Pipe group isolation pipe-jacking construction method

A construction method and pipe jacking technology, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve problems such as increasing project risk and cost, lengthening open-cut and buried sections, and increasing the thickness of segments to achieve social effects Significantly, reduce the effect of covering soil and reducing settlement deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

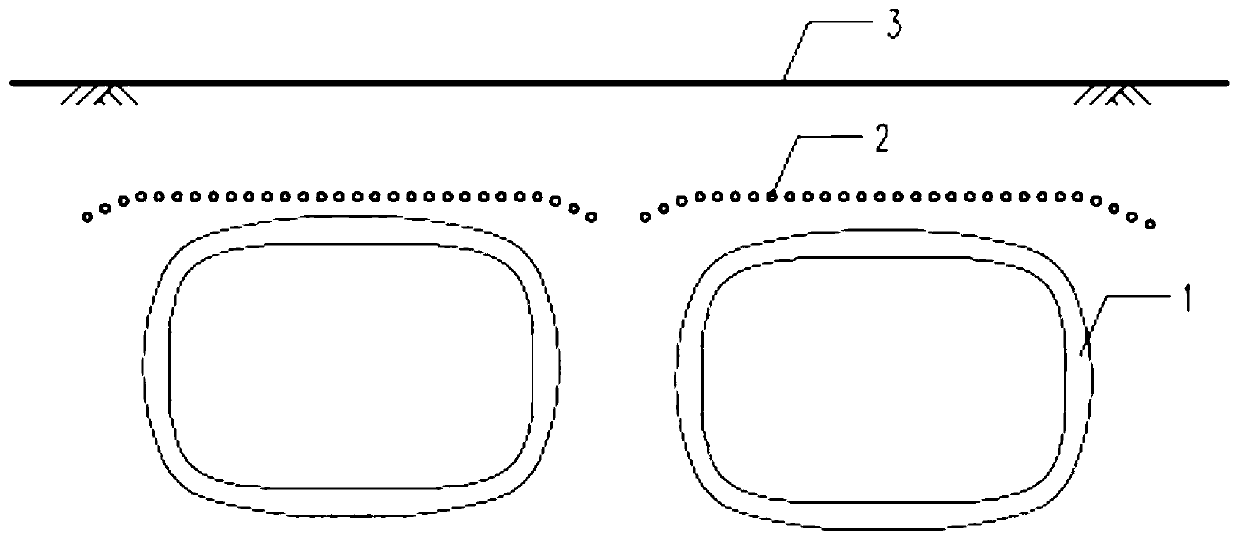

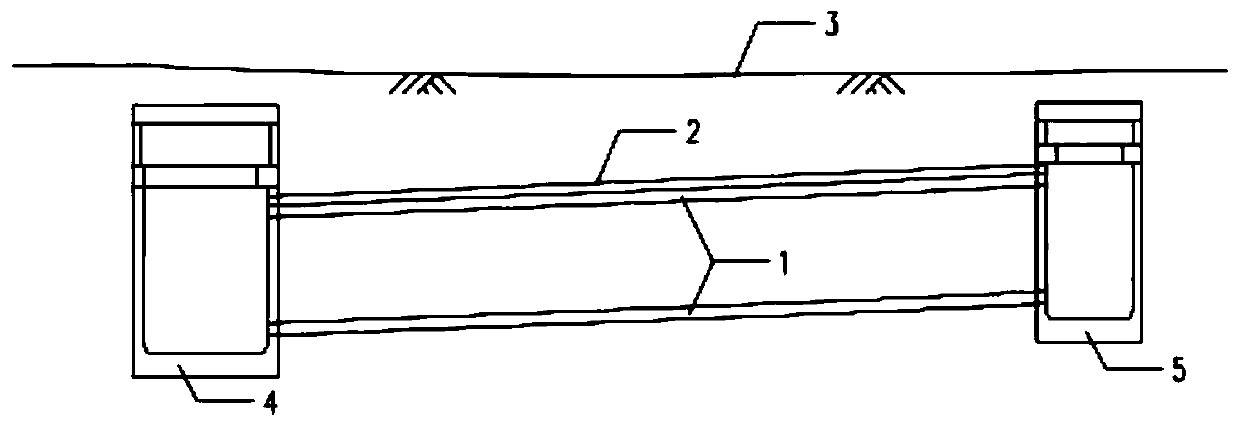

[0035] Such as Figure 1 to Figure 4 As shown in the pipe group isolation pipe jacking construction method, there are deformation-sensitive structures on the ground 3; the steps are as follows:

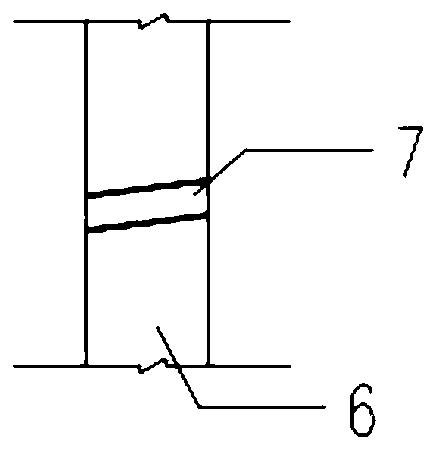

[0036] Step 1, pre-embed a number of seamless steel pipe guide pipes 7 in the side wall 6 of the originating shaft 4 of the pipe jacking 1;

[0037] Step 2: Drilling a number of seamless steel pipes 2 above the corresponding pipe jacking 1 by micro-pipe jacking technology to form a group of ribbed pipes; each seamless steel pipe 2 extends from the starting shaft 4 along the corresponding seamless steel pipe guide pipe out, and penetrate into the receiving well 5 of the pipe jacking 1;

[0038] The laying elevation angle of each seamless steel pipe 2 must be kept within the range of 1:1 to 1:1.2 with the corresponding pipe jacking 1 elevation angle, and the laying length range should be more than 4m beyond the outer edge of the structure on the ground;

[0039] Step 3: After the seam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com