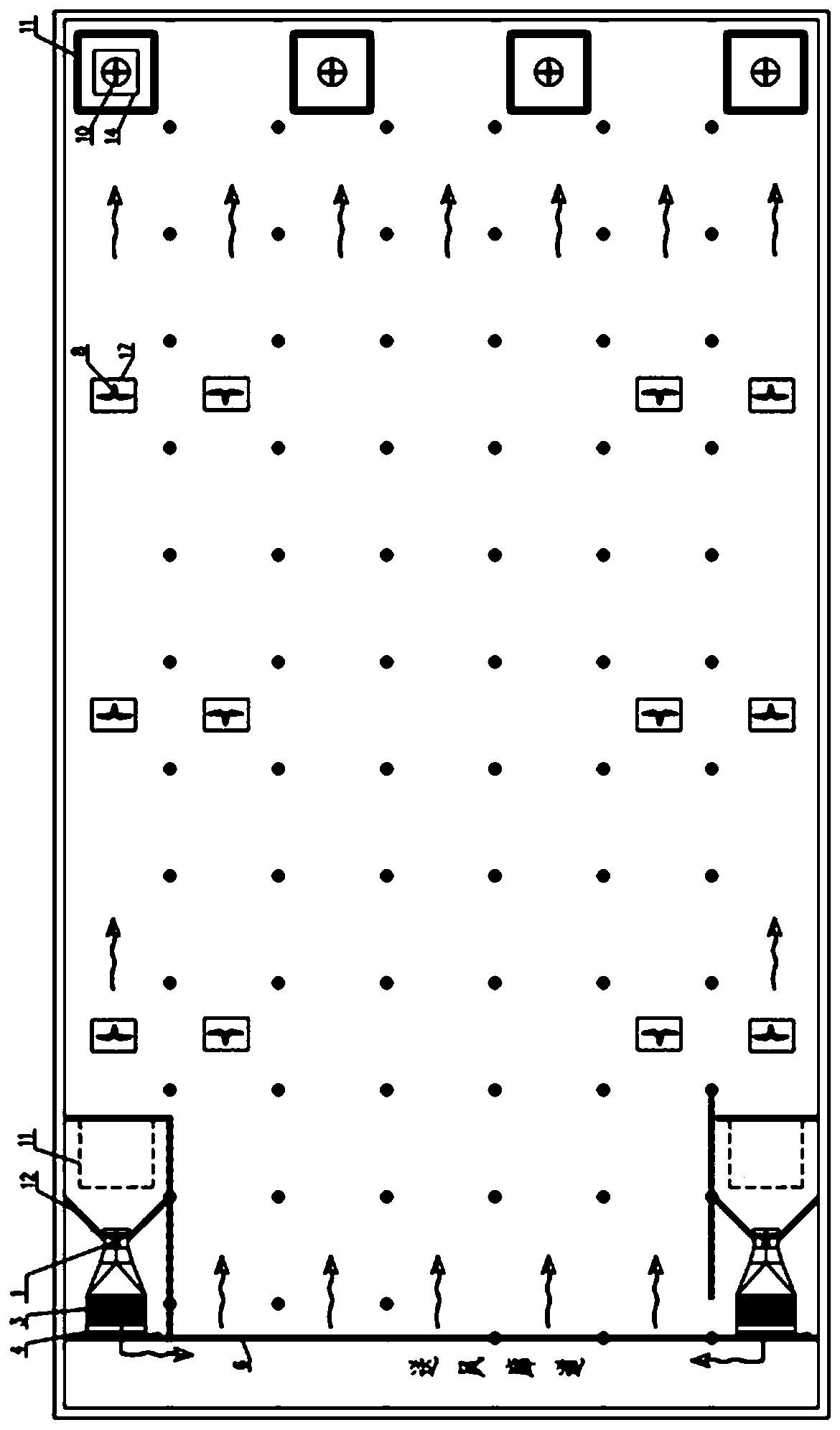

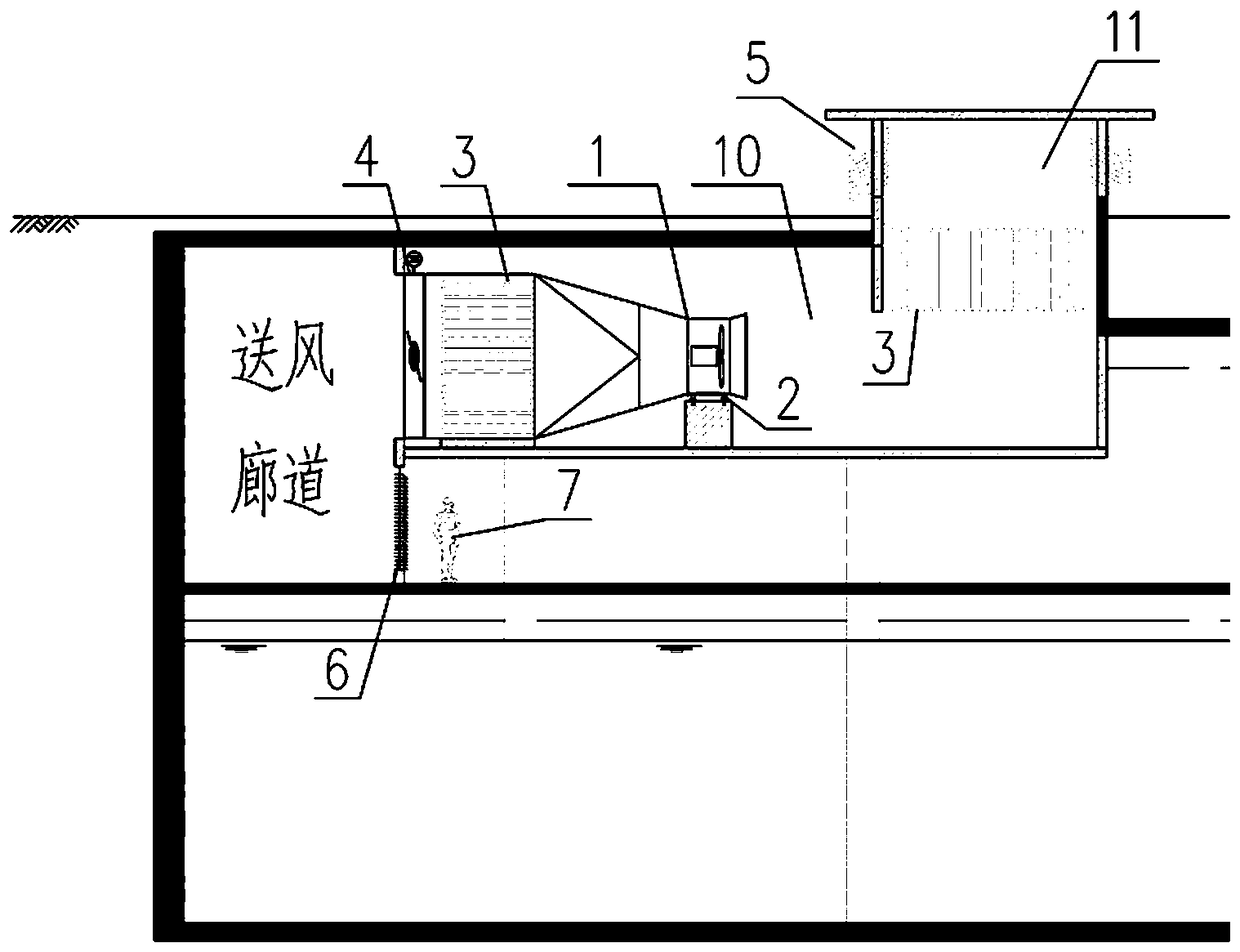

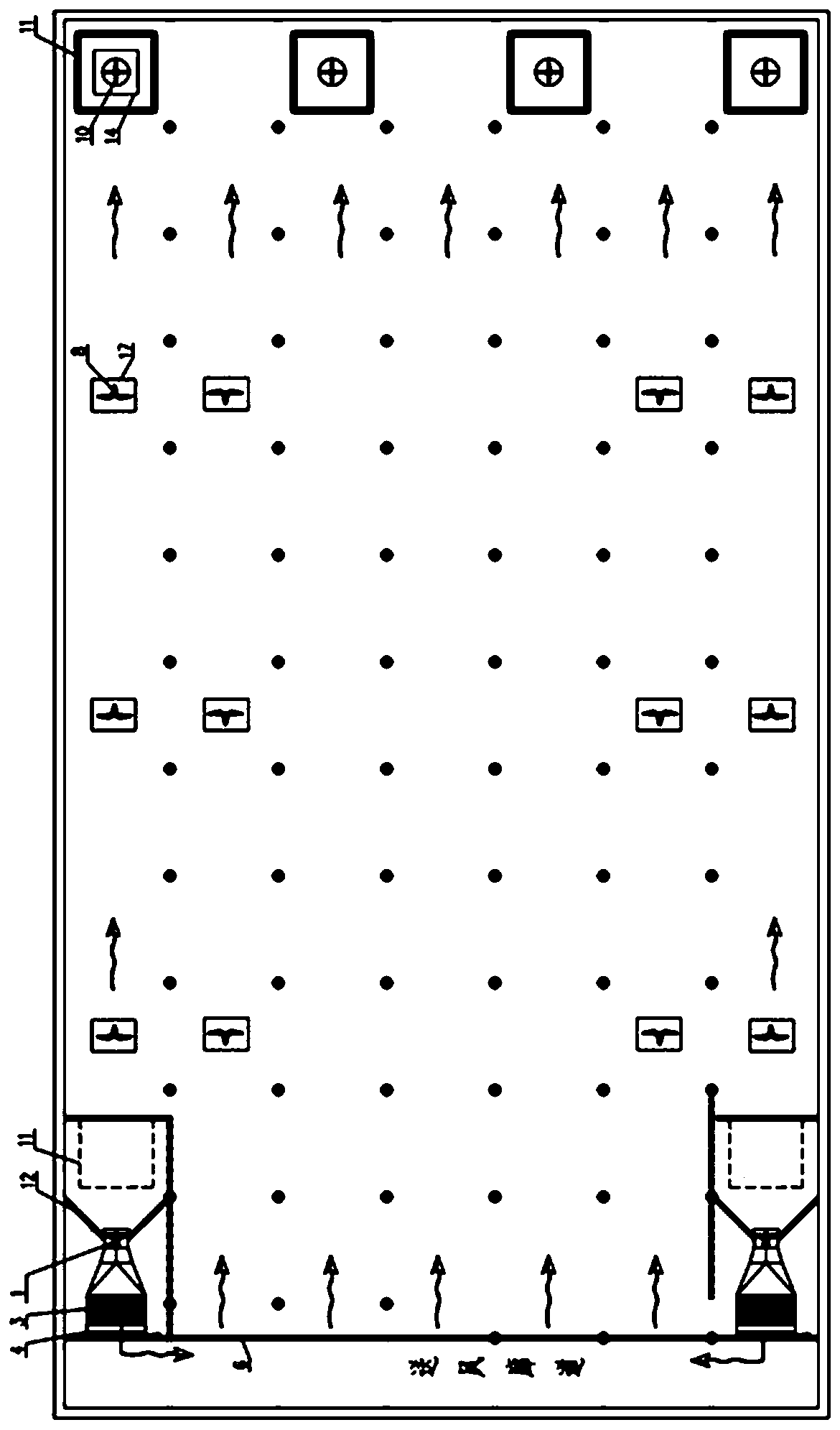

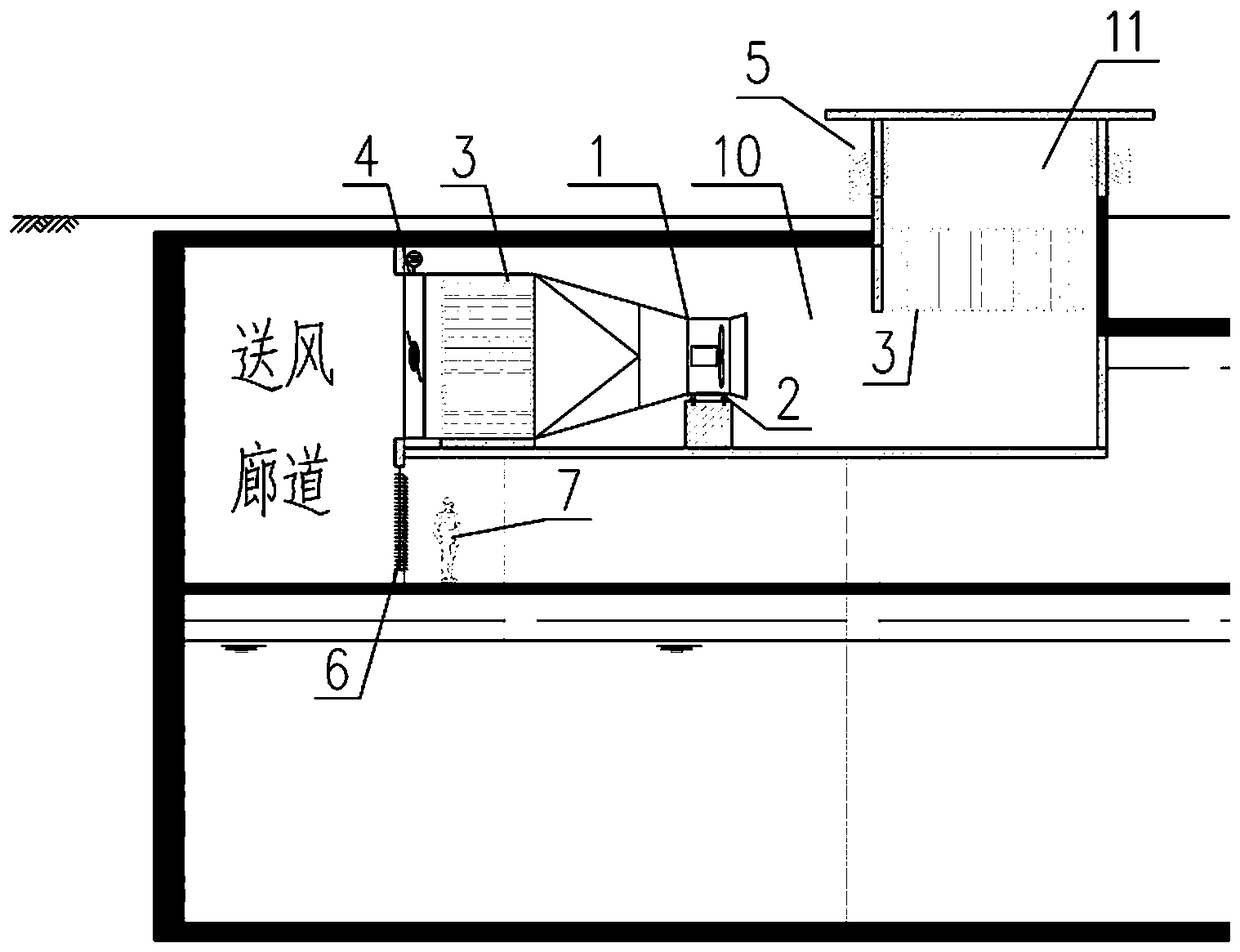

Ductless ventilation method for underground water treatment structure

PendingCN109440910AReduce buried depthReduce running noiseSewerage structuresSewage treatmentMuffler

The invention discloses a ductless ventilation method for an underground water treatment structure. The method includes the following steps that after an air supply fan is turned on, outdoor fresh airenters an air supply well; the fresh air enters the air supply well after passing through an array muffler located in the air supply well; after being pressurized with a pressure fan, fresh air reaches the array muffler at an air outlet of the pressure fan and then is introduced to an air supply corridor through an electric regulating valve, an outlet louver of the air supply corridor is adjusted, and fresh air is sent to a target ventilation area in the form of one-way piston flow through the air supply corridor, and air carrying indoor gaseous pollutants is discharged by an exhaust fan. A ductless ventilation system is arranged in the target ventilation area, thus the system is attractive, the burial depth of an underground sewage treatment plant is reduced, and the initial investment in civil engineering is reduced, the air age and the pollutant concentration in the patrol area of large space are reduced, and the ventilation efficiency and the sewage discharge efficiency are improved.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

