Sealed terminal board anti-gas leakage surface treatment process for high pressure switch

A technology for sealing terminals and high-voltage switches, which can be used in electric switches, surface pretreatment, devices for coating liquid on surfaces, etc., and can solve problems such as air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

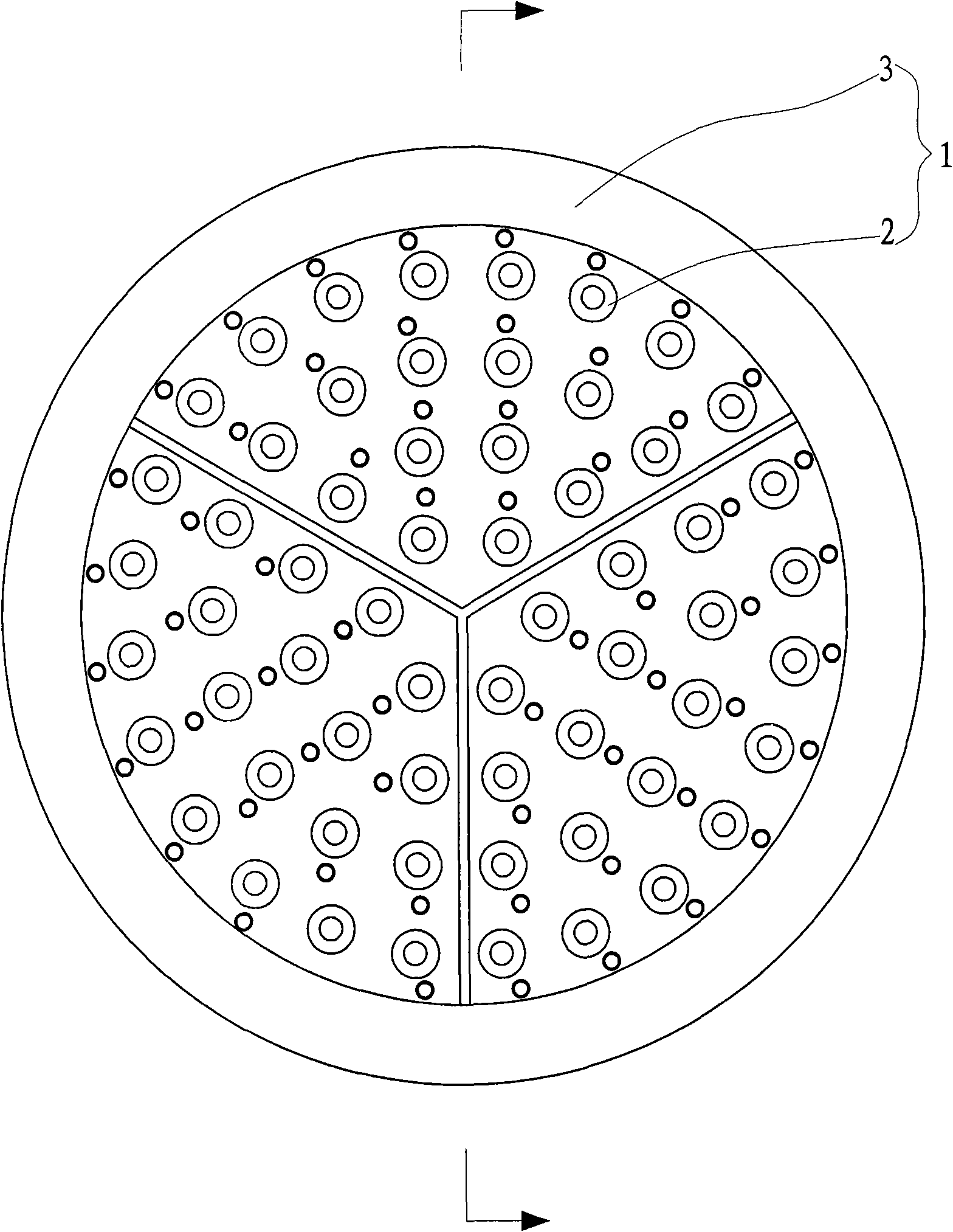

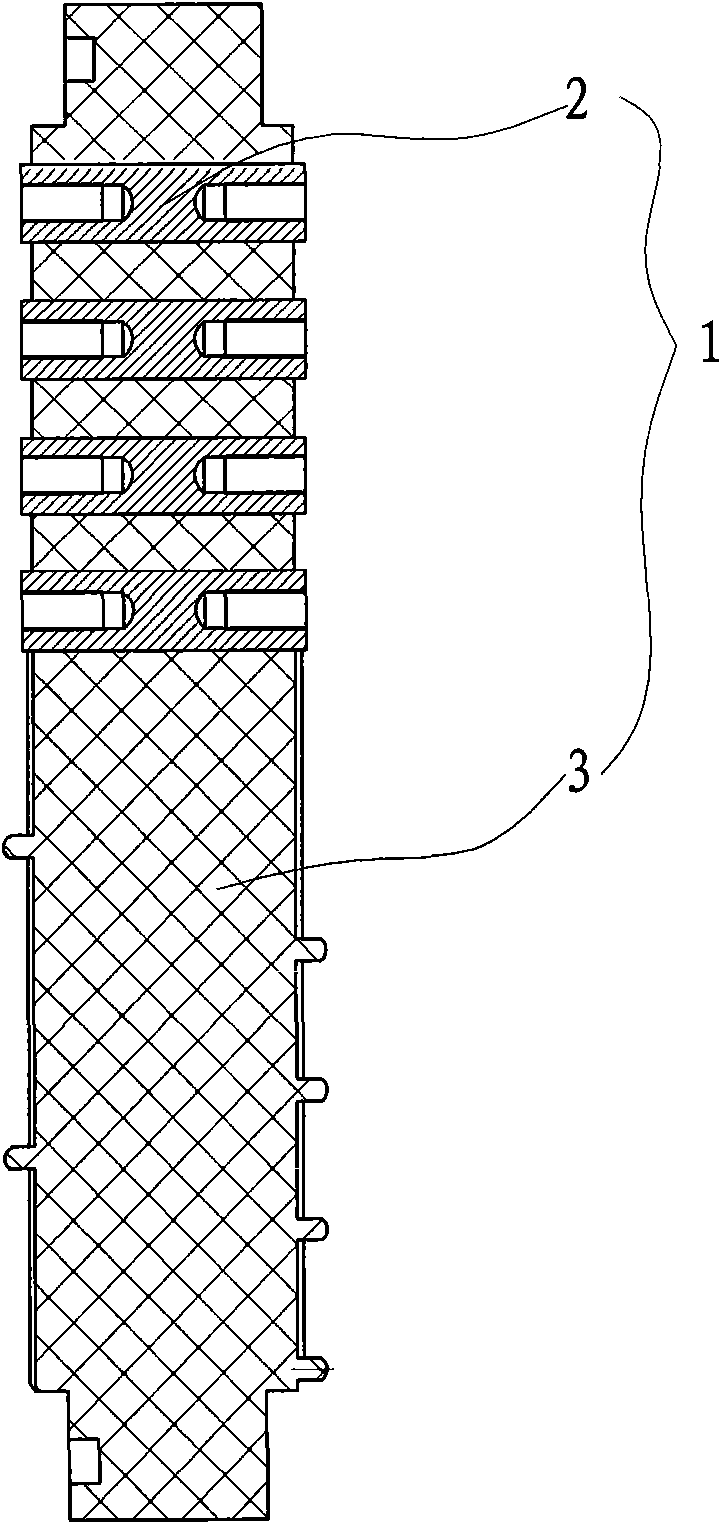

[0033] The anti-air-leakage surface treatment process of the high-voltage switch sealed terminal board of the present invention is to perform sandblasting or knurling treatment on the surface of the metal terminal, and then perform adhesive coating treatment.

