Composite foundation for collapsible loess region and construction method

A technology of collapsible loess and composite foundation, which is applied in the field of composite foundation and construction, which can solve the problems of reducing earthwork excavation volume, construction difficulty and construction cost, unable to prevent foundation offset inclined settlement, and difficult to meet collapsibility level, etc. problems, to achieve the effect of reducing the amount of earthwork excavation, reliable quality and easy control, and improving overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

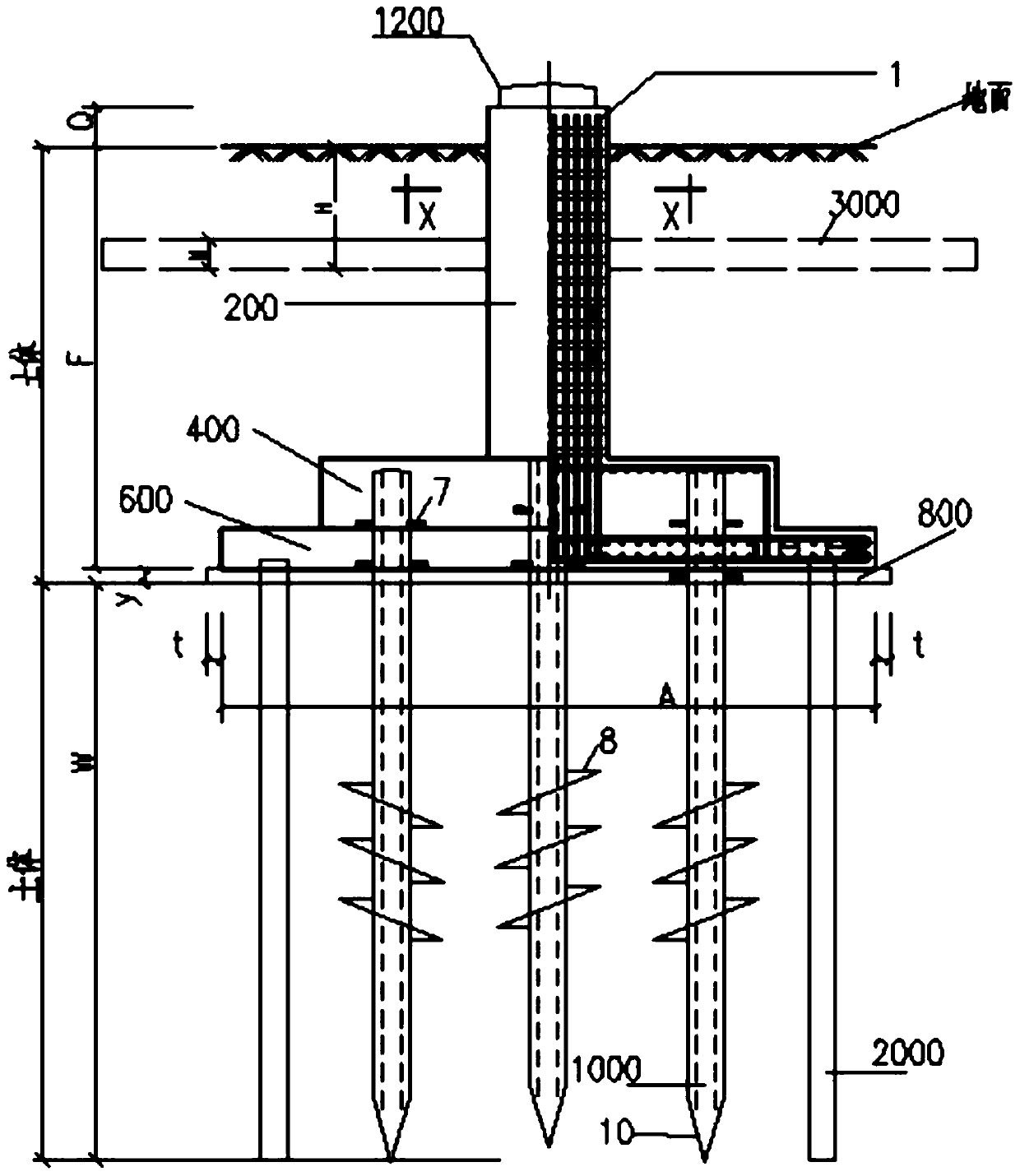

[0039] In a typical implementation of the present application, such as Figure 1-3As shown, a composite foundation for collapsible loess areas is proposed.

