Assembly type flat-top large-span column-free underground structure

An underground structure, prefabricated technology, applied in underwater structures, infrastructure engineering, water conservancy engineering and other directions, can solve the problems of high requirements for surrounding environment control, poor vision of underground space, and increased depth of foundation pits, etc. Realize the effect of industrialization promotion and application, improve waterproof performance and overall stress performance, and save construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

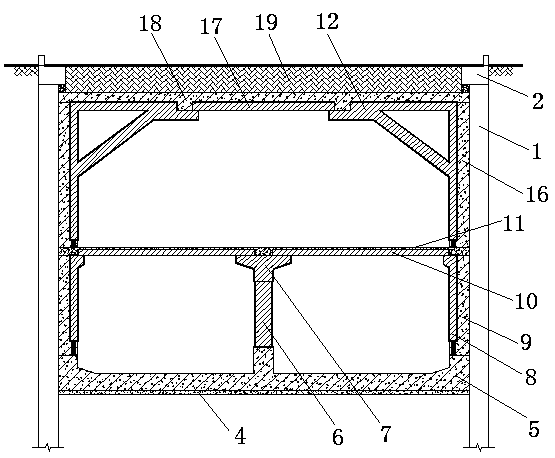

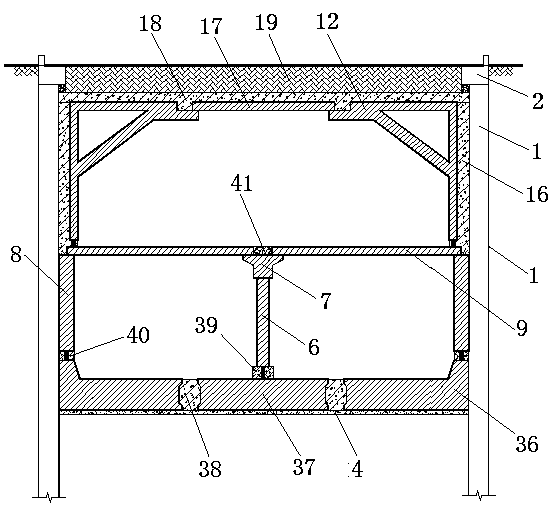

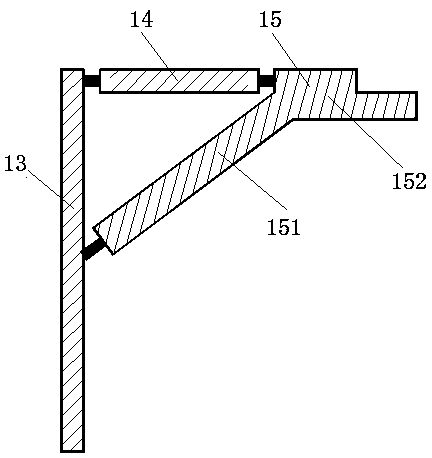

[0045] like Figure 1-2 As shown, this embodiment provides a prefabricated flat-roofed large-span column-free underground structure, including two enclosure structures 1, a flat-roof layer, a first layer and a first side wall prefabricated part 12, and the two enclosures Structure 1 is provided with a flat top floor and a first floor, both sides of the first floor are provided with first side walls, and the two ends of the flat top floor are respectively arranged on the two first side walls on both sides ; The first side wall comprises a first side wall prefabricated part 12, and the first side wall prefabricated part 12 comprises a vertical section 13, a horizontal section 14 and an oblique support section 15, and the bottom of the vertical section 13 is connected with the first laminate, and the vertical The top of the straight section 13 is connected with one end of the horizontal section 14, and the other end of the horizontal section 14 is connected with one end of the ob...

Embodiment 2

[0059] Such as Figure 4-6 As shown, this embodiment provides a connection structure between the prefabricated part and the cast-in-place concrete layer, which can be used when the first side wall in the first embodiment adopts a laminated structure, and the first layer adopts a fully cast-in-place or laminated structure The connection between the first side wall prefabricated part 12 and the first cast-in-place layer 11 or the first cast-in-place laminate can also be used for the second side wall to adopt a laminated structure, and the second laminate to adopt a fully cast-in-place or laminated structure. The connection between the second side wall prefabricated part 8 and the second layer slab cast-in-place layer or the reinforced concrete cast-in-place layer 5 during structure; For example, the connection structure between the first side wall prefabricated part 12 and the first cast-in-place laminate, the connection structure between the second side wall prefabricated part ...

Embodiment 3

[0068] This embodiment provides a prefabricated part-to-prefabricated connection structure, which can be used for the connection between the first ply prefabricated part 10 and the first ply prefabricated part 10 when the first ply board adopts a superimposed structure in the first embodiment. Connection, the connection between the second layer prefabricated part and the second layer prefabricated part when the second layer adopts the superimposed structure, the flat top layer prefabricated part 16 and the flat top layer prefabricated part 16 when the flat top layer adopts the superimposed structure The connection between; now take the connection structure of two first layer prefabricated parts 10 when the first layer board adopts a superimposed structure as an example to illustrate, the connection structure of two second layer board prefabricated parts, two flat top layer boards The connection structure of the prefabricated part 16 is the same as it, and will not be described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com