Closed impeller centrifugal pump

A closed impeller and centrifugal pump technology, applied in the direction of non-variable pumps, non-volume pumps, pumps, etc., can solve the problems of increased trouble in use or transfer work, high noise of cooling fan blades, and increased equipment load, etc. Achieve the effects of low noise, elimination of electric energy, and reduction of fan loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

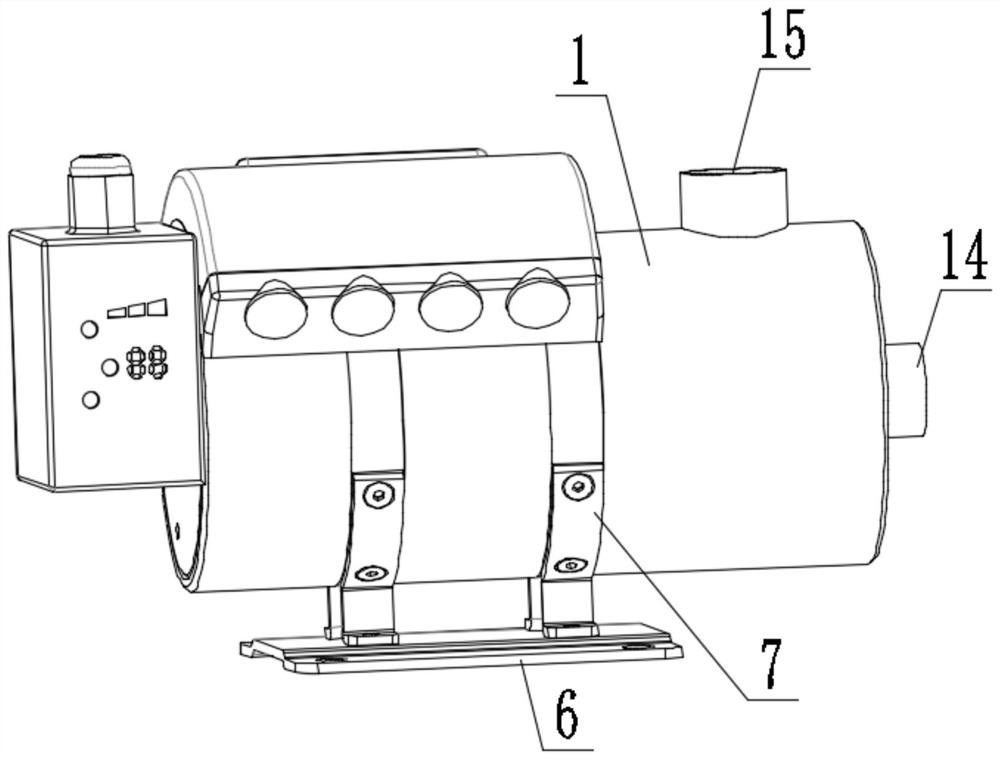

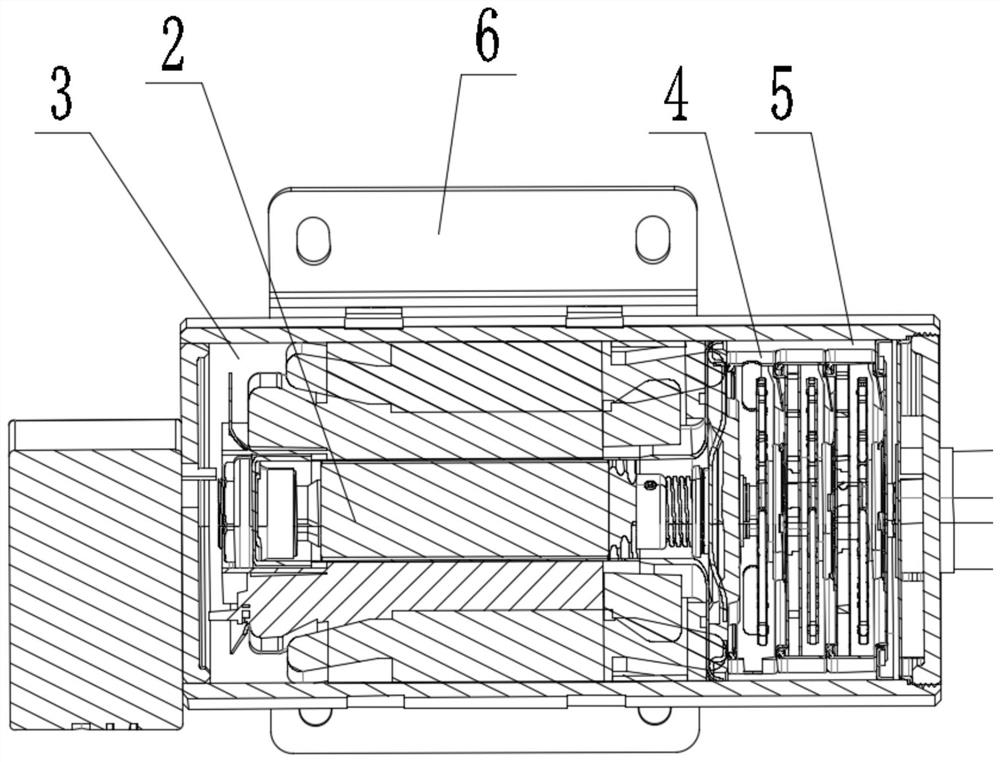

[0032] like figure 1 , figure 2 and Figure 8 , The present embodiment provides a closed impeller centrifugal pump, comprising a pump body, the pump body accommodating the impeller body has a first opening 4 of the body 5 in the cavity 1, the pump 1 has a further opening receiving the motor 2 second cavity 3, a spindle motor 2 through the second chamber 4 is connected to the impeller body 3 extends into the first chamber 5, the axis along which guide holes are opened on the rotating shaft, the One end of the second cavity of the guide hole 3 is turned on, the other end of the first cavity 5 is turned on, and close to the impeller 5 and the motor main body 2 between a first side of the cavity 4 having a shaft channel reserved space .

[0033] For application of the cooling, heating circulation pump equipment requirements, such as communications equipment 5G, wind power, robots, and other areas of the charging post, in order to solve this embodiment the impeller body 2 and the motor ...

Embodiment 2

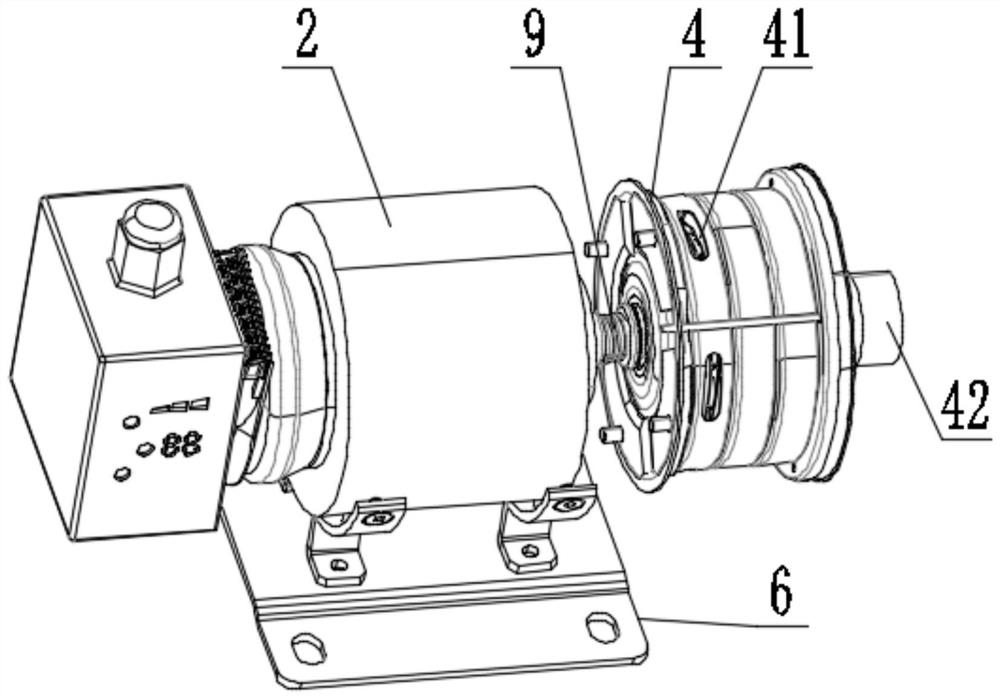