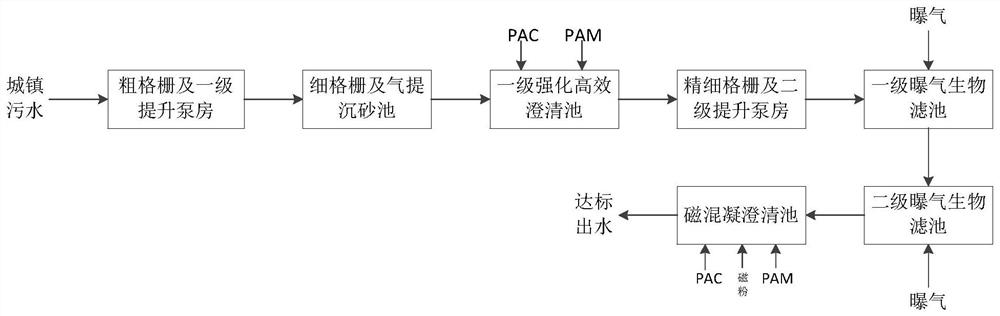

Combined process for enabling effluent COD, BOD5, NH3-N and TP indexes to reach ground surface IV-type water standard

PendingCN112390463AEfficient decontaminationIncrease gravitational potential energyWater/sewage treatment by centrifugal separationWater treatment parameter controlSludgeFiltration

The invention relates to a combined process for enabling effluent COD, BOD5, NH3-N and TP indexes to reach ground surface IV-type water standard. The combined process comprises the following steps: acoarse screen and a primary lifting pump room module are used for carrying out primary filtration and sewage lifting; a fine grid and a gas stripping grit chamber module are used for filtering and removing sand again; a primary enhanced efficient clarification tank module is used for carrying out PAC and PAM sewage treatment reaction; a fine grid and a secondary lifting pump room module are used for filtering again and lifting the sewage to increase a water head; a primary biological aerated filter module decomposes COD, BOD and NH3-N in the sewage; a secondary biological aerated filter moduleperforms nitration reaction by utilizing NH3N in the sewage; and magnetic powder is added into a magnetic coagulation clarification tank module, sludge flows back, and tiny flocs wrap the magnetic powder, so that subsequent flocculation and sedimentation are facilitated. The process is suitable for low-concentration town sewage treatment, and reaches the ground surface IV-class water standard; and the two stages of lifting pump stations reduce the filling and excavation work amount during construction, and are particularly suitable for places with poor geological conditions.

Owner:深圳市金锋环境有限公司

A method for determining the minimum buried depth of underwater tunnels

ActiveCN107806350BShorten the lengthGive full play to the function of traffic reliefMining devicesEngineeringWater seepage

The invention discloses a method for determining the minimum buried depth of an underwater tunnel. The method comprises the steps that the influences of a reinforcing scheme in the designing process of the underwater tunnel and a construction segment partition scheme in the construction process on the tunnel buried depth are considered; firstly, the vertical section of the tunnel is preliminarilydetermined according to the wiring conditions at the two ends of an underwater tunnel project and the route slope, then a crucial section of the tunnel is selected, the crucial section under the condition that reinforcement is conducted is calculated, and therefore the minimum buried depth of tunnel construction safety is ensured; and meanwhile the water seepage amount in the operational period after the tunnel is reinforced is calculated, and when the water seepage amount obtained through calculation is smaller than a water seepage amount control standard in the tunnel operational period, thedetermined buried depth is the minimum buried depth of the tunnel. When the minimum buried depth of the tunnel is determined, all crucial sections of the whole tunnel all need to meet the requirements of the minimum buried depth, and the method can further appropriately reduce the project construction cost under the premise that the tunnel construction safety is ensured.

