Lateral tree root hole digging pile and installation equipment thereof

A technology for installing equipment and tree root piles, which is applied to sheet pile walls, buildings, and connection contact materials, etc., can solve the problems of being unable to withstand ultra-high voltage lightning strikes, heavy workload of workers, and general lightning protection effect, etc., to reduce earthwork The effect of reducing the amount of work, reducing the amount of engineering, and improving corrosion resistance and structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

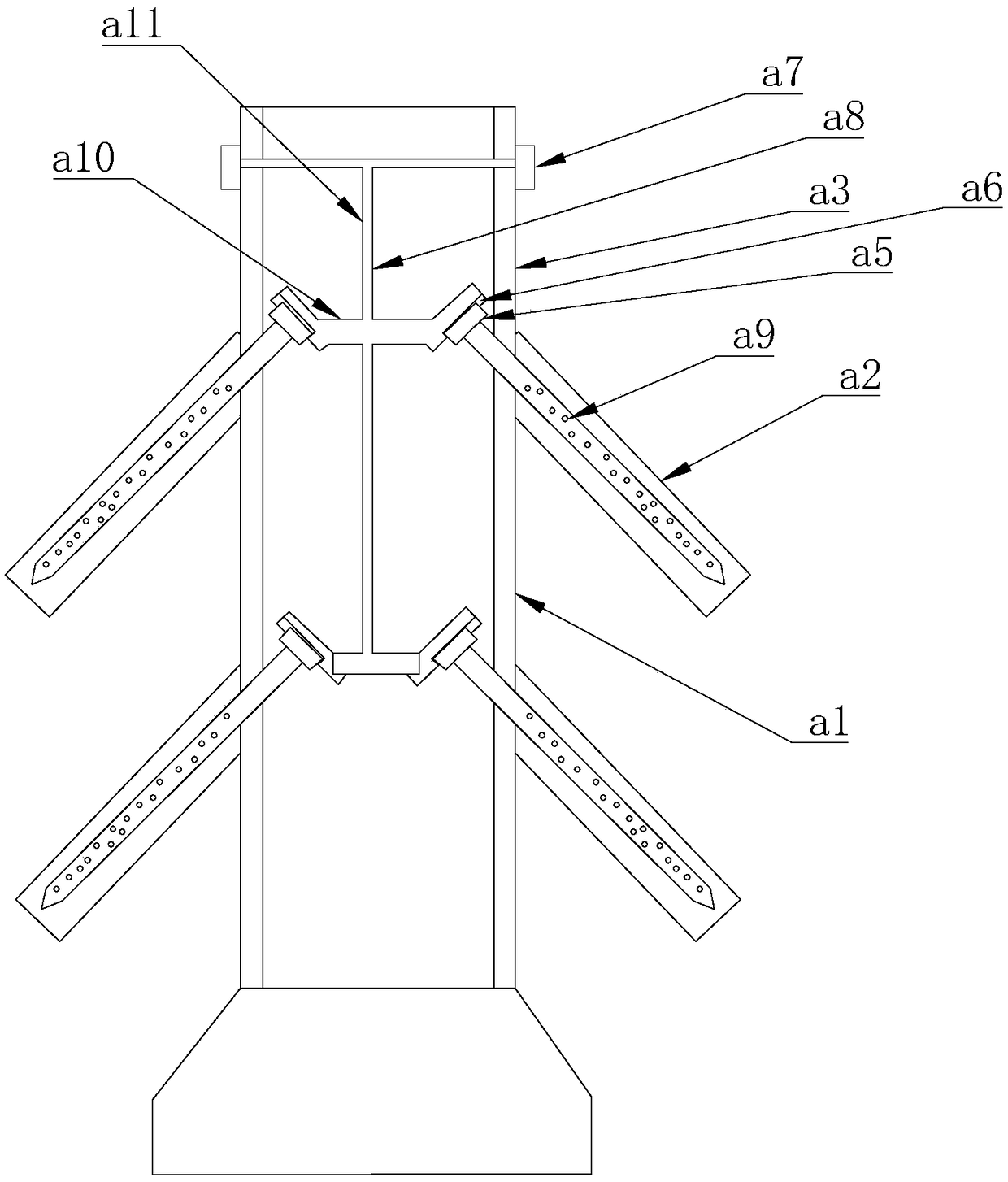

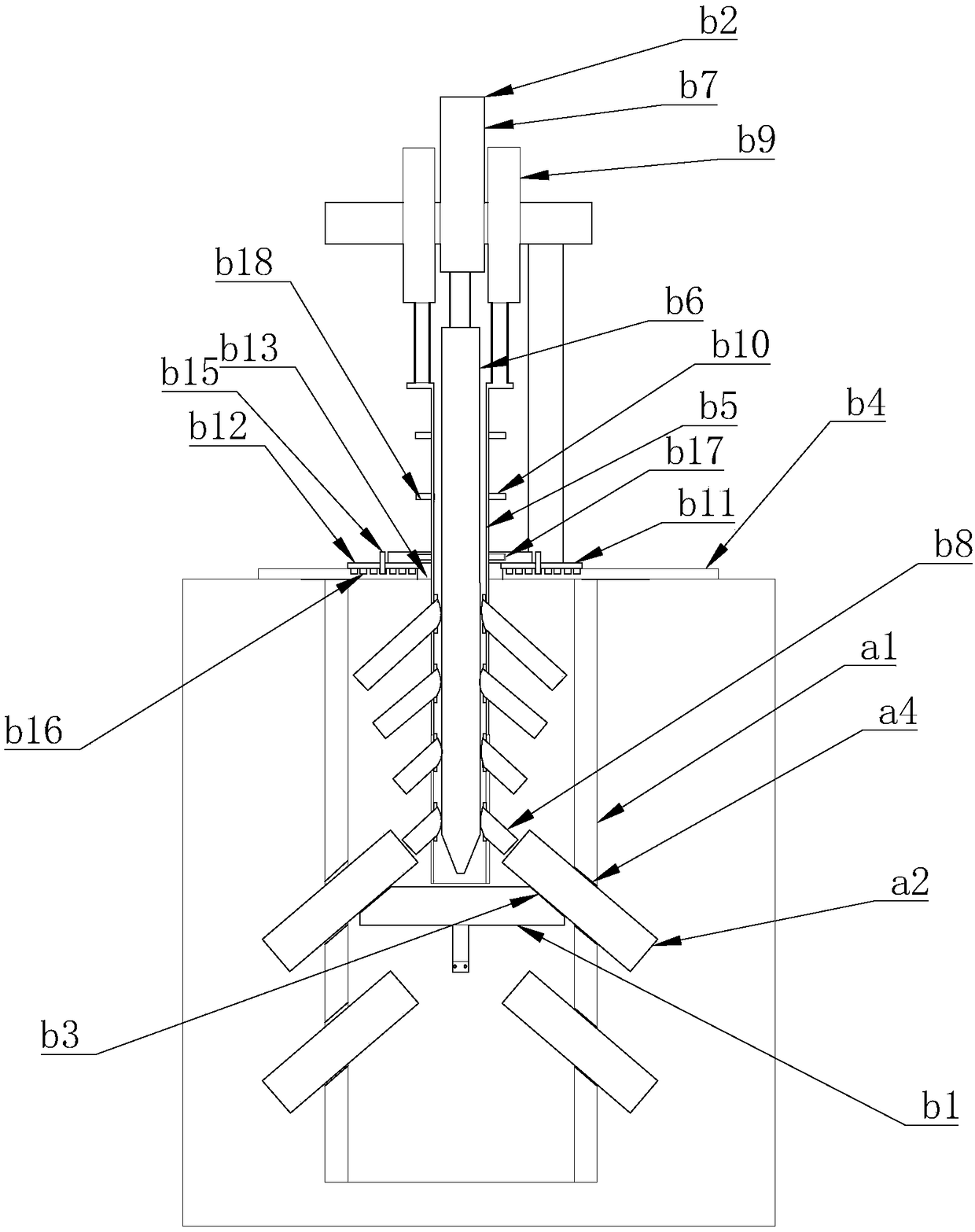

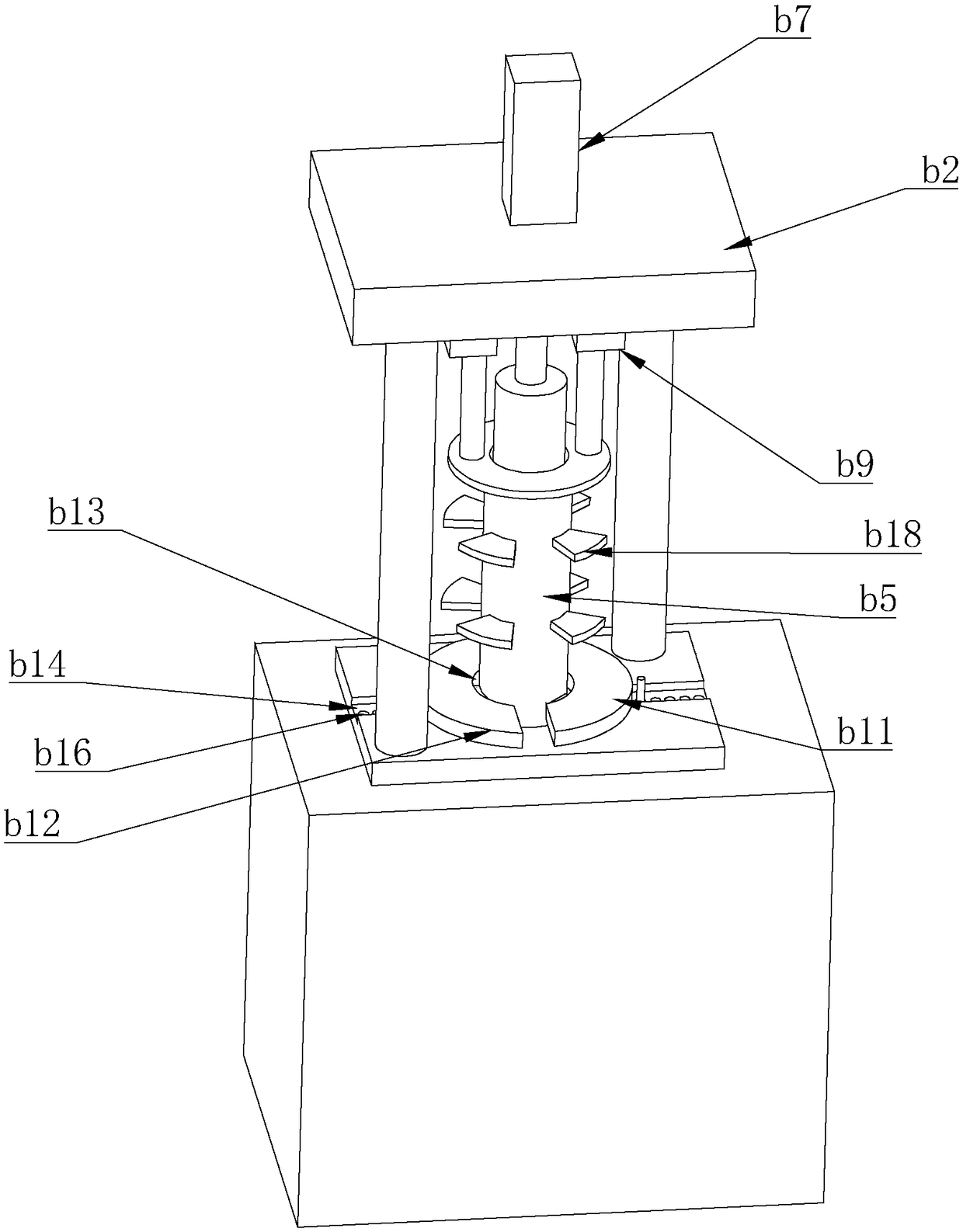

[0027]Embodiment 2 A kind of installation equipment for lateral tree root digging piles, including a positioning seat b1 and a piling device b2, the positioning seat b1 is in the shape of a ring, and the positioning