Buried turning plate type water stop gate

A flap-type, gate technology, applied in the direction of flood control panels, windows/doors, door/window protection devices, etc., can solve the problems of complex and difficult construction of water-stop gates, inconvenient passage and maintenance of water-stop gates, etc., and achieve the overall size The effect of small size, low cost and small buried depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

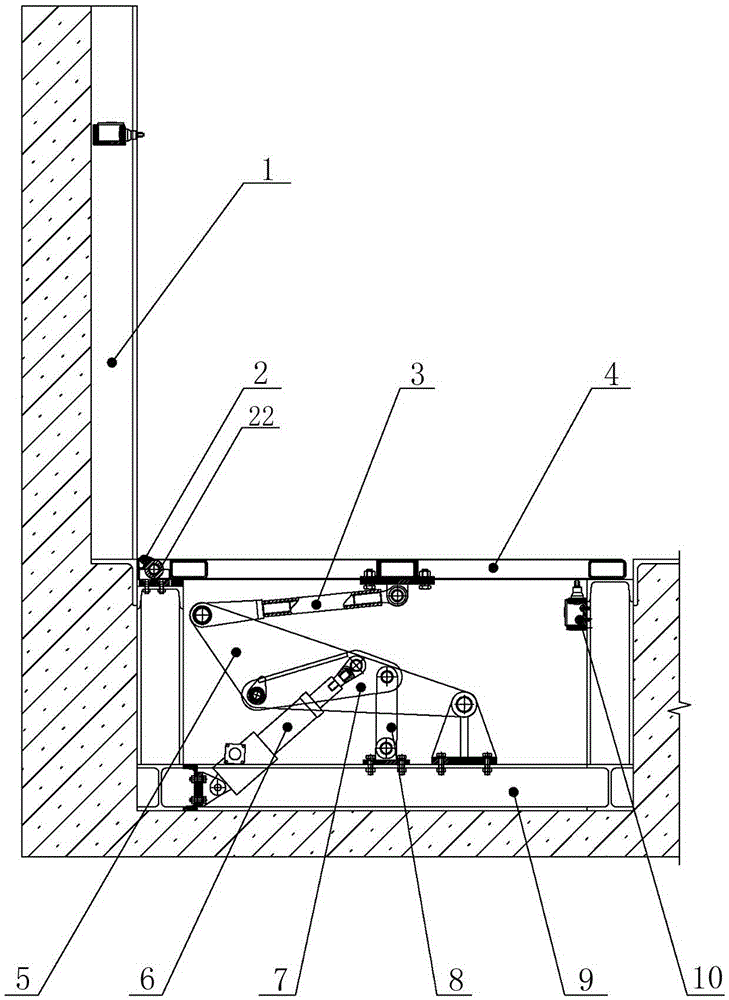

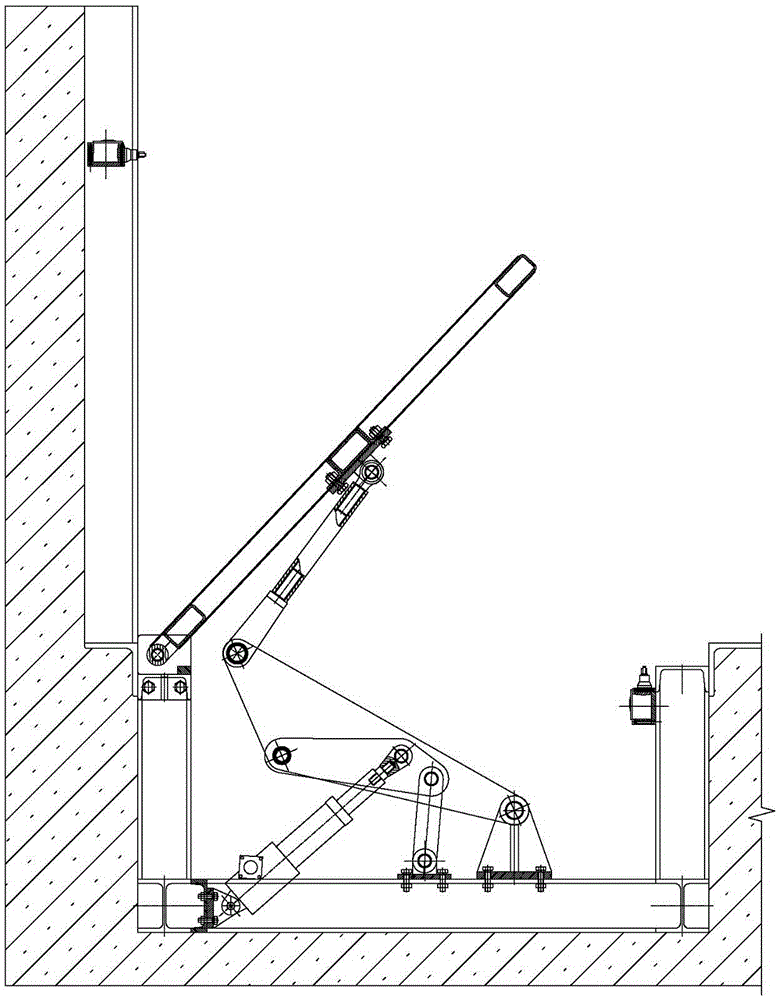

[0045] Embodiment one sees figure 1 As shown, this buried flap type water-stop gate includes a gate frame 1, a bottom frame 9 buried in the buried space and connected to the buried foundation, and a water-stop gate plate 4 hinged to the bottom frame 9, which is connected