Owner:CENT SOUTH UNIV

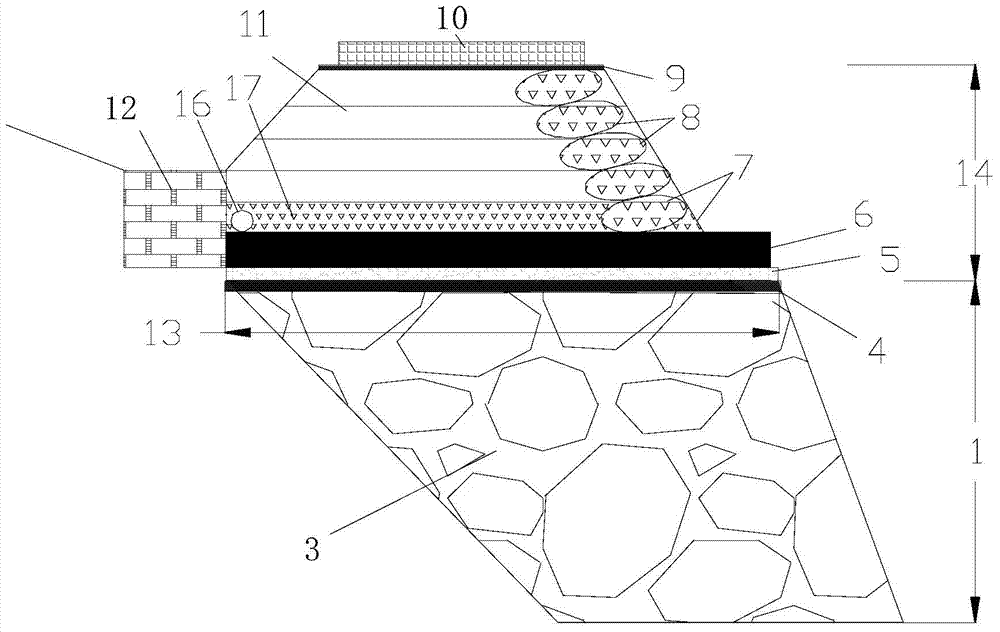

Rubble stone stack and reinforced soil composite embankment culvert pipe structure

ActiveCN103898844AEasy constructionCoordinating uneven settlementGround-workSediment trapCrushed stone

The invention discloses a rubble stone stack and reinforced soil composite embankment culvert pipe structure which comprises a bottom rubble stone stack embankment, middle culvert pipes and an upper flexible reinforced soil embankment. The rubble stone stack embankment is the same as a conventional rubble stone stack, however, the top width of the rubble stone stack embankment is expected to be larger than 7 meters, the height of the rubble stone stack embankment is expected not to be larger than 8 meters, the flexible reinforced soil embankment is consistent with a conventional reinforced soil embankment, however, the bottom width of the flexible reinforced soil embankment is larger than 7 meters, the height of the flexible reinforced soil embankment is smaller than 6 meters, impervious geotextile is arranged on the top and at the bottom of the flexible reinforced soil embankment, and the bottom of the flexible reinforced soil embankment is provided with a drainage layer composed of flexible permeable hoses and gravel soil; sand sediment traps are arranged on the side close to natural side slopes. According to the rubble stone stack and reinforced soil composite embankment culvert pipe structure, the characteristic that the flexible reinforced soil embankment improves differential settlement of the culvert pipe and improves the longitudinal stress state of the culvert pipe is maintained, the advantage that the rubble stone stack embankment is easy to construct in a narrow position of a slope toe and low in cost is also maintained, and the rubble stone stack and reinforced soil composite embankment culvert pipe structure is mainly applied to maintain streams of low-cost roads for reaching the peak.

Owner:佳风工程设计有限公司

Assembly type flat-top large-span column-free underground structure

PendingCN110080291ANo thrustImprove stabilityArtificial islandsUnderwater structuresStructural stabilityBuilding construction

The invention belongs to the field of underground engineering construction and relates to an assembly type flat-top large-span column-free underground structure which comprises an enclosure structure,a flat-top layer board, a first layer board and first side wall prefabricated parts. The flat-top layer board and the first layer board are arranged in the enclosure structure, first side walls are arranged on the two sides of the first layer board, the two ends of the flat-top layer board are arranged on the two first side walls on the two sides respectively, and the first side walls comprise the first side wall prefabricated parts. Each first side wall prefabricated part comprises a vertical section, a horizontal section and an inclined supporting section, the bottom of the vertical sectionis connected with the first layer board, the top of the vertical section is connected with one end of the horizontal section, and the other end of the horizontal section is connected with one end ofthe inclined supporting section, and the other end of the inclined supporting section is connected with the vertical section. The flat-top layer board is supported through the triangular-frame-shapedfirst side wall prefabricated parts, the flat-top column-free effect is achieved, the vision column-free large-space effect of the building is well achieved, the foundation pit buried depth is slightly increased, no arch foot external expansion thrust exists, and the structural stability is improved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Pipe group isolation pipe-jacking construction method