[0034] Wherein, performing sandblasting or knurling treatment on the surface of the metal terminal belongs to the prior art, and will not be described in detail herein.

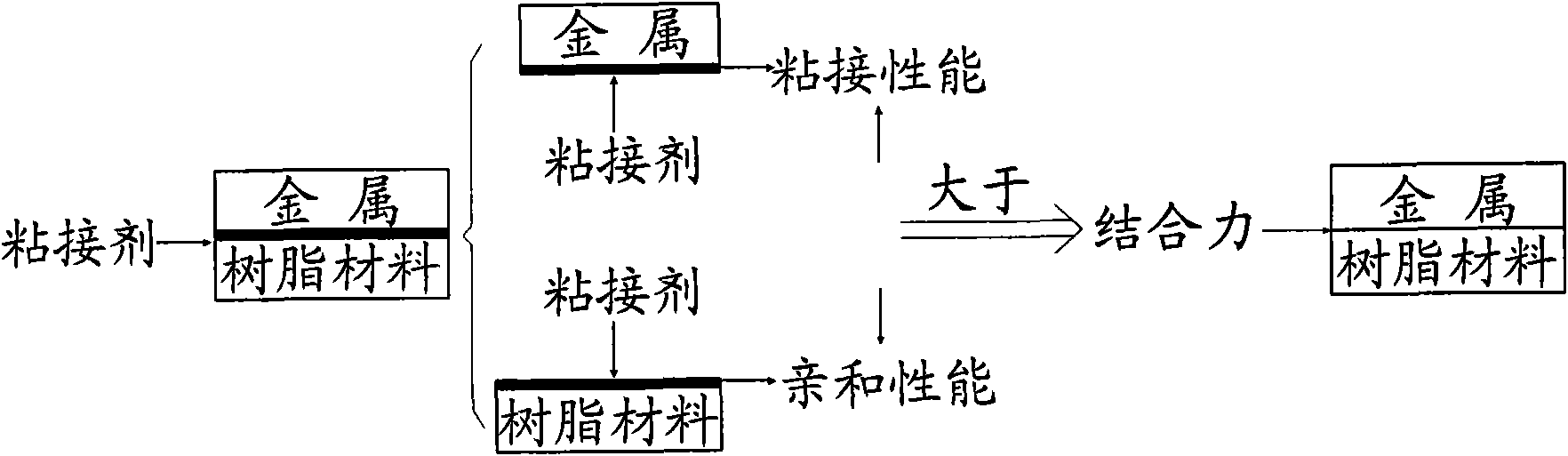

[0035] The key to this case is the coating treatment of the adhesive. The formula of the adhesive used is as follows:

[0036]

[0037] The specific coating process is as follows:

[0038] First weigh 175 parts of methyl ethyl ketone and 175 parts of toluene according to the weight ratio requirements, and then mix them evenly; then pour 100 parts of epoxy resin and 50 parts of phenolic resin weighed according to the weight ratio into methyl ethyl ketone and in the mixed solution of toluene; then stir the mixed solution intermittently at room temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com