Direct-buried gas filter

A filter and direct-buried technology, which is applied in the field of filters, can solve the problems of large vertical size, increased construction volume, and difficult installation, so as to reduce the vertical size and buried depth, and reduce the amount of buried construction , The effect of reducing the difficulty of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] First of all, it needs to be explained that the orientation words such as up, down, left, right, front, and back described in the present invention are only described according to the accompanying drawings, so as to facilitate understanding, and are not intended to limit the technical solution and scope of protection of the present invention. .

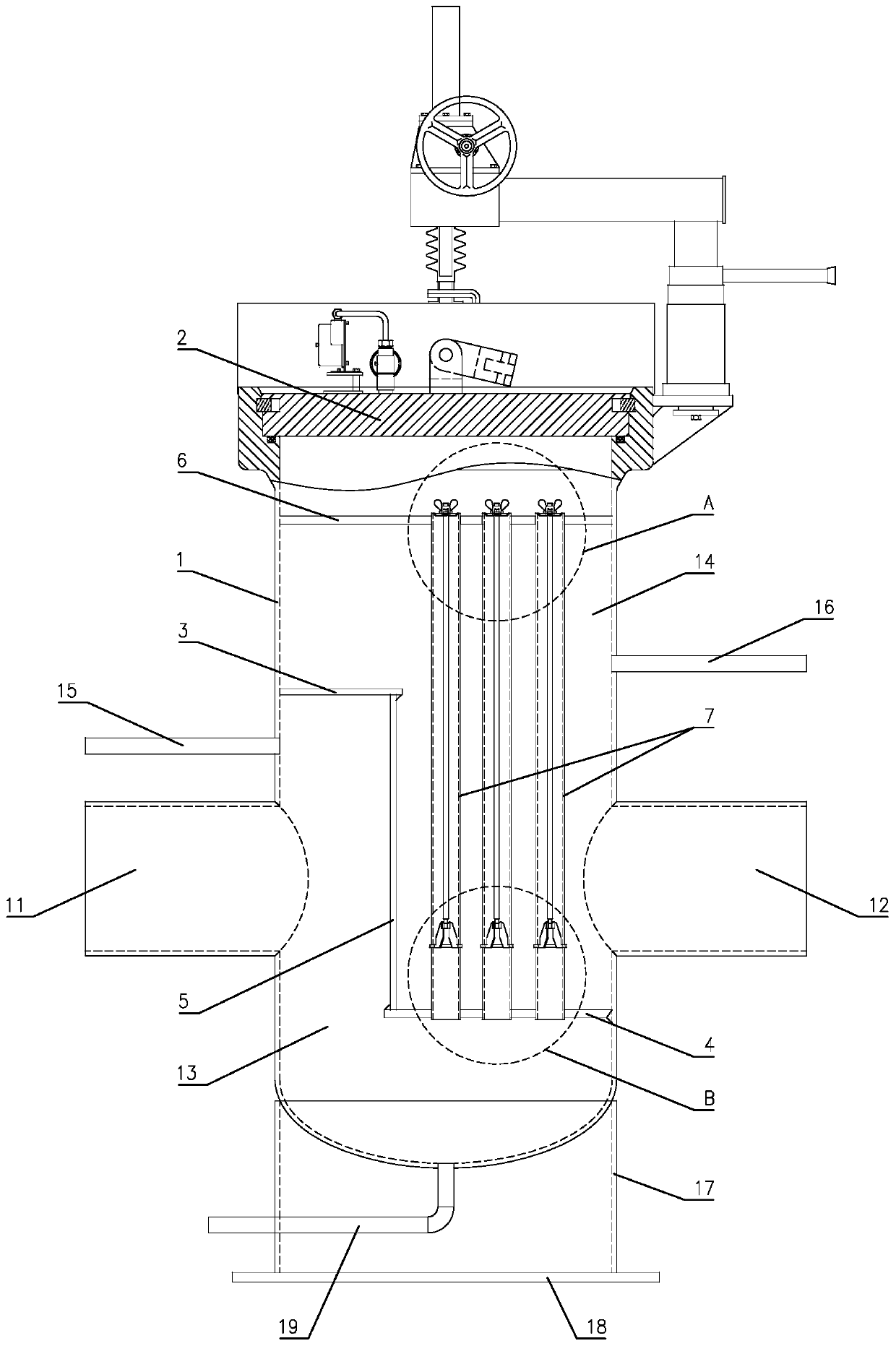

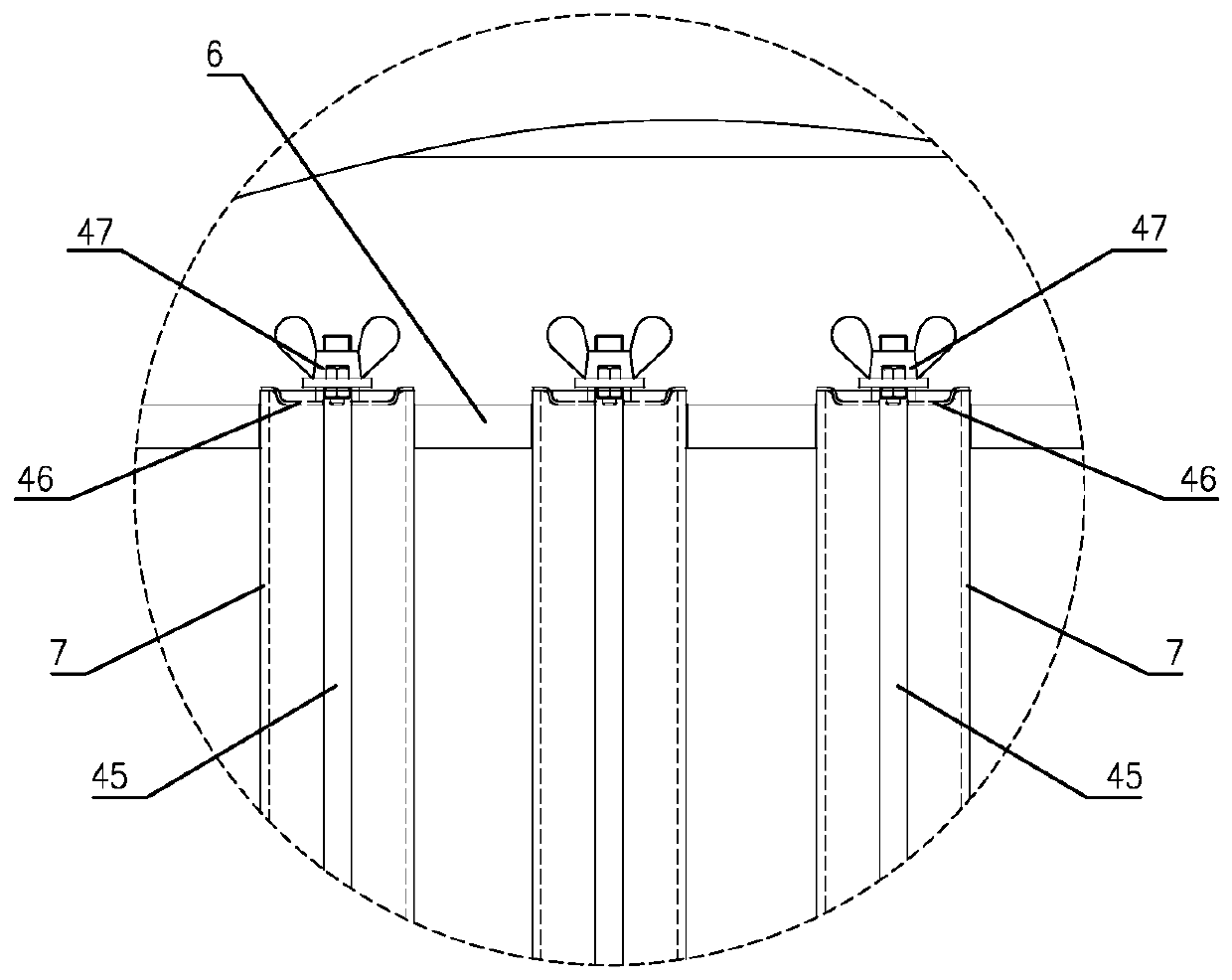

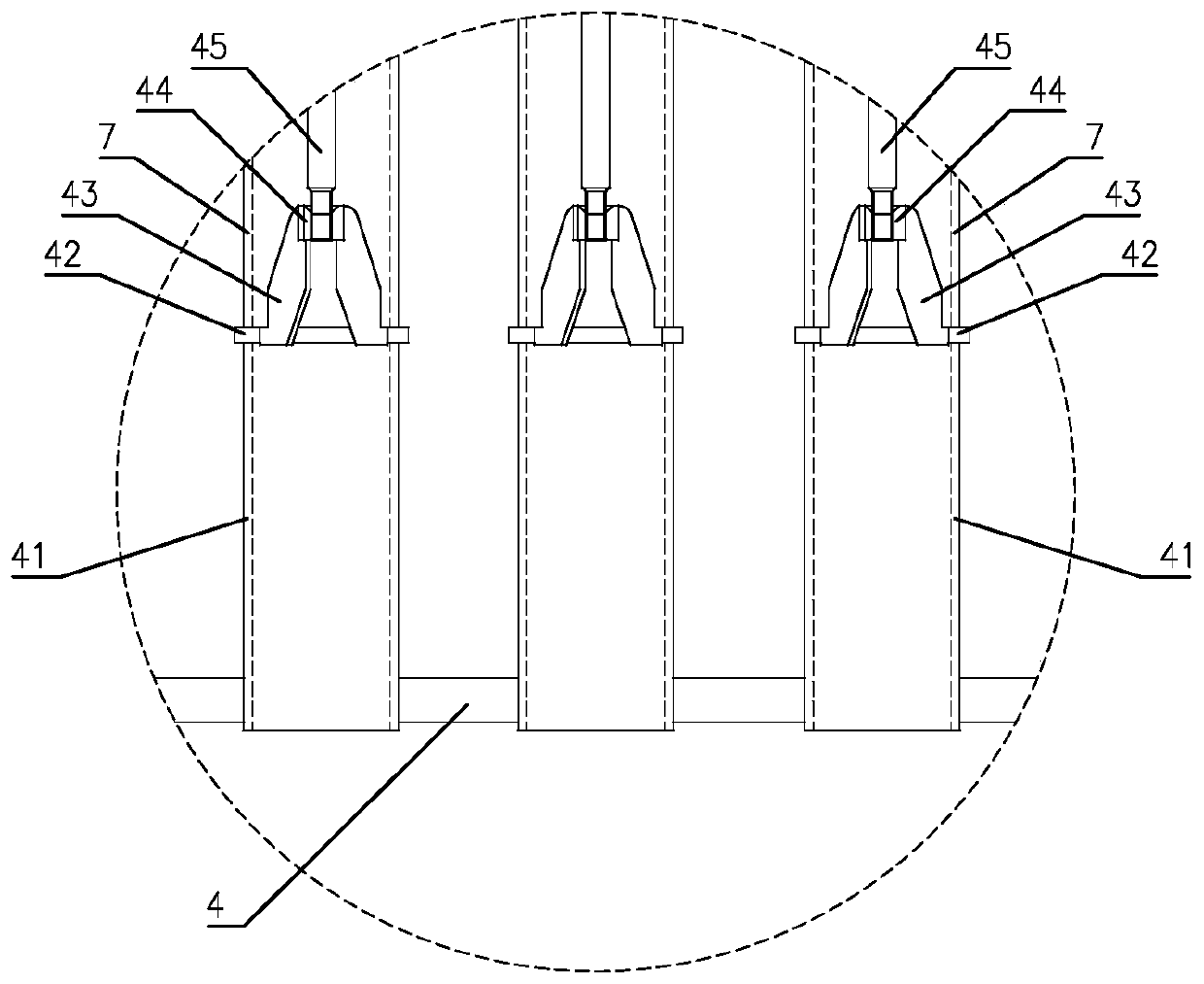

[0024] Such as Figure 1 to Figure 9 Shown is a specific embodiment of a direct-buried gas filter of the present invention, which includes a casing 1 with an open upper end and a quick-opening blind plate 2 installed at the opening of the casing 1 . An air inlet 11 and an air outlet 12 are correspondingly arranged on the left and right sides of the housing 1 , and the inner cavity of the housing 1 is divided into an air inlet chamber 13 and an air outlet chamber 14 by a baffle assembly. The baffle assembly specifically includes a left baffle 3, a right baffle 4 and a vertical baffle 5, the left baffle 3 is arranged horizontall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com