InactiveCN111206934AReduce deformation effectsReduce buried depthUnderground chambersTunnel liningSocial benefitsArchitectural engineering

The invention discloses a pipe group isolation pipe-jacking construction method, which is suitable for structures sensitive to deformation on the ground. The method comprises the following steps thatfirstly, a plurality of seamless steel tube guide pipes are pre-buried in a side wall of a pipe-jacking originating well; secondly, a plurality of seamless steel pipes are arranged above a corresponding jacking pipe through a miniature pipe jacking technology, and therefore a rib pipe group is formed; each seamless steel pipe extends out of an originating well along the corresponding seamless steel pipe guide pipe and penetrates into a receiving well of the jacking pipe; thirdly, after the seamless steel pipes are arranged, slurry is injected into each seamless steel pipe; after the slurry issolidified, the construction of the rib pipe group is completed; and finally, construction of the jacking pipe is conducted. The construction method gives consideration to economical efficiency and practicability, and disturbance to an upper soil body can be effectively isolated during pipe jacking construction under the condition that the upper soil body of a pipe jacking section is not excavatedor damaged, influence of construction on the surrounding environment is reduced, the tunnel burial depth is decreased, the underground space is saved, and therefore remarkable social benefits are achieved.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

Rainwater pipe gallery with rainwater and sewage diversion function

InactiveCN113529897AAvoid many problems caused by too many access pointsRelieve stressArtificial islandsFatty/oily/floating substances removal devicesWater storageSewage

The invention provides a rainwater pipe gallery with a rainwater and sewage diversion function, and belongs to the technical field of urban rainwater pipe galleries. The rainwater pipe gallery mainly comprises rainwater cabins, a water storage cabin and a sewage cabin. The rainwater cabins are symmetrically distributed along the axis of the water storage cabin, the sewage cabin is located below the water storage cabin and the rainwater cabins, and the rainwater cabins are connected with the pavement through rainwater cabin inspection wells. According to the rainwater pipe gallery, collection, regulation, storage and reasonable utilization of rainwater are facilitated, the pressure of sewage plants in a sponge city is relieved, the structural design is reasonable, the rainwater cabins and the water storage cabin are arranged in parallel, the burial depth is reduced, the functions of seepage, stagnation, storage, purification, use and drainage in the sponge city are achieved, the practicability is high, and the pipe gallery is easy to popularize and use; and meanwhile, the sewer and the inspection well are connected into the pipe gallery in a fishbone shape, so that many problems caused by too many access ports are avoided, and important significance is achieved for solving the problem that rain and sewage enter the gallery.

Owner:SHENYANG JIANZHU UNIVERSITY

Air-hose-free ventilation system applicable to underground type water treatment structure

PendingCN109357351ASolve installation and maintenance problemsReduce buried depthLighting and heating apparatusNoise suppressionDischarge efficiencySewage treatment

The invention discloses an air-hose-free ventilation system applicable to an underground type water treatment structure. The system comprises a ventilation target area, an air supply gallery, an air feeding unit and an air exhaust unit, wherein the start end of the ventilation target area communicates with the air supply gallery, the tail end of the ventilation target area is provided with the exhaust unit, the air supply gallery is arranged on one side of the ventilation target area, the side, facing the ventilation target area, of the air supply gallery is provided with an outlet adjusting louver, the air feeding unit comprises an air feeding channel, an air supply blower is arranged in the air feeding channel, the air feeding channel communicates with the outdoor space through an air supply well, the air exhaust unit comprises an exhaust fan and an exhaust well located above the exhaust fan, and the exhaust unit is used for exhausting air in the ventilation target area. Air-hose-free ventilation system arrangement in the target ventilation area is achieved, attractiveness is achieved, meanwhile, the burial depth of an underground type sewage treatment plant is reduced, and initial investment in civil engineering is reduced; the air age and pollutant concentration in a large-space internal inspection area is reduced, and ventilation efficiency and pollution discharge efficiency are improved.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com