Construction method for achieving underground excavation and reverse operation by utilizing combined pipe jacking

A construction method and pipe jacking technology, which are applied in the fields of earthwork drilling, mining equipment, climate change adaptation, etc., can solve the problems of low project cost, large construction site, slow construction speed, etc., to reduce project cost, improve utilization rate, The effect of fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

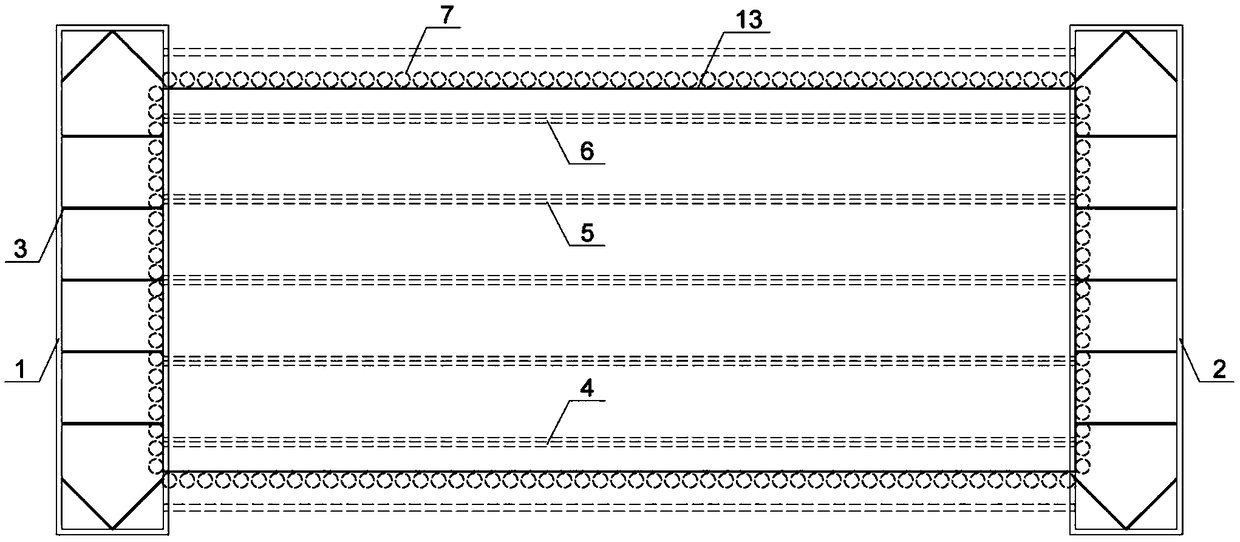

[0029] The embodiment of the present invention discloses a construction method of using combined pipe jacking to realize underground excavation and reverse work, which includes the following steps: see the attached figure 1 Shown: Construct the enclosure structure at the end of the station, erect the support structure (3) in the pipe jacking well, and excavate the pipe jacking originating shaft (1) and the pipe jacking receiving shaft (2) at the station end by the open cut method;

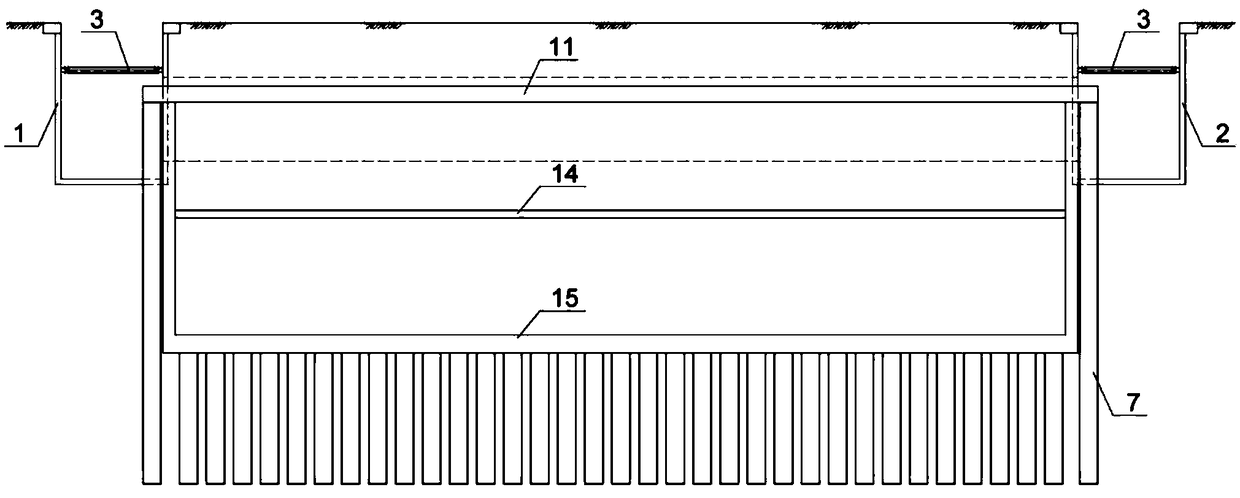

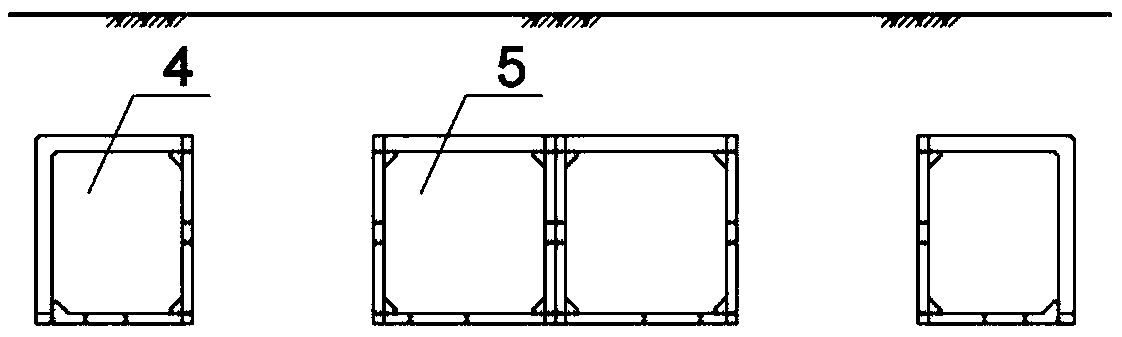

[0030] See attached figure 2 , attached image 3 Shown: Use the pipe jacking launch shaft (1) as the pipe jacking construction work space, install the pipe jacking machine and supporting equipment, use the rectangular pipe jacking machine to jack in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com