Electrically-controlled automatic adjustable overflow weir intercepting well

A technology of overflow weirs and interception wells, applied in waterway systems, drainage structures, water supply devices, etc., can solve the problems of treatment capacity pressure of sewage plants, deep burial of water inlet pipes, overflow, etc., and achieve the effect of reducing barriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

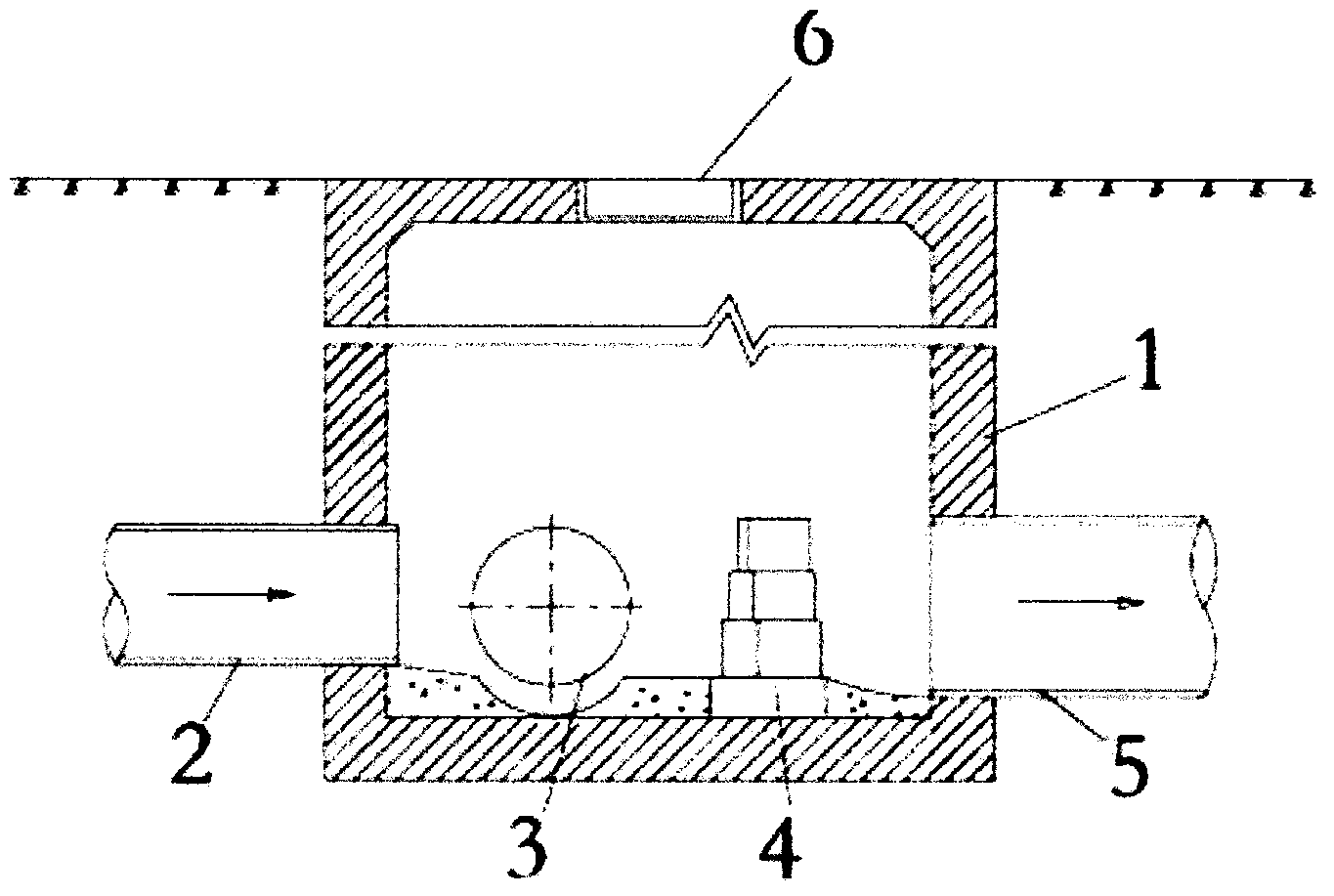