seat b1 is provided with an installation angle parallel to the tree root pile a2 The positioning groove b3, the piling device b2 includes a mounting seat b4, a guide cylinder b5, an impact member b6, and a first driving device b7 that drives the impact member b6 to move up and down in the guide cylinder b5, and the installation seat b4 is fixed on the ground Above, the guide cylinder b5 is installed on the installation seat b4 and extends into the ground pile foundation a1, and the outer wall of the guide cylinder b5 is provided with several sets of piling units, and several sets of piling units are equally spaced along the axial direction of the guide cylinder b5 , the piling unit includes a piling head b8 aligned with the tree root pile, the piling head b8 is slid...

specific Embodiment approach

[0031] As an improved specific implementation, the first mounting plate b11 and the second mounting plate b12 are provided with an annular mounting groove b17, and the adjustment seat b10 includes several disc-shaped positioning flaps b18, the The installation groove b17 is used to clamp the positioning flap b18, and the installation groove b17 restricts the up and down movement of the positioning flap b18, so as to prevent the reaction force of the impact member b6 on the guide cylinder b5 from causing the guide cylinder b5 to move in reverse. The preferred positioning flap b18 and piling head b8 Set at intervals in the horizontal direction.

[0032] As an improved specific implementation, the end of the impact part b6 and the piling head b8 that conflict with each other is tapered. When the piling head b8 and the conical surface of the impact part b6 contact each other, when the piling head b8 goes down, the impact part b6 pushes The piling head b8 performs piling on the roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com