[0035] In this embodiment, on the basis of an embodiment of the launching, in response to the centrifugal pump efficiency of previously used relatively low problems, therefore the present embodiment is also designed in an end portion 4 of the spindle motor 2 to make improved impeller body, and at least two impeller body 4, such as Figure 4 , Figure 5 and Figure 7 As shown in particular by: a plurality of blades 4 in the impeller body 11, the adjacent guide grooves 12 constituting the clearance exists between the blades 11, a first flow chamber 5 flows into the impeller body under the action of centrifugal force 4, since the blades 11 and the outer periphery of the impeller body 12 into the guide groove of the water discharge pipe 4, outlet end located inwardly of the guide groove 12 formed recessed grooves 13, the adjacent guide grooves 12 communicates through the groove 13, which, as image 3 , On the impeller housing body 4 with a drain opening end 41, the particular shape may be...

Embodiment 4

[0038] This embodiment is based on the basis of Example 1, such as figure 1 As shown, a support base 6 is provided at the bottom of the pump body 1, and the top of the support base 6 is a semicircular curved structure, and a pump body of a semicircular arc-shaped portion is tightened by a pump body of a columnar body, a pump of a columnar body? The body 1 mates, the circular arc portion 7 of the base 6 is supported, the circular arc portion 7 is a semi-circular curved structure, so the circular arc portion 7 increases its contact area, which is not easy to fall off, followed by the motor 2 in the pump body 1. The blade of the impeller body 4 rotates, this process is vibrated, the structure can be well loaded, such as Image 6 As shown, the cone scroll 10 is inserted on the shaft of the motor 2, the cone scroll wheel 10 and the rotating shaft, and the magnetoelectric speed sensor 16 for detecting the shaft rotation speed is provided in the pump body 1. The magnetoelectric rotation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com