Clean water tank suction well system and use method thereof

A technology of water absorption wells and clear water pools, applied in the configuration of water supply pools, water supply devices, buildings, etc., can solve problems such as high water level self-irrigation start-up pumps with low buried depth, inconvenient personnel to patrol up and down, and poor ventilation conditions in pump rooms, etc. , to achieve the effect of improving the disinfection effect, reducing the buried depth, and reducing the cost of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

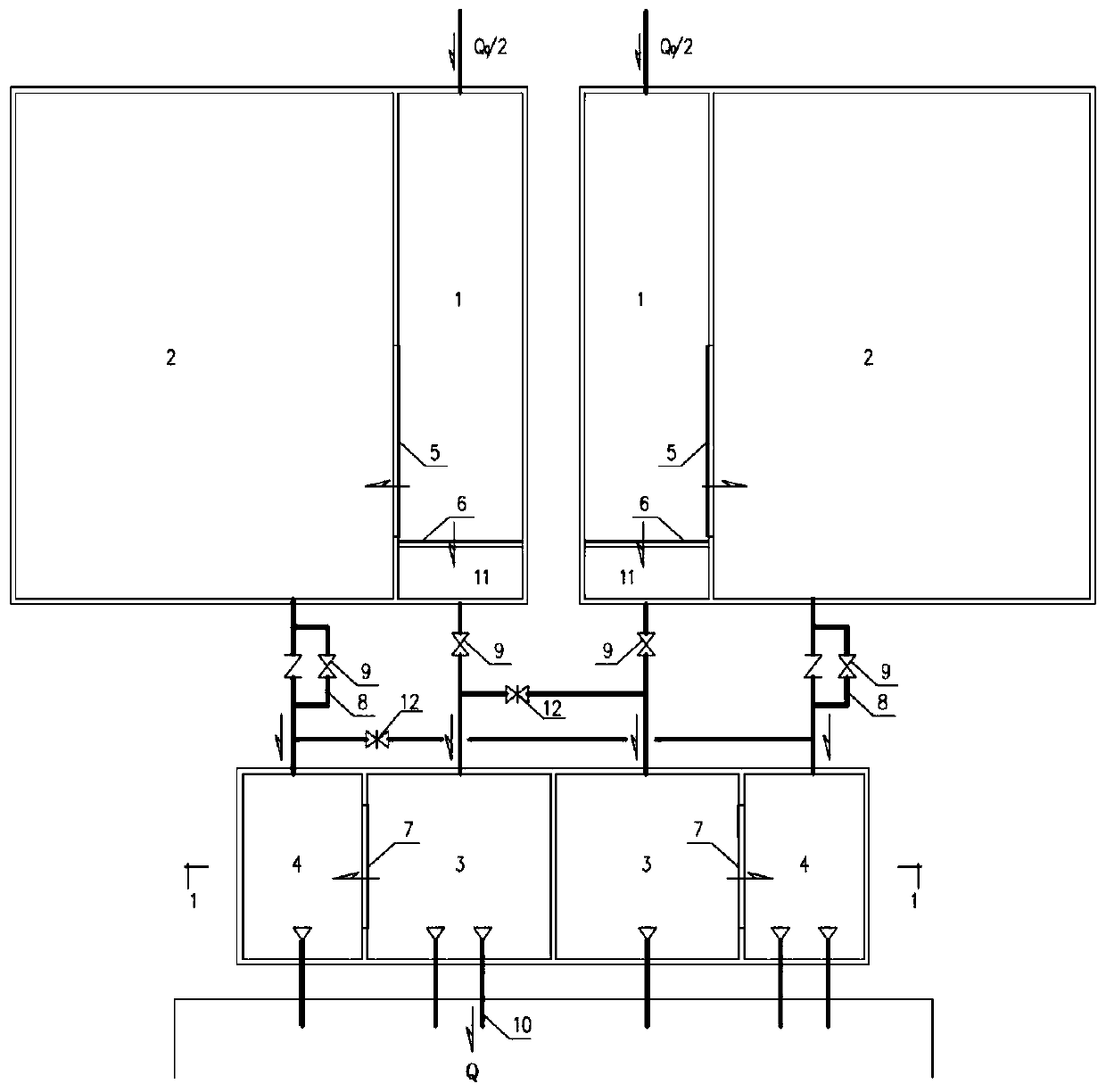

[0027] See attached figure 1 , A clean water suction well system, including a chlorination contact tank 1, a clean water tank 2, a main suction well 3, an auxiliary suction well 4, an anti-backflow device 8, a flow regulating valve 9, a water pump suction pipe 10, and a water outlet well 11;