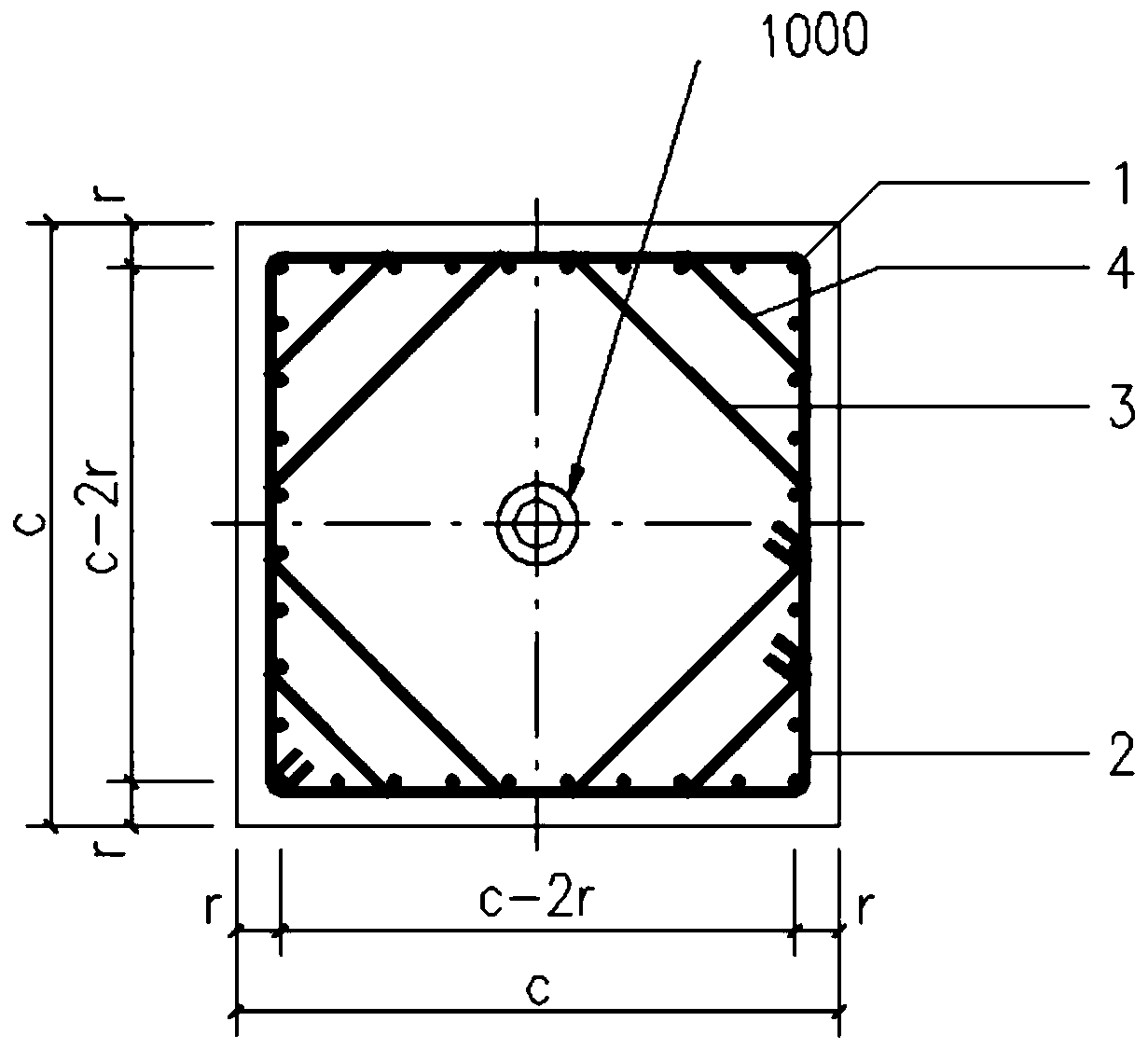

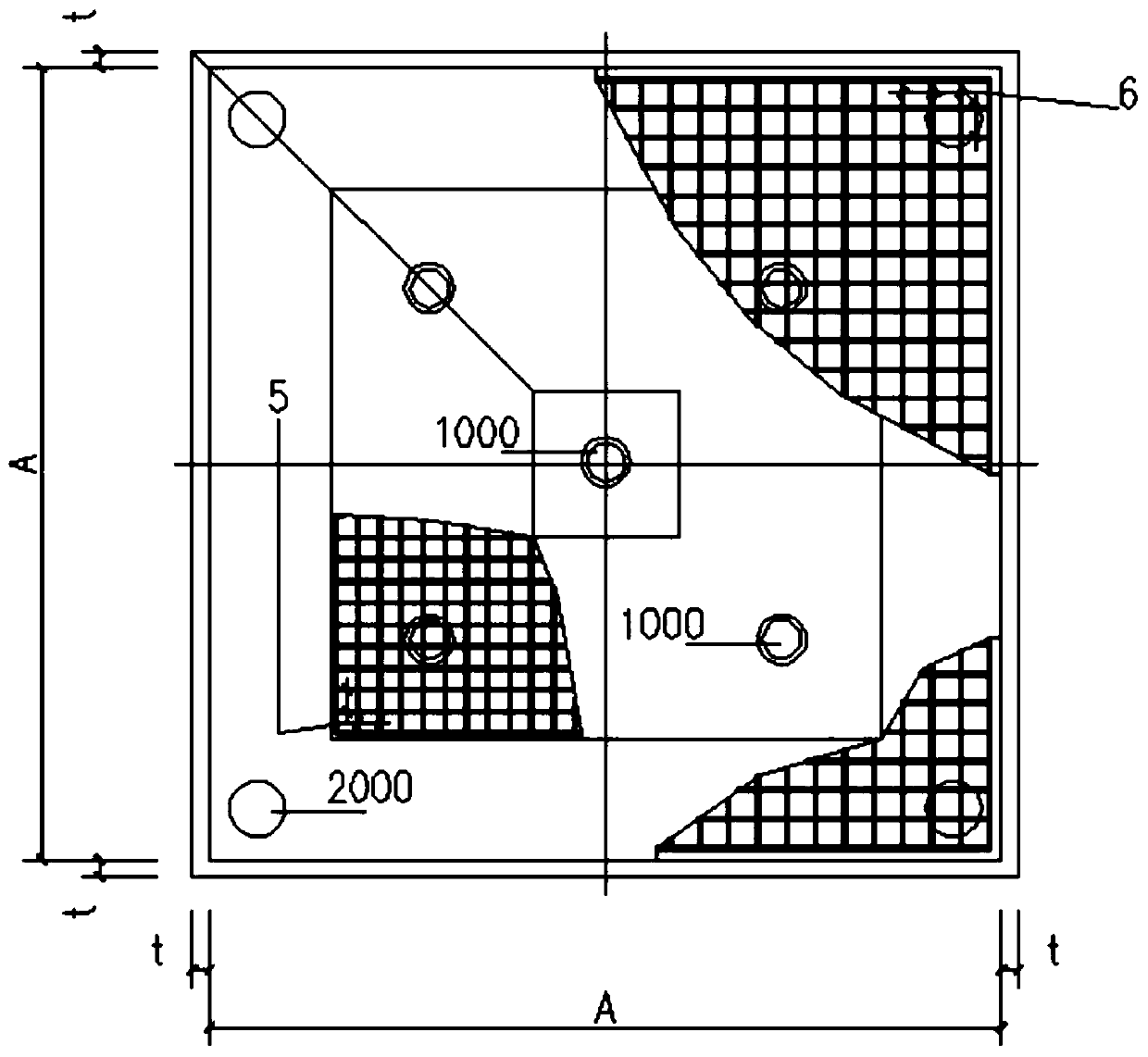

[0040] Composite foundations such as figure 1 , figure 2 and image 3 shown. figure 1 It is a schematic front view of a composite foundation composed of slab foundation-concrete piles-screw anchors. The foundation type includes main columns 200, steps 400, floor 600, concrete piles 2000, waterproof layer 3000, concrete cushion 800 and screw anchors 1000. Among them, the main column, steps, floor and concrete piles are all reinforced concrete structures, which are arranged in sequence in the vertical direction, and 800 is a plain concrete structure. The main column 200, the steps 400, the bottom plate 600 and the concrete cushion 800 form a slab foundation part, 2000 is a pile foundation part, and a plurality of concrete piles are connected to the bottom surface of the bottom plate, and the plurality of concrete piles...

Embodiment 2

[0050] In another typical embodiment of the present application, a construction method of the composite foundation described in Embodiment 1 is provided, using the following steps:

[0051] Excavate the foundation pit according to the size of the bottom surface of the slab foundation;

[0052] Drive the spiral anchor into the soil body corresponding to the layout of the bottom plate in the foundation pit, and the top is exposed;

[0053] Arrange drilling holes in the foundation pit corresponding to the bottom plate, make steel cages and lower them into the holes, pour concrete to form concrete piles, and expose the top;

[0054] Concrete cushion is poured at the bottom of the foundation pit, and the steel bars corresponding to the slab foundation are bound, and the spiral anchor and the top of the concrete pile are connected to the slab foundation steel bars;

[0055] Formwork is supported, and concrete is poured to form a slab foundation;

[0056] Backfill the foundation pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Vertical height | aaaaa | aaaaa |

| Vertical length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com