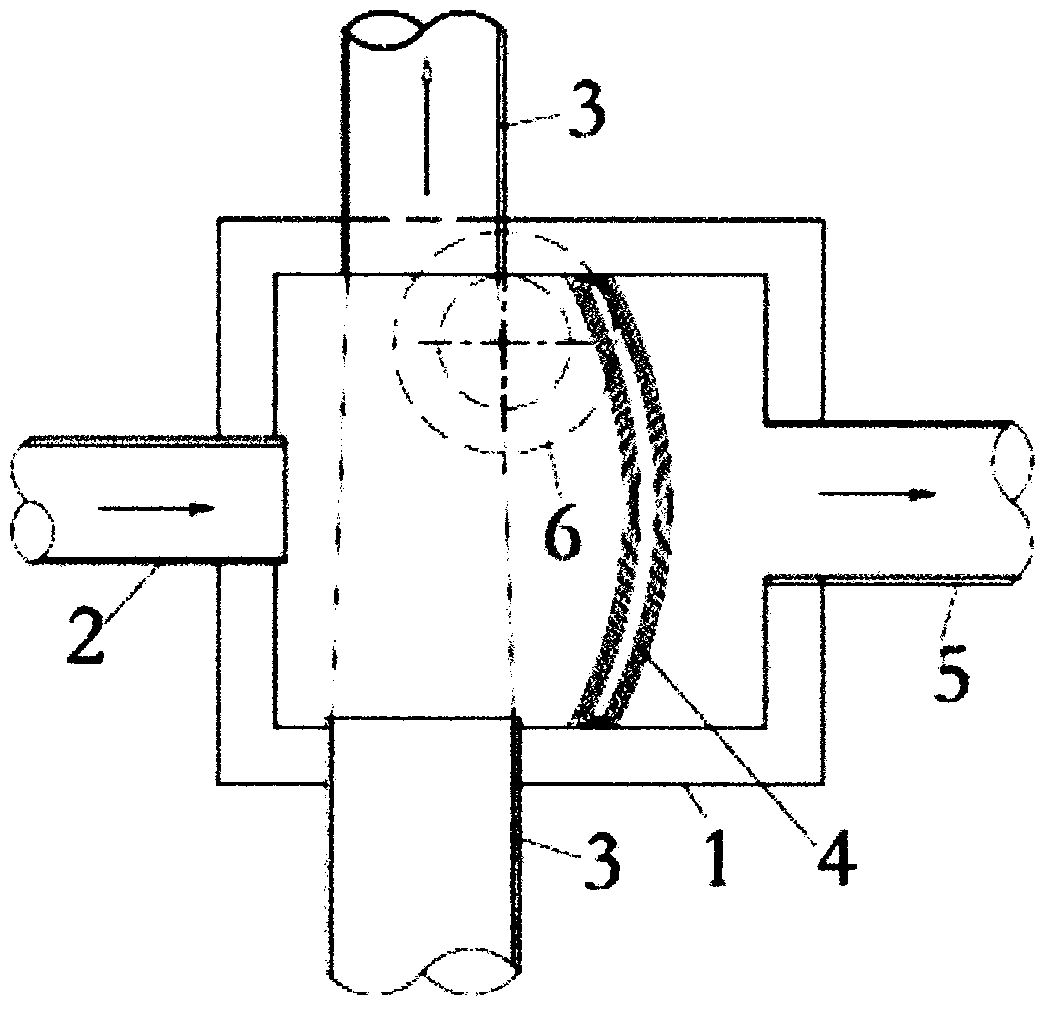

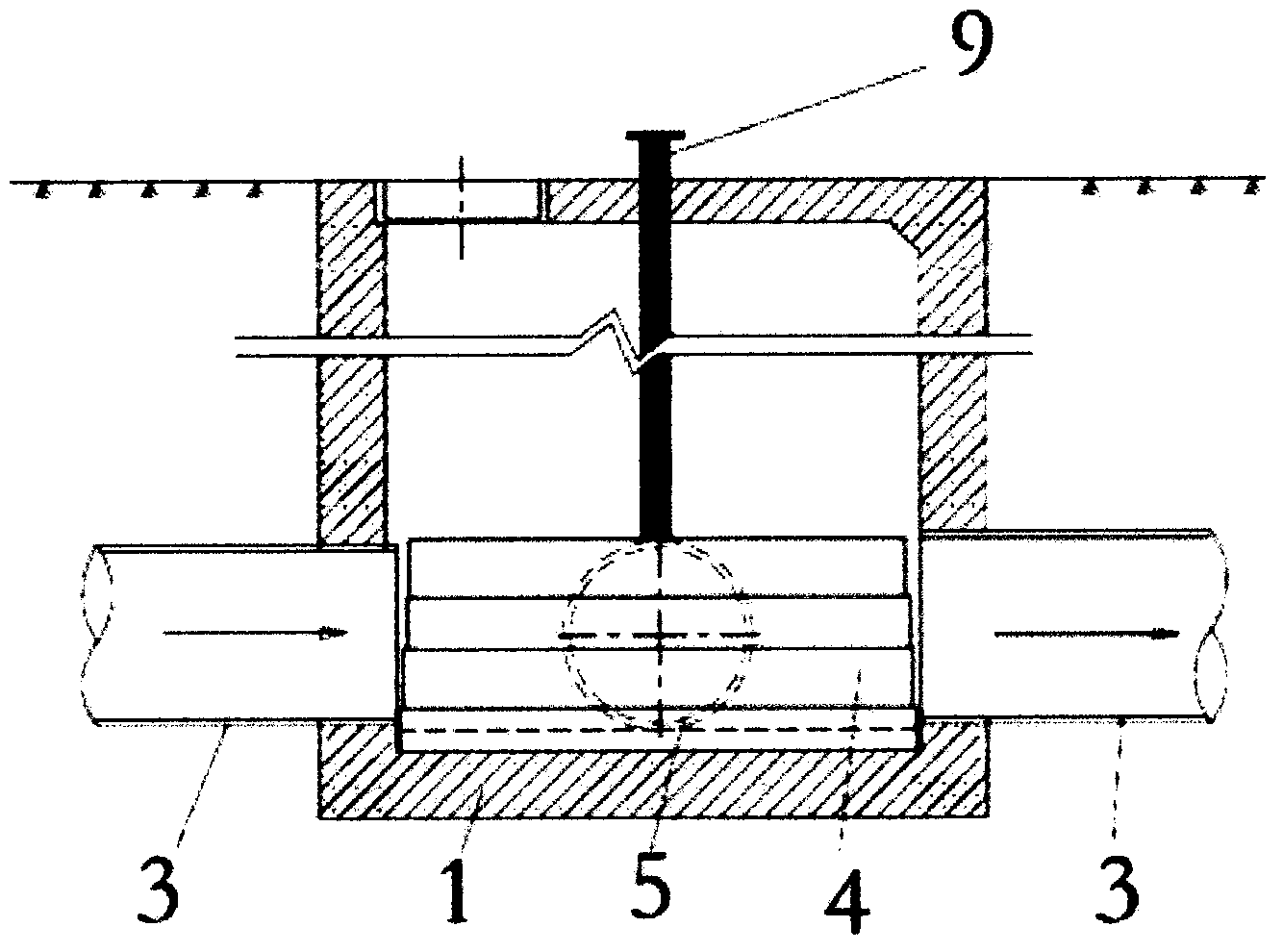

[0026] see figure 1 As shown, an electronically controlled and automatically adjustable overflow weir interceptor well includes a hollow well body 1, an adjustable arc-shaped overflow weir 4 is arranged inside the well body 1, and a telescopic weir is installed inside the overflow weir 4. A rod 7 is connected to the well body 1 with a confluence pipe 2, a sewage interceptor pipe 3, and an overflow pipe 5 whose nozzle is tangent to the inner wall of the well body 1, and the upper port of the well body 1 is covered with an interception well cover 6.

[0027] Further, the shape of the well body 1 is one of a cube, a cuboid or a cylinder. The inside of the well body 1 is hollow and has a certain large volume; The mixed water flow inlet, the intercepting main pipe 3 of the intercepted sewage and the overflow pipe 5 .

[0028] Further, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com