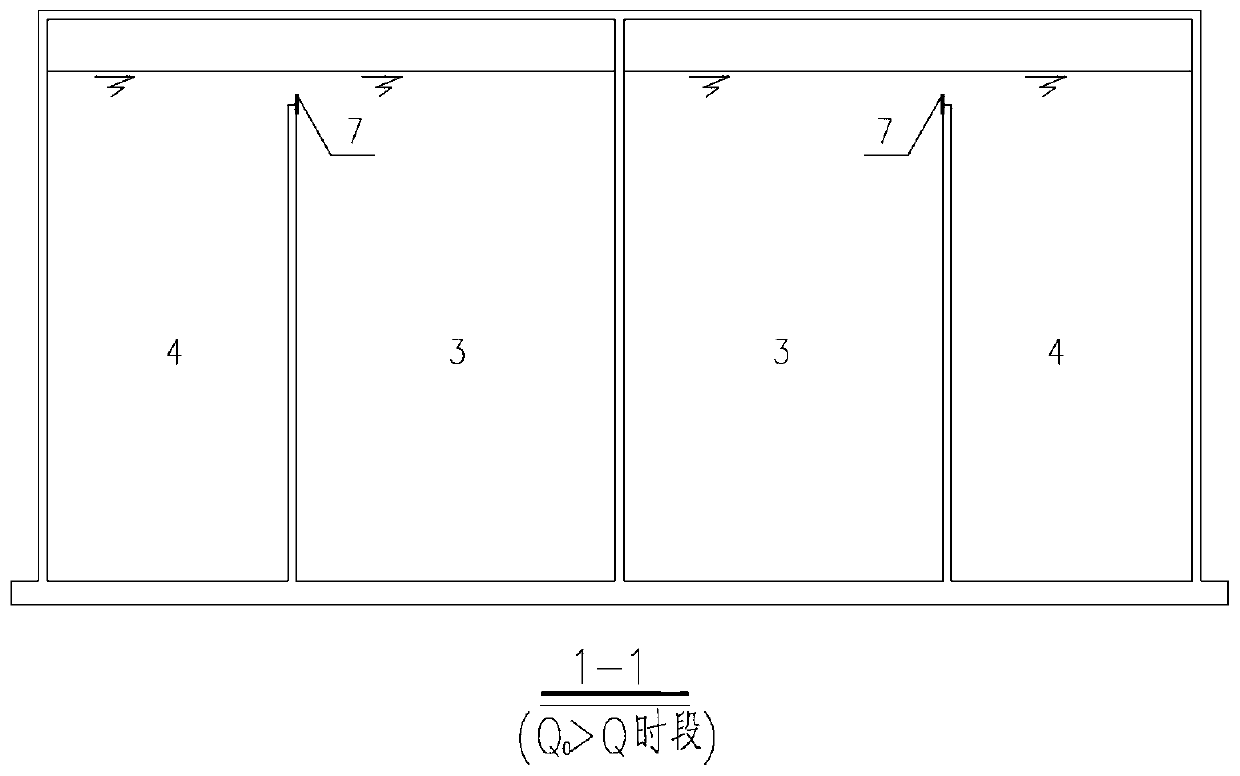

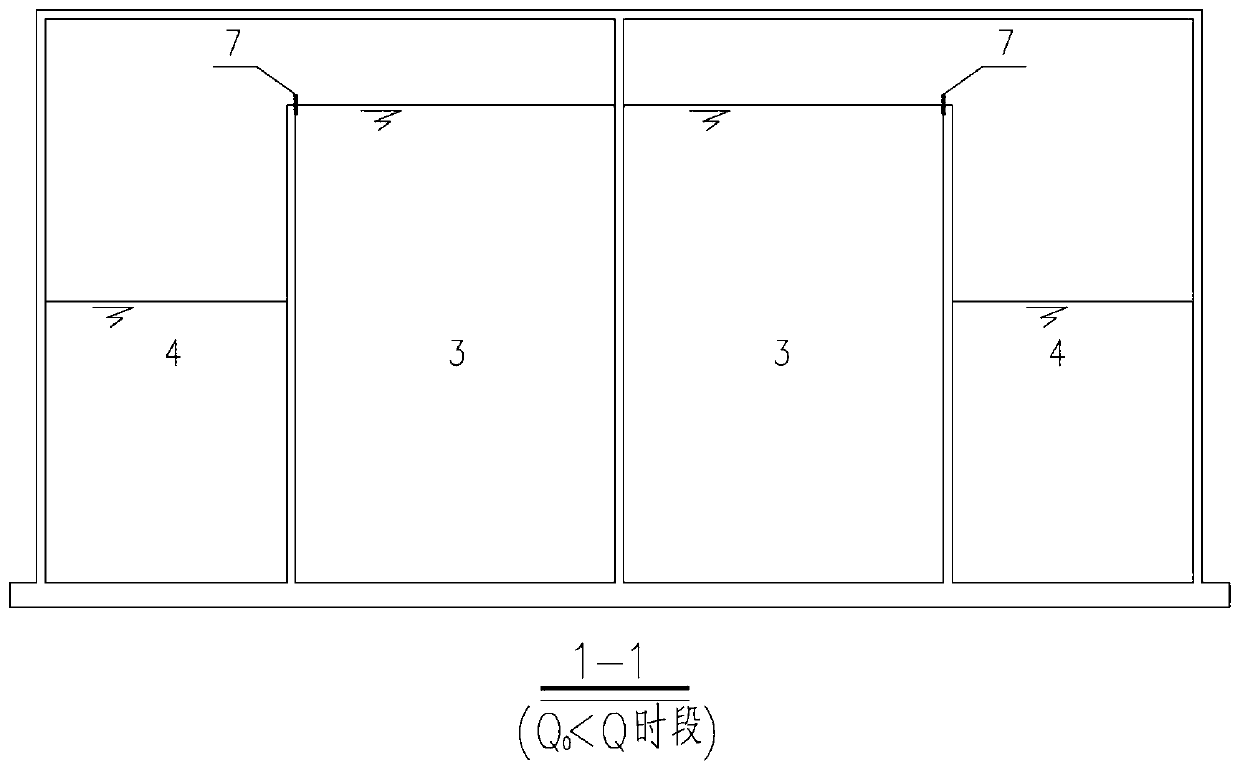

[0028] The chlorination contact tank 1 communicates with the clean water tank 2 through a high weir 5, and the chlorination contact tank 1 communicates with the outlet well 11 through a low weir 6 provided above. The outlet well 11 The main suction well 3 is communicated with the main suction well 3 through a pipeline and the flow is adjusted by the flow regulating valve 9, the main suction well 3 is communicated with the auxiliary suction well 4 through the low weir two 7, the high weir 5, the low weir one 6. The two low weirs 7 are arranged in order from high to low; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com