to the The power actuator between the water stop gate plate 4 and the bottom frame 9 and the power control system for controlling the power actuator.

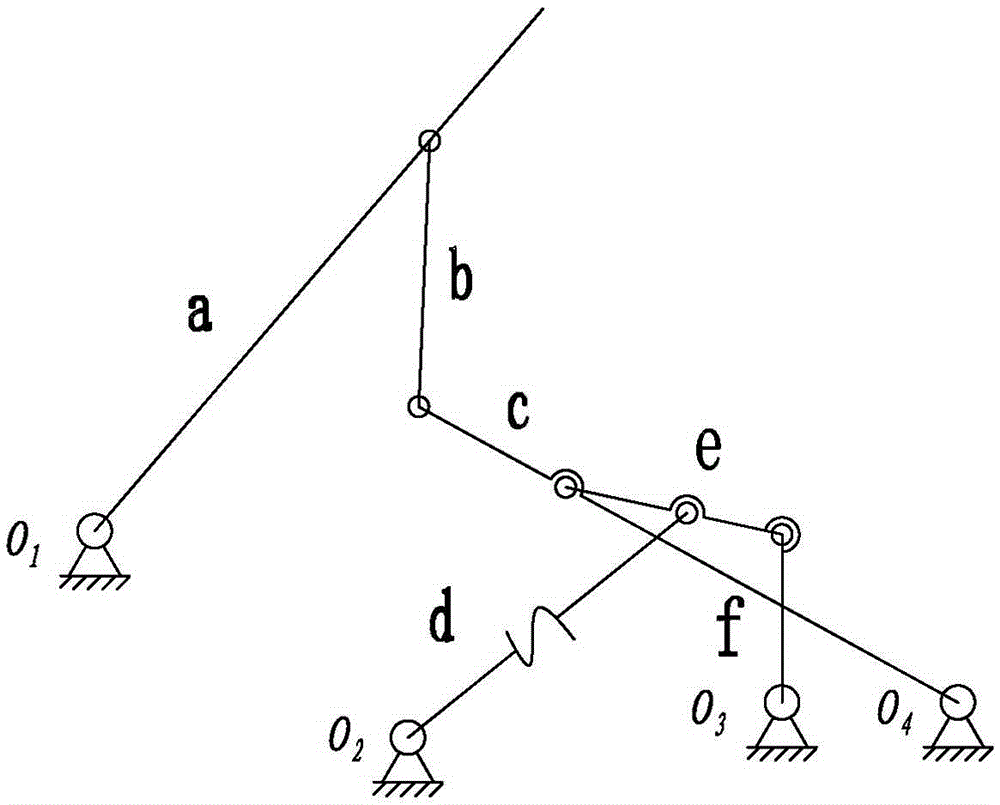

[0046] see image 3 , Figure 4 As shown, the power actuator shown sequentially includes an adjustable connecting rod 3, a large triangle arm 5, a small triangle arm 7, a small connecting rod 8 and a power drive device 6, and one end of the adjustable connecting rod 3 is hinged to the water stop gate plate 4 , the other end is hinged with a corner of the big triangle arm 5; the second corner of the big triangle arm 5 is hinged with the bottom frame 9, and the third corner of the big triangle arm 5 is hinged with a corner of the small triangle arm 7; The seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com